National Hardwood Magazine - February 2024

Get the latest news on the Hardwood industry in this month's issue of National Hardwood Magazine! This issue features stories on Dura Supreme Cabinetry's expansion, Stolzfus Forest Products, KopCoat and much more.

Get the latest news on the Hardwood industry in this month's issue of National Hardwood Magazine! This issue features stories on Dura Supreme Cabinetry's expansion, Stolzfus Forest Products, KopCoat and much more.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 1

INDUSTRIES<br />

CONTROLS<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1240 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry JoeScan<br />

JS-50X6 Heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

n Over 170 systems sold<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

STEFAN DRACOBLY PAUL CLEEREMAN DAN TOOKE<br />

President Of<br />

VP Cleereman Senior Optimization<br />

Controls<br />

Industries & Controls & Controls Engineer<br />

2 FEBRUARY <strong>2024</strong> n NATIONAL SalesHARDWOOD MAGAZINE info@cleereman.com<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> FEBRUARY <strong>2024</strong> Volume 98 No. 1<br />

Features & Industry Events<br />

22<br />

24<br />

26<br />

28<br />

Dura Supreme Cabinetry Starts<br />

Production At Their Multi-Million<br />

Dollar Expansion<br />

Stoltzfus Forest Products: Doing It<br />

All From Timber Tract To Lumber<br />

Board<br />

KopCoat’s Reach Expands In The<br />

<strong>Hardwood</strong> Sector<br />

Lumber Shipping Companies Are<br />

Cautiously Optimistic As Traditional<br />

Trends Return<br />

Departments<br />

6 <strong>Hardwood</strong> Calendar<br />

8 U.S.A. Trends<br />

10 Canadian Trends<br />

12 Industry News<br />

14 HMA Update<br />

16 AHEC Report<br />

18 NWFA Review<br />

20 NHLA: Why Knot...<br />

54 In Memoriam<br />

72 Who’s Who<br />

30<br />

34<br />

SWHMC Meeting Attendees Share<br />

Insights About Market Conditions<br />

West Side <strong>Hardwood</strong> Club Enjoys<br />

Annual Holiday Lunch<br />

22<br />

78 Classified Profit<br />

Opportunities<br />

80 Advertisers Index<br />

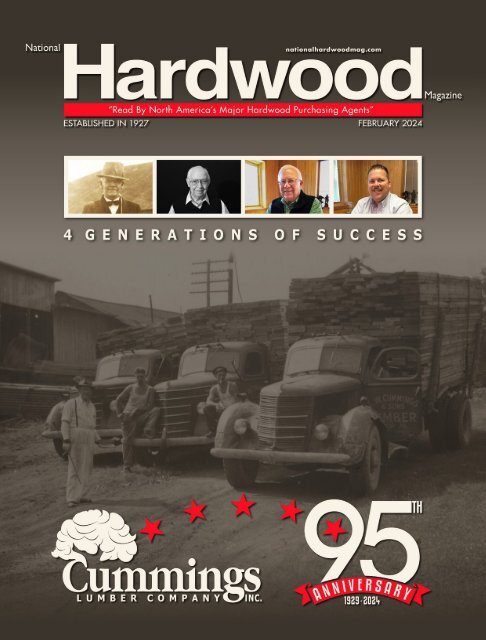

About The Cover<br />

CUMMINGS LUMBER COMPANY, INC.<br />

Lee William Cummings moved to Troy,<br />

Pennsylvania in 1929 to found L.W. Cummings<br />

& Son Lumber Company. Because there was<br />

no electricity in Troy at that time, he built<br />

his mill close to a road and stream and used<br />

steam engines for power. Logs were skidded<br />

with horses and lumber was shipped on rail<br />

cars. Roy W. Cummings, Sr. joined his father<br />

in 1942. Roy W. Cummings Jr. joined his father<br />

in 1968 and they continued to expand the<br />

business under the name of Cummings Lumber Company, Inc. Today<br />

Scott Cummings the founder’s great grandson directs the company. The<br />

lumber company prospered through the years thanks to their undying<br />

commitment to provide customers with quality products and service. For<br />

four generations, that commitment to quality has become a Cummings<br />

family tradition.<br />

Cummings Lumber Company, Inc.<br />

Troy, PA<br />

570-297-4771<br />

CummingsLumber.com<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Terry Miller – President<br />

Paul J. Miller Jr. – Co-owner<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Cadance Hanson - Staff Writer<br />

