National Hardwood Magazine - March 2024

Read the March 2024 issue of National Hardwood Magazine to get the latest hardwood industry news! This issue features stories on Edensaw Woods Ltd., updates to the American Hardwood Lumber Grading workshop, the LSLA Winter Meeting, insights from the the ALC meeting and much more.

Read the March 2024 issue of National Hardwood Magazine to get the latest hardwood industry news! This issue features stories on Edensaw Woods Ltd., updates to the American Hardwood Lumber Grading workshop, the LSLA Winter Meeting, insights from the the ALC meeting and much more.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

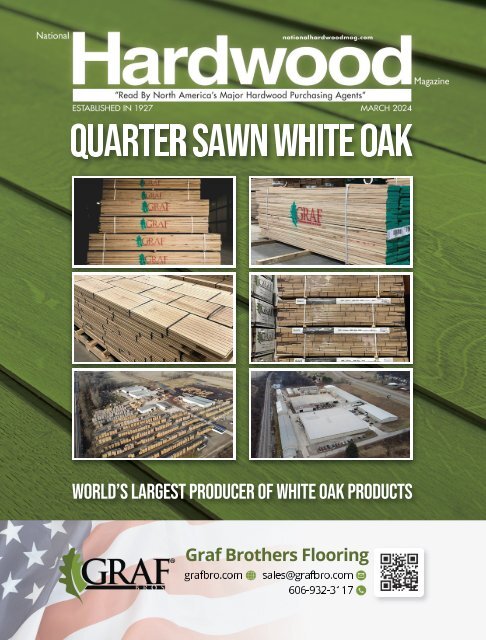

QUARTER SAWN WHITE OAK<br />

WORLD’S LARGEST PRODUCER OF WHITE OAK PRODUCTS<br />

Graf Brothers Flooring<br />

grafbro.com<br />

sales@grafbro.com<br />

606-932-3117<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 1

INDUSTRIES<br />

CONTROLS<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

TODAY<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

A customized solution:<br />

MIXED<br />

LOADS<br />

We can easily combine a wide<br />

range of items on a single order<br />

to suit your specific needs.<br />

OUR PRODUCTS:<br />

NORTHERN AND NORTH<br />

APPALACHIAN LUMBER<br />

Producer | Large Inventory | Thick Stock | Imported Wood<br />

primewood.com<br />

2 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1240 Carriages sold<br />

n Lowest cost of ownership<br />

n All parts in stock and reasonably priced<br />

n In-house engineering department<br />

n Everything from single piece equipment to<br />

turn-key mills<br />

STEFAN DRACOBLY<br />

President Of<br />

Controls<br />

PAUL CLEEREMAN<br />

VP Cleereman<br />

Industries & Controls<br />

Sales<br />

DAN TOOKE<br />

Senior Optimization<br />

& Controls Engineer<br />

n Simple easy to use touch<br />

screen with additional<br />

tactile buttons<br />

n Remote access for<br />

troubleshooting<br />

n No custom electrical<br />

hardware, all parts are<br />

off-the-shelf components<br />

n Industry JoeScan<br />

JS-50X6 Heads<br />

n 3D data used for<br />

opening the log and<br />

estimating the back of<br />

log profile<br />

n Realistic views of the log<br />

n Sure Grip Joystick<br />

handles<br />

n Operational statistics and<br />

reports<br />

n Over 170 systems sold<br />

Cleereman Industries<br />

and Cleereman Controls<br />

715-674-2700<br />

www.cleereman.com<br />

info@cleereman.com

grafbro.com<br />

sales@grafbro.com<br />

606-932-3117<br />

About The Cover<br />

GRAF BROTHERS FLOORING<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> MARCH <strong>2024</strong> Volume 98 No. 2<br />

QUARTER SAWN WHITE OAK For over two decades, Graf Brothers has<br />

been serving the wood products industry<br />

worldwide with logs, lumber, barrel staves,<br />

plycore, and <strong>Hardwood</strong> flooring products to fit<br />

the industry’s needs. As the global leader in<br />

the rift and quarter sawn industry with a customer<br />

base that extends all over the world, it<br />

WORLD’S LARGEST PRODUCER OF WHITE OAK PRODUCTS<br />

Graf Brothers Flooring<br />

is no surprise that Graf Brothers is the world’s<br />

largest manufacturer of rift and quarter sawn<br />

White Oak products.<br />

Graf Brothers Flooring is an environmentally conscious company<br />

located in the heart of the Appalachian foothills, a geographic region<br />

known for its abundant natural resources of the choicest <strong>Hardwood</strong>s.<br />

Graf Brothers occupies an 80-acre site in South Shore, Kentucky where<br />

it houses the entire manufacturing process that is overseen through<br />

each step. Skilled workforce across a range of disciplines, scaling<br />

support through manufacturing operation, taking full responsibility for<br />

long-term product performance. Graf Brothers is proud to manufacture<br />

100% American-Made products.<br />

Reach out and partner with Graf Brothers at 606-932-3117 or visit<br />

www.grafbro.com for more info.<br />

Features & Industry Events<br />

26<br />

Diverse <strong>Hardwood</strong> Lumber And<br />

Lumber Products At Edensaw<br />

Woods Ltd.<br />

36<br />

ALC Meeting: Logging Leader Says<br />

Rising Costs Hurt The Industry<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

30<br />

32<br />

AHEC Updates American <strong>Hardwood</strong><br />

Lumber Grading Workshop<br />

LSLA Winter Meeting Includes<br />

<strong>Hardwood</strong> Industry Updates<br />

40<br />

Penn-York Kicks Off New Year<br />

Of Meetings<br />

Terry Miller – President<br />

Paul J. Miller Jr. – Co-owner<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Cadance Hanson - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

Departments<br />

26<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

10 <strong>Hardwood</strong> Calendar<br />

12 U.S.A. Trends<br />

14 Canadian Trends<br />

16 Industry News<br />

18 HMA Update<br />

20 AHEC Report<br />

22 NWFA Review<br />

24 NHLA: Why Knot...<br />

64 Who’s Who<br />

70 Classified Profit<br />

Opportunities<br />

72 Advertisers Index<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

2 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 3

FOREST PRODUCTS<br />

EXPORT DIRECTORY<br />

TARGETING BUYERS AROUND THE GLOBE!<br />

91% Renewal Rate in the 48th Forest Products Export Directory<br />

Introducing...<br />

Abenaki Timber Corporation<br />

Allegheny Wood Products, Inc.<br />

Ally Global Logistics LLC<br />

Almond Brothers Lumber Co.<br />

Anderson-Tully Lumber Co.<br />

Baillie Lumber Co.<br />

Banks <strong>Hardwood</strong>s, Inc.<br />

Bingaman & Son Lumber, Inc.<br />

Broadleaf Lumber Co.<br />

Cardin Forest Products, LLC<br />

Clark Lumber Co., Inc.<br />

Cole <strong>Hardwood</strong>, Inc.<br />

Crown <strong>Hardwood</strong> Co., Inc.<br />

Cummings Lumber Co., Inc.<br />

Deer Park Lumber International<br />

Devereaux Sawmill, Inc.<br />

East Ohio Lumber Co.<br />

HHP, Inc.<br />

Harold White Lumber Co.<br />

“...the Most Comprehensive Buyer’s Guide for the International Buyer...”<br />

Call NOW to reserve your<br />

space in the 49th EDITION!<br />

Published in FALL <strong>2024</strong><br />

Hanafee Bros. Sawmill Co., Inc.<br />

Hermitage <strong>Hardwood</strong> Lumber<br />

Sales, Inc.<br />

J.D. Irving Limited<br />

JYS <strong>Hardwood</strong>s<br />

Kendrick Forest Products<br />

King City / Northway<br />

Forwarding Ltd.<br />

Legacy Wood Products LLC<br />

Matson Lumber Company<br />

McClain Forest Products LLC<br />

Merrick <strong>Hardwood</strong>s<br />

Midwest <strong>Hardwood</strong> Company<br />

NELMA (Northeastern Lumber<br />

Manufacturers Assoc.)<br />

NWH<br />

Nyle Dry Kilns<br />

Parton Lumber Co., Inc.<br />

Penn-Sylvan International, Inc.<br />

Prime Lumber Company<br />

Primewood<br />

Quality <strong>Hardwood</strong>s Ltd.<br />

Ram Forest Products, Inc.<br />

Ron Jones <strong>Hardwood</strong> Sales, Inc.<br />

Rossi Group<br />

Roy Anderson Lumber Company, Inc.<br />

Salamanca Lumber Company, Inc.<br />

SFPA (Southern Forest Products Assoc.)<br />

Softwood Export Council<br />

TMX Shipping Company, Inc.<br />

Taner Timber Co., Inc.<br />

Thompson Appalachian <strong>Hardwood</strong>s<br />

Turman Forest Products<br />

Two Rivers Timber Company, Inc.<br />

Vexco, Inc.<br />

Wagner Lumber Company<br />

Wheeland Lumber Co., Inc.<br />

WOODBOX<br />

VisionTally set a new standard for end-tally accuracy, automatically scanning<br />

and measuring bundles from both ends at once with unmatched laser accuracy.<br />

