National Hardwood Magazine - July 2021

In this issue of National Hardwood Magazine, learn about Mans Lumber and Millwork, Prime Lumber Company and Woods on Wheels. The issue also features highlights from the Appalachian Lumbermen and Southwestern Hardwood Manufacturers Club meetings.

In this issue of National Hardwood Magazine, learn about Mans Lumber and Millwork, Prime Lumber Company and Woods on Wheels. The issue also features highlights from the Appalachian Lumbermen and Southwestern Hardwood Manufacturers Club meetings.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 1

Since 1936<br />

Load Part 1<br />

Order 10056<br />

Load Part 2<br />

Order 10056<br />

Load Part 3<br />

Order 10056<br />

Load Part 4<br />

Order 10056<br />

Now Offering Rift & Quartered<br />

White Oak!<br />

Cants being sawn into lumber at the resaw<br />

3 MBF<br />

WEST 4/4<br />

ALDER<br />

PREMIUM S2S<br />

6 MBF<br />

APP 4/4<br />

SOFT MAPLE #1<br />

COMMON SAP RGH<br />

4.5 MBF<br />

GLA 6/4<br />

RED OAK<br />

PRIME WHEAT S2S<br />

1.5 MBF<br />

EXOTIC 5/4<br />

SIPO SEL &<br />

BTR KD RGH<br />

One of three band mills<br />

Customer #1010<br />

Mixed Load<br />

Order 10056<br />

Delivery: Elkhart, IN 6/25/21<br />

Dry Kilns<br />

Walnut Steamer<br />

Material<br />

Handling System<br />

Warehouses<br />

Getting what you need can be complex. We make it feel easy.<br />

You should not be spending your time chasing down the parts and pieces of an order. That’s our job. As the nation’s<br />

largest hardwoods provider, we handle everything as quickly and efficiently as it should be. Species, supply,<br />

specialized production and logistics, we are a single source with the infrastructure to deliver exactly what you need.<br />

We make working with hardwoods as simple as can be.<br />

S382 Newman Planer<br />

Loading a Container for Export<br />

Annual Production 22,000,000 Board Feet<br />

sawing veneer logs and sawlogs<br />

We make it feel easy.<br />

APPALACHIAN SPECIES AVAILABLE IN 4/4 – 8/4 THICKNESS<br />

ASH • HICKORY • POPLAR • RED OAK • WHITE OAK • WALNUT<br />

900,000’ Dry Kiln Capacity • Walnut Steamer • Ripped-to-Width • Planer<br />

bhughes@cardinfp.com • kgriffith@cardinfp.com<br />

ruthcardin@cardinfp.com • ghamaker@cardinfp.com<br />

lreed@cardinfp.com<br />

(423) 837-4041 www.cardinfp.com<br />

northwesthardwoods.com<br />

2 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 1<br />

“Bringing You the Best Mother Nature has to Offer Around the Globe!”

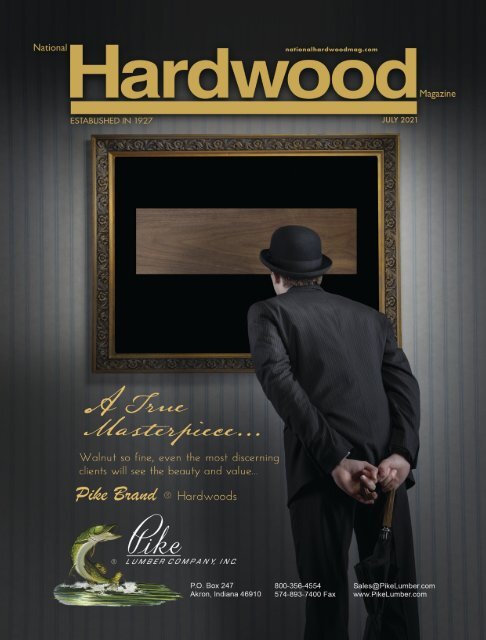

About The Cover<br />

Undeniably Beautiful…<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> JULY <strong>2021</strong> Volume 95 No. 6<br />

Features & Industry Events<br />

The hardwood industry faces tough<br />

challenges every day. One issue that<br />

can be avoided: quality issues related<br />

to your lumber supply. Selecting Pike<br />

Lumber Company as your first choice<br />

for the finest kiln dried hardwood<br />

lumber found anywhere is your first<br />

step in sourcing beautiful, problem free<br />

lumber.<br />

Since 1904, Pike Lumber Company continues to supply<br />

the finest quality lumber to the most discerning distributors<br />

and manufacturers around the world. Our broad product<br />

line includes Ash, Basswood, Cherry, Hard Maple, Hickory,<br />

Poplar, Red Oak, White Oak, and Walnut. We also offer Rift &<br />

Quartered in both Red Oak and White Oak. With our state of<br />

the art equipment, we carefully saw and kiln dry our lumber<br />

to ensure consistent thickness and stress free drying to 6%<br />

to 8% moisture content. All lumber is graded after kiln drying<br />

to ensure you receive the finest quality available anywhere.<br />

When you buy Pike Brand <strong>Hardwood</strong>s, you have one less<br />

thing to worry about!<br />

www.pikelumber.com<br />

20<br />

22<br />

Over a Century of Quality and<br />

Service at Mans Lumber &<br />

Millwork<br />

Prime Lumber Company, with<br />

a Sawmill Added, Is Growing<br />

to Meet Customers’ Needs<br />

24 Appalachian Lumbermen<br />

Enjoy Annual Myrtle Beach<br />

Event<br />

28<br />

Natchez Welcomes Back<br />

Southwestern <strong>Hardwood</strong><br />

Maufacturers Club<br />

Departments<br />

4 <strong>Hardwood</strong> Calendar<br />

6 U.S.A. Trends<br />

8 Canadian Trends<br />

10 News Developments<br />

12 HMA Update<br />

14 AHEC Report<br />

30<br />

36<br />

16 <strong>Hardwood</strong><br />

Federation Update<br />

18 NAFF Bulletin<br />

19 NHLA News<br />

48 Who’s Who<br />

52 Trade Talk<br />

Expo Richmond Returns to the<br />

Raceway<br />

Interactive Woods on Wheels Brings<br />

the Forest to Life for Guests of All<br />

Ages<br />

20<br />

55 In Memoriam<br />

58 Classified Profit<br />

Opportunities<br />

60 Advertisers Index<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Paul J. Miller Jr. – President<br />

Terry Miller – Vice President<br />

Zach Miller – Sales<br />

Sue Putnam – Editor<br />

Matthew Fite – Staff Writer<br />

Lydian Kennin – Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Pamela McFarland – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

2 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 3

HARDWOOD CALENDAR<br />

<strong>July</strong><br />

<strong>National</strong> Wood Flooring Association, EXPO,<br />

Orlando, FL. www.nwfaexpo.org. <strong>July</strong> 7-9.<br />

Mississippi Lumber Manufacturers Assoc., <strong>2021</strong><br />

Convention and Trade Show, Beau Rivage, Biloxi, MS.<br />

www.mlmalumber.com. <strong>July</strong> 8-11.<br />

Penn-York Lumbermen’s Club, hosted by: Ron Jones<br />

<strong>Hardwood</strong> Sales Inc. at Wanango Country Club, Reno,<br />

PA. www.pennyork.org. <strong>July</strong> 19.<br />

AWFS Fair, Las Vegas Convention Center, Las Vegas,<br />

NV. www.awfsfair.org. <strong>July</strong> 20-23.<br />

Wood Component Manufacturers Association,<br />

Monthly Virtual Round Table, Open to WCMA members<br />

and companies eligible for membership. Topic: “US<br />

<strong>Hardwood</strong> Supply and Demand Update,” Presented<br />

by: Judd Johnson with <strong>Hardwood</strong> Market Report. Learn<br />

more at www.wcma.com. <strong>July</strong> 22.<br />

Lake States Lumber Assoc., Summer Golf Outing,<br />

Minocqua, WI. www.lsla.com. <strong>July</strong> 28-29.<br />

August<br />

Appalachian <strong>Hardwood</strong> Manufacturers Inc., <strong>2021</strong><br />