Graham Sweeney - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

Quit Your<br />

Pitching<br />

with our proven system<br />

Prevent resin and pitch buildup by reducing friction<br />

when applied with our Lube Master 1000 Spray<br />

System. Biolube offers formulations for all species.<br />

100% satisfaction guarantee!<br />

Installs on:<br />

• Head Rigs • Line Bars<br />

• Edgers • Pallet Saws<br />

• Gang Rips • Moulders<br />

• Finger Jointers<br />

New Customer Special:<br />

$100 shipping credit on a Lube Master Spray<br />

System. Expires 12-31-24. Mention code NH24.<br />

BIOLUBE<br />

The original innovator in saw lubrication.<br />

www.biolube1.com • 260-414-9633<br />

2 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 3

DO MORE<br />

WITH LESS<br />

eLIMBS | Agility | TallyExpress | Neural Grader<br />

Ease the pain of staffing shortages with inventory<br />

management solutions made for hardwoods. DMSi is<br />

your one software partner from timber to consumer.<br />

Watch the success story<br />

SCAN TO WATCH<br />

FRANK MILLER<br />

LUMBER CO<br />

SEE US AT IHLA<br />

BOOTH #511 & 610<br />

dmsi.com

HARDWOOD CALENDAR<br />

<strong>February</strong><br />

Indiana <strong>Hardwood</strong> Lumbermens Assoc., Convention,<br />

Marriott Indianapolis Downtown, Indianapolis, IN.<br />

www.ihla.org. Feb. 5-7<br />

Appalachian <strong>Hardwood</strong> Manufacturers Inc., Annual<br />

Meeting, The Hammock Beach Resort, Palm Coast, FL.<br />

www.appalachianhardwood.org. Feb. 21-25<br />

March<br />

Appalachian Lumbermen’s Club, The Hotel Roanoke,<br />

Roanoke, VA. www.lumberclub.org. March 12<br />

<strong>Hardwood</strong> Manufacturers Assoc., <strong>National</strong><br />

Conference and Expo, The Charleston Place,<br />

Charleston, SC. www.hmamembers.org.<br />

March 25-27 n<br />

NAHB IBS, Las Vegas Conv. Ctr., Las Vegas, NV.<br />

www.buildersshow.com. Feb. 27-29<br />

6 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

• Tigerton Lumber Co., providing<br />

quality hardwoods since 1887<br />

• 80-acre site; 95,000 sq. ft. under roof<br />

• 50,000 acres of our own forest lands<br />

in Wisconsin, USA<br />

• Sawing 18,400,000 board feet/year<br />

• 12 on-site KDS Kilns drying up to<br />

780,000 board feet/month<br />

• 1,500,000 board feet of inventory<br />

to meet your needs<br />

• We offer color, width & length sorts to<br />

your specifications behind our planer<br />

• Export prep capabilities<br />

Unparalleled in quality, rich consistent color and<br />

exceptionally tight grain make northern hardwoods the premier<br />

choice in wood flooring, kitchen cabinets, architectural millwork,<br />

moldings, door & stair parts.<br />

From the forests of northern Wisconsin and Michigan, where<br />

rich soil, cold winters and a short growing season combine<br />

to create the perfect atmosphere for producing hardwoods<br />

of unrivaled excellence and beauty … Tigerton Lumber brings<br />

you a full line of premium northern hardwoods.<br />

Available for export worldwide!<br />

Contact Mike Schulke today!<br />

715.535.2181<br />

mike@tigertonlumber.com<br />

www.tigertonlumber.com

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

While lumbermen in the Lake States continued to<br />

steadily “move wood” through the fourth quarter of 2023,<br />

they agreed that “something must change” in order to hit<br />

the ground running in <strong>2024</strong>.<br />

A Wisconsin source called the 2023 fourth quarter<br />

market “steady” but added that nothing is “booming.”<br />

“We are still moving most species except Aspen and<br />

Basswood,” he noted. “The prices are not what I’d like in<br />

most cases.”<br />

He said that White Oak sales are “great” and that there<br />

have been no issues procuring the sought after species.<br />

Noting that his best months for sales are traditionally<br />

January through March, he said that interest rates must<br />

be lowered to keep the trend intact.<br />

Specializing in 4/4 and 5/4 Red and White Oak, Hard<br />

and Soft Maple, Ash, Aspen and Basswood, the source<br />

Overall, lumber sources in the Northeast region said<br />

that their sales were better than they were six months<br />

ago.<br />

A lumberman in Maryland said that aside from White<br />

Oak remaining strong and with prices rising, he has noticed<br />

that Poplar and Red Oak have gotten harder to<br />

move. “Some species are easier to move and some are<br />

harder to move than they were six months ago, but all in<br />

all, I would say that we are doing better than we were six<br />

months ago,” he stated.<br />

He offers Red and White Oak and Poplar, as well as<br />

some Gum, Maple, Hickory and Beech in a variety of<br />

grades and in 5/4 thickness.<br />

He sells his upper grade lumber to distribution yards,<br />

while he sells his lower grade lumber to pallet, mat and<br />

crosstie manufacturers. “The distribution yards that I sell<br />

Please turn to page 53 Please turn to page 56<br />

Throughout the Southeast region lumber sources<br />

agreed that their markets are rather quiet, at the time of<br />

this writing. One source noted that while his sales are<br />

slow, he has started to receive more inquiries out of Asia<br />

than expected.<br />

In North Carolina, a sawmill representative said that<br />

his sales have been slower than they were six months<br />

ago aside from an uptick in inquiries from Asia. He noted<br />

that for his domestic sales it is most likely due to the time<br />

of year that has caused a slowdown.<br />

His company offers Red and White Oak and Poplar, in<br />

all NHLA grades and in thicknesses of 4/4 through 8/4.<br />

“White Oak is selling best for us right now,” he stated.<br />

He mentioned that White Oak is likely selling better due<br />

in part to the stave mills looking to buy lower grade logs<br />

which in turn affects the regular random width and random<br />

length markets.<br />

Please turn to page 57<br />

Lumbermen on the West Coast recently spoke with<br />

nervous intrigue regarding the first quarter of <strong>2024</strong>.<br />

At the time of this writing, three sources were slogging<br />

through a “sporadic” December that saw many lumber<br />

suppliers selling “order-to-order.”<br />

“Customers are concerned (with high interest rates)<br />

and everyone’s orders have slowed down,” said a Washington<br />

source with 35 years of experience in the business.<br />

“We have been in the black for the last 11 months.<br />

December could put us in the red.<br />

“The sales volume is off at least 50 percent from 2022<br />

in December,” he added. “So, this really stands out from<br />

previous years.”<br />

When asked what it would take to get business back<br />

on track, he said “home loans should be more affordable.”<br />

Please turn to page 58<br />

4/4 White Oak Rift/Quarter Sawn - 4/4 White Oak Plain Sawn - 4/4 Red Oak - 4/4 Poplar<br />

GTL Lumber, Inc.<br />

Ironton, OHIO 45638<br />

est. 2018<br />

Contact: Erin Cox<br />

740-250-4227<br />

erin@GTLlumber.com<br />

STOP WORRYING<br />

When you think Quarter Sawn, think GTL Lumber!<br />

Manufacturing premium quality creates structural integrity, sustainability and<br />

