The Garage 323

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CASESTUDY<br />

Lean Storage Solutions - R-Reforged<br />

R-Reforged keeps Aston Martin<br />

Zagato project neat and tidy -<br />

with help from Lean Storage<br />

Solutions<br />

Only a total of 38 customer vehicles will<br />

be produced in the limited run of Aston<br />

Martin Vantage V12 Zagato Heritage TWINS<br />

by R-Reforged, which are being built under<br />

licence by Aston Martin.<br />

With such a restricted client<br />

list, greater importance was<br />

added to the design of the<br />

new R-Reforged facility and workshop<br />

where the cars would be hand built;<br />

and play host to customers wishing to<br />

see their vehicles in production. Clean<br />

lines and colour co-ordination to match<br />

the corporate image were vital, for this<br />

the company turned to Lean Storage<br />

Solutions, whose expertise in design,<br />

project management and product<br />

range secured the contract for such a<br />

prestigious undertaking.<br />

<strong>The</strong> connection between Lean Storage<br />

Solutions and R-Reforged goes back to<br />

the end of 2019, when plans were being<br />

formulated to update R-Reforged’s<br />

existing workshop space, then along came<br />

Covid 19 and things were put on hold. In<br />

the meantime, the Aston Martin Vantage<br />

V12 Zagato Heritage TWINS by R-Reforged<br />

project came to the fore, with it a more<br />

pressing requirement for a completely<br />

new workshop. “<strong>The</strong>re are a few specialist<br />

companies supplying workshop storage<br />

systems, but the work we had already<br />

done with Lean Storage Solutions gave<br />

us the confidence that the team could<br />

deliver on price, design and quality,” says<br />

R-Reforged Head of Operations, Paul<br />

Kelly.<br />

“We needed a supplier that could<br />

work with us to tailor the workshop to<br />

our particular needs, specifically drawer<br />

depths to suit tools, and cupboards with<br />

enough space to keep everything neat and<br />

tidy. Colour of the equipment was also<br />

important to fit our corporate scheme.<br />

Dean O’Neill from Lean Storage Solutions<br />

listened to our needs and configured the<br />

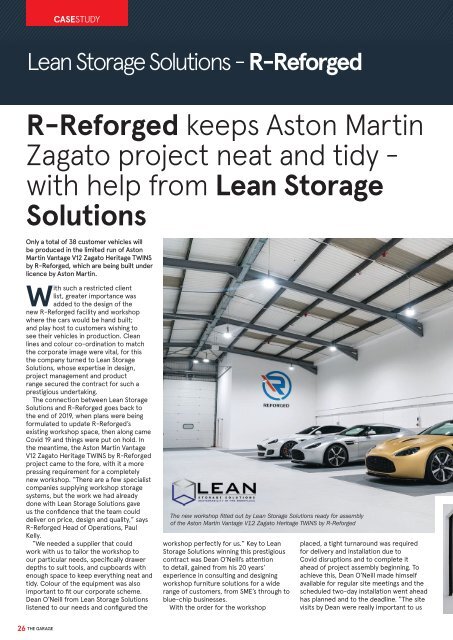

<strong>The</strong> new workshop fitted out by Lean Storage Solutions ready for assembly<br />

of the Aston Martin Vantage V12 Zagato Heritage TWINS by R-Reforged<br />

workshop perfectly for us.” Key to Lean<br />

Storage Solutions winning this prestigious<br />

contract was Dean O’Neill’s attention<br />

to detail, gained from his 20 years’<br />

experience in consulting and designing<br />

workshop furniture solutions for a wide<br />

range of customers, from SME’s through to<br />

blue-chip businesses.<br />

With the order for the workshop<br />

placed, a tight turnaround was required<br />

for delivery and installation due to<br />

Covid disruptions and to complete it<br />

ahead of project assembly beginning. To<br />

achieve this, Dean O’Neill made himself<br />

available for regular site meetings and the<br />

scheduled two-day installation went ahead<br />

has planned and to the deadline. “<strong>The</strong> site<br />

visits by Dean were really important to us<br />

26 THE GARAGE<br />

26, 27 Case Study.indd 1 21/01/2021 15:11