Summer Conference, The Greenbrier, White Sulphur<br />

Springs, WV. www.appalachianhardwood.org.<br />

Aug. 1-4.<br />

SFPA Expo, Georgia World Congress Center, Atlanta,<br />

GA. www.sfpaexpo.com. Aug. 11-13.<br />

Wood Component Manufacturers Association,<br />

Monthly Virtual Round Table, Open to WCMA members<br />

and companies eligible for membership. Topic: “Tips<br />

and Tricks for Sanding Operations,” Presented by:<br />

Timesavers Inc. Learn more at www.wcma.com.<br />

Aug. 26. n<br />

We do.<br />

Call it unconditional, all-encompassing, you name it.<br />

As a software developer committed solely to the lumber and<br />

building materials industry, DMSi has every corner of your<br />

operation covered. From inventory and sales to production<br />

and procurement, we make sure no corners are cut<br />

and no detail is left out. And that’s a promise we’ll hold true.<br />

GTL LUMBER<br />

16<br />

Dry Kilns<br />

800,000<br />

BF Dry Kiln Capacity<br />

2,000,000<br />

BF Air Dry Capacity<br />

GRAF & THOMAS LUMBER<br />

GTL Lumber, Inc. (est. 02/19)<br />

4/4 Rift & Quartered - White Oak • Poplar<br />

4/4 Plain Sawn - White Oak • Hickory • Poplar • Red Oak<br />

SLR2E & HM Available<br />

Contact: Erin Cox 740-250-4227 • erin@gtllumber.com<br />

Graf & Thomas Lumber (est. 02/17)<br />

4 Log Yard Locations<br />

Vanceburg, KY • Grayson, KY • South Shore, KY • Ironton, OH<br />

Container Logs - Ties - Timbers - Crane Mats - Cants<br />

Contact: Damon Graf 740-727-1003 • damon@grafwood.com<br />

4<br />

LOG YARDS<br />

2<br />

SAWMILLS<br />

Visit DMSi.com<br />

4 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 5

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

Across the board, sawmills in the Lake States region<br />

are reporting “strong” markets with high demand that are<br />

keeping lumber suppliers “really busy.”<br />

In Michigan, one contact explained, “We’ve got a lot<br />

of demand, we’re just trying to keep up.” He reported<br />

that demand is not as “crazy” as it was two months ago,<br />

“but there is good demand on everything.” His company<br />

offers Hard and Soft Maple, Red and White Oak, Hickory,<br />

Walnut, Cherry, and Poplar. “I’d say the main demand is<br />

in Hard Maple and White Oak,” he stated.<br />

This Michigan supplier sells “50/50” to end users and<br />

distribution yards. When asked about what customers<br />

are saying about the market for their products, the<br />

source explained, “Those guys said they all have a ton<br />

of orders,” and “pretty much anyone I talk to is busy.” The<br />

lumber supplier said that transportation has been “okay,”<br />

with access to flatbeds being easier to obtain than shipping<br />

containers. “Containers are a challenge,” he said.<br />

“Rates are up, but I think rates are up everywhere in the<br />

world.”<br />

A sawmill representative in Wisconsin reported similar<br />

market trends. “It doesn’t matter what I saw,” said the<br />

contact. “I can sell it.” He explained that turnover is rapid<br />

with inventory moving quickly. “In most cases, they’re<br />

trying to sell domestically before it even comes out of the<br />

kilns,” the source stated.<br />

Compared to several months ago, this sawmill is seeing<br />

a better market. “Six months ago, my market was still<br />

very strong, but the prices are better now,” he said. His<br />

company is heavy to Red Oak and White Oak, Basswood,<br />

Cherry, Hickory, and both Hard and Soft Maple,<br />

sawn mostly to 4/4 and 5/4.<br />

When asked which species are selling best, the source<br />

laughed. “It really doesn’t matter, everything sells,” he<br />

replied. The sawmill sells mostly to end users, and some<br />

distribution yards. “They say their markets are really<br />

strong,” he said. “But I’m not going to lie to you. I get calls<br />

every week, and they’re trying to feel me out on what<br />

I’m hearing.” Transportation is giving this contact some<br />

trouble, but “not a lot.” He noted that getting containers is<br />

The market for <strong>Hardwood</strong> lumber in the Northeast is<br />

strong. According to a lumber provider in Pennsylvania,<br />

it is “very strong,” even “exceptionally strong.” This lumberman<br />

stated, “Our kilns are full. We are producing lumber<br />

as quickly as we can. Orders are going out at a very<br />

brisk pace, with many customers ordering ahead so they<br />

do not run out of inventory. We’re busy.” Asked if there<br />

are any “dead items,” he replied, “There’s really not any<br />

dead items. We’re moving at a pretty good pace here.<br />

It’s great to see.”<br />

Compared to several months earlier, he observed<br />

that the market was “of course, much better. We really<br />

saw the increase starting to come around last September.<br />

Business has been strong since then and has been<br />

steadily increasing. I don’t know when a slowdown will<br />

happen. We’ve gone through some difficult markets over<br />

the years. Each day we have now is certainly a good<br />

thing. There doesn’t seem to be any let-up in sight right<br />

now with the customers that we talk to.”<br />

He handles Hard and Soft Maple, Cherry, Poplar, Red<br />

Oak, Hickory and Ash in 4/4 through 8/4, FAS through<br />

Rustic. Sales are to distribution yards, end users and<br />

wholesalers. These customers’ businesses are faring<br />

“exceptionally well right now,” he stated. “One of the<br />

biggest challenges for a lot of our competitors, suppliers<br />

and customers is labor,” he noted. “You can’t get the<br />

labor. You also can’t find trucks. We have many loads<br />

of lumber that are ready; you just can’t put a truck underneath<br />

it. We really need to get some people back to<br />

work.”<br />

A concentration yard executive in Pennsylvania said<br />

demand is high and product is “not as hard to get.”<br />

Therefore, he stated, his market was better than it had<br />

been several months ago.<br />

He handles mainly 4/4 No. 2 Common and Better Walnut,<br />

No. 2 Common and Better Hard and Soft Maple and<br />

Cherry. Walnut, he said, is “by far the best seller.”<br />

He sells his lumber to distribution yards, end users and<br />

“anyone who needs lumber.” His customers’ fiscal health<br />

can be seen in the fact that they keep buying more lum-<br />

The <strong>Hardwood</strong> markets in the Southeast are “very<br />

good.” That’s the word from a lumber provider in Virginia.<br />

It’s a sentiment echoed by other lumber companies in<br />

the region.<br />

The Virginia source also said the market for her company<br />

is “much better” than it was a few months ago.<br />

“Prices are higher, and all lumber is moving,” she stated.<br />

She handles Red and White Oak, Poplar and Walnut<br />

in 4/4 through 10/4 in No. 3 Common and Better. Her<br />

sales are to domestic distribution yards and exporters.<br />

Her customers’ sales are good, she noted.<br />

Transportation is not a problem for her because, she<br />

observed, “I have local truckers we’ve worked with for<br />

years. They cover us when I need it.”<br />

In Georgia, an international lumber supplier observed<br />

that everything in his company’s business is strong – with<br />

one exception. “The problem is getting logs,” he stated.<br />

“We’re just now starting to get a few logs coming in. It<br />

doesn’t matter what the price is if you don’t have any<br />

lumber to sell. The entire pipeline from the woods to the<br />

customer is pretty much depleted. There’s not a whole<br />

lot of kiln-dried inventory. There’s not a whole lot of in<br />

process, air-drying. There’s not a ton of containers on the<br />

water. The distributors’ warehouses and the customers’<br />

warehouses are empty. So, it’s going to take a while to<br />

fill that pipeline up. If we start getting logs tomorrow, it’s<br />

four months at a minimum by the time we get it sawn,<br />