highlights the natural beauty of Quarter Sawn lumber.<br />

Choose GTL for your Appalachian Oak and Poplar! Give us a call today!<br />

8 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 9

ONTARIO<br />

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

In advance of the 2023 Holiday season and into New<br />

Year’s, sawmills sawed more lumber ahead of this period.<br />

Many secondary manufacturers took extended<br />

breaks during this time in most areas on both sides of<br />

the border. This resulted in lower demand for raw materials.<br />

In certain areas, obtaining logs and pricing were<br />

a challenge thus impacting output. As we move into a<br />

new year, facing uncertainty, volatility and complexities<br />

will be top of mind, as will be employee retention and<br />

recruitment for the <strong>Hardwood</strong> industry.<br />

Ash production was down in certain areas and green<br />

lumber had seen a contraction over the Holidays. Markets<br />

are reported to be absorbing developing supplies.<br />

Kiln-dried stocks are controlled, however, domestic and<br />

international customers are being adequately supplied.<br />

Most are purchasing for immediate needs.<br />

Supplies of Hard Maple were ample for most sec-<br />

QUEBEC<br />

Another year has begun and the <strong>Hardwood</strong> industry<br />

is busy, striving to improve efficiencies, boost margins,<br />

deal with supply chain shortages, rising interests rates,<br />

expand their sales while serving established customers<br />

and vying for new ones, all in the hopes of increasing<br />

profits. Contacts remain cautiously optimistic that business<br />

will improve this year as they face the new challenges<br />

before them through innovation and creativity.<br />

Ash sales have slowed and shipments to China are not<br />

increasing, stated contacts. Prices are in a downward<br />

trend. However, green Ash is moving to concentration<br />

yards. Basswood sales have deteriorated noted contacts.<br />

Secondary manufacturers have reduced their purchases<br />

of this species due to a slowdown in their business<br />

sector and also competition from other materials<br />

that are being used as alternates. Moulding producers<br />

Please turn to page 59 Please turn to page 60<br />

SMART RESAW<br />

FOR SUPERIOR<br />

PRODUCTS<br />

BID’S NEW RESAWEXPERT<br />

Introducing BID’s AI-powered linear ResawExpert with<br />

vision—where precision, efficiency, and innovation<br />

redefine hardwood processing.<br />

Our revolutionary technology intelligently maximizes yield<br />

and minimizes waste, ensuring every inch of your raw<br />

material is utilized efficiently.<br />

BID’s leading AI-powered optimization applied<br />

to resaw features:<br />

• Independent optimization and grading of all four faces<br />

of your product to maximize its value<br />

• Rotation validation scanner<br />

• Optimization by unit of clear wood, NHLA cutting grades<br />

or custom grades<br />

• Quick and easy installation on an existing line<br />

The new optimizer can be installed during ongoing operations<br />

and activated once tuning is completed!<br />

Contact us today to upgrade your wood processing capabilities!<br />

#MWC<strong>2024</strong><br />

450-435-2121 | info@bidgroup.ca | www.bidgroup.ca<br />

10 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry

INDUSTRY NEWS<br />

AN UPDATE COVERING THE LATEST NEWS ABOUT<br />

HARDWOOD SUPPLIERS/VENDORS<br />

MiCROTEC Appoints Ofer Heyman As<br />

New Corvallis CEO<br />

MiCROTEC, a global leader in innovative scanning<br />

solutions for the wood products industry, is pleased to<br />

announce the appointment of Ofer Heyman as its new<br />

Chief Executive Officer in Corvallis, OR. Heyman brings<br />

a wealth of experience and a background in the industry,<br />

making him a valuable addition to the MiCROTEC team.<br />

Prior to returning to MiCROTEC, Heyman served an<br />

impressive 17-year tenure at Lucidyne Technologies,<br />

acquired by MiCROTEC in 2020. Beginning as an image<br />

processing engineer in 1999, Heyman assumed<br />

project is one of nine projects in Oregon to receive grants<br />

totaling more than $4 million during FY 2023 through the<br />

forest service’s wood innovations and community wood<br />

grants programs. The programs’ primary purpose is to<br />

support local economies while directly contributing to im-<br />

Please turn to page 62<br />

Ofer Heyman<br />

roles like senior product and project<br />

manager, director of business development,<br />

and ultimately, director of<br />

operations from 2014 to 2016.<br />

Frank Jöst, MiCROTEC Group<br />

CEO, expressed his enthusiasm<br />

about Ofer’s return, “We are happy<br />

that we convinced Ofer to come<br />

back to Corvallis and support us as<br />

we continue the MiCROTEC vision<br />

for the North American Market.” Mi-<br />

CROTEC looks forward to leveraging<br />

Heyman’s leadership and industry<br />

experience to further strengthen<br />

its position as a pioneer in wood<br />

scanning solutions.<br />

MiCROTEC is a global technology<br />

partner for the wood processing<br />

industry, constantly developing new<br />

approaches and solutions to add<br />

value to the sawmilling and wood<br />

processing industry.<br />

For more information, visit www.<br />

microtec.us.<br />

Merrick <strong>Hardwood</strong>s<br />

Welcomes Chad Hinton<br />

Merrick <strong>Hardwood</strong>s located in<br />

Somerset, KY is pleased to introduce<br />

Chad Hinton as the <strong>Hardwood</strong><br />

Flooring Sales Manager. Hinton is<br />

12 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 13<br />

Chad Hinton<br />

replacing Diana Gurley who recently<br />

retired after 35 years with the company.<br />

In his new role Hinton will<br />

oversee all of Merrick’s unfinished<br />

<strong>Hardwood</strong> flooring sales. Merrick<br />

produces unfinished solid flooring in<br />

both Red and White Oak, Hard Maple<br />

and Hickory.<br />

Hinton graduated from the University<br />

of Kentucky in 2011 with a bachelor’s<br />

degree in economics. Upon<br />

graduation Hinton entered the United<br />

States Air Force where he served his<br />

country for six years as an Airbourne<br />

Systems Engineer. He returned to<br />

Somerset, KY and worked for four<br />

years with a convenience store distribution<br />

company as the Equipment<br />

Service and Sales Manager.<br />

Hinton and his wife Sarah have<br />

one son. He is an avid golfer and<br />

plays as much as possible.<br />

For more information visit www.<br />

merrickgroup.com or call 606-561-<br />

4146.<br />

Patrick Lumber<br />

Manufacturing Adds<br />

Sawmill With U.S.<br />

Forest Service Grant<br />

Patrick Lumber Manufacturing<br />

(PLM) has begun work to add a<br />

sawmill at its manufacturing facility<br />

located in Philomath, OR. The mill is<br />

being funded in part by a $1 million<br />

Community Wood Grant provided by<br />

the USDA Forest Service. Patrick’s

HMA UPDATE<br />

Will We See You In Charleston?<br />

Our industry has<br />

stories to tell.<br />

HMA’s <strong>2024</strong> <strong>National</strong> Conference and<br />

Expo is just around the corner. And we<br />

hope we’ll see you at The Charleston<br />

Place in Charleston, SC, Monday–<br />

Wednesday, March 25–27. Remember,<br />

this HMA event is open to all <strong>Hardwood</strong><br />

industry stakeholders — producers,<br />

processors, distributors, and suppliers.<br />

If you haven’t yet registered, take care<br />

of business today. Registration rates<br />

increase March 1.<br />

This year’s Conference theme is Pathways to<br />

Success and our slate of learning sessions is focused<br />

on helping you navigate your company’s future, adapting<br />

to our industry’s ever-evolving landscape, dealing with<br />

economic markets, and much more. There will also be<br />

a virtual tour of NWH’s facility in Longview, WA. Get a<br />

close-up look of their operations and see how sawmilling<br />

is done in the Pacific Northwest!<br />

You also won’t want to miss the sold-out Expo portion of<br />

the event to visit with industry suppliers, as well as learn<br />

about their new equipment and services. The Southern<br />

Cypress Manufacturers Association will also be holding<br />

its <strong>2024</strong> Annual Meeting during the Conference. So,<br />

there’s sure to be plenty of opportunities for networking<br />

and information exchange.<br />

All of the details can be found online at<br />

www.HMAmembers.org. Join us!<br />

Calling All Golfers<br />

Are you a golfer? Then we have some<br />

good news to share with you! HMA will host<br />

its second annual NatCon Golf Tournament<br />

on Monday, March 25, at the Patriots Point<br />

Links. Located on Charleston Harbor, the<br />

beautiful course is just 10 minutes from The<br />

Charleston Place and features sweeping views of Fort<br />

Sumter, Shem Creek, and the historic downtown skyline.<br />

Tee times begin at 8:30 am.<br />

The fee is $130 and that covers your round of golf and<br />

golf cart rental. Clubs can be rented from the clubhouse.<br />

Golfers are responsible for their own transportation.<br />

Register online at www.HMAmembers.org and consider<br />

adding on a sponsorship! Funds raised will be donated to<br />

the Real American <strong>Hardwood</strong> Coalition in support of their<br />

work promoting Real American <strong>Hardwood</strong> to consumers<br />

and the design build community!<br />

If you have any questions, reach out to golf organizer<br />

and TS Manufacturing sales representative Peter<br />

McCarty at PeterM@tsman.com.<br />

That’s all for now. Linda and I are looking forward to<br />

seeing you in Charleston! n<br />

We’re telling them.<br />

Contribute Now to Build Your World<br />

The Real American <strong>Hardwood</strong> Coalition has launched its Build Your World<br />

campaign in partnership with Magnolia Network. The ads are inspiring a national<br />

audience by educating them on the benefits of Real American <strong>Hardwood</strong>® products.<br />

BY IAN FAIGHT<br />

CHIEF OPERATING OFFICER<br />

HARDWOOD MANUFACTURERS ASSOCIATION<br />

WARRENDALE, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

The campaign was made possible thanks to voluntary contributions from the<br />

hardwood industry. Your continued support is critical to advance the initiative and<br />

reclaim market share for the benefit of all industry stakeholders.<br />

Help Build Your World. Learn more about the RAHC’s promotion efforts,<br />

see a list of supporters, and make a voluntary, tax-deductible contribution at<br />

RealAmerican<strong>Hardwood</strong>.com/industry or scan the QR code.<br />

14 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 15<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.

AHEC REPORT<br />

GET A KICK.<br />

AHEC And Disegno Launch Season 4<br />

Of Words On Wood Podcast<br />

The award-winning podcast Words on Wood is returning for its fourth season.<br />

This season delves even deeper into the<br />

world of wood, featuring unexpected and<br />

timely topics from across forestry, architecture<br />

and design, as well as the introduction<br />

of new, bite-sized ‘Making Shorts’, which<br />

shine a light on different production techniques<br />

for designing and building with timber.<br />

Photo By Petr Krečí<br />

Venturing into the world’s forests, sites of timber production,<br />

and design and architecture studios, the podcast<br />

examines how these industries intersect through material.<br />

Each episode is structured around interviews with<br />

leading architects, designers, educators, manufacturers,<br />

and forestry professionals who live amongst and care for<br />

trees on a day-to-day basis.<br />

The fourth season launches with an in-depth<br />

exploration of an often overlooked and misunderstood<br />

timber product: veneer. Featuring<br />

contemporary designers Jorge Penadés and<br />

Rio Kobayashi, as well as Cathy Lynn Danzer<br />

of timber manufacturer Danzer, the episode<br />

explores the design potential of this thinly<br />

sliced material and how a new generation of<br />

practitioners are pushing it in experimental<br />

and playful directions.<br />

Returning to the classroom, the season’s<br />

second episode explores what is missing<br />

in architectural education when it comes to<br />

wood. While timber is a common building<br />

material, each species offers different properties<br />

- are architects provided with sufficient information<br />

about these varied materials in their training? This episode<br />

brings together educators Kenn Busch, Hanif Kara<br />

and Izaskun Chinchilla Moreno to discuss how to develop<br />

more rigorous timber curriculums.<br />

Introducing Making Shorts<br />

Building on the success of previous seasons’ ‘Tree<br />

Shorts’, this season introduces a new series of ‘Making<br />

Shorts’. These bite-sized episodes zoom into production<br />

Please turn to page 74<br />

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

Improving your bottom line is our goal line. That’s why we quote fairly and<br />

deliver hardwood to maximize quality and help minimize waste. We also offer<br />

mixed species and sizing with J.I.T. shipments to reduce inventory costs.<br />

And those are just two of our plays.<br />

CALL COLE TODAY. WE’RE ON YOUR TEAM.<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

