National Hardwood Magazine - January 2024

The first National Hardwood Magazine issue of 2024 features stories about Jackel Enterprises, the NHLA Inspector Training School's latest graduating class, the challenging lumber market and much more.

The first National Hardwood Magazine issue of 2024 features stories about Jackel Enterprises, the NHLA Inspector Training School's latest graduating class, the challenging lumber market and much more.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>National</strong><br />

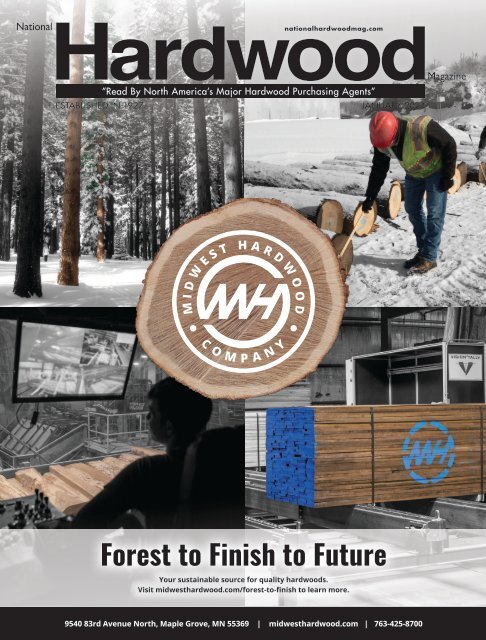

Forest to Finish to Future<br />

Your sustainable source for quality hardwoods.<br />

Visit midwesthardwood.com/forest-to-finish to learn more.<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 1<br />

9540 83rd Avenue North, Maple Grove, MN 55369 | midwesthardwood.com | 763-425-8700

ONE SOFTWARE PARTNER<br />

FROM TIMBER TO CONSUMER<br />

QUARTER SAWN<br />

WHITE OAK LUMBER<br />

TIMBER, LOGGING & LUMBER<br />

Handheld & desktop software<br />

DISTRIBUTION AND RETAIL<br />

Inventory and order management<br />

Width Sorted<br />

Ready to ship!<br />

You need it,<br />

WE HAVE IT.<br />

HARDWOOD END TALLIES<br />

Mobile app with A.I.<br />

WORLD’S LARGEST<br />

MANUFACTURER<br />

of Rift & Quartered<br />

White Oak Products<br />

VISIT DMSi.COM TO LEARN MORE<br />

Graf Brothers Flooring<br />

grafbro.com sales@grafbro.com<br />

606-932-3117<br />

2 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 1

<strong>National</strong><br />

Your sustainable source for quality hardwoods.<br />

Visit midwesthardwood.com/forest-to-finish to learn more.<br />

9540 83rd Avenue North, Maple Grove, MN 55369 | midwesthardwood.com | 763-425-8700<br />

About The Cover<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> JANUARY <strong>2024</strong> Volume 97 No. 13<br />