air-dried, kiln-dried, graded and ready to put in a container.<br />

It’s going to be awhile before we overcome this<br />

shortage.”<br />

His market, he noted, is “considerably better” than it<br />

was in the recent past. “We’ve got a little bit of wood coming<br />

through the system. I think you’ll see the <strong>Hardwood</strong>s<br />

pick up. But we’ll always keep some pine in the system.”<br />

Among <strong>Hardwood</strong>s, he handles Red and White Oak,<br />

Poplar and Ash in 4/4 in all standard grades. “All of these<br />

species are selling well,” he stated. “It’s not a difficult situation.<br />

You consider which customer has been with you<br />

the longest, and you support the ones who have worked<br />

with you up to this point. You ration the lumber among<br />

Out on the West Coast, lumber providers report the<br />

same phenomenon that is occurring across the country:<br />

high demand and low supply.<br />

A Washington lumberman stated, “People are hungry<br />

for lumber. They are definitely freaked out about the<br />

pricing changing so fast. So, there’s demand for a lot of<br />

species, and supply is tight.”<br />

Compared to six months earlier, his company is financially<br />

better. “But it is a struggle to operate, between finding<br />

the lumber and, definitely, issues with trucking. Problems<br />

with transportation have been going on all year. It<br />

is getting continuously worse. All freight costs are up 40<br />

percent since November and December.”<br />

He handles most all eastern species: Red and White<br />

Oak, Poplar, Hard and Soft Maple, Walnut and Hickory,<br />

primarily 4/4 and some thicker stock. Grades are mainly<br />

upper but with Common grades, as well. “All species are<br />

moving well, if we can get a fair price, we can move it,”<br />

he stated. “From the time a vendor tells us the lumber is<br />

available, we call our customers and within half an hour,<br />

we have it sold. However, it’ll take weeks to get it moved<br />

with the trucking situation.”<br />

He sells to end users, distribution yards and sawmills,<br />

which buy green and kiln-dried lumber from him. “Some<br />

mills don’t produce everything they need or are in short<br />

supply, so they buy from us to supplement when they<br />

have to,” he explained. Many of his customers are in<br />

the housing industry – cabinets, flooring, moulding, stair<br />

treads: “We pretty much cover them all.” He also sells to<br />

RV manufacturers. “But the housing industry seems to<br />

be the real driver,” he said.<br />

Compared to several months ago, he said, “It takes<br />

two times as long to get trucks as it used to. There are<br />

just not as many trucks available, and prices have gone<br />

way up.”<br />

An Oregon lumber provider stated, “The market is robust,<br />

but unfortunately the supply chain is very limited.<br />

We could sell a lot more product, but getting replacement<br />

product in is challenging. The reality is: there’s a<br />

shortage of labor. It starts there, and it ends there. The<br />

Please turn to page 42 Please turn to page 42<br />

Please turn to page 43 Please turn to page 44<br />

6 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 7

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

ONTARIO<br />

With the arrival of summer, sawmills and logging companies<br />

were busy processing whitewoods before stain<br />

set in. Supplies of <strong>Hardwood</strong>s were noted as slightly<br />

improved, as many reported having low log decks, with<br />

continued demand for Hard and Soft Maple and other<br />

whitewoods. Sawmill operators noted that orders were<br />

ahead of developing production. The focus was still on<br />

Hard Maple rather than other species at this time. Some<br />

contacts noted that supplies of green Hard Maple had<br />

improved although there was a shortage for most other<br />

species. With Ontario being in lockdown mode into<br />

early June, it was hoped that the inoculation efforts to<br />

fight COVID-19 would provide the needed break so the<br />

country can move forward and focus on rebuilding the<br />

economy.<br />

The strong housing markets in both Canada and the<br />

U.S. are encouraging news for those in the <strong>Hardwood</strong><br />

finished goods sectors, as consumer demand is very<br />

strong. Secondary manufacturers state they have large<br />

order files, and some have to turn orders away because<br />

they cannot meet shipment dates. Kiln-dried inventories<br />

are also reported as low overall. The lack of labor<br />

throughout the supply stream is also causing some issues<br />

in certain areas contacted, thus limiting operations.<br />

Prices for most species are reported to be at historically<br />

high levels.<br />

Competition for Ash logs is high, due to most area<br />

mills not being able to obtain supplies. Availability of this<br />

species is also due to the Emerald Ash Borer which has<br />

decimated many stands across Canada and the U.S.<br />

Demand for kiln-dried stocks on domestic and international<br />

markets is good. There is a shortage, however, for<br />

most grades and thicknesses, noted wholesalers.<br />

With trends being towards painted finishes and the<br />

shortages of higher valued species, Aspen has been<br />

used as an alternate, driving increased demand on the<br />

marketplace. Even though many wholesalers and sawmills<br />

are providing it, supplies are not meeting demand,<br />

and prices have increased as well.<br />

QUEBEC<br />

Business continues to improve for some in the<br />

<strong>Hardwood</strong> sector as we move through a third wave of<br />

COVID-19. Vaccination efforts ramped up across the<br />

country, with some positive results being seen in lower<br />

new case numbers, with easing of restriction plans rollout<br />

to what is hoped will be a return to normal for people and<br />

the economy. Log supplies have increased for sawmills.<br />

There is a labor shortage that is holding back logging<br />

productivity and log supplies. Contacts note that domestic<br />

and export markets are doing well, however. Demand<br />

is strong for Red and White Oak and Walnut. Contacts<br />

note that supplies for a vast majority of species, grades<br />

and thicknesses of green and kiln-dried lumber supplies<br />

are limited with strong to growing demand. Sales of pallet<br />

material, rail ties and timbers are reported as good. Low<br />

sawmill production and strong demand for pallet lumber<br />

and cants from the wooden pallet and container industry<br />

is driving prices higher. Markets are improving for board<br />

road supplies in areas contacted.<br />

Improvements to the supply of the regionally important<br />

Hard Maple production has helped, but not enough to fill<br />

inventory decks for all sectors. Sawmills are looking to<br />

get more quantities of Hard Maple logs. Buyers are also<br />

seeking additional stock but with mixed results. Prices<br />

are firm to higher, they noted. There is also a shortage of<br />

kiln-dried lumber, and with new home construction and<br />

renovation markets booming in Canada and the U.S.,<br />

Hard Maple is in short supply. While the cabinet and<br />

wood component industries make up a large part of the<br />

market for Hard Maple, this species is also gaining ranks<br />

from the flooring sector.<br />

Demand for Soft Maple, according to areas contacted,<br />

is good, but varies according to grade and thickness. Upper<br />

grades are consistent for both green and kiln-dried<br />

markets.<br />

Ash is in demand to the Chinese market and appears<br />

to have lost some of its momentum in mid-May. Contacts<br />

reported no difficulty getting orders to China and elsewhere.<br />

There has been an increase in demand from the<br />

High Quality Northern <strong>Hardwood</strong>s<br />

Specializing High Quality in Green and Northern Kiln Dried Hard <strong>Hardwood</strong>s<br />