HARDWOOD LUMBER FOR ALL YOUR HARDWOOD NEEDS<br />

Quotes: 800-536-3151 • Export: 574-753-3151 • colehardwood.com<br />

16 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry

NWFA REVIEW<br />

Moisture Content And Wood<br />

Many who work in the wood products<br />

industry know that trees are comprised<br />

mostly of water, more than 50 percent<br />

in some species. Because of this, it is<br />

important to understand moisture and<br />

how it affects the products our industry<br />

produces.<br />

Wood is a hygroscopic material, which means it can<br />

absorb or lose moisture. When wood absorbs moisture,<br />

it expands; when wood loses moisture, it shrinks.<br />

Moisture can exist in wood as liquid water or water<br />

vapor in the cell cavities of the wood. This is called<br />

free water. Moisture also can exist in wood as water<br />

chemically held within the cell walls. This is called bound<br />

water.<br />

The moisture content at which the cell walls are<br />

saturated completely, but no water exists in the cell<br />

cavities, is called the fiber saturation point (FSP). FSP<br />

usually is between 25 percent to 30 percent, depending<br />

on the species. Wood fibers are dimensionally stable<br />

when the moisture content is above the FSP. When<br />

below the FSP, all moisture gained or lost is bound water.<br />

As the wood gains or loses bound water, the dimension<br />

of the wood begins to change.<br />

Wood also is an anisotropic material, meaning it<br />

shrinks and swells differently in each<br />

direction. Wood shrinks and swells the<br />

most along the circumference of the<br />

growth rings (tangentially), about half as<br />

much perpendicular to the growth rings<br />

(radially), and only in miniscule amounts<br />

along the grain (longitudinally). The<br />

average range for shrinkage for most wood species from<br />

FSP to oven-dry is 5 percent to 15 percent tangentially, 2<br />

percent to 8 percent radially, and .1 percent to .2 percent<br />

longitudinally. In some species, juvenile wood from near<br />

the center of the tree, called pith, can shrink up to 2<br />

percent or more from FSP to oven-dry.<br />

The moisture content (MC) of wood is measured as<br />

the weight of the water in the wood expressed as a<br />

percentage of the weight of the wood itself. The weight<br />

of the wood is determined by drying the wood to a point<br />

where all of the moisture is removed. This is referred to<br />

as oven-dried.<br />

This MC affects other properties of the wood, such as<br />

its weight, shrinkage, and strength. In living trees, for<br />

example, the MC may be as high as 200 percent of the<br />

weight of the wood. When wood is harvested and milled,<br />

however, it is dried to a MC for its end use. This typically<br />

ranges from 6 percent to 9 percent.<br />

Please turn to page 76<br />

TRUSTED<br />

NATIONAL<br />

LEADER<br />

FULL BIOMASS WOOD<br />

BOILER SYSTEM<br />

Design, Fabrication and Installation – Hot Water and Steam<br />

• Lifetime Support of Equipment with Full-Service Team and Parts Division<br />

• Experts in All Aspects of Boiler Room Equipment – Combustion System, Boiler, Emissions<br />

Control Equipment, Controls, and Material Conveying Equipment<br />

• Installing throughout the US and Internationally<br />

BY BRETT MILLER,<br />

VICE PRESIDENT OF TECHNICAL<br />

STANDARDS, TRAINING & CERTIFICATION,<br />

NATIONAL WOOD FLOORING ASSOCIATION,<br />

CHESTERFIELD, MO 800-422-4556<br />

WWW.NWFA.ORG<br />

906-466-9010<br />

www.BurnChips.com sales@burnchips.com<br />

18 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 19

NHLA: Why Knot...<br />

Hire Your Replacement<br />

I interviewed some job candidates<br />

today, as NHLA is looking<br />

to hire a new office administrator.<br />

I asked each candidate “Where<br />

do you see yourself in 10 years?”<br />

I received the traditional answer,<br />

“working for you and learning<br />

new things.” What a bunch of bull, and I called them<br />

on it. Let’s be honest; no one grows up saying, “I want<br />

to work for the <strong>Hardwood</strong> industry.” Yes, there are a few<br />

exceptions. So, we settle for those who stumble into our<br />

industry. Once in a while, we pull someone away, but for<br />

the most part, we have been a male-dominated, closeknit<br />

group and allowed few outsiders to come in.<br />

That is not to complain about the talent in our industry.<br />

We are intelligent, hard-working go-getters, and many<br />

people in our industry have accomplished extraordinary<br />

things. Every day, I see the skills of the trade as lumber<br />

graders bring value to a board. I see mills in small rural<br />

towns shipping their wood across the world. I visited a<br />

mill this month that was started by a schoolteacher with<br />

a few thousand dollars, and it is now worth millions.<br />

I was impressed as the schoolteacher-turned-lumberman<br />

walked me through his plant and the smiles with<br />

which his staff greeted him. They were happy working<br />

there. That is a critical thing for any employee. They<br />

must be satisfied at work. If they<br />

are not, it is a lose-lose. They<br />

lose their motivation, and you<br />

lose their productivity and commitment.<br />

Before I was willing to<br />

interview the candidates, I told<br />

them about our industry and why<br />

we cut deciduous trees into <strong>Hardwood</strong> lumber. I asked<br />

them if they were okay with that and understood the benefits<br />

of using wood that I had just described to them. After<br />

asking them about themselves, I got into the heavy questions.<br />

When I called them out on the 10-year question<br />

and asked, “Where do you want to end up?” I got the real<br />

answers. Some were still in our industry, and some were<br />

not. But they were real dreams, and why would I encourage<br />

them to do anything else? I don’t mind NHLA being<br />

a steppingstone on their career path.<br />

If they are happy and working hard at NHLA and see<br />

the Association as a way to accomplish their dreams,<br />

they will be productive employees. When they leave,<br />

they will always say good things about NHLA; if they go<br />

on to other areas within our industry, they will advocate<br />

for us. If they leave our industry, they will be advocates<br />

for the forests and the importance of <strong>Hardwood</strong> products<br />

and infrastructure. That is what we need more people in<br />

our world to understand. So don’t be afraid to hire out-<br />

Please turn to page 77<br />

BY DALLIN BROOKS,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-377-1082<br />

