National Hardwood Magazine - December 2023

The December 2023 issue of the National Hardwood Magazine features stories on Houston Hardwoods, HHP Inc., and a 2024 industry forecast.

The December 2023 issue of the National Hardwood Magazine features stories on Houston Hardwoods, HHP Inc., and a 2024 industry forecast.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

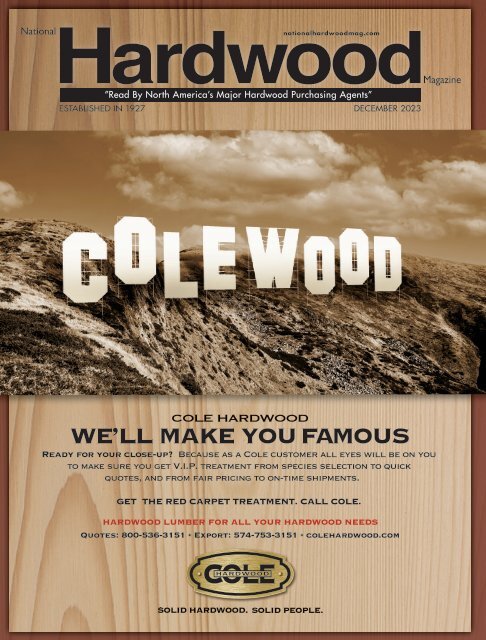

COLE HARDWOOD<br />

WE’LL MAKE YOU FAMOUS<br />

Ready for your close-up? Because as a Cole customer all eyes will be on you<br />

to make sure you get V.I.P. treatment from species selection to quick<br />

quotes, and from fair pricing to on-time shipments.<br />

GET THE RED CARPET TREATMENT. CALL COLE.<br />

HARDWOOD LUMBER FOR ALL YOUR HARDWOOD NEEDS<br />

Quotes: 800-536-3151 • Export: 574-753-3151 • colehardwood.com<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 1

Learn More<br />

<br />

Boost Efficiency and Profits<br />

Heat Recovery Vents<br />

• Saves Up To 80% Of Lost Heat<br />

A customized solution:<br />

MIXED<br />

LOADS<br />

We can easily combine a wide<br />

range of items on a single order<br />

to suit your specific needs.<br />

OUR PRODUCTS:<br />

NORTHERN AND NORTH<br />

APPALACHIAN LUMBER<br />

• More Consistent Drying<br />

• Ensures Your Kiln Runs At<br />

Peak Efficiency<br />

NDKR Kiln Controls<br />

• Enhanced Sensor Technology<br />

• Felxible Control Modes<br />

• Can Be Installed Any Kiln<br />

Regardless of Manufacturer.<br />

2 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

primewood.com<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 1<br />

Producer | Large Inventory | Thick Stock | Imported Wood

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

Ready for your close-up? Because as a Cole customer all eyes will be on you<br />

to make sure you get V.I.P. treatment from species selection to quick<br />

quotes, and from fair pricing to on-time shipments.<br />

GET THE RED CARPET TREATMENT. CALL COLE.<br />

HARDWOOD LUMBER FOR ALL YOUR HARDWOOD NEEDS<br />

Quotes: 800-536-3151 • Export: 574-753-3151 • colehardwood.com<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> DECEMBER <strong>2023</strong> Volume 97 No. 11<br />

About The Cover<br />

Flexibility in the marketplace and employee<br />

involvement are hallmarks of Cole <strong>Hardwood</strong>,<br />

Inc., a 34-acre concentration yard supplying<br />

U.S. and overseas markets, Cole specializes<br />

in lumber that is indigenous to the forests of<br />

Indiana, Michigan, Ohio and Illinois. These<br />

COLE HARDWOOD<br />

WE’LL MAKE YOU FAMOUS<br />

species are Red Oak, White Oak, Ash, Poplar,<br />

Hard Maple, Soft Maple, Cherry, Hickory and<br />

Walnut. Thicknesses in most species are 4/4<br />

through 8/4, with some species up to 16/4.<br />

Cole <strong>Hardwood</strong> has kiln capacity of<br />

1,300,000 BF. The facility also has over 225,000 square feet of climatecontrolled<br />

warehouse, housing 4 KD inspection stations, 2 green lumber<br />

inspection stations, 2 stackers, a retail store, the office, planing mill and<br />

approximately 8,000,000 BF of kiln dried inventory. Total kiln dried and<br />

air-dried inventory stands at 12,000,000 BF.<br />

Cole <strong>Hardwood</strong>, Inc. is committed to making sure every step, from<br />

computer-controlled kiln drying to their one-on-one customer service is<br />

focused on quality—the kind that is only possible with commitment from<br />

every department, every person, every day!<br />

colehardwood.com<br />

COLE HARDWOOD<br />

Features & Industry Events<br />

26<br />

30<br />

34<br />

40<br />

52<br />

Integrity, Knowledge And Premium<br />

<strong>Hardwood</strong> Selection At Houston<br />

<strong>Hardwood</strong>s<br />

HHP, Inc.: Taking Pride In<br />

Quality Products<br />

Despite The Challenges That<br />

<strong>2023</strong> Brought There Is Hope<br />

Going Into 2024<br />

NHLA Teams Up With Louisville To<br />

Celebrate Convention & Expo’s<br />

126 Years<br />

Robinson Lumber Welcomes NHLA’s<br />

First-Ever Offsite Convention Mill Tour<br />

Departments<br />

54<br />

Rossi Welcomes Guests<br />

To Reception<br />

Hall Of Fame Jockey Visits<br />

56 <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> Dinner<br />

Lumbermen’s Luncheon Club Digs<br />

56 Deep, Raises Largest Donation Ever<br />

30<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Paul J. Miller Jr. – President<br />

Terry Miller – Vice President<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Cadance Hanson - Staff Writer<br />

Graham Sweeney - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

10 <strong>Hardwood</strong> Calendar<br />

12 U.S.A. Trends<br />

14 Canadian Trends<br />

16 Industry News<br />

18 HMA Update<br />

20 AHEC Report<br />

22 NHLA: Why Knot...<br />

24 NAFF Bulletin<br />

57 In Memoriam<br />

78 Who’s Who<br />

82 Classified Profit<br />

Opportunities<br />

84 Advertisers Index<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in <strong>December</strong>, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

2 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 3

INDUSTRIES<br />

CONTROLS<br />

One Success Story<br />

After Another<br />

Paul, I would like to personally thank you for the incredible work you and your<br />

team did putting together Pennsylvania <strong>Hardwood</strong>s’ article in your magazine.<br />

This was our first published article with your company. Directly after the article<br />

published, we were approached by a company on the west coast, that we<br />

weren’t previously connected with. Thank you for the great work you and your<br />

team provided to our company, and for the impact you have on the industry as a<br />

whole. We look forward to working with you for many years to come.<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

John Pysh<br />

Pennsylvania <strong>Hardwood</strong>s, LLC<br />

President/Export Sales<br />

Pennsylvania <strong>Hardwood</strong>s, LLC, strategically located in northwestern Pennsylvania, is dedicated<br />

to providing high-quality services and products for our customers, both domestic and abroad.<br />

Our company strongly believes that every step of the process is equally important. From the<br />

harvesting of some the world’s finest timber, to the manufacturing of the log on the sawmill, to the<br />

packaging of our final product, Pennsylvania <strong>Hardwood</strong>s takes no short cuts. When you choose<br />

Pennsylvania <strong>Hardwood</strong>s, you choose a company that focuses on quality and consistency. We<br />

look forward to doing business with you. We can be reached by phone (814) 590-6730, fax (814)<br />