MIDWEST HARDWOOD<br />

CORPORATION<br />

Midwest <strong>Hardwood</strong> is a complete forest-to-finish<br />

hardwood lumber manufacturer.<br />

All eyes are on sustainability,<br />

whether it’s carbon neutrality (choose<br />

hardwood), supply chain reliability and<br />

risk mitigation (forest to finish), or forest<br />

Forest to Finish to Future<br />

management (FSC Certified since 1995).<br />

Take the random out of your hardwood<br />

sourcing and start with us. Success in<br />

today’s world can’t be left up to chance. Our sales reps can consult<br />

with you on ripped-to-width or special sorts and programs<br />

to ensure a sustainable supply. Truly Forest to Finish to Future.<br />

www.midwesthardwood.com/forest-to-finish<br />

Features & Industry Events<br />

18<br />

Just-In-Time At<br />

Jackel Enterprises Inc.<br />

Appalachian Lumbermen Learn<br />

34 About Energy Grants<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

21<br />

22<br />

24<br />

Class 204 Graduates From NHLA<br />

Inspector Training School<br />

New Year, New Business:<br />

How The <strong>Hardwood</strong> Industry<br />

Can Continue Growing In <strong>2024</strong><br />

Equipment And Services Providers<br />

Accept The Challenges That The<br />

Market Brings<br />

Departments<br />

37<br />

NELA Members Remain Optimistic<br />

Despite Challenging Lumber Markets<br />

19<br />

Terry Miller – President<br />

Paul J. Miller Jr. – Co-owner<br />

Zach Miller – Sales Executive<br />

Chris Fehr – Sales Executive<br />

Sue Putnam – Editor<br />

Cadance Hanson - Staff Writer<br />

Graham Sweeney - Staff Writer<br />

Dolores Buchanan - Who’s Who Coordinator<br />

Rachael Stokes – Graphic Artist<br />

Camille Campbell – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

5 <strong>Hardwood</strong> Calendar<br />

6 U.S.A. Trends<br />

8 Canadian Trends<br />

10 Industry News<br />

12 HMA Update<br />

14 AHEC Report<br />

15 <strong>Hardwood</strong> Federation<br />

Info<br />

16 WCMA Insights<br />

17 NHLA: Why Knot...<br />

46 In Memoriam<br />

52 Who’s Who<br />

58 Classified Profit<br />

Opportunities<br />

60 Advertisers Index<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

2 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 3

HARDWOOD CALENDAR<br />

<strong>January</strong><br />

Appalachian Lumbermen’s Club, Meeting,<br />

Embassy Suites, Greensboro, NC.<br />

www.lumberclub.org. Jan. 9.<br />

Lake States Lumber Assoc., Annual Winter Mtg.,<br />

Hilton Appleton Paper Valley Hotel, Appleton, WI.<br />

www.lsla.com. Jan. 17-19.<br />

February<br />

Indiana <strong>Hardwood</strong> Lumbermen’s Assoc.,<br />

Convention, Indianapolis Marriott Downtown,<br />

Indianapolis, IN. www.ihla.org. Feb. 5-7.<br />

Appalachian <strong>Hardwood</strong> Manufacturers Inc.,<br />

Annual Meeting, The Hammock Beach Resort,<br />

Palm Coast, FL. www.appalachianhardwood.org.<br />

Feb. 21-25.<br />

<strong>National</strong> Association of Home Builders,<br />

International Builders’ Show, Las Vegas Convention<br />

Center, Las Vegas, NV. www.buildersshow.com.<br />

Feb. 27-29. n<br />

<strong>Hardwood</strong> marketIng dIrectory<br />

online will give you access to over 6,000 buyers!<br />

Green Book’s<br />

<strong>Hardwood</strong><br />

Marketing<br />

directory<br />

“The World’s Leading Information Source on <strong>Hardwood</strong> Markets!”<br />

71st Edition/2023<br />

The HARDWOOD PRODUCTS SALES GUIDE that te ls you the species, grades, thicknesses and quantities of<br />

HARDWOOD LUMBER, IMPORTED WOODS, PLYWOOD, DIMENSION, ETC. purchased by woodworking<br />

plants in the United States and Canada.<br />

FEBRUARY COVERS 2023.in d 1 1/16/23 10:40 AM<br />

You can get your share of this market<br />

quicker when these buyers know who you are<br />

and where you’re located!<br />

Advertising Sparks Sales!<br />

These are high grade & low grade<br />

buyers listed with their buying<br />

specifications including distribution/<br />

concentration yards that buy 100,000<br />

board feet or more throughout North<br />

America!<br />

LEASE ONLINE NOW<br />

FOR $2,100.00!<br />

Imported Buyers<br />

Red Oak .........................2535<br />

White Oak .......................1692<br />

Poplar .............................1644<br />

Ash .................................788<br />

Hard Maple .....................1810<br />

Soft Maple ......................1451<br />

Walnut ............................1203<br />

Cherry .............................1673<br />

TRUE. DEPENDABLE. RELIABLE.<br />

Consistently Exceeding Expectations<br />

and Adding Value.<br />

Mahogany .................... 746<br />

Sapele ......................... 221<br />

Teak ............................. 125<br />

These are the BIG THREE species in our Imported section<br />

of the <strong>Hardwood</strong> Marketing Directory online!<br />

Proud Manufacturer of<br />

The <strong>Hardwood</strong> Marketing Directory has 68 years of research helping firms discover new<br />

buying opportunities and contains all North American species and also Imported Woods.<br />

GREEN BOOK, INC.<br />

P.O. Box 34908 Memphis, TN 38184<br />

Phone: (901) 372-8280 FAX: (901) 373-6180<br />

4 JANUARY <strong>2024</strong> n NATIONAL<br />

www.millerwoodtradepub.com<br />

HARDWOOD MAGAZINE<br />

E-mail: greenbook@millerwoodtradepub.com<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 5<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