Maple and Birch<br />

- QUALITY AND SUSTAINABILITY SINCE 1882 -<br />

Specializing in Green and Kiln Dried Hard Maple and Birch<br />

- QUALITY AND SUSTA INABILITY SINCE 1882 -<br />

Over 40 million FBM annual<br />

production of hardwood makes<br />

Over J.D. Irving, 40 million Limited FBM one of annual the<br />

largest producers in Eastern<br />

J.D.<br />

Canada<br />

Irving,<br />

and<br />

Limited<br />

New England.<br />

one of the<br />

largest As one of producers the top 5 private in Eastern<br />

Canada landowners and in New North England. America<br />

we ensure a long term quality<br />

As wood one supply. of the top 5 private<br />

landowners in North America<br />

we ensure a long term quality<br />

wood supply.<br />

Contact for more info:<br />

Denis Dubé, Sales Manager<br />

506.992.9025<br />

Contact for more info:<br />

dube.denis@jdirving.com<br />

Jan Coburn, Denis Dubé, Sales Coordinator Sales Manager<br />

506.992.9040 506.992.9025<br />

coburn.jan@jdirving.com<br />

dube.denis@jdirving.com<br />

Jonathan Connely, Sales Representave<br />

506.992.9024<br />

connely.jonathan@jdirving.com<br />

Jan Coburn, Sales Coordinator<br />

506.992.9040<br />

coburn.jan@jdirving.com<br />

Please turn to page 45 Please turn to page 47<br />

Visit us online:<br />

Visit us online:<br />

www.JDIrvingLumber.com<br />

8 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 9

NEWS DEVELOPMENTS<br />

GLENN RIEDER LLC ACQUIRES PALM CITY<br />

MILLWORK<br />

Milwaukee, WI-based Glenn Rieder LLC has acquired<br />

Palm City Millwork of Palm City, FL. Founded in 1987,<br />

Palm City Millwork is a leading manufacturer of custom<br />

A Complete line of Machinery,<br />

Controls and Software to fit your Mill.<br />

sales@tsman.com | tsman.com<br />

705.324.3762 | 24/7 Support 1-844-44-TSSVC<br />

RUGGED | DEPENDABLE | INNOVATIVE<br />

10 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

millwork products including doors, windows, mouldings,<br />

trims and shutters for the high-end residential market.<br />

Palm City primarily sells its millwork products to residential<br />

builders of custom homes on the Atlantic Coast of South<br />

Florida. Palm City maintains 76,000 square feet of manufacturing,<br />

office and showroom space<br />

in Palm City, FL.<br />

Glenn Rieder LLC is a custom architectural<br />

millwork manufacturer and<br />

commercial interior contractor serving<br />

all major markets across the United<br />

States. Glenn Rieder utilizes solid<br />

U.S. <strong>Hardwood</strong>s, including Poplar,<br />

Cherry, White Oak and Walnut.<br />

Since 1946, Glenn Rieder has produced<br />

and installed millwork for the<br />

hospitality, gaming, corporate, institutional,<br />

restaurant, winery, sports,<br />

retail and high-end residential markets.<br />

Through its subsidiaries, which<br />

include Quality Cabinet & Fixture Co.,<br />

Shamrock Metals LLC and Shamrock<br />

Installations LLC, the company operates<br />

manufacturing facilities in Milwaukee,<br />

WI, Tijuana, Mexico and Las<br />

Vegas, NV. Glenn Rieder also maintains<br />

offices in Fort Lauderdale, FL,<br />

New England and San Diego, CA.<br />

For more information, go to<br />

www.glennrieder.com and www.<br />

palmcitymillwork.com.<br />

MOST TREES ARE NOT<br />

SIGNIFICANTLY HARMED<br />

BY BROOD X CICADAS<br />

Seemingly straight out of a sci-fi<br />

movie, the Mid-Atlantic region is experiencing<br />

a unique natural phenomenon:<br />

Billions of periodical cicadas<br />

are starting to emerge across 15<br />

states, including the Baltimore-Washington<br />

metro area. So-called Brood<br />

X, the largest of 12 periodical cicada<br />

broods, is creating quite a buzz in a<br />

region home to more than 9 million<br />

people.<br />

“People really shouldn’t worry. Cicadas<br />

are not defoliating insects and<br />

NEWS ABOUT NORTH AMERICAN INDUSTRIAL<br />

HARDWOOD CONSUMERS INCLUDING MERGERS,<br />

PLANT EXPANSIONS & ASSOCIATION ACTIVITIES<br />

have nothing to do with locusts,” said Sandy Liebhold,<br />

research entomologist with the USDA Forest Service’s<br />

Northern Research Station in Morgantown, WV. “They<br />

won’t eat your plants, vegetables, or even the leaves of<br />

trees. They are emerging only to mate and lay eggs.”<br />

As for their effect on trees and<br />

forests, USDA scientists today are<br />

investigating cicada behavior both<br />

above and below ground. “Before<br />

they emerge, juvenile cicadas feed<br />

by sucking water and nutrients from<br />

tree roots,” said Liebhold. “Once they<br />

emerge, they tend to aggregate on<br />

trees grown in open spaces. The females<br />

lay their eggs by cutting slits<br />

in the green shoots of tree limbs.<br />

Neither of these behaviors is known<br />

to significantly harm trees. With one<br />

notable exception: very young trees<br />

can be overwhelmed by too many females<br />

cutting slits to lay eggs.”<br />

One way to protect your recently<br />

planted saplings is to secure a fine<br />

mesh netting around the canopy for<br />

a few weeks.<br />

For more information, go to www.<br />

fs.usda.gov/.<br />

USDA AWARDS $15 MILLION<br />

TO EXPAND USE OF WOOD<br />

PRODUCTS<br />

The U.S. Department of Agriculture<br />

(USDA) recently awarded more than<br />

$15 million to fund grant proposals to<br />

develop and expand the use of wood<br />

products, strengthen emerging wood<br />

energy markets and protect community<br />

forests. Agriculture Secretary<br />

Tom Vilsack made the announcement<br />

in Colorado recently while visiting<br />

prescribed fire and wildfire recovery<br />

areas adjacent to the Roosevelt<br />

<strong>National</strong> Forest Northern Colorado<br />

Front Range landscape.<br />

The grant funding, delivered<br />

through USDA Forest Service programs,<br />

will support 60 projects that<br />

cover a diverse range of activities<br />

UPGRADE YOUR<br />

OPTIMIZATION EXPERIENCE<br />

BIG enough to support your operation; small enough to care.<br />

09 Members on<br />

the software team<br />

13 Members on<br />

the controls team<br />

24/7Support<br />

with experts<br />

in 3 time zones<br />

across the globe<br />

40+Optimization<br />

systems<br />

700+ Control<br />

Systems installed<br />

worldwide<br />

from the development of affordable housing to expanding<br />

markets for mass timber, biochar, wood energy and other<br />

emerging wood products. The grants also include funds<br />

to help tribes, local governments and qualified non-profit<br />

704.200.2350<br />

sales@automationelecusa.com<br />

automationelecusa.com<br />

Please turn to page 50<br />

JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 11

HMA UPDATE<br />

GOOD NEWS FOR THE HARDWOOD INDUSTRY<br />

Midyear already! And with each<br />

new day, I’m feeling a greater<br />

sense of “normalcy.” On the<br />

home front, it’s wonderful to again<br />

be out and about with family and<br />

friends. Professionally, I’m keeping<br />

my fingers crossed that very soon all<br />

industry events will resume as faceto-face<br />

gatherings. We have a lot of<br />

catching-up to do! And some exciting<br />

work ahead!<br />

I’ve been reading with great interest, reports regarding<br />

behavioral changes in the wake of the pandemic,<br />

especially those about how American consumers are<br />

exhibiting greater enthusiasm and effort in creating “a<br />

healthier home environment.” Those same reports also<br />

indicate that today’s consumers are willing to pay for<br />

those “healthier” wants. And that’s the good news for our<br />

industry.<br />

The interesting facts:<br />

•The latest consumer preference survey, conducted<br />

by the <strong>National</strong> Association of Home Builders (NAHB),<br />

reports that “47 percent of buyers rate an exercise<br />

room essential or desirable” - up from 27 percent in<br />

2003 - and that their “most wanted list” includes <strong>Hardwood</strong><br />