Now, the next generation VisionTallyHD pushes that standard even further:<br />

• Higher accuracy<br />

• Reduced labor<br />

• Increased reliability<br />

• Faster scanning under 1 minute<br />

• Enhanced wane detection<br />

• Improved dark lumber scanning<br />

SYSTEM UPGRADES<br />

Upgrade your system with VisionTallyHD technology!<br />

Contact us for more information<br />

The VisionTally Difference<br />

• The most accurate, automated,<br />

complete end-tally solution available<br />

• The only end-tally device that measures<br />

actual width and actual length<br />

• World-wide reputation for accuracy that<br />

gives you confidence and builds trust with<br />

your customers<br />

800-844-1280<br />

Full Page Rate: $2,950<br />

Half Page Rate: $2,500<br />

Color Additional<br />

forestproductsexport.com • exd@millerwoodtradepub.com<br />

<br />

Industrial Vision Systems, Inc.<br />

sales@visiontally.com<br />

(215) 393-5300<br />

www.VisionTally.com<br />

Sawmill MD<br />

SawmillMD@mindspring.com<br />

Mike Ballard (850) 974-1195

606-932-3 17<br />

Our digital<br />

footprint is<br />

a big deal.<br />

QUARTER SAWN WHITE OAK<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> MARCH <strong>2024</strong> Volume 98 No. 2<br />

Features & Industry Events<br />

26<br />

30<br />

32<br />

Diverse <strong>Hardwood</strong> Lumber And<br />

Lumber Products At Edensaw<br />

Woods Ltd.<br />

AHEC Updates American <strong>Hardwood</strong><br />

Lumber Grading Workshop<br />

LSLA Winter Meeting Includes<br />

<strong>Hardwood</strong> Industry Updates<br />

Departments<br />

10 <strong>Hardwood</strong> Calendar<br />

12 U.S.A. Trends<br />

14 Canadian Trends<br />

16 Industry News<br />

18 HMA Update<br />

20 AHEC Report<br />

36<br />

40<br />

22 NWFA Review<br />

24 NHLA: Why Knot...<br />

ALC Meeting: Logging Leader Says<br />

Rising Costs Hurt The Industry<br />

Penn-York Kicks Off New Year<br />

Of Meetings<br />

64 Who’s Who<br />

70 Classified Profit<br />

Opportunities<br />

72 Advertisers Index<br />

WORLD’S LARGEST PRODUCER OF WHITE OAK PRODUCTS<br />

26<br />

About The Cover<br />

For over two decades, Graf Brothers has<br />

been serving the wood products industry<br />

worldwide with logs, lumber, barrel staves,<br />

plycore, and <strong>Hardwood</strong> flooring products to fit<br />

the industry’s needs. As the global leader in<br />

the rift and quarter sawn industry with a customer<br />

base that extends all over the world, it<br />

is no surprise that Graf Brothers is the world’s<br />

largest manufacturer of rift and quarter sawn<br />

White Oak products.<br />

Graf Brothers Flooring is an environmentally conscious company<br />

located in the heart of the Appalachian foothills, a geographic region<br />

known for its abundant natural resources of the choicest <strong>Hardwood</strong>s.<br />

Graf Brothers occupies an 80-acre site in South Shore, Kentucky where<br />

it houses the entire manufacturing process that is overseen through<br />

each step. Skilled workforce across a range of disciplines, scaling<br />

support through manufacturing operation, taking full responsibility for<br />

long-term product performance. Graf Brothers is proud to manufacture<br />

100% American-Made products.<br />

Reach out and partner with Graf Brothers at 606-932-3117 or visit<br />

www.grafbro.com for more info.<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Terry Miller – President<br />

Paul J. Miller Jr. – Co-owner<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Cadance Hanson - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

Graf Brothers Flooring<br />

grafbro.com sales@grafbro.com<br />

606-932-3117<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

2 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 3<br />

QUARTER SAWN WHITE OAK<br />

WORLD’S LARGEST PRODUCER OF WHITE OAK PRODUCTS<br />

Graf Brothers Flooring<br />

grafbro.com sales@grafbro.com<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

GRAF BROTHERS FLOORING<br />

Scan to sign up and<br />

recieve our virtual<br />

issues FREE.<br />

6 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 7

www.exporichmond.com<br />

MEADOW EVENT PARK ■ DOSWELL, VA<br />

Don't miss out on the largest sawmill, logging, and pallet<br />

equipment expo on the East Coast! Our new venue has<br />

75,000 sq. ft. of indoor space and close to 30 acres of<br />

outdoor space! You don't want to be left out of<br />

this year's event- it's gonna be BIG!<br />

REGISTER TODAY at www.exporichmond.com<br />

ALL need to get aboard<br />

& invest in your future!<br />

Real American <strong>Hardwood</strong> Coalition<br />

Donor Update - February <strong>2024</strong><br />

It’s industry trade show time, which means many of you are seeing in-person<br />

updates about the Real American <strong>Hardwood</strong> Coalition. Earlier this month, at<br />

the IHLA annual meeting, RAHC released a video showcasing the Coalition’s<br />

progress to date, as well as its plans for the future. It will be shown again at<br />

the AHMI meeting later this month. If you missed it, scan the QR code and<br />

take a look or use this link:<br />

https://www.youtube.com/watch?v=kwaBd2-wsno<br />

From the start, the goals for RAHC have been ambitious. They have to be if<br />

you expect to influence consumer perceptions, but with the financial support<br />

of industry stakeholders, we have accomplished just that. Website traffic is<br />

up, social media engagement is up, consumer advertising is happening, and<br />

resources for architects, builders, and designers are being developed. Your<br />

support has made this possible:<br />

• $1.82 million raised to date<br />

• $12,000 raised through fundraisers<br />

• 2023 contributions doubled<br />

Those are impressive numbers, but to maintain our momentum,<br />

we need to maintain our fundraising efforts. If you have<br />

contributed to RAHC, we thank you. If you have committed to a<br />

multi-year donation, we encourage you to make those continuing<br />

contributions now. If you have yet to give, we ask that you do so<br />

today.<br />

Donate at:<br />

https://realamericanhardwoodcoalition10.wildapricot.org/Join-us<br />

SCAN QR CODE TO<br />

DONATE TODAY!<br />

We are all stakeholders!<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

WE NEED YOUR HELP!<br />

Furniture, flooring, millwork/moulding and cabinet manufacturers<br />

- industrial markets, we need you to participate!<br />

All wholesalers, distribution/concentration yards<br />

and sawmills need to participate!<br />

All of us are already invested in our businesses, SO PROTECT IT!<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 9