WWW.NHLA.COM<br />

20 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry

“Dura Supreme is focused on growth and despite some economic<br />

uncertainty in the broader market, demand for Dura Supreme cabinetry<br />

continues to grow...”<br />

-Tony Sugalski, CEO, Supreme Cabinetry Brands<br />

finishing, woodworking and machining skills. VP of Marketing,<br />

Karen Wistrom, said the North Carolina facility<br />

will enable Dura Supreme to meet growing demand with<br />

a regional manufacturing site, expanded manufacturing<br />

capacity, and advantageous delivery times. “Dura Supreme<br />

acquired the manufacturing assets of another<br />

cabinet manufacturer and that equipment and machinery,<br />

along with considerable additional investments, will<br />

be installed in Statesville at the company’s newest manufacturing<br />

location,” she explained.<br />

“Dura Supreme is focused on growth and despite<br />

some economic uncertainty in the broader market, demand<br />

for Dura Supreme cabinetry continues to grow,”<br />

said Tony Sugalski, CEO of Supreme Cabinetry Brands.<br />

“A second manufacturing facility enables us to continue<br />

meeting the ever-increasing demand for our premium,<br />

quality cabinetry and better serve our dealer partners.”<br />

The acquisition of Bertch Cabinet Manufacturing in<br />

2021 was part of the company’s expansion in the pre-<br />

Please turn to page 36<br />

This design concept features Dura Supreme’s Middleton door<br />

style in the Coriander stain on Cherry and our Curated Color,<br />

“Cyberspace”.<br />

Dura Supreme Cabinetry kitchen with the Reese Inset door style in the Dove paint paired with the Avery Inset door style in the Coriander<br />

stain on Quarter-Sawn White Oak and black metal accent doors.<br />

Dura Supreme Cabinetry<br />

Starts Production At Their<br />

Multi-Million Dollar Expansion<br />

Dura Supreme Cabinetry, headquartered in Howard<br />

Lake, MN, is experiencing remarkable growth. The<br />

<strong>Hardwood</strong> cabinet manufacturer offers semi-custom to<br />

custom cabinetry throughout the home. Included in the<br />

company’s product offerings are kitchen cabinets, islands,<br />

bathroom vanities, fireplace mantles, mudroom<br />

lockers, home office furniture, entertainment centers,<br />

and more. More than 1 million board feet of <strong>Hardwood</strong>s<br />

are purchased annually in Cherry, Maple, Red Oak,<br />

Quarter-sawn White Oak, Knotty Alder and Hickory (No.<br />

1 and 2 Common, Select and Better).<br />

With new manufacturing operations starting production<br />

in Statesville, NC, the company expects its new manufacturing<br />

site to create over 200 new jobs in the first<br />

few years including cabinet-making, furniture-making,<br />

By Michelle Keller<br />

With new manufacturing operations underway in Statesville, NC,<br />

the company expects its new manufacturing site to create over<br />

200 new jobs in the first few years including cabinet-making, furniture-making,<br />

finishing, woodworking and machining skills.<br />

A professional cabinet maker handcrafting a custom wood hood at the Dura Supreme factory in Howard Lake, MN.<br />

22 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 23

Stoltzfus Forest Products has a combined 24,000 square feet of dry lumber storage between their two yards.<br />

Stoltzfus Forest Products:<br />

Doing It All From Timber Tract To Lumber Board<br />

By Paul Miller Jr.<br />

Located in the small town of Peach Bottom, PA, Stoltzfus<br />

Forest Products was established in 1990 by Samuel<br />

Stoltzfus, father to Benuel Stoltzfus, who currently manages<br />

the business. This family-run sawmill has evolved<br />

from humble beginnings to become a thriving force in<br />

the <strong>Hardwood</strong> industry.<br />

The story began when Samuel, a dairy farmer with a<br />

fascination for sawmills, decided to delve deeper into<br />

this interest. During the quieter periods on the farm, he<br />

took a big step and acquired a small mill. At first, he ran<br />

the mill in tandem with the daily demands of dairy farming.<br />

Orders started coming in, thus, in 1990, Stoltzfus<br />

Forest Products was created.<br />

Since its modest beginnings, Stoltzfus Forest Products<br />

has undergone significant growth. In 2016, the company<br />

made a substantial move by purchasing a 10-acre property,<br />

to which they relocated their mill. Today, Stoltzfus<br />

Forest Products provides a range of <strong>Hardwood</strong>s, including<br />

Poplar, Red and White Oak, Walnut, Hickory, Soft<br />

Maple and Cherry. With an annual production capacity<br />

Located in the southeastern region of Pennsylvania, in Lancaster<br />

County, Stoltzfus Forest Products sources its logs from the surrounding<br />

areas.<br />

of 10.5 million board feet through the mill and 3.5 million<br />

board feet through the dry kilns, the company consistently<br />

delivers top-notch lumber to their customers. Their<br />

products include No. 2 Common and Better lumber,<br />

which accounts for approximately 70 percent of their<br />

output. The remaining 30 percent is dedicated to various<br />

specialty orders, such as railroad ties, pallet cants,<br />

industrial blocking, and mat timbers. They also handle<br />

special requests from local woodworkers and farmers in<br />

need of custom-cut pieces for projects like wagons. “We<br />

are drying the upper grades and selling the lower. We<br />

don’t dry much No. 2 Common at all. Walnut would be<br />

the only thing that we are drying in No. 2 Common. The<br />

other species in No. 2 Common are sold green,” Benuel<br />

added.<br />

While they used to<br />

work with Ash, it has seen<br />

a large decline in recent<br />

years. “I would say at<br />

this point we are 90 percent<br />

4/4, and the other<br />

10 percent is 5/4 to 16/4.<br />

When we put the kilns in<br />

two years ago it kind of<br />

changed the thicknesses we dry. We are heavier to 4/4<br />

to better accommodate our current markets, as well as<br />

quicken our production time since it goes through the<br />

kilns faster,” Benuel commented.<br />

Located in the southeastern region of Pennsylvania,<br />

in Lancaster County, Stoltzfus Forest Products sources<br />

its logs from the surrounding areas. “We will go up to<br />

120 miles for a nice piece of timber. It must be good<br />

quality and good timber to go that far. The majority are<br />

less than 50 miles. Lancaster county doesn’t have a<br />

whole lot of timber, so we don’t get a lot of timber out of<br />

our county. It’s more out of York County across the river<br />

to the west and Chester County to the east and then we<br />

get quite a bit of timber out of Maryland. I think we get<br />

more timber out of Maryland than we do Pennsylvania,”<br />

Benuel added.<br />

“We are able to control the quality<br />

from the standing tree the whole way<br />

to the local wood shop.”<br />

In terms of storage, the company utilizes around<br />

12,000 square feet of dry storage, although some of this<br />

space houses equipment. Additionally, they have approximately<br />

14,000 square feet of dry storage at another<br />

yard. Stoltzfus also uses Breeze Dried Sticks to prepare<br />

lumber stored on the yard. Looking ahead, they have<br />

plans to expand with two new buildings, a 12,000 square<br />

foot warehouse, and a 36,000 square foot production<br />

building, expected in 2025.<br />

Stoltzfus Forest Products boasts a diverse team of<br />

dedicated employees, many of whom come from the local<br />

Amish community, celebrated for their strong work<br />

ethic. The leadership team includes the general manager,<br />

Benuel Stoltzfus, as well as Samuel Stoltzfus,<br />

responsible for sawdust<br />

sales and truck loading.<br />

Abner and Henry, both of<br />

whom are Benuel’s brothers,<br />

play crucial roles in<br />

the company. Abner oversees<br />

the mulch operation<br />

and manages log procurement,<br />

including logging<br />

activities, while Henry<br />

serves as the mill maintenance supervisor and has<br />

prior experience on the Head Saw; he also manages<br />

parts inventory and oversees the filing room. Other valuable<br />

team members include Levi King, who manages<br />

dry storage and the processing of kiln-dried lumber, and<br />

Phillip Smith, responsible for kiln-dried lumber sales.<br />

Omar King holds the position of grading and lumber<br />

quality supervisor, ensuring high-quality standards in<br />

grading and yield processes. In addition to these crucial<br />

roles, Melvin, the youngest brother, contributes by loading<br />

and unloading kilns and serving as a sawyer. Amos<br />

Beiler, the log yard manager and production manager,<br />

oversees the two hour shift schedule, managing the logistics<br />

of both the mill and dry storage. His responsibilities<br />

include coordinating schedules, ensuring efficient<br />

operations and filling in for absent team members when<br />

– Benuel Stoltzfus, Stoltzfus Forest Products<br />

Please turn to page 42<br />

“We are drying the upper grades and selling the lower. We don’t dry much No. 2 Common at all. Walnut would be the only thing that<br />

we are drying in No. 2 Common. The other species in No. 2 Common are sold green,” said Benuel Stoltzfus.<br />