flooring. (Good news, right?)<br />

•And according to the U.S. Environmental Protection<br />

Agency, because of the growing concern regarding<br />

indoor air quality due to mold, radon and toxic chemicals<br />

found in many homes and home products, “consumers<br />

are willing to pay up to $5,000 more for homes<br />

designed to deliver improved indoor air quality.”<br />

vinyl, because “health” for the home is<br />

their biggest concern.<br />

So, if there is a Bottom Line here,<br />

it’s this: Let’s not miss this opportunity<br />

to “win consumers over to <strong>Hardwood</strong>!”<br />

Now is the crucial time for the consuming<br />

public to hear/accept/act-upon<br />

our “message” that distinct <strong>Hardwood</strong><br />

products speak to the desire for and<br />

need of a “healthy home.” And the<br />

naturally inherent qualities that make<br />

<strong>Hardwood</strong> products unique, differentiate<br />

them from the competition!<br />

If they are willing to invest in an inhome<br />

exercise room, let’s show them<br />

how and why they should invest in<br />

<strong>Hardwood</strong> products that are not only<br />

healthy, but also beautiful, long-lasting, sustainable, and<br />

environmentally friendly.<br />

WHAT CAN YOU DO?<br />

Now is a great time to begin using the Real American<br />

<strong>Hardwood</strong> logo on your company website, products,<br />

sales and marketing communications, company<br />

vehicles and in-house operations. And to spread the<br />

word, follow @RealAmerican<strong>Hardwood</strong> on Instagram<br />

and Facebook, and in your social media posts, tag<br />

#RealAmerican<strong>Hardwood</strong>.<br />

And if you are able, make a voluntary contribution<br />

to help fund this consumer promotion campaign.<br />

As our recent ads have said, “moving the campaign<br />

forward and expanding its reach will take the support<br />

of the entire industry. The RAHC is building something<br />

BIG—for the benefit of the entire industry.” Visit www.<br />

RealAmerican<strong>Hardwood</strong>.org to add your support. n<br />

For our industry, and the advancement of the Real<br />

American <strong>Hardwood</strong> Coalition (RAHC), the timing<br />

couldn’t be better. This renewed interest in creating a<br />

healthier home environment coincides with the RAHC’s<br />

research findings that Consumers and Prosumers want<br />

their families to have healthy products<br />

in their homes, and that they trust<br />

wood, over something chemical like<br />

BY LINDA JOVANOVICH,<br />

EXECUTIVE VICE PRESIDENT,<br />

HARDWOOD MANUFACTURERS ASSOCIATION,<br />

PITTSBURGH, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

12 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 13

AHEC REPORT<br />

PERPETUUM MOBILE EXHIBITS IN BARCELONA<br />

In May <strong>2021</strong>, AHEC exhibited Perpetuum<br />

Mobile, a design project in American <strong>Hardwood</strong>s<br />

that celebrates the work of globally<br />

renowned Catalan architect Enric Miralles to<br />

mark the occasion of the 20th anniversary<br />

of his death. Perpetuum Mobile is a partnership<br />

with late architect’s wife and business<br />

partner, designer Benedetta Tagliabue and<br />

their firm EMBT to celebrate the architect’s<br />

life and show a lesser-known side of Enric<br />

Miralles as a furniture designer. While the architecture<br />

studio he set up and ran with Benedetta<br />

Tagliabue works on interior projects,<br />

this is the first time his design work is shown<br />

collectively at an exhibition.<br />

Although Miralles took care of every detail of the interior<br />

design of many of his private and public projects, the<br />

architect never designed furniture thinking of reproducing<br />

it commercially. In this exhibition, models of furniture<br />

and objects that were developed mainly for the architect’s<br />

home have been reproduced for display with a selection<br />

of sustainable American <strong>Hardwood</strong>s donated by<br />

AE Maderas. Miralles’ creative process was often aimed<br />

at bringing life to his designs. In the Disseny Hub it will<br />

be possible to appreciate the intention of bringing life and<br />

movement applied to his furniture designs.<br />

The last home of the architect in Barcelona was an<br />

old warehouse with the walls knocked down, leaving an<br />

open and versatile space perfect for Miralles, who imagined<br />

a house in motion, where the furniture did not have<br />

an established place or shape, but could be moved or<br />

modified according to the needs of each moment.<br />

To make this contemporary vision of the interior space<br />

come true, he personally designed his furniture, sharing<br />

his sketches with craftsmen and carpenters, with whom<br />

he debated and experimented on these pieces. Perpetuum<br />

Mobile started from an intense search for documentation<br />

among the architect’s most private archives,<br />

and from a close dialogue with AHEC about<br />

the reproduction of the nine pieces. The original<br />

design of each piece of furniture has<br />

remained the same with just a few technical<br />

updates and an update to the materials.<br />

While the original pieces were made in other<br />

timbers, the reproductions have been manufactured<br />

using a selection of four underused<br />

American <strong>Hardwood</strong> species including Red<br />

Oak, Maple, Cherry and Tulipwood, chosen<br />

for their aesthetic, performance, and environmental<br />

credentials.<br />

During the research phase, a notebook<br />

with a detailed drawing of an unknown table<br />

was found. Named ‘Mistery’ table, this piece<br />

has been built for the first time at La Navarra by deciphering<br />

the instructions that Miralles left in his notes. The<br />

exhibition showcases more than 20 pieces, among them<br />

the ‘Inestable’, ‘Dolmen’, ‘Troncs’ and ‘Tropical’ tables,<br />

the ‘Lelukaappi’ shelf inspired by the work of the architect<br />

Alvar Aalto, several chairs that were used in projects<br />

such as the Scottish Parliament or the headquarters of<br />

the Círculo de Lectores in Madrid, as well as unpublished<br />

lamps, which Enric had started to design and left<br />

unfinished.<br />

The structure of the exhibition symbolically reproduces<br />

the private house of Miralles and Tagliabue; the pieces<br />

of furniture are distributed in the space imitating their<br />

original position, sketches and drawings on the walls unveil<br />

details of their designs, and photos of the architect’s<br />

family life show them in use. The lamps designed by Miralles<br />

illuminate the furniture and are used as decorative<br />

elements. The exhibition is accompanied by a stop - motion<br />

video and a documentary produced by AHEC that<br />

explains the meticulous process of rebuilding the pieces<br />

of furniture, based on the original idea and shows the<br />

movements that bring this furniture to “life.” n<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT<br />

COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

WE ARE GRAF BROTHERS<br />

The world’s largest manufacturer of<br />

rift & quarter sawn white oak products<br />

From logs to lumber, timber to flooring, and everything in between,<br />

consider us your sole source for all your hardwood needs.<br />

LOG SALES<br />

Partner with us!<br />

ROUGH LUMBER<br />

FLOORING INVENTORY<br />

QUALITY / LOYALTY / TRADITION<br />

606-932-3117<br />

sales@grafbro.com<br />

14<br />

www.grafbro.com<br />

JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 15

HARDWOOD FEDERATION INFO<br />

INDUSTRIES<br />

CONTROLS<br />

THE BIDEN AGENDA - GOALS, COSTS AND CHALLENGES<br />

The Biden Administration<br />

is moving quickly and aggressively<br />

to deliver on key<br />

promises made during the Presidential<br />

election campaign. In addition<br />

to the $1.9 trillion COVID<br />

economic relief package passed<br />

into law in late January, the Administration<br />

has introduced two<br />

additional major policy initiatives totaling almost $4 trillion<br />

in spending and taxes this spring—one to address our<br />

country’s aging infrastructure and the second to shore up<br />

the financial footing of lower and middle class families as<br />

the country finally emerges from the pandemic.<br />

In terms of priority, the sequencing is telling with the<br />

infrastructure-focused American Jobs Plan hitting the<br />

streets weeks ahead of the American Family Plan that<br />

was unveiled in late April. White House staff has noted<br />

that the President has long wanted to pursue an infrastructure<br />

package and appears more passionate about<br />

that effort.<br />

Specific details of the American Jobs Plan are scarce.<br />

The 25-page high-level summary document that was released<br />

on the day the proposal was unveiled is all that<br />

exists. The proposal lays out hundreds of billions of dollars<br />

for roads, bridges and ports among other items and,<br />

although there is disagreement on funding levels and<br />

areas of focus, spending on infrastructure enjoys bipartisan<br />

support at least on a conceptual basis. Congress is<br />

now in the beginning stages of considering legislation reauthorizing<br />

our nation’s surface transportation programs.<br />

Known as “the highway bill,” this measure will serve as<br />

the lynch pin for any comprehensive<br />

infrastructure package that is<br />

forged this Congress. The current<br />

highway bill expires in September.<br />

The aspect of both the infrastructure<br />

plan and the American Family<br />

Plan that has attracted the most attention<br />

is how to pay for all of this<br />

new spending. Here again, the tax<br />

titles in these proposals are generally short on specifics<br />

but paint a decidedly clearer picture of who will be<br />

impacted than the spending components of these measures.<br />

Media coverage has focused on the jump in the<br />

corporate tax rate to 28 percent from 21 percent. Also<br />

receiving attention are the many provisions to curb off<br />

shoring—most notably the doubling of the global minimum<br />

tax (known as GILTI or Global Intangible Low Tax<br />

Income) from 10.5 to 21 percent. These two major tax<br />

increase planks are tagged as the funding mechanisms<br />

for the programs outlined in the American Jobs Plan.<br />

Additional tax increases are outlined in the American<br />

Family Plan, most prominently the proposed capital<br />

gains increase to 39.6 percent from 20 percent for those<br />

earning $1 million or more. The other widely discussed<br />

proposed change is ending long-standing capital gains<br />

tax break on inheritances known as “step-up in basis,”<br />

which allows tax payers to use the market value of assets<br />

at the time of inheritance rather than the actual purchase<br />

price as the cost basis for capital gains when the<br />

holdings are sold.<br />

What has not been widely reported on are the many<br />

potential revenue raisers not in either proposal that<br />

BY DANA LEE COLE,<br />

EXECUTIVE DIRECTOR,<br />

HARDWOOD FEDERATION,<br />

WASHINGTON, DC<br />

202-463-5186<br />

WWW.HARDWOODFEDERATION.WILDAPRICOT.ORG<br />

Please turn to page 56<br />

CLEEREMAN<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1175 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

16 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE Sales<br />

JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 17<br />

STEFAN DRACOBLY<br />

President Of<br />

Controls<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

PAUL CLEEREMAN<br />

VP Cleereman<br />

Industries & Controls<br />

DAN TOOKE<br />

Senior Optimization<br />

& Controls Engineer<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry Standard<br />