589-7831, email jpysh@pahardwoods.com, website www.pahardwoods.com.<br />

NATIONAL HARDWOOD MAGAZINE<br />

P.O. Box 34908 • Memphis, TN 38184-0908 • Toll Free: 800-844-1280<br />

Website: www.millerwoodtradepub.com<br />

Email address: tammy@millerwoodtradepub.com<br />

www.nationalhardwoodmag.com<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1240 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

Controls<br />

Industries & Controls & Controls Engineer<br />

4 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 5<br />

STEFAN DRACOBLY<br />

President Of<br />

PAUL CLEEREMAN<br />

VP Cleereman<br />

Sales<br />

DAN TOOKE<br />

Senior Optimization<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry JoeScan<br />

JS-50X6 Heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

n Over 170 systems sold<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

info@cleereman.com

PRECISION BEYOND<br />

IMAGINATION<br />

Green Book’s<br />

<strong>Hardwood</strong><br />

Marketing<br />

directory<br />

“The World’s Leading Information Source on <strong>Hardwood</strong> Markets!”<br />

71st Edition/<strong>2023</strong><br />

The HARDWOOD PRODUCTS SALES GUIDE that te ls you the species, grades, thicknesses and quantities of<br />

HARDWOOD LUMBER, IMPORTED WOODS, PLYWOOD, DIMENSION, ETC. purchased by woodworking<br />

plants in the United States and Canada.<br />

FEBRUARY COVERS <strong>2023</strong>.in d 1 1/16/23 10:40 AM<br />

You can get your share of this market<br />

quicker when these buyers know who you are<br />

and where you’re located!<br />

Advertising Sparks Sales!<br />

Mahogany .................... 746<br />

Sapele ......................... 221<br />

Teak ............................. 125<br />

<strong>Hardwood</strong> marketIng dIrectory<br />

online will give you access to over 6,000 buyers!<br />

These are high grade & low grade<br />

buyers listed with their buying<br />

specifications including distribution/<br />

concentration yards that buy 100,000<br />

board feet or more throughout North<br />

America!<br />

LEASE ONLINE NOW<br />

FOR $2,100.00!<br />

Imported Buyers<br />

Red Oak .........................2535<br />

White Oak .......................1692<br />

Poplar .............................1644<br />

Ash .................................788<br />

Hard Maple .....................1810<br />

Soft Maple ......................1451<br />

Walnut ............................1203<br />

Cherry .............................1673<br />

These are the BIG THREE species in our Imported section<br />

of the <strong>Hardwood</strong> Marketing Directory online!<br />

Meet BID’s hardwood optimizer,<br />

the automated grading solution<br />

that transforms your production.<br />

• Unmatched precision and defect detection<br />

• 24/7 reliability and consistency<br />

• Smooth operations with minimal upkeep<br />

• Quick payback<br />

Looking for a geometric edging or trimming scanner?<br />

BID’s expertise extends to retrofitting all scanners<br />

and AI can be seamlessly integrated later.<br />

DON’T LET THE WORKFORCE<br />

SHORTAGE HINDER YOUR<br />

PROGRESS—LET AI REDEFINE<br />

THE WAY YOU WORK.<br />

The <strong>Hardwood</strong> Marketing Directory has 68 years of research helping firms discover new<br />

buying opportunities and contains all North American species and also Imported Woods.<br />

GREEN BOOK, INC.<br />

P.O. Box 34908 Memphis, TN 38184<br />

Phone: (901) 372-8280 FAX: (901) 373-6180<br />

www.millerwoodtradepub.com E-mail: greenbook@millerwoodtradepub.com<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE NOVEMBER <strong>2023</strong> n NATIONAL RealAmerican<strong>Hardwood</strong>.com/industry<br />

HARDWOOD MAGAZINE<br />

6<br />

9<br />

OCTOBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

Contact us today to unlock a world of possibilities!<br />

450-435-2121 | info@bidgroup.ca | www.bidgroup.ca

Our industry has<br />

stories to tell.<br />

We’re telling them.<br />

Contribute Now to Build Your World<br />

Contribute Now to Build Your World<br />

Contribute Now to Build Your World<br />

The Real American <strong>Hardwood</strong> Coalition has launched its Build Your World<br />

campaign The Real American in partnership <strong>Hardwood</strong> with Magnolia Coalition Network. has launched The ads its Build are inspiring Your World a national<br />

audience campaign The Real American<br />

by in partnership educating <strong>Hardwood</strong><br />

them with on Magnolia Coalition<br />

the benefits Network. has<br />

of launched<br />

Real The American ads its Build are inspiring <strong>Hardwood</strong>® Your World a national products.<br />

audience campaign by in partnership educating them with on Magnolia the benefits Network. of Real The American ads are inspiring <strong>Hardwood</strong>® a national products.<br />

The audience campaign by educating was made them possible on the thanks benefits to of voluntary Real American contributions <strong>Hardwood</strong>® from the<br />

products.<br />

hardwood The campaign industry. was made Your continued possible thanks support to is voluntary critical to contributions advance the from initiative the and<br />

reclaim hardwood The campaign<br />

market industry. was<br />

share made Your for the continued possible<br />

benefit thanks support of all industry to is voluntary critical stakeholders.<br />

to contributions advance the from initiative the and<br />

reclaim hardwood market industry. share Your for the continued benefit support of all industry is critical stakeholders.<br />

to advance the initiative and<br />

Help reclaim Build market Your share World. for Learn the benefit more about of all industry the RAHC’s stakeholders.<br />

promotion efforts,<br />

see Help a Build list of Your supporters, World. Learn and make more a about voluntary, the RAHC’s tax-deductible promotion contribution efforts, at<br />

RealAmerican<strong>Hardwood</strong>.com/industry see Help a Build list of Your supporters, World. Learn and make more a about voluntary, the<br />

or RAHC’s<br />

scan tax-deductible the promotion<br />

QR code. contribution efforts, at<br />

RealAmerican<strong>Hardwood</strong>.com/industry see a list of supporters, and make a voluntary, or scan tax-deductible the QR code.<br />

contribution at<br />

RealAmerican<strong>Hardwood</strong>.com/industry or scan the QR code.<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.<br />

8 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 9<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.

HARDWOOD CALENDAR<br />

<strong>December</strong><br />

Southwestern <strong>Hardwood</strong> Manufacturers Club,<br />

The Grand Hotel, Point Clear, AL.<br />

www.swhmc.com. Dec. 1-2<br />

January 2024<br />

Appalachian Lumbermen’s Club, Meeting,<br />

Embassy Suites., Greensboro, NC.<br />

www.lumberclub.org. Jan. 9.<br />

February<br />

Indiana <strong>Hardwood</strong> Lumbermen’s Assoc.,<br />

Convention, Indianapolis Marriott Downtown,<br />

Indianapolis, IN. www.ihla.org. Feb. 5-7.<br />

Appalachian <strong>Hardwood</strong> Manufacturers Inc.,<br />

Annual Meeting, The Hammock Beach Resort,<br />

Palm Coast, FL. www.appalachianhardwood.org.<br />

Feb. 21-25.<br />

<strong>National</strong> Association of Home Builders,<br />

International Builders’ Show, Las Vegas, NV.<br />

www.buildersshow.com. Feb. 27-29. n<br />

Introducing...<br />

VisionTally set a new standard for end-tally accuracy, automatically scanning<br />

and measuring bundles from both ends at once with unmatched laser accuracy.<br />