HARDWOOD CALENDAR<br />

<strong>March</strong><br />

Appalachian Lumbermen’s Club, The Hotel Roanoke,<br />

Roanoke, VA. www.lumberclub.org. <strong>March</strong> 12<br />

Penn-York Lumbermen’s Club, host: Fitzpatrick &<br />

Weller/WJ Cox Associates, Ellicottville, NY.<br />

www.pennyork.org. <strong>March</strong> 18.<br />

<strong>Hardwood</strong> Manufacturers Assoc., <strong>National</strong><br />

Conference and Expo, The Charleston Place,<br />

Charleston, SC. www.hmamembers.org. <strong>March</strong> 25-27<br />

CRAFTMANSHIP ISN’T DEAD.<br />

HIDING IN MIDDLE TENNESSEE.<br />

#<br />

2<br />

April<br />

Kentucky Forest Industries Association, Embassy<br />

Stes., Lexington, KY. www.kfia.org. April 2-4.<br />

Canadian <strong>Hardwood</strong> Bureau, Meeting, Double Tree by<br />

Hilton, Montreal, QC.<br />

www.canadianhardwoodbureau.com. April 9-10.<br />

Montreal Wood Convention, Fairmont the Queen<br />

Elizabeth Hotel, Montreal, QC.<br />

www.montrealwoodconvention.com. April 9-11.<br />

Expo Richmond, Meadow Event Park, Doswell, VA.<br />

www.exporichmond.com. April 12-13.<br />

<strong>National</strong> Wood Flooring Association, Expo, Ernest N.<br />

Morial Convention Center, New Orleans, LA.<br />

www.nwfa.org. April 16-18. n<br />

DO MORE<br />

WITH LESS<br />

eLIMBS | Agility | TallyExpress | Neural Grader<br />

Ease the pain of staffing shortages with inventory<br />

management solutions made for hardwoods. DMSi is<br />

your one software partner from timber to consumer.<br />

CRAFTMANSHIP ISN’T DEAD.<br />

IT’S HIDING IN MIDDLE TENNESSEE.<br />

Watch the success story<br />

SCAN TO WATCH<br />

FRANK MILLER<br />

LUMBER CO<br />

615-740-5100<br />

WWW.MIDTNLUMBER.COM<br />

10 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

dmsi.com

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

Among the factors for the recent slowdown in many<br />

lumber yards throughout the Lake States, a Michigan<br />

lumberman recently suggested that a “lack of vision”<br />

loomed as a primary culprit in the downturn.<br />

“It is kind of odd,” he noted. “Six months ago, customers<br />

had a little pep in their step. Usually we’d say that<br />

(the market) is ‘slow, but it will pick up in a couple weeks.’<br />

Now, people have week-to-week or even day-to-day vision.<br />

“Instead of saying, ‘go ahead and bring (the lumber) in.<br />

Let’s go ahead and do this,’” he added. “Customers are<br />

now waiting. Our overall volume is similar to six months<br />

ago. However, it goes right back again to the customers.”<br />

The source, who specializes in Hard Maple, Red and<br />

White Oak and Hickory cut to 4/4 thickness, said that<br />

Throughout the Northeast region lumber contacts<br />

were varied in their response to whether or not the market<br />

was doing better than it was six months ago, but they<br />

all agreed that, at the time of this writing, their sales are<br />

depressed.<br />

In Maine, a lumber spokesperson said that while<br />

his sales are currently doing worse than they were six<br />

months ago he doesn’t believe that this is a static trend,<br />

noting that he is currently getting more for Ash and Hard<br />

Maple than he is able to saw. “Six months ago, I had<br />

more logs in the yard, now I’ve got enough to saw in<br />

about a day. The mud season started last <strong>March</strong> and it<br />

hasn’t stopped,” he continued.<br />

His company offers Hard and Soft Maple, White Ash<br />

and Red Oak, as well as Cherry, on occasion, in grades<br />

Across the Southeast region sources agreed that lumber<br />

prices have been better, while varying on their responses<br />

as to how much business they had, at the time<br />

of this writing.<br />

In Mississippi a lumber saleswoman said their markets<br />

are slow right now and that they are worse than they<br />

were six months ago, which she attributes to the economy<br />

and interest rates.<br />

Her company offers Red and White Oak, Sycamore,<br />

Ash, Hickory, Pecan and Cypress in grades Nos. 1 and<br />

2 Common and in one- and two-inch thicknesses. She<br />

noted that Cypress is currently their best seller.<br />

In Tennessee a lumberman said that he has continued<br />

to stay busy while prices continue to become depressed.<br />

“We are probably doing about the same as we were six<br />

A California lumberman recently noted that business<br />

was “adequate” and that he would “take that any day”<br />

over the “chaos” that the pandemic created in the lumber<br />

market.<br />

“It was no fun during the pandemic,” he noted. “We all<br />

want to be profitable, but that was insane. Now we are<br />

moving along and still profitable.”<br />

The source said that a banker recently commented<br />

on an “uptick” of loan applications, meaning that interest<br />

rates are “coming down.”<br />

Selling nearly every <strong>Hardwood</strong> species from Alder to<br />

Zebrawood, he noted that most of his wood comes from<br />

the Appalachia region.<br />

He added that he hoped White Oak has “run its<br />

course.”<br />

Please turn to page 44 Please turn to page 45<br />

Please turn to page 46<br />

Please turn to page 47<br />

The <strong>National</strong> Solution to Your Local Risk <br />

contund.com<br />

If you’re in the Forest<br />

Products Industry,<br />

get to know us.<br />

WE PROVIDE INSURANCE TO PROTECT<br />

THE WAY YOU DO BUSINESS.<br />

Get the insurance coverage you need<br />

and the service you deserve.<br />

To learn how, call 804.643.7800<br />

BINGAMANLUMBER.COM<br />

PO Box 247, Kreamer, PA 17833<br />

☎ 570.374.1108 | 570.374.5341<br />

12 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 13

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

ONTARIO<br />

It was a slow start to the new year as customers let<br />

their inventories slide over the end of 2023 and placed<br />

orders in December for January receipts, which caused<br />

a boost in current business by end of January. Most primary<br />

and secondary manufacturers did not see a significant<br />

increase in demand for <strong>Hardwood</strong> finished goods<br />

or grade <strong>Hardwood</strong> lumber. Best sellers noted are Hard<br />

Maple, Soft Maple and White Oak. There is some interest<br />

in Aspen, Basswood, and Beech. Sawmills have not<br />

been producing a lot in many areas. Prices vary widely,<br />

with items in short supply bringing higher prices. It was<br />

noted that kiln-dried prices were not rising at the same<br />

rate as green prices, putting pressure on concentration<br />

yards, especially. It was noted that railroad tie business<br />

was doing well, and wooden pallet and container manufacturers<br />

were slightly busier.<br />

QUEBEC<br />

Sawmills and concentration yards reported better<br />

business early in the new year compared to the period<br />

before the holidays. Activity was mostly seen to replenish<br />

inventories as opposed to secondary manufacturers<br />

increasing their consumption of <strong>Hardwood</strong>s. However, it<br />

was reported that overall for most species business was<br />

rather slow.<br />

Ash markets are mixed, noted contacts, and exports<br />

to Chinese markets are lukewarm they added. In other<br />

markets things are quieter, as is for domestic markets.<br />

Supply is keeping pace with demand.<br />

With low production of the regionally important Hard<br />

Maple species and inventories now being replenished<br />

by concentration yards and end users, prices are firming<br />

in many areas. Wholesalers and end users are ordering<br />

Please turn to page 49 Please turn to page 51<br />

PATENTED<br />

MAXIMUM AIR FLOW DESIGN<br />

Sure-grip, anti-slip corrugated surface<br />

Angled design clears moisture more<br />

efficiently vs. straight fluted sticks<br />

Removes moisture, decreases dry time<br />

and increases drying quality<br />

Trusted quality & service for 20+ years<br />

Discounts for program customers<br />

“Often Imitated,<br />

Never Duplicated”<br />