JoeScan X6 heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

info@cleereman.com

NAFF BULLETIN<br />

NHLA NEWS<br />

“FEEL FREE TO PRINT THIS EMAIL” —<br />

EMPOWERING THE NEXT GENERATION<br />

NHLA ANNUAL CONVENTION:<br />

NEVER UNDERESTIMATE THE POWER OF FRESH IDEAS<br />

Over the years, all of us have received emails with<br />

a note at the bottom suggesting that you better<br />

not print that email, or else! (cue the horror music<br />

here)<br />

A bi-product of the false messaging and beliefs that doing<br />

so will surely aid in the destruction of our forests. This<br />

simple suggestion has contributed to the misunderstanding<br />

and misperceptions regarding the realities of how we<br />

manage our forests in North America.<br />

So, in effect, you could call this learned behavior.<br />

As a life-long learner yourself, would you say you’re a<br />

quick-study or a gotta read it three times to retain it kind<br />

of learner?<br />

When you were a kid, didn’t it feel a whole lot easier<br />

to learn?<br />

Not surprising, since kids have more neurons actively<br />

creating new connections than adults do, so they can do<br />

things like learn to play tennis or memorize the multiplication<br />

tables or learn to play video games or fix a computer<br />

much more easily than we can.<br />

Because of this, it makes logical sense for children to<br />

be exposed to lots of different things—repeatedly, ideally—to<br />

allow those connections to be formed early on,<br />

rather than trying to catch up later.<br />

Things like the value and importance of forest stewardship.<br />

Why should they care? Clean air, food, water, and<br />

clothing and housing, to name a few.<br />

And, on top of that, what does this stewardship and<br />

forest growth mean for the health of our planet?<br />

“Over the course of a year, 100 trees can remove 53<br />

tons of the greenhouse gas carbon dioxide. Those same<br />

trees can also pull 430 pounds of other pollutants out of<br />

the air. This is in addition to the increased biodiversity<br />

of flora and fauna that comes with expanding, thriving<br />

forest habitat. So yes, removing a tree is good for the<br />

planet — when that tree is an American <strong>Hardwood</strong>. This<br />

precious natural resource adds beauty to the world in<br />

finished products and represents the ultimate in sustainability.”<br />

–Criswell Davis<br />

While people in different age-groups learn differently,<br />

most learning occurs in three stages:<br />

•gaining an initial awareness of a subject<br />

•acquiring basic knowledge of the subject<br />

•applying information and knowledge about the subject<br />

to a real-life situation<br />

If we can stimulate children to be more aware of forests,<br />

to learn more about them, and to understand how<br />

they function, they’ll be well-equipped with the awareness,<br />

knowledge, and passion to apply what they’ve<br />

learned and create a healthier planet, for generations.<br />

They’ll confidently share a well-informed and truthful<br />

message, “Yes, please feel free to print this email.”<br />

You may think special expertise is needed to teach forest<br />

stewardship.<br />

While a degree in forestry, wildlife science, biology, or<br />

botany might be helpful, nothing is more important than<br />

enthusiasm and a willingness to learn.<br />

It’s also not necessary to have all the answers to be a<br />

good teacher. A keen interest in youth and being receptive<br />

to continuous learning are the essential ingredients<br />

for success.<br />

Mixing these ingredients with sound information and<br />

age-appropriate curriculum is at the heart of our efforts,<br />

so that young people will actually enjoy learning and discovering<br />

the truth about trees.<br />

At the North American Forest Foundation, we’re focused<br />

on changing hearts and minds about wood, for<br />

good, by harvesting the next generation through education.<br />

A<br />

few weeks ago, I received an email<br />

from an individual who was not a<br />

member of NHLA. The email was to<br />

inquire about the benefits of attending the<br />

NHLA Annual Convention & Exhibit Showcase.<br />

It made me pause and think. As the convention<br />

planner for NHLA, this is the ultimate<br />

question. The answer to this question<br />

may be slightly different for each person,<br />

but in the end, there are five fundamental reasons as to<br />

why people attend and the benefits they receive.<br />

1. To network<br />

I believe the biggest reason for going to the NHLA Annual<br />

Convention is to meet with like-minded people and<br />

industry peers. We come together from all different geographical<br />

areas but share the common denominator of<br />

working in some aspect of the <strong>Hardwood</strong> industry. The<br />

annual convention allows you to see this network of resources,<br />

which is especially important this year, as it’s<br />

been more than 18 months since we have all gathered<br />

in person.<br />

2. To expand your knowledge and find solutions<br />

to problems<br />

The NHLA Annual Convention always strives to provide<br />

attendees with a unique learning experience. From<br />

keynote speakers and educational seminars specific to<br />

the <strong>Hardwood</strong> industry to new types of equipment or<br />

techniques, the NHLA Annual Convention wants you to<br />

hear new information and leave with tangible takeaways.<br />

3. For motivation<br />

The NHLA Annual Convention is the best place to get<br />

motivated and recharged! Sometimes we get so busy<br />

with the day-to-day of the work that taking a moment to<br />

network and learn has the added benefit of<br />

providing us with much-needed motivation:<br />

motivation for yourself and your business.<br />

You can learn and feel inspired by other<br />

business owners who are facing the same<br />

challenges and succeeding.<br />

4. Find suppliers and service providers<br />

The NHLA Exhibit Showcase is unlike a<br />

traditional trade show, as most of these industry<br />

suppliers are NHLA members. These companies<br />

have committed to the <strong>Hardwood</strong> industry by joining the<br />

Association to support the overall health and success of<br />

the industry. They have the pulse of the current business<br />

climate, and these vendors who sell to the industry fully<br />

grasp what is happening inside your business and your<br />

competition. Discovering innovative products and services<br />

for your business is necessary to stay competitive,<br />

and having these suppliers as friends and allies can only<br />

help your business prosper.<br />

5. Belief in the industry<br />

At our last in-person convention, during the Opening<br />

Session of the NHLA Annual Convention, then-President<br />

Darwin Murray asked the crowd to participate in a collective<br />

text to members of Congress. At one time, everyone<br />

in the crowd sent coordinated texts to Washington,<br />

DC, and the message was received loud and clear.<br />

Feeling the energy, hearing the conversations, and pulling<br />

together the collective voice and power of the <strong>Hardwood</strong><br />

industry is remarkable! That is what happens at<br />

the NHLA Annual Convention. Never underestimate the<br />

power of fresh ideas and a little fun mixed with some<br />

interesting people!<br />

To register for the <strong>2021</strong> NHLA Annual Convention &<br />

Exhibit Showcase visit www.nhla.com. n<br />

Please turn to page 57<br />

BY ALLISON DEFORD,<br />

EXECUTIVE DIRECTOR,<br />

NORTH AMERICAN FOREST FOUNDATION,<br />

COLLIERVILLE, TN<br />

901-860-4131<br />

adeford@northamericanforestfoundation.org<br />

BY RENEE HORNSBY,<br />

DIRECTOR OF MARKETING & COMMUNICATIONS,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-399-7560<br />