24 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 25

Protect your lumber in transit, resale, and during construction with KopCoat Protection Products.<br />

Take a hard stand on protecting your <strong>Hardwood</strong>s with KopCoat’s innovative chemical solutions.<br />

KopCoat’s Reach Expands<br />

In The <strong>Hardwood</strong> Sector<br />

KopCoat has been a behind the scenes supporter of<br />

the <strong>Hardwood</strong> industry for years. KopCoat’s preservative<br />

technologies and products have protected <strong>Hardwood</strong><br />

lumber from sapstain, mold and metal staining<br />

for years but hasn’t been known as a brand name in<br />

that role. However, with the support of a new leadership<br />

team and the addition of new products, KopCoat<br />

is expanding their market share in the forest products<br />

industry and specifically the <strong>Hardwood</strong> sector.<br />

KopCoat has built a world class organization in raw<br />

material procurement, logistics, and research and development<br />

with the support of parent company RPM<br />

Industrial Coatings Group. RPM Industrial Coatings<br />

Group is home to eleven industry-leading brands, including<br />

KopCoat Protection Products. RPM Industrial<br />

Coatings Group is a division of RPM International Inc.,<br />

KopCoat sales and service specialist performing<br />

QC checks at a mill.<br />

a $7.3B global company with market- and industry-leading<br />

brands in specialty coating, sealants, building materials,<br />

and related services. This network creates advantages<br />

that benefit KopCoat’s customers and will help<br />

drive KopCoat’s emergence as a recognizable force in<br />

the wood preservation market within specific customer<br />

spaces like <strong>Hardwood</strong> lumber. KopCoat’s research and<br />

development laboratory resides in their Pittsburgh, PA<br />

headquarters. Their facility incorporates a mycology lab<br />

for identifying organism infections in wood, testing labs<br />

for flood, dip and spray treatments, as well as a pressure<br />

treating cylinder for pressure vacuum testing. KopCoat’s<br />

R&D facilities and personnel have established and support<br />

over 100 patents in wood preservation technology.<br />

KopCoat also operates a manufacturing company, TDS<br />

Manufacturing, that designs, builds, programs and supports<br />

wood preservative application systems. TDS has years of experience<br />

building dip tanks, linear and transverse spray boxes and automated<br />

chemical mixing rooms. The ability to develop and test new<br />

technology and offer equipment support is invaluable for the service that<br />

dominates KopCoat’s approach to the market.<br />

Totally Outrageous Service is KopCoat’s tagline for the customer first<br />

approach that emanates throughout the organization. KopCoat’s R&D<br />

lab is directly tied to each customer through a sales and service specialist<br />

that facilitates communication between the customer’s field application<br />

and testing in the lab setting. Communication is key for KopCoat’s<br />

customer support mechanism as <strong>National</strong> Business Development Manager<br />

Josiah Wilfong describes, “Our sales and service representatives<br />

interact regularly with customers using our products and become defacto<br />

employees for our customers supporting the wood preservation<br />

aspect of their business.” KopCoat’s customer service approach was<br />

established to earn business as KopCoat developed market share early<br />

in it’s 40 year existence. Sustaining the customer first approach, however,<br />

has required commitment that Director of Business Development Bo<br />

Hammond explains this way, “customer service is what has allowed us<br />

to build our business since it’s inception and we are sticking with it when<br />

our competitors are giving up on it because of the cost. We believe<br />

that a long term customer service approach will produce the business<br />

longevity that will prove our model of customer first works in the market<br />

Please turn to page 45<br />

26 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 27

Stephen A. Zambo<br />

The AGL Group<br />

Jacksonville, FL<br />

Lumber Shipping Companies<br />

Are Cautiously Optimistic As<br />

Traditional Trends Return<br />

Lumber shipping companies saw that their trends year over<br />

year have begun to revert back to how traditional markets have<br />

been in the past, but they hold a cautious optimism as geopolitical<br />

factors can easily affect the supply chain strategies. One<br />

shipper noted, “We slowly saw the industry normalize over the<br />

last 12 months and it is back to pre-pandemic levels. I do not<br />

foresee any substantial increases in our export shipments over<br />

the next 12 months.”<br />

Despite seeing their markets slowly return to the traditional<br />

trends, a lumber shipper remarked, “Asking me to predict<br />

shipping volumes in the first quarter of <strong>2024</strong> is akin to throwing<br />

spaghetti at the wall and seeing ‘what sticks.’”<br />

A shipper stated, “The only constant across all industries is<br />

that margins are being squeezed. Going into the New Year, we<br />

can all be hopeful that the economy starts to pick back up, but<br />

I am not sure that is what we will see.”<br />

2023 was a very interesting year. There are trends<br />

within the marketplace that we see year over year, decade<br />

over decade. The trends may have some variability,<br />

think COVID, but outside of that, trends have remained<br />

relatively spot on over the long term. In 2023,<br />

we saw the first quarter buck normal export trends. We<br />

typically see a slow January and <strong>February</strong> with freight<br />

picking up in March. This past year we saw a very strong<br />

first and second quarter. Export volumes took a large hit<br />

from June all the way through about October in 2023.<br />

That is more in line with how traditional markets have<br />

been in the past.<br />

In 2023, the supply chain issues were nothing in<br />

comparison to 2021 and 2022. 2023 has been stable.<br />

Trucking availability has been a non-issue and steamship<br />

lines on most lanes have availability. Of course,<br />

this fluctuates from time to time, but rarely is a booking<br />

more than two weeks out as it stands. One item to<br />

keep an eye on is a potential strike on the East Coast<br />

sometime in <strong>2024</strong>. After negotiating record deals on the<br />

West Coast, the union on the East Coast is saying that<br />

it will hold firm by striking in <strong>2024</strong> if there is not a new<br />

deal negotiated. That would be a very large issue for the<br />

forest products industry as 80 percent of <strong>Hardwood</strong> exports<br />