Improved Yard Safety,<br />

Increased Drying Efficiency<br />

& Reduced Drying Costs<br />

20 +<br />

MILLION SOLD<br />

LUMBER DRYING STICKS<br />

<br />

•STICKS & CROSSERS<br />

•STANDARD & CUSTOM SIZES<br />

Dependable•Durable•Long Lasting<br />

The Company that Defeated Sticker Stain<br />

519.842.6841 | info@breezedried.com<br />

We Also Buy Lumber !<br />

breezedried.com<br />

14 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry

INDUSTRY NEWS<br />

AN UPDATE COVERING THE LATEST NEWS ABOUT<br />

HARDWOOD SUPPLIERS/VENDORS<br />

Bingaman & Son Lumber Inc.<br />

Introduces New President<br />

Chris Bingaman announced that Scott Hurst assumed<br />

the role of president of Bingaman & Son Lumber Inc. on<br />

January 1st, <strong>2024</strong>. Hurst joined Bingaman as accounting<br />

manager in 1994 and served as CFO since 2008. When<br />

making the announcement Chris stated, “I am confident<br />

Scott is dedicated to maintaining our core values and<br />

possesses the skills we need for our future.” Chris will<br />

remain as CEO.<br />

Chris added, “One of our company’s core values is<br />

stewardship. We describe it as, managing our relation-<br />

very happy to recognize Jim’s accomplishments in this<br />

way while also keeping him engaged in the next phase<br />

of Koppers evolution.”<br />

Sullivan added, “It is my honor to accept this new responsibility<br />

as President of Koppers. I am proud of our<br />

Please turn to page 54<br />

Scott Hurst<br />

ships and resources as a trust given<br />

from God, which inspires our vision<br />

for the future!” This value applies to<br />

the stewardship of the organization.<br />

In 2017 Bingaman created an<br />

Executive Team to plan corporate<br />

leadership transition that would<br />

bring continuity to the values and<br />

the talent that the company needed<br />

for a successful future. They are<br />

making this change now to demonstrate<br />

an intentional transition plan to<br />

their employees and business partners.<br />

Bingaman & Son Lumber Inc.<br />

headquartered in Kreamer, PA is an<br />

ESOP company with five locations in<br />

Pennsylvania.<br />

For more information, visit<br />

www.bingamanlumber.com.<br />

James A. Sullivan<br />

Koppers Names James<br />

A. Sullivan President And<br />

Chief Operating Officer<br />

Koppers Holdings Inc. announced<br />

the election of James A. Sullivan as<br />

president and chief operating officer,<br />

effective January 1, <strong>2024</strong>. Sullivan<br />

has been Executive Vice President<br />

and Chief Operating Officer since<br />

January 2020. Leroy M. Ball will continue<br />

to serve as Chief Executive Officer<br />

of Koppers.<br />

As president, Sullivan will have<br />

a bigger role in the development of<br />

Koppers 2030 strategy, which is expected<br />

to build upon the company’s<br />

2025 Expand and Optimize strategy<br />

that has consistently produced improved<br />

safety performance, steady<br />

progress in sustainability, and record<br />

financial results. Ball will continue to<br />

apply his leadership to drive shareholder<br />

value, which includes setting<br />

the company’s corporate strategy,<br />

advancing its people-first culture<br />

and building key stakeholder relationships.<br />

With over 20 years of direct industry<br />

experience, Sullivan joined Koppers<br />

in June 2013 as Vice President<br />

of Business Development before advancing<br />

into various roles of increasing<br />

responsibility, culminating in his<br />

appointment to Executive Vice President<br />

and Chief Operating Officer in<br />

January 2020.<br />

Commenting on the change, Ball<br />

said, “Jim has contributed so much<br />

to the evolution of Koppers since he<br />

joined the company over 10 years<br />

ago. From spearheading the restructuring<br />

and resurgence of the Carbon<br />

Materials and Chemicals business,<br />

to breaking down business unit silos<br />

by uniting operational leadership,<br />

and advancing our 2025 Expand and<br />

Optimize strategic plan, he has driven<br />

a culture of performance. I am<br />

16 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 17

HMA UPDATE<br />

Industry Education And Networking<br />

In Charming Charleston<br />

In just a few short weeks, HMA<br />

members, non-members, industry<br />

suppliers, and other stakeholders will<br />

be convening at The Charleston Place<br />

in Charleston, South Carolina, for<br />

HMA’s <strong>2024</strong> <strong>National</strong> Conference and<br />

Expo. Slated for Monday–Wednesday,<br />

<strong>March</strong> 25–27, the event will provide<br />

plenty of in-demand learning sessions;<br />

sold out exhibit space; and networking<br />

opportunities to mix, mingle, and share knowledge with<br />

industry colleagues—old and new.<br />

This year’s theme is Pathways to Success and our<br />

agenda is geared toward helping your company navigate<br />

volatile markets, economic uncertainty, and other<br />

challenges ahead.<br />

•<strong>2024</strong> <strong>Hardwood</strong> Industry Outlook<br />

Hear from industry experts on a range of topics,<br />

including forecasts on pallets, railway ties, and residuals,<br />

as well as gain insights into the battle against misleading<br />

claims from alternative products and U.S. forest inventory<br />

and analysis.<br />

•Funding Improvements: Grant Opportunities<br />

What is the USDA Forest Service’s Wood Innovations<br />

Grant (WIG) Program? How can a grant help your<br />

company make equipment and operational<br />

upgrades? What companies are eligible?<br />

How do you apply for a grant? Marcus<br />

Taylor, Wood Innovations coordinator for the<br />

Southern Region, will be with us to provide<br />

all the details and answer questions.<br />

•Effective Communication Panel<br />

Times have changed and communicating<br />

with workers from different generations can<br />

be challenging and frustrating for all involved. This panel<br />

discussion, moderated by Steve James—president and<br />

CEO of Frank Miller Lumber Company and a certified<br />

John C. Maxwell coach, trainer, and speaker—will<br />

bring together three generations to candidly discuss<br />

collaboration, stereotypes surrounding different age<br />

groups, and why generational spread is a strength, not<br />

a weakness.<br />

•Sawmilling in the Pacific Northwest<br />

Go on a virtual tour of NWH’s facility in Longview,<br />

Washington, to get a close-up look at their operations,<br />

and soar high above an Alder forest while learning about<br />

this beautiful yet underutilized species.<br />

•Economic Predictions: Hits and Misses<br />

This year, we’re welcoming back our 2023 presenter,<br />

Dr. Christopher Kuehl, co-founder of Armada Corporate<br />

Please turn to page 66<br />

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

<strong>2024</strong> HMA <strong>National</strong><br />

Conference and Expo<br />

Monday–Wednesday, <strong>March</strong> 25–27<br />

The Charleston Place | 205 Meeting St | Charleston, SC 29401<br />

BY IAN FAIGHT<br />

CHIEF OPERATING OFFICER<br />

HARDWOOD MANUFACTURERS ASSOCIATION<br />

WARRENDALE, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

Conference Highlights<br />

• <strong>2024</strong> Economic <strong>Hardwood</strong> Predictions: Industry Hits Outlook & Misses<br />

» Raw Pallets Material Trends<br />

» Federal Railway Funding Ties Programs<br />

» Industry Residuals Updates<br />

» Panel Forest on Inventory Generational and Communications<br />

Analysis<br />

» Sawmilling The Battle in the Against Pacific False Northwest Advertising Claims<br />

• US Forest Service Wood Innovations Grants for Mill Improvements<br />

• Sawmilling in the Pacific Northwest<br />

412.244.0440 | info@hardwood.org | HMAmembers.org<br />

A virtual tour of NWH’s facility in Longview, Washington<br />

Register online at HMAmembers.org Williamsburg Place, Suite 108 | Warrendale, PA 15086<br />