Now, the next generation VisionTallyHD pushes that standard even further:<br />

• Higher accuracy<br />

• Reduced labor<br />

• Increased reliability<br />

• Faster scanning under 1 minute<br />

• Enhanced wane detection<br />

• Improved dark lumber scanning<br />

The VisionTally Difference<br />

• The most accurate, automated,<br />

complete end-tally solution available<br />

• The only end-tally device that measures<br />

actual width and actual length<br />

• The only device certified by the NHLA<br />

Tally Machine Certification Program<br />

• World-wide reputation for accuracy that<br />

gives you confidence and builds trust with<br />

your customers<br />

BINGAMANLUMBER.COM<br />

PO Box 247, Kreamer, PA 17833<br />

☎ 570.374.1108 | 570.374.5341<br />

10 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

<br />

Industrial Vision Systems, Inc.<br />

sales@visiontally.com<br />

(215) 393-5300<br />

www.VisionTally.com<br />

Sawmill MD<br />

SawmillMD@mindspring.com<br />

Mike Ballard (850) 974-1195

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

Four lumber suppliers from the Lake States region recently<br />

agreed that market conditions have been “sluggish”<br />

overall in the last six months.<br />

According to one Wisconsin based lumber provider at<br />

the time of this writing, “Everyone is just buying what they<br />

need and not buying anything ahead.<br />

“It has been that way for the last 4-to-5 months,” he noted.<br />

“The buying part is the same as six months ago but<br />

the supply is not. No one is really caring about it as much<br />

because they don’t need much.<br />

“No one knows what to do,” he continued. “So, everyone<br />

is sitting on their hands because they don’t want to<br />

get stuck with the wrong materials.”<br />

His company, which deals with Poplar (typically 4/4,<br />

5/4 and 6/4), Red Oak and Aspen (4/4 and Select Commons),<br />

and Soft and Hard Maples (4/4 and Upper Commons),<br />

primarily provides materials to moulding, cabinet<br />

and RV companies.<br />

He added that recent mill closures have already begun<br />

to affect the industry.<br />

“There are going to be some problems coming down<br />

the road up here in Wisconsin,” he said. “People have<br />

nowhere to take their pulp. They are not going to cut up<br />

lumber not knowing what they’re going to do with the majority<br />

of their pulp.”<br />

A lumber representative in Indiana agreed that the<br />

“market is not as good as we wish.”<br />

“It has been pretty quiet,” she said. “Transportation<br />

doesn’t seem to be a problem like it was in the past. I<br />

assume that all of the matters overseas have affected<br />

sales.”<br />

Noting that her company handles Red and White Oak,<br />

Walnut, Hard and Soft Maple, Cherry and Poplar, she<br />

said that it specializes in 4/4 – 16/4.<br />

A supplier in Ohio said that the market has been “upand-down”<br />

recently.<br />

Noting that domestic lumber sales have been stronger<br />

than the European market, he said that the industry is “a<br />

little on the downside.”<br />

Throughout the Northeast lumber sources have mixed<br />

sentiments as to how the market is currently faring, with<br />

some stating that they are doing worse than they were<br />

six months ago and another stating that they are doing<br />

about the same.<br />

In Pennsylvania, a mill owner said that his business<br />

is not doing well, at the time of this writing. “We aren’t<br />

doing as well as we were six months ago,” he continued.<br />

“With everything that is going on globally, I think that<br />

people are worried and they are going to start spending<br />

less than they already were.”<br />

His sawmill offers Red, White and Black Oak, Cherry,<br />

Hard and Soft Maple, Beech, Hickory and Ash. “We harvest<br />

all <strong>Hardwood</strong>s that are native to Pennsylvania and<br />

saw mainly 4/4, with the occasional 5/4, 6/4 and 8/4,” he<br />

noted. “White Oak has been our best seller. It’s hot right<br />

now, between the stave mills and it being the specie of<br />

choice in the high-end homes, it has sold very well.”<br />

He said that his company sells to end users with kilns,<br />

pallet manufacturers and stave mills. When asked if his<br />

customers have recently offered any comments as to<br />

how their business is doing, he said that they seem to<br />

be in the same boat that he is.<br />

He mentioned that he owns a trucking company as<br />

well that hauls all of his sawmill’s lumber, from the time<br />

that the timber is cut to when it is shipped out. “The cost<br />

of fuel has affected our sales with how high the price of<br />

fuel has gotten.”<br />

A lumberman in New York said that his market seems<br />

to be fair. “We are able to move everything that we saw,”<br />

he said. “Pallet cants have been a challenge, but as far<br />

as the grade lumber we are able to move it, even if the<br />

prices aren’t what we want them to be.”<br />

He noted that his sales are about the same as they<br />

were six months ago, with it being a challenge then and<br />

a challenge now.<br />

His company offers Hard and Soft Maple and Cherry<br />

in 4/4 thickness and in grades No. 2 Common and Better.<br />

“Cherry seems to be easy to sell even though the<br />

Lumber sources throughout the Southeast region are<br />

a mixed bag, with comments ranging from the market<br />

has improved to sales have slowed down.<br />

In Tennessee a sawmill representative said that his<br />

market has improved, at the time of this writing. “We are<br />

doing better than we were six months ago. I think this is<br />

due to supply being down and the demand starting to<br />

pick up.”<br />

His company offers Ash, Cherry, Hard and Soft Maple,<br />

Hickory, Poplar and Red and White Oak in grades FAS,<br />

Nos. 1, 2 and 3A Common. “We are able to offer our<br />

Poplar in 4/4-6/4 thicknesses and White Oak in 4/4 and<br />

6/4 thicknesses, while we offer everything else in 4/4<br />

thickness,” he added. He also mentioned that White Oak<br />

has been a hot item for his company.<br />

His company sells to flooring companies, moulding<br />

and trim manufacturers, distribution centers and furniture<br />

manufacturers, as well as American exporters. “It seems<br />

that the U.S. and domestic business is fairly firm, while<br />

exports into Asia have been slow. Exports to Europe<br />

have been stronger than they have been to Asia lately,”<br />

he noted.<br />

He mentioned that the labor shortage continues to<br />

affect his company to an extent.<br />

In Alabama a lumber spokesperson said his White<br />

Oak sales have been doing well and Ash seems to be<br />

holding its own, while his Red Oak and Poplar sales are<br />

not doing as well.<br />

When asked if his sales were better than they were<br />

six months ago he mentioned that they might be doing a<br />

touch better than they were.<br />

The four main species that his company offers are Red<br />

and White Oak, Poplar and Ash in grades FAS Common<br />

and No. 2A Common and in thicknesses of 4/4 and 5/4.<br />

“We are worldwide, we sell into the international and<br />

the domestic markets,” he said. “Vietnam and China<br />

have both really slowed down and we aren’t hearing<br />

good things about either country.” He also mentioned<br />

that the domestic market wasn’t doing well, at the time<br />

<strong>Hardwood</strong> lumber suppliers on the West Coast reported<br />

stable to busy activity. Niche markets accounted for<br />

increased business while other markets stayed the same<br />

as the previous report. Throughout the region, several<br />

contacts mentioned challenging transportation concerns<br />

and are expecting availability shortages in the near term.<br />

One source in California said <strong>Hardwood</strong> activity is<br />

steady. “We’re seeing stable activity. I don’t know about<br />

our competitors but we haven’t seen much of a change.<br />

It’s been steady the last three months for us.”<br />

Carrying high-end and wider width lumber, he said,<br />

“We set ourselves apart from the commodities. The hospitality<br />

markets are looking for specialty products and<br />

that’s what we carry.”<br />

Carrying every species from Alder to Zebrawood, the<br />

source said the best moving item for his operation currently<br />

is Walnut and White Oak. “It doesn’t matter what<br />

cut, the Oak is moving,” he explained. “Rift cut, plain<br />

sliced, and quarter cut are all moving well in White Oak<br />

and Walnut. Probably our slowest species is Cherry right<br />

now.”<br />

As for transportation, he said availability of trucks has<br />