www.nhla.com<br />

18 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 19

“As a local lumber supplier, we maintain<br />

three lumberyards in southeast Michigan.<br />

Serving both professional contractors and the<br />

public at large, we get our best clients from those<br />

who have been disappointed with the wood selection<br />

at other big-box stores. We carry hard-to-find<br />

building materials no one else will warehouse in<br />

our region.”<br />

–Doug Mans, President,<br />

Mans Lumber & Millwork<br />

Over a Century of<br />

Quality and Service at<br />

Mans Lumber & Millwork<br />

By Michelle Keller<br />

Trenton, MI– With acres of <strong>Hardwood</strong> and softwood<br />

lumber available for use by contractors, homeowners,<br />

and builders, quality lumber has been among<br />

Mans Lumber & Millwork’s specialties for more than 100<br />

years. “Those hard-to-find materials are our specialty,”<br />

said Doug Mans, company president.<br />

Additionally, Mans Lumber & Millwork manufactures<br />

<strong>Hardwood</strong> flooring, custom millwork, kitchen and bath<br />

accessories, windows and offers Trex decking.<br />

Headquartered here, Mans Lumber & Millwork annually<br />

purchases approximately 30 million board feet of<br />

lumber for distribution in a variety of <strong>Hardwood</strong>s and<br />

softwoods, with <strong>Hardwood</strong>s comprised of Oak, Poplar<br />

and Walnut. Softwood lumber includes such species as<br />

cedar, pine, spruce, Douglas fir and hemlock fir.<br />

With four local locations conveniently located across<br />

Trenton, Canton, Birmingham, and Ann Arbor, MI, Mans<br />

Lumber & Millwork has been offering comprehensive<br />

home improvement services for more than a century. The<br />

company has remained focused on exceeding customers’<br />

expectations. Mans explained, “Our customer-centric<br />

approach has helped us thrive since we started. We<br />

guarantee prompt returns on estimates, on-time delivery,<br />

friendly phone call follow-ups, fair bidding practices, and<br />

quick responses.” Mans added that the firm takes pride<br />

in providing comprehensive home improvement services<br />

that can enhance any home’s interior and/or exterior.<br />

The company also offers a wide range of doors. Mans<br />

said, “We can suggest remodeling design options that<br />

incorporate interior or exterior doors and provide all the<br />

necessary hardware to complete the project.” With builder-grade<br />

hollow-core doors, custom wood doors, and<br />

more, Mans Lumber will also help measure and install<br />

doors.<br />

Over decades of quality production, the team at Mans<br />

has developed a reputation for exceptional deck design.<br />

Regarding <strong>Hardwood</strong> flooring, Mans Lumber & Millwork<br />

has an extensive selection of styles and colors to satisfy<br />

aesthetic, quality, and budgetary desires.<br />

“We have been recognized as Michigan’s top Trex dealer,”<br />

Mans offered. “We can provide composite decking<br />

for homeowners who want the appearance of wood<br />

without the maintenance requirements, but we also offer<br />

high-quality treated lumber for picturesque wood decking.”<br />

He continued, “As a local lumber supplier, we maintain<br />

three lumberyards in southeast Michigan. Serving both<br />

professional contractors and the public at large, we get<br />

our best clients from those who have been disappointed<br />

with the wood selection at other big-box stores. We carry<br />

hard-to-find building materials no one else will warehouse<br />

in our region.”<br />

For example, when it comes to <strong>Hardwood</strong> flooring,<br />

Mans Lumber & Millwork also has an extensive selection<br />

of styles and colors to satisfy aesthetic, quality and budgetary<br />

desires. A seasoned staff helps in the selection<br />

process so that the customer makes not only the right<br />

choice aesthetically but the one that is just right for the<br />

job. “We can also refinish existing <strong>Hardwood</strong> flooring if<br />

that makes more sense than a new installation,” Mans<br />

said.<br />

Furthermore, Mans Lumber can adeptly transform<br />

kitchens in its kitchen design center. Whether it is renovation<br />

or design assistance, building a new custom<br />

Please turn to page 38<br />

Pictured are (from left): Doug Mans, Chris Mans, Anna Mans<br />

Motschall, Jim Mans and Pete Mans.<br />

Headquartered in Trenton, MI, Mans Lumber & Millwork annually<br />

purchases approximately 30 million board feet of lumber for<br />

distribution in a variety of <strong>Hardwood</strong>s and softwoods, with <strong>Hardwood</strong>s<br />

comprised of Oak, Poplar and Walnut. Softwood lumber<br />

includes such species as cedar, pine, spruce, Douglas fir and<br />

hemlock fir. Pictured is the company’s Canton, MI location, one<br />

of four owned by Mans.<br />

Mans Lumber & Millwork is committed to providing premium<br />

moulding and lumber.<br />

20 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 21

Three of Prime Lumber’s eight SII dry kilns are shown. Total drying<br />

capacity is about 480,000 board feet.<br />

Walnut lumber is stored on the air-dry yard at Prime Lumber.<br />

From left is the Prime Lumber sales team: Bill Graban, Greg Hubble, Jeffrey Neidert, Matt Neidert and Whitney Donithan.<br />

Prime Lumber Company, with a Sawmill Added,<br />

Is Growing to Meet Customers’ Needs<br />

Thomasville, NC—Prime Lumber Company, headquartered<br />

here, and Prime Lumber Sawmill, in<br />

Kentucky, are members of an industry in which the<br />

growth of trees leads to valuable products. Within this<br />

industry, these two related companies, themselves, are<br />

growing.<br />

Prime Lumber Company, a distribution/concentration<br />

yard, was started in a one-room office as a wholesaler<br />

in 1988. Shortly after that, the firm began custom-drying<br />

lumber. After renting a warehouse for a few years, Prime<br />

Lumber bought the current 48 acres in North Carolina<br />

and built the original facility in 1994. Since then, “Prime<br />

Lumber has been growing and adding to our facility and<br />

capacity as our customers’ needs grow,” stated CEO Bill<br />

Graban. “Prime Lumber’s future plans revolve around<br />

expansion plans for better serving our customers.<br />

“A big part of our expansion was solidifying our relationship<br />

with Joey Gray, whom we’ve known for many<br />

years and bought primarily Walnut and Cedar lumber<br />

from him when he was running three sawmills prior to<br />

the Great Recession of 2007 in Eastview, KY.”<br />

“It just got to a point where I couldn’t keep going from a<br />

business standpoint and all the stress. So, in November<br />

of 2019 Prime Lumber bought me out of J&J Sawmill<br />

and decided to consolidate to one circle mill. I wanted<br />

to stay in the lumber business and had a crew of employees<br />

that had worked for me a number of years that I<br />

wanted to take care of. So,<br />

because of our relationship<br />

for many years of working<br />

with Prime Lumber Company,<br />

it worked out great<br />

for me, my employees and<br />

Prime Lumber as well. This<br />

circle mill is new, and production<br />

just came online in<br />

March of <strong>2021</strong>,” said Joey<br />

Gray, general manager of<br />

Prime Lumber Sawmill.<br />

Production at Prime<br />

Fred Teague<br />

Poplar lumber is stored in one of the warehouses.<br />

Lumber Sawmill is approximately 10 million board feet<br />

per year. The sawmill utilizes Red and White Oak, Poplar,<br />

Walnut, Eastern Red Cedar and other species to produce<br />

cants, ties and veneer and stave logs.<br />

Prime Lumber Company handles most species of<br />

<strong>Hardwood</strong>s including Red and White Oak, Walnut, Poplar,<br />

Hard and Soft Maple, Ash, Cherry, Hickory, Cypress<br />

and other species including Southern Yellow Pine, Eastern<br />

Red Cedar and imports. “Diversification is a key to<br />

Prime Lumber Company’s success,” noted Bill Graban.<br />

“Mixed truckloads and CTRs are the norm now more<br />

than the exception. Having a diverse inventory helps our<br />

A Brewco 1600 resaw at Prime Lumber Sawmill, operated by a<br />

sawyer in the cab, cuts dimension lumber to the required specs.<br />

“Prime Lumber has been growing<br />

and adding to our facility and<br />

capacity as our customers’ needs<br />

grow. Prime Lumber’s future plans<br />

revolve around expansion plans for<br />

better serving our customers.”<br />

– Bill Graban, CEO<br />

Prime Lumber Company<br />

customers to acquire several items at one place.”<br />

Jeffrey Neidert is president of Prime Lumber Company;<br />

Bill Graban is CEO and in sales; Greg Hubble is general<br />

manager of Prime Lumber Company, and the other<br />

salespeople are Fred Teague, Whitney Donithan, Jeffrey<br />

Neidert and Matt Neidert. Storage capacity includes six<br />

warehouses, totaling 140,000-square-feet of storage<br />

space, and a production facility that is located here on<br />

the North Carolina property. The company has eight SII<br />

dry kilns with a total drying capacity of about 480,000<br />

board feet. Thirty-five people are employed by Prime<br />

Lumber Company and six by Prime Lumber Transport,<br />

Inc.<br />

Please turn to page 40<br />

White Oak grade logs are ready to be sawn at Prime Lumber Sawmill.<br />

Production at the sawmill is approximately 10 million board<br />

feet per year.<br />

22 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 23

Appalachian Lumbermen Enjoy<br />

Annual Myrtle Beach Event<br />

Photos by Terry Miller<br />

Jeff Dougherty, Ally Global Logistics, Jacksonville, FL; Steve<br />

Leonard, Lawrence Lumber Co. Inc., Lexington, NC; Jay Reese,<br />

Penn-Sylvan International, Spartansburg, PA; and Karl Schmertzler,<br />

Yoder Lumber Co. Inc., Lenoir, NC<br />

Paul Zheng, ATI International LLC, Roanoke, VA; John Evans and<br />

Mary Evans, Ontario <strong>Hardwood</strong> Co. Inc., Keysville, VA; and Carlene<br />