• Effective Communication Panel Discussion<br />

• Economic Predictions: Hits and Misses<br />

412.244.0440 | info@hardwood.org | HMAmembers.org<br />

18 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

Register<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

online at HMAmembers.org<br />

1 Williamsburg Place, Suite 108 | Warrendale, PA 15086<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 19

AHEC REPORT<br />

ESTABLISHED 1977 ESTABLISHED 2013<br />

How Can Your Company Benefit From AHEC Membership?<br />

MOVING YOUR<br />

Over the past several months, I have spoken<br />

with many of you in the <strong>Hardwood</strong> industry<br />

and have found one topic that keeps<br />

coming up: finding new markets. Either domestically<br />

through the Real American <strong>Hardwood</strong><br />

promotion program or internationally<br />

through AHEC activities, there is a critical<br />

need to create new <strong>Hardwood</strong> consumers<br />

all around the globe. While I have found general<br />

support for AHEC’s overall mission to<br />

“grow the pie” for U.S. exporters through generic<br />

educational and promotional activities,<br />

I have also learned that there is a perception<br />

among the industry that generic promotion<br />

is the only thing that AHEC does, and there<br />

are no real direct benefits to members who pay dues as<br />

opposed to the industry at large who all benefit from generic<br />

promotion.<br />

As with any trade association, the benefits you receive<br />

from AHEC membership tend to be directly proportional<br />

to your involvement with the organization. Those members<br />

who participate in events overseas and remain in<br />

contact with the AHEC overseas staff on a regular basis<br />

will certainly get more out of their investment than an inactive<br />

member. Nevertheless, the direct benefits even<br />

for less active members are substantial, and are outlined<br />

below:<br />

•American <strong>Hardwood</strong> Environmental Profile (AHEP):<br />

Simply put, AHEPs are a consignment-specific shipping<br />

document which will provide access to information on<br />

the risk of illegality as well as sustainability of<br />

the U.S. <strong>Hardwood</strong> species contained in that<br />

consignment, together with quantitative data<br />

on the environmental impacts associated with<br />

delivering each specific consignment to an individual<br />

customer anywhere in the world. In<br />

the short term, this document is designed to<br />

satisfy “due diligence” requirements arising<br />

from illegal logging legislation such as the<br />

Lacey Act in the U.S., the EU Timber Regulation,<br />

and Japanese “Green Procurement”<br />

laws. This document is free and exclusive to<br />

AHEC members, and can be filled out on our<br />

new website platform: ahec.org. This system<br />

will be updated this year in advance of changing<br />

EUDR requirements.<br />

•Participation in AHEC Trade Show Pavilions: AHEC<br />

offers several opportunities per year for members to exhibit<br />

in AHEC-funded trade show pavilions at a greatly<br />

reduced cost. AHEC takes charge of the stand build,<br />

space rental, signage and even the furniture and electrical<br />

service. For <strong>2024</strong> AHEC will host (or has hosted)<br />

pavilions at IndiaWood Bangalore, Dubai Wood Show,<br />

Interzum Guangzhou, SylvaWood, & FMC Shanghai in<br />

China, TechnoMueble in Guadalajara, Mexico, TIWF in<br />

Bangkok, Thailand, and INTERMOB in Istanbul, Turkey.<br />

•Conventions: AHEC holds regional conventions in<br />

Greater China/Southeast Asia, Europe, and Mexico.<br />

These events provide unique opportunities to network<br />

with a large number of potential overseas buyers and<br />

Please turn to page 66<br />

FREIGHT FORWARD<br />

S P E C I A L I Z I N G I N<br />

L U M B E R E X P O R T S<br />

O U T O F N O R T H<br />

A M E R I C A<br />

Contact Us<br />

855-682-1637<br />

kingcitynorthamerica.com<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

3 OFFICES TO SERVE YOU BETTER:<br />

MONTREAL, QC<br />

ALLISTON, ON<br />

CHESAPEAKE, VA<br />

20 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

Scan to Request a Quote

NWFA REVIEW<br />

NWFA Expo Heads To New Orleans<br />

The <strong>National</strong> Wood Flooring Association<br />

(NWFA) is planning to “Raise the Bar” at<br />

its Wood Flooring Expo, scheduled for<br />

April 16 – 18, at the New Orleans Ernest<br />

N. Morial Convention Center in New<br />

Orleans, LA. This is the first time the<br />

Expo has been held in New Orleans, and<br />

the NWFA team is busy planning a variety of fun events<br />

for attendees and exhibitors alike.<br />

The Expo will start with the Big Easy Kickoff where<br />

NWFA leadership will provide timely industry updates,<br />

showcase the NWFA Wood Floor of the Year awards, and<br />

recognize other industry standouts for their volunteerism<br />

and leadership. Following these presentations, the<br />

celebration will continue with the Jazz It Up Reception<br />

showcasing a lively New Orleans atmosphere with local<br />

entertainment and food.<br />

As in past years, nearly 250 companies will be on the<br />

trade show floor to share the industry’s latest products<br />

and services with an international audience of about<br />

3,000. Multiple exhibitor product demonstrations will<br />

be held throughout show hours, with NWFA Regional<br />

Instructors demonstrating specific hands-on techniques<br />

as well.<br />

For you and your staff, the Expo offers a variety<br />

of educational opportunities for<br />

professionals looking to grow and expand<br />

their industry knowledge and expertise.<br />

Attendees can focus their learning on<br />

technical skills, growing your business,<br />

understanding how our industry’s products<br />

are made, and jobsite demonstrations. All<br />

education sessions are presented by industry experts<br />

giving you the information and knowledge you need to<br />

stay competitive and adapt quickly to changing market<br />

conditions and trends.<br />

If you are new to the industry, and do not know where<br />

to start, the New Members Reception will provide an<br />

opportunity to meet with NWFA leadership, committee<br />

members, and staff to learn how NWFA can best meet<br />

your professional needs. And women trying to navigate<br />

in this male-dominated industry will want to attend the<br />

Women’s Industry Network (WIN) Breakfast where<br />

NWFA will bring together women from across the supply<br />

chain to make connections, support each other, and<br />

share achievements and challenges.<br />

NWFA once again will host local high school and<br />

technical college students to learn about career<br />

opportunities in the wood flooring industry. Students<br />

will take part in industry panel discussions, participate<br />

Please turn to page 68<br />

TRUSTED<br />

NATIONAL<br />

LEADER<br />

FULL BIOMASS WOOD<br />

BOILER SYSTEM<br />

Design, Fabrication and Installation – Hot Water and Steam<br />

• Lifetime Support of Equipment with Full-Service Team and Parts Division<br />

• Experts in All Aspects of Boiler Room Equipment – Combustion System, Boiler, Emissions<br />