improved but pricing continues to rise. “We have seen<br />

tremendous increases in fuel prices along with surcharges<br />

that just seem to continue to rise,” he said.<br />

Looking ahead, the contact expects his market to remain<br />

the same but doesn’t think the same is true for<br />

commodity markets. “It’s a hard market if you’re not a<br />

specialty supplier right now. Due to prices of fuel rising<br />

and availability tightening, not everyone is willing to pay<br />

those increases.”<br />

“Most of our customers are booked for the next few<br />

months,” a contact in Washington noted. One issue that<br />

challenges them, he added, is “freight costs are starting<br />

to go back up because of fuel cost.”<br />

The <strong>Hardwood</strong> supplier, who handles mostly White<br />

Oak, said he expects lumber shortages in the coming<br />

months. “We’ll probably see some shortages in the<br />

whitewoods, such as the Maples and Walnut. Walnut<br />

Please turn to page 67 Please turn to page 68<br />

Please turn to page 68 Please turn to page 69<br />

12 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 13

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

ONTARIO<br />

With the American Thanksgiving and hunting season<br />

behind us, and as we approach the Holiday Season,<br />

businesses are winding down for this usual break and<br />

slowdown in business until the new year. They are taking<br />

this time to look ahead and plan, while remaining cautiously<br />

optimistic that inflation will go down, <strong>Hardwood</strong><br />

lumber and products sales will improve both on the domestic<br />

and international markets, and that the new year<br />

will yield a better profit. With demand still being down<br />

for <strong>Hardwood</strong> products, it is challenging to find lumber<br />

and logs as production has not increased much, and demand<br />

for finished goods also remains on the slow side.<br />

Businesses are purchasing what they need for the short<br />

term, only replenishing stocks as required. According to<br />

sources, industrial products are more in demand at this<br />

time, with the railroad tie and wooden pallet and container<br />

sectors the most significant end users. It was noted<br />

that <strong>2023</strong> was heading to be a record low year for consumption<br />

of <strong>Hardwood</strong>s.<br />

Ash production has been steady over the summer,<br />

and so demand for this species has been absorbing developing<br />

production, noted contacts. Kiln-dried business<br />

is reported as decent, even though domestic and international<br />

markets are not strong, it is however keeping<br />

inventories low for many grades and thicknesses with<br />

prices being noted as steady to firm.<br />

End users commented that Aspen supplies are ample.<br />

However, orders are a challenge to find, with pricing being<br />

highly competitive. Some sawmills are keeping their<br />

Aspen logs to a minimum at this time due to sales issues<br />

and possible staining if this species is not sawn at appropriate<br />

time. Demand for green lumber is in line with<br />

production output.<br />

Industries that were using Basswood as an alternative<br />

to the higher priced species have reverted back to<br />

purchasing sheet stock or reverted to buying other species.<br />

Competition for orders is intense noted contacts,<br />

with the Common grades cited as problematic, although<br />

all grades appear to be under price pressure at this<br />

QUEBEC<br />

The fall and early winter is seeing lackluster demand<br />

for lumber and finished <strong>Hardwood</strong> products. Secondary<br />

manufacturers such as residential flooring, cabinets,<br />

wood components, some millwork and moulding manufacturers<br />

noted they were keeping busy, compared to<br />

other markets. Several sawmills have reduced their production<br />

as lack of available logs is making it challenging<br />

for them at this time. Several contacts noted that inventories<br />

are low. With the Christmas Holiday coming up, they<br />

don’t foresee any improvements over the near future.<br />

Contacts noted green Ash is moving well for most<br />

grades and thicknesses, with prices being firm. Exports<br />

at this time are steady with China being the main buyer.<br />

On the domestic side, shipments are steady, although at<br />

low levels.<br />

The wood components manufacturers, cabinets, and<br />

other finished goods are more assertive with their purchases<br />

of the regionally important Hard Maple, as are<br />

many wholesalers. End users have not increased their<br />

purchasing. Trends are driven by tighter supplies. Some<br />

have expressed concerns there will be tighter supplies<br />

in the coming months as prices continue to climb for this<br />

species.<br />

Wholesalers, end users and distributors of Soft Maple<br />

are looking to fill inventories, which have been depleted<br />

due to limited purchases in the past few months. Developing<br />

supplies of green lumber are not that readily available,<br />

stated contacts. As kiln-dryers did not process that<br />

much Soft Maple over the summer months because of<br />

lower interest for this species it has resulted in weaker<br />

prices. Many contacts noted they are low on specific<br />

grades and thicknesses of this species.<br />

Millwork and moulding manufacturers reduced their<br />

purchases of Basswood as did the shutter and window<br />

blinds manufacturers. Wholesalers are also limiting their<br />

purchases. Sawmill output has been low, and supply and<br />

demand has narrowed.<br />

Green lumber supplies of Cherry have contracted said<br />

contacts. Kiln-drying operations are looking for more<br />

High Quality Northern <strong>Hardwood</strong>s<br />

Specializing High Quality in Green and Northern Kiln Dried Hard <strong>Hardwood</strong>s<br />

Maple and Birch<br />

- QUALITY AND SUSTAINABILITY SINCE 1882 -<br />

Specializing in Green and Kiln Dried Hard Maple and Birch<br />

- QUALITY AND SUSTA INABILITY Contact for more SINCE info: 1882 -<br />

Over 40 million FBM annual<br />

production of hardwood makes<br />

Over J.D. Irving, 40 million Limited FBM one of annual the<br />

largest producers in Eastern<br />

J.D.<br />

Canada<br />

Irving,<br />

and<br />

Limited<br />

New England.<br />

one of the<br />

largest As one of producers the top 5 private in Eastern<br />

Canada landowners and in New North England. America<br />

we ensure a long term quality<br />

As wood one supply. of the top 5 private<br />

landowners in North America<br />

we ensure a long term quality<br />

wood supply.<br />

Denis Dubé, Sales Manager<br />

506.992.9025<br />

dube.denis@jdirving.com<br />

Contact for more info:<br />

Jan Coburn, Sales Coordinator<br />

506.992.5360 Denis Dubé, Sales Manager<br />

coburn.jan@jdirving.com<br />

506.992.9025<br />

dube.denis@jdirving.com<br />

Eric Desjardins, Sales Representative<br />

506.401.0060<br />

Jonathan Connely, Sales Representave<br />

desjardins.eric@jdirving.com<br />

506.992.9024<br />

connely.jonathan@jdirving.com<br />

Jan Coburn, Sales Coordinator<br />

506.992.9040<br />

coburn.jan@jdirving.com<br />

Please turn to page 69 Please turn to page 71<br />

Visit us online:<br />

Visit us online:<br />

www.JDIrvingLumber.com<br />

14 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 15

INDUSTRY NEWS<br />

AN UPDATE COVERING THE LATEST NEWS ABOUT<br />

HARDWOOD SUPPLIERS/VENDORS<br />

Robinson Lumber Company Continues<br />

To Ensure They Are At The Forefront Of<br />

The Industry<br />

Robinson Lumber Company, is proud to announce a<br />

significant expansion of its operations in New Albany, IN.<br />

The company has acquired an additional five acres of<br />

land adjacent to its flagship yard, marking a major step in<br />

its ongoing commitment to growth and innovation.<br />

The centerpiece of this expansion is the installation of<br />

the new Combilift CSS Slip Loader, a cutting-edge piece<br />

of equipment that streamlines container loading, reducing<br />

the process to an impressive under-six-minute timeframe.<br />

This advancement underscores Robinson Lumber's<br />

dedication to efficiency and safety in its operations.<br />

Joe Buckhaults<br />

leadership and dedication have left an indelible mark on<br />

the company, and his retirement is a moment of well-deserved<br />

recognition.<br />

To carry the torch forward, the company is pleased<br />

to introduce its new Chief Financial Officer (CFO), Cliff<br />

Worley. Worley joined the Robinson Lumber team in<br />

September <strong>2023</strong> and brings a deep commitment to excellence.<br />