and Byron Chute, Nyle Systems LLC, Brewer, ME<br />

Myrtle Beach, SC–Approximately 100 members<br />

and families of the Appalachian Lumbermen’s<br />

Club recently held their annual Beach Meeting<br />

here and installed new officers.<br />

The club visits Myrtle Beach each spring for a time of<br />

networking and social development. The group participates<br />

in golf, beach games and receptions each evening.<br />

The golf tournament winners for <strong>2021</strong> were:<br />

1st place A Flight<br />

Jeff Dougherty<br />

Most Honest Golfer<br />

Will Schmertzler<br />

2nd place A Flight<br />

Josh Turner<br />

#2 Longest drive M Jeff Dougherty<br />

3rd place A Flight<br />

4th place A Flight<br />

5th place A Flight<br />

Paul Zheng<br />

Peter McCarty<br />

Jay Reese<br />

#3 Closest in 3 par 5 Linwood Truitt<br />

#5 Closest in 2 par 4 Jeff Dougherty<br />

#8 Longest drive W Ray Turner<br />

Clark Delabar, Graf Custom <strong>Hardwood</strong>, Portsmouth, OH; Erin<br />

Cox, GTL Lumber Inc., Ironton, OH; and Ross Frazier, Turman<br />

Lumber Co., Salem, VA<br />

Jeremiah and Brittany Hawley, Turman Lumber Co., Salem, VA;<br />

Lance Johnson, ISK Biocides Inc., Memphis, TN; and Eric Carroll,<br />

S&S Sprinkler Co. LLC, Charlotte, NC<br />

1st place B Flight<br />

Steve Leonard<br />

#9 Closest in 3 par 5 Peter McCarty<br />

2nd place B Flight<br />

Shannon Garland<br />

#11 Closest to pin par 3 Shannon Garland<br />

3rd place B Flight<br />

Ray Turner<br />

#17 Closest to pin par 3 Linwood Truitt<br />

4th place B Flight<br />

Terry Miller<br />

5th place B Flight<br />

Robert Coleman<br />

The club installed the new officers for <strong>2021</strong>-22 and are:<br />

President – Shannon Garland<br />

Vice President – Brandon Reavis<br />

Secretary/Treasurer – Jimmy Clay<br />

Past President – John Evans<br />

Jesse Cockram and Larry Cockram, Griffith Lumber Co., Woolwine,<br />

VA; Robert Coleman, Robert S. Coleman Lumber Co. Inc.,<br />

Culpeper, VA; and Kendell Cockram, Griffith Lumber Co.<br />

Hank Buchanan, Richard Buchanan and Elissa Buchanan, Granite<br />

<strong>Hardwood</strong>s Inc., Granite Falls, NC; Ken and Mary Stephens,<br />

Associated <strong>Hardwood</strong>s Inc., Granite Falls, NC; and Karen and<br />

Mark Bland, American <strong>Hardwood</strong> Industries Inc., Waynesboro, VA<br />

The next meeting of the ALC will be Sept. 14 and<br />

the location will be announced soon. n<br />

For more information,<br />

visit www.lumberclub.org.<br />

24 JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

Lee Lybrand, The Timbermen Inc., Johnston, SC; Will Schmertzler,<br />

Rex Lumber Co., Crozet, VA; and Andy and Brianna Nuffer,<br />

DMSi Software/TallyExpress/eLIMBS, High Point, NC<br />

Tony Honeycutt, Mullican Flooring, Johnson City, TN; Karl<br />

Schmertzler, Yoder Lumber Co. Inc., Lenoir, NC; Linwood Truitt,<br />

Beasley Group, Hazlehurst, GA; Kellye Miller, <strong>National</strong> <strong>Hardwood</strong><br />

<strong>Magazine</strong>, Memphis, TN; Robert Coleman, Robert S. Coleman<br />

Lumber Co. Inc., Culpeper, VA; and Paul Zheng, ATI International<br />

LLC, Roanoke, VA<br />

Additional photos on next page<br />

JULY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 25

ALC PHOTOS Continued<br />

Josh Turner and Sara Beth Kight, Beasley Group, Hazlehurst,<br />

GA; Peter McCarty, TS Manufacturing, Dover-Foxcroft, ME; and<br />

Kristin and Shannon Garland, Peakwood Forest Products LLC,<br />

Roanoke, VA<br />

John Turner, YAK MAT, Hazlehurst, GA; Trish Turner, Noah White,<br />

Amber White, Haggard Turner, and Ray Turner, Beasley Group,<br />

Hazlehurst, GA<br />

Targeting Buyers Around the Globe!<br />

Forest Products Export Directory<br />

“...the Most Comprehensive Buyer’s Guide for<br />

the International Buyer...”<br />

Published in Fall <strong>2021</strong><br />

80% Renewal Rate in the 45th<br />

Forest Products Export Directory<br />

*<br />

Denotes advertisers are NEW in the 46th Edition 3Denotes advertisers that have RENEWED in the 46th Edition<br />

Tye and Becky Jordan, Associated <strong>Hardwood</strong>s Inc., Granite Falls, NC; Peter McCarty, TS Manufacturing, Dover-Foxcroft, ME; and John<br />

and Wendy Bowman, Appalachian <strong>Hardwood</strong> Manufacturers Inc., High Point, NC<br />

Stuart Deacon, Robin Lunsford, and Meagan and Seth Deacon,<br />

W.R. Deacon & Sons Timber Inc., Lexington, VA<br />

Shane Pappas, and Jennie and Greg Pappas, Cove City, NC<br />

3Abenaki Timber Corporation<br />

3Allegheny Veneer LLC<br />

3Allegheny Wood Products, Inc.<br />

3Ally Global Logistics LLC<br />

3American Lumber Co.<br />

3Anderson-Tully Lumber Co.<br />

*<br />

Atlanta <strong>Hardwood</strong> Corporation<br />

3Baillie Lumber Co.<br />

*<br />

Broadleaf Lumber Co.<br />

3Cardin Forest Products, LLC<br />

3Clark Lumber Co., Inc.<br />

3Cole <strong>Hardwood</strong>, Inc.<br />

3Crown <strong>Hardwood</strong> Co., Inc.<br />

3Cummings Lumber Co., Inc.<br />

3Deer Park Lumber International<br />

3Devereaux Sawmill, Inc.<br />

3East Ohio Lumber Co.<br />

3HHP, Inc.<br />

3Harold White Lumber Co.<br />

3Hanafee Bros. Sawmill Co., Inc.<br />

3Hermitage <strong>Hardwood</strong> Lumber<br />

Sales, Inc.<br />

3J.D. Irving Limited<br />

*<br />

Kamps <strong>Hardwood</strong>s, Inc.<br />

3King City / Northway<br />

Forwarding Ltd.<br />

*<br />

Lawrence Lumber<br />

Company, Inc.<br />

3Legacy Wood Products LLC<br />

3Matson Lumber Company<br />

3McClain Forest Products LLC<br />

3Midwest <strong>Hardwood</strong> Corp.<br />

3MO PAC Lumber Company<br />

3NELMA (Northeastern Lumber<br />

Manufacturers Assoc.)<br />

3 Northern Appalachian Logging<br />

& Forestry LLC<br />

3Northwest <strong>Hardwood</strong>s, Inc.<br />

3Nyle Systems LLC<br />

3Parton Lumber Co., Inc.<br />

3Penn-Sylvan International, Inc.<br />

3Prime Lumber Company<br />

3Primewood<br />

3Ralph Taylor Lumber Co., Inc.<br />

3Ram Forest Products, Inc.<br />

3Ron Jones <strong>Hardwood</strong> Sales, Inc.<br />

3Rossi Group<br />

*<br />

Salamanca Lumber Company, Inc.<br />

3SFPA (Southern Forest Products<br />

Assoc.)<br />

*<br />

Sisler Lumber Co., Inc.<br />

3Snowbelt <strong>Hardwood</strong>s, Inc.<br />

3Softwood Export Council<br />

3Somerset Wood Products, Inc.<br />

3TMX Shipping Company, Inc.<br />

3Taner Timber Co., Inc.<br />

3Two Rivers Timber Company, Inc.<br />

3Vexco, Inc.<br />

3Wagner Lumber Company<br />

3Wheeland Lumber Co., Inc.<br />