are routed via the East Coast. Until there is more<br />

concrete information and the date of strike approaches,<br />

this is something to monitor.<br />

A very important topic no one talks about when looking<br />

forward at freight rates is the amount of steamship line<br />

capacity coming onto the market in the next 18 months.<br />

On average there are about 375,000 containers worth of<br />

new space entering the market annually. In <strong>2024</strong> alone<br />

there is north of 1,200,000 containers worth of new ship<br />

builds coming online. Unit economics lead us to the obvious<br />

conclusion of continued cheap freight rates. More<br />

space with the same demand equals low freight rates.<br />

More space with less demand equals low freight rates. I<br />

am confused as to what the steamship line carriers are<br />

doing from a unit economics standpoint.<br />

At the end of 2023, we were back to enjoying historically<br />

low freight rate levels. The rates have no where<br />

to go but up. I do not believe we will see large increases,<br />

10-15 percent over the course of <strong>2024</strong> on the ocean<br />

carrier side. Trucking companies on the other hand are<br />

having a very challenging time. There is less freight both<br />

on the export and import side, with more trucking capacity<br />

leading to reduced trucking rates over the last six<br />

months. I believe you will see some companies reduce<br />

fleet size, close their doors or start to increase prices.<br />

They do not have an option.<br />

Containers are readily available at the ports and are<br />

not readily available at some inland locations. I expect<br />

this trend to remain as it typically does. The cost of containers<br />

are stable for now, and may increase over the<br />

next year or so by about 10-15 percent.<br />

Shipping volumes in the fourth quarter were higher<br />

than what we forecasted based off of the second quarter<br />

and the third quarter. Economists and banks are calling<br />

for around 2 percent global growth in <strong>2024</strong>. If that<br />

actually happens, we will see modest gains in export<br />

volumes, however, I am not so certain that we will actually<br />

see 2 percent growth. Asking me to predict shipping<br />

volumes in the first quarter of <strong>2024</strong> is akin to throwing<br />

spaghetti at the wall and seeing “what sticks.”<br />

Where the economy goes is anyone’s guess. We are<br />

heading into an election year with much uncertainty.<br />

There are currently multiple wars globally, interest rates<br />

have been elevated compared to the last decade and inflation<br />

has been a major issue. The only constant across<br />

all industries is that margins are being squeezed. Going<br />

into the New Year, we can all be hopeful that the economy<br />

starts to pick back up, but I am not sure that is what<br />

we will see. J<br />

Please turn to page 49<br />

28 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 29

SWHMC Meeting Attendees Share<br />

Insights About Market Conditions<br />

Photos By Terry Miller<br />

The Southwestern <strong>Hardwood</strong> Manufacturers Club<br />

(SWHMC) Christmas meeting at The Grand Hotel, Point<br />

Clear, AL, was reported as a great meeting despite seasonal<br />

rainfall. Attendance was good. The roundtable<br />

discussion was informative as well. Generally, attendees<br />

reported that sales are down overall and log supplies<br />

are really good for the most part. Cross tie and<br />

switch tie production is still the primary focus right now<br />

with a hope that there will be greater demand for grade<br />

lumber soon.<br />

As a reminder, SWHMC annual dues renew in January<br />

and will remain at $1,000 per year. If you need<br />

an invoice for your dues, please let SWHMC know.<br />

SWHMC’s website was due to be updated by the time<br />

this issue of <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> was published,<br />

so attendees could make dues payments via<br />

credit card on the website.<br />

SWHMC leadership is also working on a meeting<br />

possibly at Mississippi State University in Starkville and<br />

announced that they will get info out on that meeting as<br />

soon as the plans can be completed.<br />

To follow are comments from the Christmas meeting<br />

discussion:<br />

Mill and Lumber Market Information:<br />

Robinson Lumber Co.:<br />

Asian sales are down and Europe is in a recession.<br />

Domestic sales are comparatively good with high end,<br />

wide flooring moving well. Low end narrow flooring is<br />

very slow. Anticipating an erratic lumber market ahead<br />

during the election year, Wesley Robinson is in the process<br />

of implementing a “Wood Is Good” promotion featuring<br />

pictures and videos of <strong>Hardwood</strong> lumber and projects<br />

as well as interviews with lumber industry leaders.<br />

This is in the developmental stage and you will probably<br />

begin to see some of Wesley’s work in future months.<br />

Buchanan <strong>Hardwood</strong>s:<br />

Due to the weather, we have too many logs. Due to<br />

the market, too much lumber inventory and too much<br />

flooring inventory. Residuals are fast becoming a problem.<br />

We need relief!<br />

Netterville Lumber:<br />

Sawing a lot of ties! Also have about 4 million feet<br />

of Cypress and Ash logs because it has been so dry.<br />

Swamps are dry, making logging them too easy! All the<br />

lowland species are plentiful!! Sawing a lot of 8/4 Ash.<br />

All-Star Forest Products:<br />

Diversification is helping us. Millwork business is slowing<br />

but margins are really good. Lumber and plywood<br />

seem to have slowed down, but still there’s some activity.<br />

The election is going to have an impact for sure.<br />

Board road into Canada has picked up some, but domestic<br />

has slowed down. It’s still moving some, but not<br />

at the volumes we have seen earlier in the year. Frame<br />

stock has slowed down considerably and still not much<br />

demand for Oak frame. There is still demand for specialty<br />

products. The Cypress market is really good right now<br />

with upward pushes on prices.<br />

Rutland Lumber:<br />

Sawmill has plenty of logs and the mill is running good.<br />

Joey Childs and Leslie Rutland, Rutland Lumber Company, Collins,<br />

MS; Robyn Birdsong, Kitchens Lumber Company, Utica,<br />

MS; Scott Wesberry, Fred Netterville Lumber Company, Woodville,<br />

MS; and Tyler Walley, Rutland Lumber Company<br />

Jay Hanna, Woodus K. Humphrey, Shreveport, LA; Rick Hanna<br />

(retired), Hanna Manufacturing Company, Winnfield, LA; and<br />

Kevin Lammons, All Star Forest Products, Nashville, TN<br />

Craig Bilberry, Barefoot Lumber, Florence, MS; Bill Price, All Star<br />

Forest Products, Jackson, MS; and Bubba Lammons, All Star<br />

Forest Products, Fairhope, AL<br />

Bill Buchanan and Cheryl Buchanan, Buchanan Lumber and<br />

<strong>Hardwood</strong> Flooring, Aliceville, AL; Kellye Miller, <strong>National</strong> <strong>Hardwood</strong><br />

<strong>Magazine</strong>, Memphis, TN; and Werner and Wesley Robinson,<br />

Robinson Lumber Company, New Orleans, LA<br />

Please turn to page 32<br />

NORTHERN & APPALACHIAN HARDWOODS<br />

Wesley Robinson, Robinson Lumber Company, New Orleans, LA,<br />

and family with The Grinch. Wills Robinson, Charlie Robinson<br />

and Werner Robinson<br />

Rubin Shmulsky, Mississippi State University, Starkville, MS;<br />

Wesley Robinson, and Toto Robinson, Robinson Lumber Company,<br />

New Orleans, LA; and Chad Smith, USNR, Hot Springs, AR<br />

[ WWW.SIMONLUSSIER.COM ]<br />

MARIO LUSSIER - General Manager mlussier@simonlussier.com<br />

450.435.6591 - 16 BOUL. DE LA SEIGNEURIE EST, BLAINVILLE, QC CANADA J7C 3V5<br />

30 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 31

SWHMC Continued from page 30<br />

Export sales and domestic sales have slowed down. Labor<br />

is still a problem. Mats have slowed down.<br />

Deepwell Energy and Forestry:<br />

Mats are slow. We’re struggling to move Gum and<br />

Poplar. The markets are just not taking much at the moment.<br />

Marietta Wood Supply:<br />

We have been running four mills with 10-12 weeks<br />

of logs on hand. Three mills are on ties and two are on<br />

Poplar. We are still building on the new mill and hope to<br />

get it finished soon.<br />

Kitchens Lumber Co.:<br />

Plenty of logs! Still dealing with labor problems and<br />

no one wants to work.<br />

Barefoot Lumber Co.:<br />

Pallet and crating production is down. Business is<br />

down overall but is okay. The industry is going through<br />

changes.<br />

Koppers Co.:<br />

Demand for ties and switch ties for <strong>2024</strong> will remain the<br />

same since the demand is for regular maintenance that<br />

goes on each year. Prices have been stable for 2023,<br />

with prices being flat right now. The holiday schedule<br />

will slow inbound ties to treating plants which will have a<br />

negative effect on mills. Regular production is expected<br />

after January 1.<br />

Somerville Tie:<br />

2023 was good for Somerville and expectations for the<br />

same in <strong>2024</strong>.<br />

Other Information:<br />

Mississippi State University:<br />

MSU is working on Crane Mat Standards based on<br />

NELMA Rules. This will be a process to establish and to<br />

implement since there are so many differing ideas and<br />

opinions in the matting industry. Presently there are not<br />

many guidelines and practically no means of enforcement<br />

of any traditional standards.<br />

USNR:<br />

This company has new innovations coming to optimize<br />

production and increase efficiency in the sawmill<br />

and remanufacture industries. Auto-graders have made<br />

a lot of headway and are beginning to make a difference<br />

for some of the first mills who have installed them. Also<br />

saw management and optimization technology is lengthening<br />

the life of both band and circle saws. We are trying<br />

to arrange a presentation of some of the technology for<br />

the Crawfish Boil in April. Watch for more info on this to<br />

come.<br />

Pierce Construction:<br />

It seems that mills producing industrial products are<br />

doing better than grade mills right now in Appalachia<br />

Bill and Rhema Behan, Koppers Inc., St. Louis, MO; Jason Bunch,<br />

Deepwell Forest Products, Waynesboro, MS; Kellye and Terry<br />

Miller, <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Memphis, TN; and Keith<br />