His expertise and vision<br />

will play a crucial role in propelling<br />

this fifth-generation business into a<br />

dynamic and prosperous future, according<br />

to a company spokesperson.<br />

"This expansion and change in<br />

leadership are significant milestones<br />

in our company's history," said<br />

Wesley Robinson, North American<br />

<strong>Hardwood</strong> Manager. "We're excited<br />

about the opportunities they present<br />

and remain dedicated to delivering<br />

top-quality products and services to<br />

our valued customers."<br />

For more information about Robinson<br />

Lumber Company and its<br />

expanded operations, please visit<br />

www.roblumco.com.<br />

ented employees in all roles.<br />

Granite Valley produces Red and White Oak, Hard<br />

and Soft Maple, Walnut, Basswood, Aspen, Hickory,<br />

Chestnut, Poplar and eastern white pine in thicknesses<br />

of 4/4 through 8/4, all Forest Stewardship Council certified,<br />

BMSB certified in Australia and New Zealand, as<br />

Please turn to page 73<br />

Designed for <strong>Hardwood</strong>s<br />

TS Manufacturing Sorters, Stackers and Stick Placers<br />

are specifically designed for the challenging needs of<br />

random width hardwoods.<br />

+1.705.324.3762<br />

sales@tsman.com | tsman.com<br />

See our equipment<br />

in action on YouTube<br />

Cliff Worley<br />

Further enhancing operational efficiency,<br />

Robinson Lumber has also<br />

introduced the Combilift Side Loading<br />

Multi-Directional Forklift. This<br />

addition enables tighter aisle configurations<br />

and more efficient storage<br />

solutions. These investments are<br />

part of a comprehensive plan to reinvest<br />

in the flagship yard over the<br />

next five years, ensuring that the<br />

company remains at the forefront of<br />

the industry.<br />

Robinson Lumber Company is<br />

also proud to celebrate the retirement<br />

of its esteemed President, Joe<br />

Buckhaults. A dedicated and valued<br />

employee, Buckhaults's journey with<br />

Robinson Lumber began over 30<br />

years ago, and he worked his way<br />

up to the position of President. His<br />

Granite Valley Forest<br />

Products Welcomes<br />

Adam Hyer<br />

Granite Valley Forest Products,<br />

located in New London, WI, recently<br />

brought Adam Hyer on board as<br />

Upgrade Your Optimization<br />

24/7 SUPPORT from 3 time zones globally.<br />

BIG enough to support your operation. SMALL enough to care.<br />

+1.704.200.2350<br />

automationelecusa.com<br />

sales@automationelecusa.com<br />

Optimizers available:<br />

•Log Merchandisers<br />

•Board Edgers<br />

•Gangs<br />

•Trimmers<br />

•Log Carriages<br />

•PLC Controls/Panels<br />

•End Doggers/Sharpchains<br />

See our equipment<br />

in action on YouTube<br />

16 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 17<br />

Adam Hyer<br />

their supply chain manager. Hyer will<br />

oversee kiln-dried lumber buying,<br />

inventory turns, product and market<br />

development, strategic growth, as<br />

well as developing and recruiting tal-

HMA UPDATE<br />

As <strong>2023</strong> winds to a close, the <strong>Hardwood</strong><br />

Manufacturers Association (HMA)<br />

is making preparations for our 2024<br />

<strong>National</strong> Conference and Expo. The<br />

much-anticipated event will take place<br />

Monday–Wednesday, March 25–27, at<br />

The Charleston Place Hotel in Charleston,<br />

South Carolina. And if you’re an HMA<br />

member, industry supplier, or a <strong>Hardwood</strong><br />

industry stakeholder, then you’re invited and encouraged<br />

to attend! This year’s theme is Pathways to Success<br />

and our lineup of presenters and sessions will provide<br />

educational opportunities for all—from your company’s<br />

senior management to our industry’s next generation of<br />

leaders.<br />

Our Opening Reception and Expo on Monday, March<br />

25, will kick off HMA’s signature event with the industry’s<br />

premiere networking opportunity. Enjoy comradery with<br />

your peers and meet with vendors, while refreshments<br />

flow and appetizer stations nourish.<br />

And we’ll give you one spoiler alert for now. On the<br />

agenda is a virtual tour of NWH’s facility in Longview,<br />

Washington. See how sawmilling is in the Pacific<br />

Northwest, get a close-up look of their operations, and<br />

experience a birds-eye view of an Alder forest.<br />

Get all the NatCon details, take care of your registration,<br />

and book your accommodations at www.HMAmembers.<br />

org.<br />

A Year-End Thank You<br />

Before we say goodbye to <strong>2023</strong>, HMA staff would like<br />

to thank the 25 companies that have gone the extra<br />

mile and supported HMA’s promotional and educational<br />

efforts. Your contributions enabled HMA to influence<br />

homeowners through editorial and social media content,<br />

educate the design/build community via CEUs, and<br />

position American <strong>Hardwood</strong>s as the natural choice<br />

for today’s homes and commercial spaces.<br />

Looking Forward To 2024<br />

HMA Member Contributors<br />

Anderson-Tully Co.<br />

Baillie Lumber Co.<br />

Bingaman & Sons Lumber, Inc.<br />

Cersosimo Lumber Co.<br />

Dwight Lewis Lumber Co.<br />

East Perry Lumber Co.<br />

Holt & Bugbee Co.<br />

Jerry G. Williams & Sons, Inc.<br />

Kretz Lumber Company, Inc.<br />

Middle Tennessee Lumber Co.<br />

MO PAC Lumber<br />

Mueller Brothers Timber<br />

Northland Forest Products, Inc.<br />

RAM Forest Products, Inc.<br />

Stella-Jones Corporation<br />

The Turman Group<br />

Wellborn Cabinet, Inc.<br />

Non-Member Contributors<br />

Cedar Creek <strong>Hardwood</strong>s<br />

Cotton-Hanlon, Inc.<br />

<strong>Hardwood</strong> Market Report<br />

Maxwell <strong>Hardwood</strong> Flooring<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong><br />