Control Equipment, Controls, and Material Conveying Equipment<br />

• Installing throughout the US and Internationally<br />

BY PENNY KEY,<br />

MEETING & TRADE SHOW DIRECTOR,<br />

NATIONAL WOOD FLOORING ASSOCIATION,<br />

CHESTERFIELD, MO 800-422-4556<br />

WWW.NWFA.ORG<br />

906-466-9010<br />

www.BurnChips.com sales@burnchips.com<br />

22 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 23

NHLA: Why Knot...<br />

Participate In Telling Our Super Sustainable Story<br />

SMART RESAW<br />

FOR SUPERIOR<br />

PRODUCTS<br />

Many things influence your<br />

business decisions. One of the<br />

growing influences is the current<br />

environmental push to lower human<br />

impact to mitigate climate<br />

change. Whether or not you<br />

believe humans impact climate<br />

change is irrelevant. Whether or not the current activities<br />

to improve the environment are helping is also irrelevant.<br />

The perception that action is necessary influences the<br />

markets and your business. The good news is that wood<br />

is renewable, sustainable, and low-impact, and we must<br />

tell that story.<br />

The concept of sustainability in the <strong>Hardwood</strong> lumber<br />

industry, particularly in sustainable forestry, is multifaceted.<br />

It goes beyond the common perception of planting<br />

more trees than harvesting and preserving habitats for<br />

recreation. The sustainable <strong>Hardwood</strong> story ensures a<br />

flourishing and thriving forest, allowing trees to replenish<br />

naturally at a pace supporting an exponentially renewable<br />

increase.<br />

One crucial aspect highlighted is the role of deciduous<br />

trees in carbon sequestration, which is the carbon<br />

embodied or stored in the <strong>Hardwood</strong> product. In natural<br />

forests and urban settings, these trees absorb significant<br />

amounts of carbon; wood is approximately 50<br />

percent carbon, contributing to<br />

carbon sequestration. The carbon<br />

absorbed is then retained in<br />

the wood products for extended<br />

periods, from decades to centuries.<br />

This carbon sequestration<br />

in <strong>Hardwood</strong> products adds an<br />

environmental benefit to the <strong>Hardwood</strong> story.<br />

Moreover, when <strong>Hardwood</strong> products reach the end of<br />

their useful life, they can be burned for energy to substitute<br />

for higher-impact fossil fuels or disposed of in landfills<br />

to sequester the carbon in the ground further. This<br />

end-of-life cycle further emphasizes the sustainability of<br />

solid <strong>Hardwood</strong>, as it minimizes the environmental impact.<br />

How does all this impact your business decisions?<br />

For the most part, this is all happening in the background<br />

and is driving policy and markets. People discuss<br />

it at the Intergovernmental Panel on Climate Change<br />

(IPCC). IPCC is the United Nations body that assesses<br />

the science related to climate change. They are pushing<br />

Product Category Rules (PCR) and Environmental<br />

Product Declarations (EPD) in conjunction with Life Cycle<br />

Assessments (LCA) of all materials. <strong>Hardwood</strong>s have<br />

the best story; we must participate or risk falling behind.<br />

The US Forest Service has awarded a Wood Innovation<br />

Grant to the American Wood Council (AWC) to work<br />

COMACT’S NEW RESAWEXPERT<br />

Introducing BID’s AI-powered linear ResawExpert with<br />

vision—where precision, efficiency, and innovation<br />

redefine hardwood processing and specialty products.<br />

Our revolutionary technology intelligently maximizes yield<br />

and minimizes waste, ensuring every inch of your raw<br />

material is utilized efficiently.<br />

BID’s leading AI-powered optimization applied<br />

to resaw features:<br />

• Independent optimization and grading of all four faces<br />

of your product to maximize its value<br />

• End cameras to detect heartwood<br />

• Rotation validation scanner<br />

• Optimization by unit of clear wood, NHLA cutting grades<br />

or custom grades<br />

• Quick and easy installation on an existing line<br />

The new Comact ResawExpert optimizer can be installed during ongoing operations<br />

and activated once tuning is completed!<br />

Please turn to page 69<br />

Scan this QR code to see it in action.<br />

BY DALLIN BROOKS,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-377-1082<br />

WWW.NHLA.COM<br />

Contact us today to upgrade your wood processing capabilities!<br />

450-435-2121 | info@bidgroup.ca | www.bidgroup.ca<br />

24 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry

“In this industry, you have to know about the products you’re selling.<br />

We have knowledge of the products, where they are going, and the<br />

applications they are being used in. We offer a wide variety of services,<br />

specializing in custom millwork, CNC design and manufacturing and<br />

delivery.”<br />

Buster Ferris, Vice President, Edensaw Woods Ltd.<br />

Edensaw Woods Ltd, located in Port Townsend, WA, carries around 100 species of domestic and exotic species.<br />

Diverse <strong>Hardwood</strong> Lumber And Lumber<br />

Products At Edensaw Woods Ltd.<br />

Port Townsend, WA, is home to <strong>Hardwood</strong> lumber and<br />

lumber products supplier Edensaw Woods Ltd. With a<br />

wide selection of products, current Vice President Buster<br />

Ferris said they carry around 100 species of domestic<br />

and exotic species. “Aside from that, we specialize in<br />

marine and cabinet grade plywood, rough and surfaced<br />

lumber, wood veneer, <strong>Hardwood</strong> flooring and specialty<br />

decking,” he explained. “Our selection of slabs are second<br />

to none in terms of range of selection and quality<br />

and is one of the largest in the Pacific Northwest.”<br />

Ferris said he is currently purchasing .5 million board<br />

feet annually in Alder, Ash, Beech, Cherry, Hickory, Walnut<br />

and Hard and Soft Maple. In addition, he also purchases<br />

about .5 million board feet in imported woods<br />

including European Beech, Bubinga, Jatoba, Spanish<br />

Cedar, and Meranti. Additionally, 100 semi-loads a year<br />

By Michelle Keller<br />

Edensaw Woods’ on-site millhouse works with customers to utilize<br />

the selection of wood to design solid wood products according<br />

to exact specifications.<br />

of plywood products come from various sources.<br />

Edensaw Woods was founded by Buster’s dad, Jim<br />

Ferris, and his now deceased business partner Charlie<br />

Moore with the initial goal to provide specialty <strong>Hardwood</strong>s<br />

to the local Port Townsend and Olympic Peninsula<br />

boat-building community.<br />

Today the company is preparing to celebrate its 40th<br />

anniversary. “As Edensaw grew, our product offering<br />

continued to increase,” Buster said. “We now offer an<br />

assortment of shop and hand tools, craft and turning<br />

woods, live edge slabs, specialty burls, high quality<br />

veneers, marine and cabinet grade plywoods, and, of<br />

course, plenty of <strong>Hardwood</strong>s.”<br />

As for what sets the company apart from others and<br />

has kept the company in business for almost four de-<br />

Please turn the page<br />

“We specialize in cutting cabinet parts, furniture pieces, moulder<br />

profiles, signs, templates, boat parts and fly cutting <strong>Hardwood</strong><br />

slabs to create flat tabletop surfaces,” Buster Ferris, Vice President,<br />

Edensaw Woods Ltd.<br />

Founder and owner Jim “Kiwi” Ferris, President of Edensaw Woods, stands with his son, Buster Ferris, VP.<br />

26 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 27

EDENSAW WOODS LTD. Continued<br />

Checking slabs moisture out of the new iDry Kiln before further processing<br />

them for sale.<br />

Edensaw Woods Ltd. offers an assortment of shop and hand tools, craft and turning woods, live edge slabs, specialty burls, high<br />

quality veneers, marine and cabinet grade plywoods, along with their vast array of <strong>Hardwood</strong>s.<br />

cades, Buster said his staff is key.<br />

The knowledge, customer service<br />

and pride for what they do set<br />

them apart. “In this industry, you<br />

have to know about the products<br />

you’re selling. We have knowledge<br />

of the products, where they<br />

are going, and the applications<br />

they are being used in. When you<br />

call us for the first time, we can<br />

help walk you through what you<br />

need and what the product is going<br />

to offer for your application in<br />

terms of stability, durability and<br />

more. We offer a wide variety of<br />

services, specializing in custom<br />

millwork, CNC design and manufacturing<br />

and delivery.”<br />

The company’s on-site millhouse<br />

works with customers to<br />

utilize the selection of wood, to design<br />

solid wood products according<br />

to exact specifications. Buster<br />

explained, “We pride ourselves on<br />

being able to individually hand pick<br />

our lumber from our own stock for<br />

each order, which increases the<br />

consistently high quality for customer<br />

projects. We supply custom<br />

materials for local boat builders,<br />

and fine home contractors. With<br />

our custom moulding capabilities,<br />

we can duplicate classic Victorian<br />

trim and siding patterns to renovate<br />

homes on the <strong>National</strong> Historic<br />

Homes Register.”<br />

Continually reinvesting in the<br />

operation Buster said the most<br />

recent additions are a Weinig<br />

moulder and an iDry Vacuum Kiln<br />

Buster Ferris, VP of Edensaw Woods<br />

increasing production and efficiency in both aspects. “With the<br />

installation of the new Weinig moulder we have reduced our<br />

lead time from three weeks plus down to just a couple of days,”<br />

he said. “We sent the entire millhouse to the Weinig HOLZ-HER<br />

Education and Training Center in Mooresville, NC, and I could<br />

not be happier with this experience. With the installation of our<br />

first vacuum kiln we can now dry material in a fraction of the<br />

time as a conventional kiln, which has been huge for drying our<br />

own stock as well as taking on customers’ orders.”<br />

The CNC Department at Edensaw specializes in small custom<br />

and large production projects. Buster offered, “We specialize<br />

in cutting cabinet parts, furniture pieces, profiles, signs,<br />

templates, boat parts and fly cutting <strong>Hardwood</strong> slabs to create<br />