Price, Corley Manufacturing Company, Chattanooga, TN<br />

and the South. Sawmill construction and remodeling is<br />

still good and Pierce is still booked out 24-36 months.<br />

There are a lot more mills looking at diversification of<br />

their production capabilities.<br />

Corley Mfg.:<br />

Still busy and booked out 24 months on steel. Controls<br />

are out 6 months or so. Still a lot of interest in making<br />

mills more efficient. n<br />

Learn more at www.swhmc.com.<br />

Carolers added to the festive Yuletide mood at the Christmas<br />

meeting of SWHMC.<br />

is Pleased to Introduce<br />

Sawmill Machinery<br />

Heavy Duty Thin Kerf<br />

Horizontal & Vertical<br />

Sawmill Systems<br />

Horizontal Carriage Sawmills<br />

Slant Carriage Sawmills<br />

COMPLETE SAWMILL SYSTEMS | HORIZONTAL & VERTICAL BAND MILLS<br />

BOARD EDGERS & GANG EDGERS | DEBARKING LINES | SAW SHOP EQUIPMENT<br />

Scott Thompson - East Coast<br />

(731) 217-6447<br />

sthompson@baileysonline.com<br />

Jim Hass - West Coast<br />

(530) 908-2466<br />

jhaas@baileysonline.com<br />

Factory Location<br />

Stranice, Slovenia<br />

wravor@wravor.sl<br />

baileysonline.com / 1222 Commerce Ave Ste D Woodland, CA 95776<br />

32 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 33

West Side <strong>Hardwood</strong> Club Enjoys<br />

Annual Holiday Lunch<br />

Photos By Paul Miller Jr.<br />

Hugg & Hall sponsored the recent annual December/<br />

Christmas meeting of the West Side <strong>Hardwood</strong> Club.<br />

It was held at YaYa’s in Little Rock, AR, with a social<br />

hour followed by lunch.<br />

Steve Bryan is the president of the West Side <strong>Hardwood</strong><br />

Club and David Brazeale is secretary.<br />

West Side <strong>Hardwood</strong> Club is situated in Sparkman,<br />

AR.<br />

You can reach them at 870-678-2317. n<br />

David Brazeale, Brazeale Lumber, Sparkman, AR; Dan Sills and Nick Robinson, Hugg & Hall, El Dorado, AR; and Les Steen, Les Steen<br />

<strong>Hardwood</strong>s, North Little Rock, AR<br />

Ronnie Fowler, Anthony Oak Flooring, Benton, AR; Denise Brazeale, Brazeale Lumber, Sparkman, AR; Rose Mary<br />

Cummings and David Engelkes, Maxwell <strong>Hardwood</strong> Flooring, Monticello, AR; and Jennifer Robinson, Hugg & Hall,<br />

Little Rock, AR<br />

Keith Price, Corley Manufacturing, Chattanooga, TN; Barry Bareker,<br />

Hugg & Hall, El Dorado, AR; Ronnie Fowler, Anthony Oak<br />

Flooring, Benton, AR; and Derek Douthit, Douthit Lumber, Camden,<br />

AR<br />

Paul Miller Jr., <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Memphis, TN; Brian<br />

Davis, Davis Forestry, Little Rock, AR; and Derek Douthit, Douthit<br />

Lumber, Camden, AR<br />

Funding<br />

For your neck of the woods<br />

Finding financial solutions built for the hardwood<br />

industry shouldn’t be difficult. That’s why we offer<br />

lending solutions that are a little closer to home. Farm<br />

Credit Mid-America understands the unique financial<br />

needs of forest products businesses and offers lending<br />

solutions built around your business’s goals.<br />

Loans subject to credit approval. Additional terms and conditions may apply.<br />

Farm Credit Mid-America is an equal opportunity lender.<br />

Let’s<br />

Connect.<br />

Visit<br />

FCMA.COM/<br />

FOREST-Products<br />

to get started.<br />

JS-50 WX SCAN<br />

HEAD<br />

SIMPLY<br />

BETTER<br />

34 FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

FEBRUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 35

DURA SUPREME CABINETRY Continued from page 23<br />

More than 1 million board feet of <strong>Hardwood</strong>s are purchased annually by Dura Supreme,<br />

located in Howard Lake, MN, in Cherry, Maple, Red Oak, Quarter-sawn White<br />

Oak, Knotty Alder and Hickory.<br />

mium, semi-custom cabinetry market. Dura Supreme is owned by GHK<br />

Capital Partners LP (GHK), a Greenwich, CT-based private equity firm<br />

that strategically partners with well-performing companies that have<br />

exceptional growth potential. The acquisition of Bertch Cabinet Manufacturing<br />

brought together two highly<br />

regarded companies with well-known<br />

brands in the premium kitchen cabinetry<br />

and premium bath cabinetry market.<br />

With over 100 years of combined history<br />

and experience, Dura Supreme and<br />

Bertch brands are uniquely positioned<br />

to provide an advantageous mix of products<br />

to their dealer partners and build on<br />

strong operating platforms to accelerate<br />

growth in new markets across the U.S.<br />

“We’re excited about the potential our<br />

business partnership with Bertch creates,”<br />

Sugalski said. “With our expanded<br />

portfolio of premium cabinetry brands<br />

in kitchen and bath markets, our ability<br />

to meet our customers’ needs and grow<br />

in this segment is expanded. The combination<br />

of companies creates a unique<br />

product mix that we believe will create<br />

advantages for our dealers and customers<br />

across the USA.”<br />

“We are extremely pleased to be partnered<br />

with the Bertch team to build upon<br />

the company’s highly regarded cabinet<br />

brands and the 40-year heritage serving<br />

designers and homeowners with premium<br />

kitchen and bath cabinetry,” said<br />

Managing Partner of GHK, Gil Klemann.<br />

Wood cabinets from Dura Supreme are<br />

certified under the Environmental Stewardship<br />

Program (ESP) administered by<br />

the independent Kitchen Cabinet Manufacturers<br />

Association (KCMA). Designed<br />

to encourage industry policies and practices<br />

that benefit both the environment<br />

and the well-being of society, this program<br />

provides companies with tangible<br />

ways to support sustainability. “We<br />

achieved certification by demonstrating<br />

our commitment to sound environmental<br />

management and sustainable practices,”<br />

Wistrom explained. “The ESP seal<br />

lets homeowners, designers, builders<br />

and architects know they are supporting<br />

sustainability when they buy or specify<br />

Dura Supreme Cabinetry. In addition to<br />

sourcing the majority of their <strong>Hardwood</strong><br />

Wood cabinets from Dura Supreme are certified under the Environmental Stewardship<br />

Program (ESP) administered by the independent Kitchen Cabinet Manufacturers<br />

Association (KCMA).<br />

from domestic forests, Dura Supreme also utilizes sustainable practices<br />

throughout all aspects of the manufacturing process.<br />

This operation also has an eye on waste and recycling. “Our comput-<br />

Please turn the page<br />

Purposely designed and built to perform, Nicholson ring debarkers<br />

can be found in wood processing facilities around the world.<br />

Nicholson ring debarkers reliably provide<br />

optimal debarking with minimal fiber loss.<br />

A variety of options provides solutions<br />

to all types of log diet and debarking<br />

conditions.<br />

Upgrade packages allow older models<br />

to take advantage of improvements<br />

introduced on newer designs.<br />

Providing value for our<br />

customers is at the core of<br />