SII Dry Kilns<br />

Swaner <strong>Hardwood</strong> Company<br />

W.M. Cramer Lumber Co.<br />

Thank you, all! And if you’d like to add your company<br />

name to these lists of supporters, send an email to<br />

myself at ljovanovich@hardwood.org or Ian Faight at<br />

ian@hardwood.org.<br />

We’ll see you in 2024! n<br />

BY LINDA JOVANOVICH,<br />

EXECUTIVE VICE PRESIDENT,<br />

HARDWOOD MANUFACTURERS ASSOCIATION,<br />

WARRENDALE, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

Please turn to page 57<br />

18 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 19

AHEC REPORT<br />

ESTABLISHED 1977 ESTABLISHED 2013<br />

2024 AHEC Events And Pavilions Are Opportunities To<br />

Connect With Customers And Find New Buyers<br />

In challenging markets, the personal relationship<br />

between suppliers and customers<br />

is more important than ever. The American<br />

<strong>Hardwood</strong> Export Council is planning a<br />

busy schedule of events in 2024 to develop<br />

these connections for your company and<br />

grow your global markets.<br />

In addition to what we expect to be a<br />

full slate of design, marketing, educational<br />

and networking events, AHEC has also<br />

planned pavilions at nine of the largest<br />

wood trade and furniture trade shows in<br />

the world in 2024, as well as an AHEC<br />

Convention in China. These pavilions will<br />

make premier representation available to<br />

American companies at the busiest events of the year<br />

for just $500 per booth.<br />

In 2024 we plan to host a U.S. <strong>Hardwood</strong> Pavilion at<br />

these events:<br />

IndiaWood, Bangalore, India (Feb 22-26)<br />

Dubai Woodshow, Dubai, UAE (Mar 5-7)<br />

Interzum Guangzhou, Guangzhou, China<br />

(Mar 28-31)<br />

FIMMA Maderalia, Valencia, Spain (May 14-17)<br />

SylvaWood, Shanghai, China (June 24-26)<br />

TechnoMueble, Guadalajara, Mexico (Aug 14-17)<br />

FMC Shanghai, Shanghai, China (Sept 10-13)<br />

INTERMOB, Istanbul, Turkey (Sept 12-15)<br />

AHEC Convention, China (September)<br />

TIWF Bangkok, Bangkok, Thailand (Sept 18-20)<br />

Each year AHEC attends over 40 trade<br />

shows globally to promote American <strong>Hardwood</strong>s,<br />

research market potential, and drive<br />

local purchasing behavior. In our experience,<br />

these shows we have selected provide the<br />

best opportunity this year for an American<br />

company to connect with local buyers and<br />

build strong relationships. Of course, our<br />

participation in all of these events is subject<br />

to travel restrictions and funding through the<br />

Farm Bill, and event dates are subject to<br />

change.<br />

IndiaWood in Bangalore, India will be our<br />

first pavilion of the year and is set up to accommodate<br />

up to 14 companies. Though traditionally<br />

a difficult place for Americans to do business,<br />

India has made rapid advances in the manufacturing<br />

sector and wood processing industry over the last few<br />

years. <strong>2023</strong> was a record year for exports of U.S. <strong>Hardwood</strong>s<br />

to India as our “exotic” woods are becoming a<br />

desired commodity in the local market. We have also<br />

seen an increase in exports of U.S. <strong>Hardwood</strong>s in value<br />

grades and species for re-export furniture. AHEC will<br />

also organize grading seminars and factory visits after<br />

this show in the Jaipur region of Rajasthan.<br />

Dubai Woodshow is the cornerstone of the timber<br />

business in the Middle East, with buyers from all over<br />

the region in attendance. Many Middle Eastern countries<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

Please turn to page 76<br />

CONVENIENCE<br />

3 offices to serve you better:<br />

Montreal, QC<br />

Alliston, ON<br />

Chesapeake, VA<br />

EXPERTISE<br />

Specializing in Lumber<br />

Exports out of North<br />

America<br />

MOVING YOUR<br />

FREIGHT FORWARD<br />

Your supply chain demands a freight<br />

forwarder that understands your products,<br />

suppliers and trade patterns, all while<br />

providing flexible customer service for your<br />

needs. We seamlessly integrate freight<br />

forwarding services with our deep<br />

knowledge of the lumber industry.<br />

Scan to request a Quote<br />

855-682-1637<br />

www.kingcitynorthamerica.com<br />

20 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 21

NHLA: Why Knot...<br />

HAVE THE HARD DISCUSSION ABOUT<br />

LONG TERM FUNDING FOR RAHC<br />

WE ARE GRAF BROTHERS<br />

The world’s largest manufacturer of<br />

rift & quarter sawn white oak products<br />

We are at the end of the year.<br />

We are also at the end of the first<br />

contract with Magnolia Network<br />

for the RAHC. We need a minimum<br />

of $1.4 million to keep it<br />

going for 2024. All our efforts last<br />

year only raised $700,000. Different<br />

companies from all sizes across the industry have<br />

stepped up to contribute. Still, we have only received donations<br />

from 200 unique companies in an industry with<br />

over 2,000 <strong>Hardwood</strong> lumber sawmills, concentration<br />

yards, distributors, and users. With less than 10 percent<br />

of the sector contributing, the RAHC will not be able to<br />

achieve its financial goals. Therefore, it cannot maintain<br />

its significant relationship with Magnolia and will lose all<br />

momentum and trust with them and Canvas. The associations<br />

are trying to step up for one year and raise an<br />

additional $700,000 on top of the $240,000 they already<br />

donated to RAHC. Please help these associations’ efforts.<br />

I have been the RAHC fundraising task force chair for<br />

a year now. I met with a task force member six months<br />

ago, and he asked me how it was going. I told him I was<br />

talking with two association executives and asking them<br />

to join the RAHC. The executive directors were interested<br />

but hesitant about the cost. I suggested they get their<br />

foot in the door by donating $5,000 and helping provide<br />

content and leadership. The $5,000 was not a significant<br />

cost to either but they needed board approval. To date,<br />

neither association has joined, but I fully expect it to happen.<br />

He asked me another question. “Is it still going to be<br />

this way five years from now? Are we going to spend<br />

hours of work chasing after $5,000 from different organizations<br />

to fund RAHC?” I replied<br />

frankly, “It’s worse than that;<br />

we are going to spend hours<br />

and hours chasing after $100,<br />

$1,000 and promises to give<br />

from everyone, each year, trying<br />

to raise 3 million dollars and getting<br />

funds from the same few people and never get close<br />

to our goal.” That statement has proven true. Of the 700<br />

companies who heard my RAHC rally cry at the NHLA<br />

convention, only 43 made donations, most of whom had<br />

already given, while all praised it and loved what we are<br />

doing.<br />

Can we be honest? And say that voluntary funding will<br />

fail in funding the RAHC long term.<br />

Can we also say that the other 30-60 associations affiliated<br />

with the <strong>Hardwood</strong> industry cannot fund RAHC<br />

long-term either? Why? Because they all have their mandates<br />

and programs beyond promotion that they need<br />

to keep doing, and they are just as strapped for cash as<br />

the <strong>Hardwood</strong> mills. NHLA gives 5 percent of its dues to<br />

the RAHC, which is still less than $100,000 annually. If<br />

NHLA gave 50 percent, it would be less than $800,000,<br />

and I would have to lay off half of the staff. Only if everyone<br />

doubles their dues will it work for associations to<br />

fund RAHC.<br />

Now what? We all want to keep it going. WHERE ARE<br />

WE GOING TO GET THE MONEY FOR RAHC? Yes, I<br />

yelled that. I have been talking about RAHC funding for a<br />

year and a half. Most people say they like the social media<br />

posts and the advertising. A few complain that it is not<br />

what they want, but even some complainers have donated.<br />

Everyone has had a chance to commit something. I<br />

have seen $100 checks and $75,000 checks. But what I<br />

We have the experience, the capacity and state-of-the-art<br />

manufacturing equipment to handle all your White Oak needs.<br />

PARTNER WITH THE ORIGINAL GRAF BROTHERS!<br />

Please turn to page 77<br />

BY DALLIN BROOKS,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-377-1082<br />

WWW.NHLA.COM<br />

QUALITY / LOYALTY / TRADITION<br />

606-932-3117<br />

sales@grafbro.com<br />

22 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry www.grafbro.com<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 23