flat tabletop surfaces. Our millhouse is equipped with a large<br />

variety of industrial equipment. We have a gang rip saw, resaw,<br />

planer, wide-belt sander, and moulder all on site to get<br />

our rough lumber one, two or three steps closer to the finished<br />

product. The wide belt sander can accommodate pieces up to<br />

50 inches across.”<br />

“If our customer doesn’t have the space for all necessary<br />

equipment, then we can mill it with ours,” Buster continued. “If<br />

you don’t have a planer, we can surface it. If you don’t have a<br />

table saw, we can straight-line it, if you don’t have the space or<br />

the time then let us do it for you. Our moulder can create custom<br />

profiles to cut that piece you can’t find anywhere in any species<br />

you want. Whether they don’t make it anymore, or they never<br />

have–we fill in the gaps. If the project is too complex for human<br />

Processing slabs to customers’ requirements.<br />

hands, our CNC department can create even<br />

the most intricate patterns and repetitive cuts.<br />

With a 5-foot x 12-foot bed, the possibilities are<br />

virtually endless.”<br />

Sustainability is at the forefront of concerns<br />

for Edensaw. “We have always been dedicated<br />

to sourcing woods from sustainable forests.<br />

Not only do we follow the Forest Stewardship<br />

Council’s® strictest guidelines, as well as those<br />

of the Program for the Endorsement of Forest<br />

Certification, (PEFC) we also adhere to our very<br />

own standards when sourcing lumber, slabs<br />

and burls from our own backyard and abroad. If<br />

we are not good stewards of the forest and land,<br />

then what is the point? To help lead the way in<br />

sustainability we took Edensaw fully solar not<br />

long ago. Installing 528 solar panels for a total<br />

output of 201.75 kWP now producing more power<br />

than we use.”<br />

As for what the next 40 years will bring, he<br />

said he’s looking at new growth opportunities in<br />

the future and Edensaw Woods Ltd. has continued<br />

plans for year-over-year growth. n<br />

For more information visit edensaw.com.<br />

28 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 29

Editor’s Note:<br />

Please view the entire video workshop on our website at<br />

www.millerwoodtradepub.com/national-hardwood-magazine/<br />

or scan the QR code provided with this article<br />

SCAN ME<br />

The grading of sawn wood into categories as it is processed helps to determine to a large extent the value and potential use possible<br />

for each board of sawn lumber.<br />

AHEC Updates American <strong>Hardwood</strong><br />

Lumber Grading Workshop<br />

The American <strong>Hardwood</strong> Export Council (AHEC)<br />

has created a new and updated video workshop to<br />

provide a simplified but informative explanation of<br />

the grading rules for American <strong>Hardwood</strong> lumber.<br />

Presented by Dana Spessert, Chief Inspector of the<br />

NHLA, the rules were established over 125 years ago<br />

by the then newly-formed <strong>National</strong> <strong>Hardwood</strong> Lumber<br />

Association (NHLA). Today the NHLA has over 650<br />

members worldwide and the NHLA rules are still the<br />

national standard for the U.S. <strong>Hardwood</strong> industry and<br />

form the basis for grading of export lumber.<br />

Wood is a natural material and by its very nature<br />

may contain different characteristics and defects that<br />

need to be understood and allowed for in any given<br />

application. The grading of sawn wood into categories<br />

as it is processed helps to determine to a large extent<br />

the value and potential use possible for each board of<br />

sawn lumber.<br />

The NHLA grading rules provide both the buyer and<br />

seller with a consistent language to use in specifying<br />

<strong>Hardwood</strong> lumber transactions. Although the NHLA<br />

grading rules are targeted for the U.S. marketplace,<br />

a reasonable knowledge is essential for buyers worldwide<br />

in order to attain their expected degree of quality.<br />

<strong>Hardwood</strong> lumber is usually graded on the basis of<br />

the size and number of cuttings (pieces) that can be<br />

obtained from a board when it is cut up and used in the manufacture of a <strong>Hardwood</strong> product. The NHLA<br />

rules were designed with the furniture trade in mind to provide a measurable percentage of clear, defect-free<br />

wood for each grade. The upper grades provide the user with long clear pieces, while the Common<br />

grades are designed to be re-sawn into shorter clear pieces.<br />

The workshop covers the following topics:<br />

- Measurement: A guide to using surface measure, board feet, cuttings and cutting units.<br />

- Characteristics: Marking and features found in lumber that are naturally occurring or are as a result<br />

of the process, with clear visual examples to help with identification.<br />

- Defects: Markings found within lumber that can affect the yield with visual examples.<br />

- The Grades; FAS, No.1 Common, No.2 Common, F1F and Selects: Recognized grades of<br />

lumber and their main uses within the industry.<br />

The American <strong>Hardwood</strong> temperate forest resource is the largest of its kind anywhere in the world, with a<br />

significant history of sustainability. Exploring the Common grades, where possible, is invaluable in achieving<br />

the most value both in lumber cost and yield. These efforts will also help to ensure the sustainability of<br />

the resource for generations. n<br />

30 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 31

LSLA Winter Meeting Includes<br />

<strong>Hardwood</strong> Industry Updates<br />

Photos By Chris Fehr<br />

The Lake States Lumber Association (LSLA) recently<br />

convened for its annual winter meeting at the Hilton<br />

Appleton Paper Valley Hotel in Appleton, WI. Approximately<br />

130 members and guests were treated to three<br />

days of networking, informational presentations and receptions.<br />

A welcome reception opened the meeting followed<br />

the next day by a welcome speech by Larry Krueger<br />

of Krueger Lumber and multiple guest speakers and<br />

presentations. Michael Snow, executive director of the<br />

American <strong>Hardwood</strong> Export Council, was the first presenter.<br />

He discussed the current market and outlook for<br />

U.S. <strong>Hardwood</strong> exports.<br />

He was followed by <strong>Hardwood</strong> Federation Executive<br />

Director Dana Lee Cole, who gave attendees an update<br />

on HF activities on Capitol Hill. She was followed by<br />

LSLA Michigan State Legislative Consultant Scott Everett<br />

and LSLA Wisconsin Legislative Consultant Amy<br />

Boyer.<br />

Following lunch, Jim Maltese of Stella-Jones brought<br />

everyone up to date on projects by Real American <strong>Hardwood</strong><br />

Coalition.<br />

The day also included an LSLA Education Board<br />

Meeting, a Carbon Credit Panel Discussion and election<br />

of LSLA directors.<br />

Additionally, during the Wednesday reception, Joel<br />

Nilsestuen, assistant deputy secretary of the Wisconsin<br />

Dept. of Transportation, gave a presentation.<br />

A Board of Directors meeting closed the event. n<br />

Tyler Francois, Snowbelt <strong>Hardwood</strong>s Inc., Hurley, WI; Nick Bunkelman, Menzner <strong>Hardwood</strong>s Co., Marathon City, WI; Brady Francois,<br />

Snowbelt <strong>Hardwood</strong>s Inc.; Jim Higgins, SII Dry Kilns, Chambersburg, PA; and Tyler Kamps, Kamps <strong>Hardwood</strong>s Inc., Dutton, MI<br />

To learn more about this association, visit www.lsla.com.<br />

John Stenson, U-C Coatings LLC, Buffalo, NY; Dan Hansen,<br />

Midwest <strong>Hardwood</strong> Company LLC, Maple Grove, MN; and David<br />

Messer, MacBeath <strong>Hardwood</strong> Co., Edinburgh, IN<br />

Aaron Ruotsala, BioSource Corp., Ironwood, MI; Nolan Mulder,<br />

Wolverine <strong>Hardwood</strong>s Inc., Allegan, MI; Kyle Jeske, Richardson<br />

<strong>Hardwood</strong>s LLC, Sheboygan Falls, WI; and Derik VanEpern, Ottawa<br />

Forest Products Inc., Amasa, MI<br />

The LSLA Board of Directors (front row, from left): Jennifer Lu, Wisconsin Dept. of Agriculture, Trade and Consumer Protection,<br />

Madison, WI; Jim Maltese, Stella-Jones Corp., Bangor, WI; William Millard, Granite Valley Forest Products Inc., Rockbridge, WI; Nikki<br />