NAFF BULLETIN<br />

THE RACE IS ON<br />

Doesn’t everyone enjoy the thrill of a great race–<br />

what’s your favorite–Formula 1, the Kentucky Derby, or<br />

the America’s Cup? While some provide entertainment<br />

for spectators, these events also may present life and<br />

death challenges for competitors.<br />

Outside the world of sports, as individuals and as industries,<br />

we’re engaged in other races. The kind that affect<br />

our wellbeing and that of the generations that follow<br />

ours.<br />

Who’s competing?<br />

The forest products industry is racing to establish a<br />

sustainable future, which will protect valuable resources<br />

and promote the benefits of wood. Using the Kentucky<br />

Derby, as an example, we’re in a race against False<br />

Messaging, Plastics Better, and Lady Laminate.<br />

And, they’re all coming up the back stretch fast and<br />

hard.<br />

Where are we now?<br />

The race is underway, and right now, the cheerleaders<br />

for using manmade materials are LOUD and extremely<br />

effective in getting their message out. Composites and<br />

products that blend synthetic substances with wood are<br />

popular for many goods, such as decking materials,<br />

flooring, and furniture.<br />

In place of wood, many of these products depend on<br />

other limited resources such as petroleum products. With<br />

the addition of these substances, the biodegradability of<br />

the finished item is reduced, as well as the amount of<br />

carbon stored.<br />

A detailed discussion of the pros and cons for these<br />

products is a topic for another day. What we need to understand<br />

is how effective is the message about sustainable<br />

forestry and why choosing wood products is best<br />

that people of all ages are seeing, hearing and acting<br />

upon.<br />

What’s at stake?<br />

Every race has a prize, and in this race the stakes are<br />

high because the “prize” is the overall health of our forests,<br />

people, industry, and planet.<br />

What’s the goal?<br />

Specifically the wood products industry needs to reach<br />

current and future generations with factual information<br />

and a compelling story to help guide their decisions as<br />

consumers and as workers making career choices.<br />

Actions we take as consumers and as members of the<br />

forest products industry have repercussions that affect<br />

us all. When consumers choose wood, and demand for<br />

real wood products is maintained, forested land remains<br />

more valuable as a working forest than as land to be<br />

co-opted for other purposes that don’t offer the same<br />

carbon-reducing benefits that trees provide.<br />

What’s the strategy?<br />

Cheerleaders play an important role; if two teams show<br />

up at an event and only one brings a cheer squad, the<br />

imbalance is easy to see.<br />

That’s why it’s so important now for the forest products<br />

industry to turn up the volume and become more effective<br />

at communicating the important roles that trees and<br />

wood products play in our world.<br />

The tactics for accomplishing this task include getting<br />

an accurate message about trees out to people of all<br />

ages; providing critical education to young people; and<br />

strengthening the pool of talented individuals entering<br />

the industry workforce.<br />

•Get the message out and repeat it. Spreading the truth<br />

about trees and wood is the key point to convey, and repetition<br />

is important in getting any message across.<br />

BY ALLISON DEFORD,<br />

EXECUTIVE DIRECTOR,<br />

NORTH AMERICAN FOREST FOUNDATION,<br />

COLLIERVILLE, TN<br />

901-860-4131<br />

adeford@northamericanforestfoundation.org<br />

Please turn to page 81<br />

• Tigerton Lumber Co., providing<br />

quality hardwoods since 1887<br />

• 80-acre site; 95,000 sq. ft. under roof<br />

• 50,000 acres of our own forest lands<br />

in Wisconsin, USA<br />

• Sawing 18,400,000 board feet/year<br />

• 12 on-site KDS Kilns drying up to<br />

780,000 board feet/month<br />

• 1,500,000 board feet of inventory<br />

to meet your needs<br />

• We offer color, width & length sorts to<br />

your specifications behind our planer<br />

• Export prep capabilities<br />

Unparalleled in quality, rich consistent color and<br />

exceptionally tight grain make northern hardwoods the premier<br />

choice in wood flooring, kitchen cabinets, architectural millwork,<br />

moldings, door & stair parts.<br />

From the forests of northern Wisconsin and Michigan, where<br />

rich soil, cold winters and a short growing season combine<br />

to create the perfect atmosphere for producing hardwoods<br />

of unrivaled excellence and beauty … Tigerton Lumber brings<br />

you a full line of premium northern hardwoods.<br />

Available for export worldwide!<br />

Contact Mike Schulke today!<br />

715.535.2181<br />

Please turn the page<br />

mike@tigertonlumber.com<br />

www.tigertonlumber.com<br />

24 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 25

“We’re constantly exploring new ways to have the best product and<br />

service possible because keeping our customers happy has definitely<br />

been the key to our success.”<br />

– Tim McCoy, Houston <strong>Hardwood</strong>s, President<br />

Tim McCoy, President of<br />

Houston <strong>Hardwood</strong>s.<br />

Guy Pike, Vice-president of<br />

Houston <strong>Hardwood</strong>s.<br />

Houston <strong>Hardwood</strong>s procures its kiln-dried domestic lumber from sawmills all over the country.<br />

Integrity, Knowledge And Premium <strong>Hardwood</strong><br />

Selection At Houston <strong>Hardwood</strong>s<br />

Houston <strong>Hardwood</strong>s, headquartered in Houston,<br />

TX, offers among the largest selection of <strong>Hardwood</strong>s<br />

in Texas. More than 600,000 board feet of <strong>Hardwood</strong>s<br />

are purchased annually in Alder, Ash, Cherry, Maple,<br />

Red and White Oak, Walnut, Birch, Pecan, Poplar and<br />

many more species. Additional product offerings include<br />

mouldings, softwood and imported lumber, plywood,<br />

MDF and melamine, edgebanding and veneer sheeting.<br />

With what may be the best balance of <strong>Hardwood</strong> species<br />

and industry experience, Houston <strong>Hardwood</strong>s continues<br />

to fit the niche it found in providing superior service<br />

and quality products. “We offer most of the common<br />

domestic <strong>Hardwood</strong>s and also quite a few of the exotic<br />

woods,” President Tim McCoy explained. “I would say<br />

75 percent of our lumber is domestic and the other 25<br />

percent is imported.”<br />

By Michelle Keller<br />

A solid business plan and reputation for excellence is<br />

what McCoy said keeps the operation successful and<br />

competitive. Houston <strong>Hardwood</strong>s was minimally (if at<br />

all) impacted by the covid pandemic that began in 2020.<br />

“It was business as usual for us,” he explained. “We<br />

changed our operating hours to adjust to the needs of<br />

our employees, but we’ve since reinstated them and<br />

we’re back at full capacity.”<br />

Founded in 1990 by McCoy, president, and Guy Pike,<br />

vice president, Houston <strong>Hardwood</strong>s also specializes in<br />

marine products which include marine grade plywood,<br />

Teak plywood, and solid Teak lumber as well as Teak and<br />

Holly boat decking. A combined 80 years of industry experience,<br />

McCoy said, “When we opened this business,<br />

I had worked at another <strong>Hardwood</strong> company and Guy<br />

was in the remodeling business prior to this operation.<br />

We have a lot of experience in the lumber industry. We<br />

brought different approaches, ways of thinking and educational<br />

backgrounds to the table; that helped set the<br />

stage for a successful business.”<br />

Today, Houston <strong>Hardwood</strong>s operates from a<br />

50,000-square-foot facility with about 18 employees.<br />

After just the first five years of operation, they started<br />

adding moulders to the equipment lineup. Now the<br />

company’s two SCMI moulders streamline the production<br />

process and designate specific machines to certain<br />

tasks. “We are continuously seeking new ways to offer<br />

the best product and service possible because keeping<br />

our customers satisfied is the key to our success,” Mc-<br />

Coy said.<br />

Since inception, the company has been growing<br />

steadily both in terms of sales and line/product expansion.<br />

“We’ve grown every year since then,” said McCoy.<br />

The company itself has also evolved into a full-blown<br />

manufacturing facility that specializes in planing wood<br />

and producing custom moulding. “Our mill capabilities<br />

were limited in the beginning,” said McCoy. “About five<br />

years into it, we started adding moulders to our equip-<br />

Please turn the page<br />

Houston <strong>Hardwood</strong>s continues to fit the niche it found in providing<br />

superior service and quality products, with what may be the best<br />

balance of <strong>Hardwood</strong> species and industry experience.<br />

26 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 27

HOUSTON HARDWOODS Continued<br />

Houston <strong>Hardwood</strong>s’ mill area.<br />

Houston <strong>Hardwood</strong>s purchases more than 600,000 board feet of<br />

<strong>Hardwood</strong>s annually in Alder, Ash, Cherry, Maple, Red and White<br />

Oak, Walnut, Birch, Pecan, Poplar and many more species.<br />

Houston <strong>Hardwood</strong>s is a<br />

full-blown manufacturing<br />

facility that specializes in<br />

planing wood and producing<br />

custom moulding.<br />

Houston <strong>Hardwood</strong>s, located in Houston, TX, operates from a<br />

50,000-square-foot facility with about 18 employees.<br />

ment lineup. That’s become a big part of our business.”<br />

Recently adding a new Powermatic planer to its<br />

equipment list, McCoy said using its two SCMI moulders,<br />

they’ve been able to streamline the production process<br />

and designate specific machines to certain tasks.<br />

“We use one of the machines to run patterns that we<br />

change up several times a day,” said McCoy, “and then<br />

we leave the other machine set up for S4S lumber. That<br />

saves us a lot of time and makes us much more efficient<br />

than if we were just using one machine for everything.”<br />

Houston <strong>Hardwood</strong>s procures its kiln-dried domestic<br />

lumber from sawmills all over the country. “We try to get<br />

some of our species like Oak and Poplar from sources<br />

that are closer to home to avoid high freight/transportation<br />

costs,” said McCoy. “Some of the other species like<br />

Maple and Walnut we usually try to get from sources<br />

further north due to the higher quality of those woods in<br />

that area of the country.”<br />

The company has maintained its focus on one of its<br />

biggest strengths: being able to turnaround orders in<br />

one to two days. Its customers – most of which are located<br />

within 100 miles of Houston – appreciate the quick<br />

turnaround time and the fact that quality is never sacrificed<br />

in lieu of speed. While most of its customers are in<br />

Texas, Houston <strong>Hardwood</strong>s does ship orders to clients<br />

in other parts of the country. “We are often surprised by<br />

where people call from, but we don’t argue. We get the<br />

order done and ship it out.”<br />

According to McCoy, most of the firm’s customers<br />

during the week are professionals, cabinet shops, contractors,<br />

furniture builders and other lumber yards that<br />

do not deal in <strong>Hardwood</strong>s. The company also caters to<br />

a number of DIY hobbyists and woodworkers. “We call<br />

them weekend warriors; they go crazy when they come<br />

in here and see our extensive selection,” said McCoy.<br />

“This is a customer segment that helps to round out our<br />

client base and gives us the opportunity to work with<br />

smaller, locally-based wood workers.”<br />

Houston <strong>Hardwood</strong>s is a member of the Lumbermen’s<br />

Association of Texas & Greater Louisiana and the Greater<br />

Houston Lumber & Building Materials Association.<br />

McCoy added, “We’re constantly exploring new ways<br />

to have the best product and service possible because<br />

keeping our customers happy has definitely been the<br />

key to our success.” n<br />

For more information, visit www.houstonhardwoods.com.<br />

28 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 29

HHP has a drying capacity of 75,000 board feet<br />

each dry kiln, with an annual drying capacity<br />

for Northern Red Oak of 6 million board feet.<br />

“ One thing that Marco and Joe<br />

have always emphasized is the<br />

quality of the products that we<br />

produce here at HHP and the<br />

pride that we have when we put<br />

it into the marketplace.<br />

Bruce Dahn, HHP<br />

<strong>Hardwood</strong> Kiln-dried Sales Manager<br />

“<br />

Taking<br />

Pride In<br />

Quality<br />

Products<br />

By Terry Miller<br />

HHP, Inc., located in Henniker, NH, was founded in<br />

1989 when Richard Carrier and Ross D’Elia purchased<br />

Henniker <strong>Hardwood</strong> Pallets. They broke ground on<br />

where the current mill stands, a few years later in 1992.<br />

HHP has since become a family affair with Richard Carrier<br />

and his brother, Marco Carrier, both now being HHP’s<br />

principals and Marco Carrier’s son, Joe Carrier serving<br />

as HHP’s general manager.<br />

HHP has an annual production of 13 million board feet,<br />

with 80 percent made up of Northern Red Oak. “The Red<br />

Oak from this region here in Central New Hampshire is<br />

sought after for its tight grain, consistent color, and its<br />

lack of mineral,” said Bruce Dahn, <strong>Hardwood</strong> kiln-dried<br />

sales manager. “Our customers won’t have to do any<br />

color sorting at the end of the day. The product that they<br />

buy from us is over trimmed and over edged so that they<br />

“Our most experienced graders oversee production being processed through the Trim Expert grading system,” said Bruce Dahn,<br />

kiln-dried sales manager at HHP, Inc.<br />

get a better yield and a better end result, allowing the<br />

customer to take our product and put it straight into their<br />

production process.” HHP is known for their consistency<br />

across all of their Red Oak production, as well as their<br />

other primary species, which include, Hard and Soft Maple,<br />

Ash and Yellow Birch.<br />

HHP saws 4/4 and 5/4 boards on a regular basis.<br />

“While our primary and biggest item is still 4/4, we always<br />

try to keep at least one kiln charge of 5/4 a month in<br />

process so we have it as a regular item across all grades<br />

from the uppers right down into the common grades,”<br />

Dahn continued.<br />

HHP offers custom widths and lengths, as well as proprietary<br />

grades. Their bin sorter allows them to hone in<br />

on their customers’ needs as they grade their kiln-dried<br />

lumber for a second time. “Re-grading our kiln-dried material<br />

ensures we catch any degrading of the lumber and<br />

to make sure our customers get the consistency and value<br />

they continue to invest in,” Dahn said.<br />

HHP has a wide range of customers, from those looking<br />

for lumber to go into high-end flooring or a millwork<br />

application to those looking for custom to standard pallets.<br />

“We manufacture what works best for our customer,”<br />

Dahn noted. “From the custom sorts that go to our<br />

high-end end-use customers to the distributors and manufacturers<br />

that need a custom designed pallet to carry<br />

the load that they want shipped, we strive to be efficient<br />

and cost effective by consuming all of the full range of<br />

products that are produced in the mill.”<br />

HHP is known to promote the ease that comes with doing<br />

business with them, whether it is moving material in<br />

and out of their facilities, or the consistency of their product,<br />

they strive to make their clients lives simpler. “You<br />

can receive HHP lumber any way you want, as long as it<br />

has the HHP logo and blue paint on the ends,” remarked<br />

Dahn. “Our customers that we sell to on a repeat basis,<br />

especially the distributors, see this as an added value on<br />

an already superior product.”<br />

Please turn the page<br />

30 DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

DECEMBER <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 31

HHP, INC. Continued<br />

Another way that HHP continues to add value to their<br />

products, is to end wax every pack of green lumber produced,<br />

all year-round, with U-C Coatings Anchorseal.<br />

Whether it is going on sticks for kiln drying in HHP’s kilns<br />

or being sold green.<br />

“One thing that Marco and Joe have always emphasized<br />

is the quality of the products that we produce here<br />

at HHP and the pride that we have when we put it into the<br />

marketplace,” said Dahn. HHP makes a point to pay attention<br />

to the little things, like putting grooved HT export<br />

blocks on every pack produced so that they are easier to<br />

move around and no loose blocks have to be picked up<br />

after moving packs.<br />

The added details that HHP puts into their products<br />

goes beyond adding extra blocks on packs leaving their<br />

sawmills. “Our most experienced graders regularly go<br />

back through packs of green & KD lumber to ensure the<br />

Trim X System’s output,” Dahn noted. “We are not trying<br />

to force boards up, into a grade. So, when a grader<br />

disagrees with how the Grade X System viewed the<br />

board, we go into the system and recalibrate the way it<br />

interprets the defects seen so we are consistently getting<br />

the production graded the way we want. We can do this<br />

because every board is sprayed with a unique identifying<br />

number as it is moved to the bin sorter.”<br />

HHP uses VisionTally with their kiln-dried lumber, ensuring<br />

that each piece is accounted for, and the footage<br />