Loehr, LSLA Coordinator, Crystal Falls, MI; and Kate Miller, JM Longyear LLC/Northern <strong>Hardwood</strong>s Inc., Atlantic Mine, MI; (back row,<br />

from left): Steve Peters, Rockland Flooring, Rockland, WI; Kirby Kendrick, Kendrick Forest Products Inc., Edgewood, IA; Michael Skenadore,<br />

Menominee Tribal Enterprises, Neopit, WI; Loren DeJonge, Constructive Sheet Metal Inc., Allendale, MI; Rick Luokkala, Performance<br />

Pallet Corporation, Seymour, WI; and missing from photo is Kyle Jeske, Richardson <strong>Hardwood</strong>s LLC, Sheboygan Falls, WI<br />

Ryan Peterson, Northern <strong>Hardwood</strong>s Inc., Atlantic Mine, MI; Jon<br />

Johnson and John Erickson, Timber Products Company, Munising,<br />

MI; Jason Brettingen, Kretz Lumber Co. Inc., Antigo, WI; and<br />

Joe Morrey, Stella-Jones Corp., Bangor, WI<br />

Amy Boyer, Boyer Consulting LLC, Madison, WI; and Rob Paradise<br />

and John Gehringer, Devereaux Sawmill Inc., Pewamo, MI<br />

Additional photos on next page<br />

32 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 33

LSLA PHOTOS Continued<br />

Scott Dickerson, Banks <strong>Hardwood</strong>s Inc., White Pigeon, MI; Ryan Peterson, Northern <strong>Hardwood</strong>s Inc., Atlantic Mine, MI; Gus Blemke,<br />

Troy Brown and Todd Breitenfeldt, Kretz Lumber Co. Inc., Antigo, WI; and Mike Schulke, Tigerton Lumber Company, Tigerton, WI<br />

Sue VanEss, NWH, Grand Rapids, MI; Jeff Brown, Konz Wood<br />

Products Co., Appleton, WI; Cal Diercks, Kretz Lumber Co. Inc.,<br />

Antigo, WI; and John Gehringer, Devereaux Sawmill Inc., Pewamo,<br />

MI<br />

David Wilson, Wolverine <strong>Hardwood</strong>s Inc., Allegan, MI; Sean Mc-<br />

Mahon, Baillie Lumber Co., Hamburg, NY; and Anthony Moody<br />

and Doug Clark, Missouri Walnut LLC, Neosho, MO<br />

Jim Maltese, Stella-Jones Corp., Bangor, WI; Dennis Gustafson,<br />

Snowbelt <strong>Hardwood</strong>s Inc., Hurley, WI; and Gus Welter, Granite<br />

Valley Forest Products Inc., New London, WI<br />

Vic Boeding, Bruggeman Lumber Inc., Sand Springs, IA; Javan<br />

Mallery, Wolverine <strong>Hardwood</strong>s Inc., Allegan, MI; Tammy Sue Donaldson,<br />

Onsite-Technologies LLC, Norwalk, WI; and Steve Bruggeman,<br />

Bruggeman Lumber Inc.<br />

Tyler Kamps, Kamps <strong>Hardwood</strong>s Inc., Dutton, MI; Matt Yest, Kendrick<br />

Forest Products Inc., Edgewood, IA; Shane Underwood,<br />

Granite Valley Forest Products Inc., New London, WI; and Kirby<br />

Kendrick, Kendrick Forest Products Inc.<br />

Rick Luokkala, Performance Pallet Corporation, Seymour, WI; Jamie<br />

Kissack and Rick Wilson, Pukall Lumber Co., Arbor Vitae, WI;<br />

and Jesse LaSon, Rossi Group, Cromwell, CT<br />

John Yeshe, Lyme Great Lakes Timberlands, Escanaba, MI;<br />

Claire Runquist, Lyme Great Lakes Timberlands, L’Anse, MI; Jesse<br />

LaSon, Rossi Group, Cromwell, CT; and Kate Miller, JM Longyear<br />

LLC/Northern <strong>Hardwood</strong>s Inc, Atlantic Mine, MI<br />

Eric Wayne, Banks <strong>Hardwood</strong>s Inc., Menomonie, WI; Chris Fehr,<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Erie, PA; and Dana Lee Cole, Executive<br />

Director, <strong>Hardwood</strong> Federation, Washington, DC<br />

Jeremy Mortl, Messersmith Manufacturing Inc., Bark River, MI;<br />

Laura Townsend and Mike Penner, Breeze Dried Inc., Tillsonburg,<br />

ON; and Lloyd Lovett, King City Forwarding USA Inc., Chesapeake,<br />

VA<br />

Michael Snow, American <strong>Hardwood</strong> Export Council, (AHEC),<br />

Sterling, VA; and Mike Schulke and Sarah Morack, Tigerton Lumber<br />

Company, Tigerton, WI<br />

Pete Johnson, Granite Valley Forest Products Inc., Weyauwega, WI; Matt Tietz, McDonough Manufacturing<br />

Company, Eau Claire, WI; Mike Shelton, Kingsford Lumber Company LLC, Kingsford,<br />

MI; and Jerry Ort, Tigerton Lumber Company, Tigerton, WI<br />

34 MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

www.RealAmerican<strong>Hardwood</strong>.com/industry<br />

MARCH <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 35

ALC Meeting: Logging Leader Says Rising Costs Hurt The Industry<br />

The logging industry must increase profitability and<br />

change public perception to maintain its workforce to<br />

survive, reports the director of the American Loggers<br />

Council.<br />

The remarks came at the recent Greensboro, NC,<br />

meeting of the Appalachian Lumbermen’s Club. Scott<br />

Dane, Council Executive Director, said the national organization<br />

represents loggers in 38 states through local<br />

chapters and was formed in 1994 to serve as a unified,<br />

national voice for professional loggers across the United<br />

States.<br />

Dane said the industry is struggling with an aging<br />

workforce and low profit margins. The average age of<br />

a logger in the U.S. is over 55 years and not enough<br />

young people are considering the profession.<br />

The Council supports the Future Logging Careers Act<br />

legislation which proposes to exempt minors of age from<br />

employment by their parents in any occupation on a job<br />

site owned and operated by their parents. Minors 16 and<br />

older may perform any job, whether hazardous or not,<br />

which is similar to the Fair Labor Standards Act.<br />

Dane said logging companies have not been able to<br />

By Tom Inman<br />

raise rates to match the rising costs of insurance, equipment,<br />

fuel, and wages. Dane noted that primary and<br />

secondary manufacturers were very profitable in 2021<br />

and 2022 when demand for products were high.<br />

“This really was not shared in the logging community,”<br />

he said. “Loggers did not receive the same increases<br />

your companies did.”<br />

The American Loggers Council is the only national<br />

organization solely dedicated to representing the rights<br />

and interests of independent loggers and log truck contractors<br />

on a national level. Dane said the Council combines<br />

the power of its members with state and regional<br />

logging associations across the country to help the industry<br />

by sharing the benefits of education, training, networking,<br />

research, promotion, and legislative advocacy.<br />

The Council is producing a series of four videos to<br />

explain forest management and sustainability, promote<br />

careers in logging and educate the public. The first is<br />

available on the group’s website www.amloggers.com.<br />

The next meeting of the ALC is <strong>March</strong> 12, <strong>2024</strong> at<br />

the Hotel Roanoke in Roanoke, VA. The Spring Beach<br />

Meeting is set for May 2-5 in North Myrtle Beach, SC. n<br />

More information is available at www.lumberclub.org.<br />

Eddie Carson, Beasley Flooring, Franklin, NC; Steve Counts,<br />

BPM Lumber, London, KY; Jamie Straka, Tree Brand Packaging,<br />

Denver, NC; and Brian Turlington, SII Dry Kilns, Lexington, NC<br />

Jesse LaSon, Rossi Group, Emporium, PA; Skipper Beal and<br />

Scott Hanks, Beal Lumber Co. Inc., Little Mountain, SC; and Beryl<br />

Beagle, Stella-Jones, Goshen, VA<br />