NOVEMBER 2023 n NATIONAL HARDWOOD MAGAZINE<br />

6<br />

9<br />

OCTOBER 2023 n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

(615)560-0324<br />

lewismilling.com

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

From mill fires to a diminishing pulp market, one Michigan<br />

lumberman recently emphasized that he has “never<br />

seen the industry this bad.”<br />

However, a source from Minnesota called the market<br />

“stable,” and added that things aren’t as “crazy as they<br />

were the last couple of years.”<br />

At the time of this writing, a third source from Wisconsin<br />

took the middle ground and noted that the market was<br />

usually “slow” during this time of year.<br />

“This is an annual trend,” she noted. “A lot of it is just<br />

our distributors who have year-end inventory coming up<br />

and don’t want to bring new inventory in,” said the Wisconsin<br />

source. “It is a trickle-down effect. So, the manufacturing<br />

plants, their customers are pushing them off<br />

orders because they want to bring new materials in.<br />

“That comes back to us,” continued the lumberwoman<br />

who primarily handles Poplar, Red Oak and Hard Maple<br />

with thickness going up to 8/4. “People really don’t want<br />

to place orders now. We’ll get going at the beginning of<br />

<strong>2024</strong>, after the holidays.”<br />

The Michigan source, who primarily handles Red Oak<br />

and Maple, acknowledged that the market was slow while<br />

emphasizing that he was also dealing with other factors.<br />

The lumber supplier said a local mill caught fire a few<br />

months ago.<br />

“So, that screwed up the local market,” he added.<br />

He also stated that the “elephant in the room is the pulp<br />

market.”<br />

“That has slowed down, too,” he said. “We have a couple<br />

of large pulp manufacturers here. They have both<br />

slowed up. That leaves a big hole in the pulp market.”<br />

He added that “loggers can’t stay profitable in the<br />

woods, and it rolls down-hill.”<br />

“The market is slow right now in all sectors,” he said. “It<br />

seems like there is less demand. Plus, interest rates are<br />

up and everything seems to be up.”<br />

At the time of this writing, the source noted that the<br />

current state of the market would further be “disrupted by<br />

the holiday season.”<br />

Lumber suppliers across the Northeast region had<br />

varied responses when asked how their sales were faring<br />

at the time of this writing.<br />

In Maryland a lumber provider noted that while his<br />

sales aren’t what they have been the past several years,<br />

he hasn’t had any trouble moving his products. “Prices<br />

aren’t what they were in 2021 or 2022, but those were<br />

radically different years.”<br />

When asked if his sales were better or worse than<br />

they were six months ago he said, “Six months ago our<br />

customers weren’t building up an inventory because we<br />

were headed into the summer, now we have customers<br />

that are willing to build up their inventories.”<br />

His company offers Poplar in 5/4, 10/4 and 12/4 thicknesses<br />

and Red and White Oak in 5/4 thickness. “We<br />

aim for Face and Better but we also cut No. 1 and 2<br />

Common and some lower grades,” he mentioned.<br />

He sells to distribution yards and pallet manufacturers.<br />

He also has some export customers.<br />

He noted that his biggest struggle has been his expenses,<br />

stating that while his prices have remained<br />

steady his bottom line has been affected.<br />

A Maine lumberman said, “We are starting to see the<br />

market tighten up on the green side. We have also seen<br />

that start to trickle into the kiln-dried side, although not<br />

with the same horsepower.”<br />

He noted that while his sales are better than they were<br />

six months ago that he expects that they will start to<br />

slow down over the next few months. “We typically see<br />

a slowdown after the holidays,” he said. “So, with the<br />

housing numbers being off and our order files are off<br />

that we have with our customers, we are going to have<br />

a pretty tough winter.”<br />

His company handles all species that are native to the<br />

Northeast region. “We have sawmills that produce Red<br />

Oak, Hard and Soft Maple, Yellow Birch and Ash. We also<br />

have a white pine mill,” he said. His company offers these<br />

species in grades Select and Better, No. 1, 2 and 3 Common<br />

in thicknesses of 4/4, 5/4, 6/4 and 8/4. His company<br />

Please turn to page 40 Please turn to page 41<br />

Throughout the Southeast region lumber suppliers<br />

agreed that while the market has slowed down, they are<br />

still able to move their products.<br />

In Tennessee a lumber spokesperson said that his<br />

company’s sales were doing OK at the time of this<br />

writing, noting that, “A lot of what we are shipping<br />

is specie dependent. White Oak is continuing to be a<br />

strong item and the majority of what we are shipping,<br />

overall, however sales have slowed down.”<br />

He added that his sales are doing worse than they<br />

were six months ago, but that is expected this time of<br />

year.<br />

His company offers Red and White Oak, Poplar,<br />

Walnut, Ash, Hard and Soft Maple, Basswood, Hickory<br />

and Cherry in grades No. 2 and Better and in thicknesses<br />

4/4 through 8/4. “We offer grades No. 2 and Better but<br />

we are heavier to FAS,” he remarked.<br />

When asked if any of his customers have offered any<br />

comments as to how their sales are doing, he said that<br />

they all seem to be in the same boat with their sales<br />

having slowed down some.<br />

A sawmill representative in Arkansas said that his<br />

market seems to have slowed down a bit but not much.<br />

“We haven’t seen too many of our products sales<br />

slowdown,” he said. “Our sales are down about 10<br />

percent from where they were six months ago.”<br />

His company offers Birch, Maple, Red and White Oak,<br />

Cherry, Ash, Hickory, Poplar and Mahogany in a variety<br />

of thicknesses and grades. “Poplar is our best seller,” he<br />

noted. “We sell more of it than anything else.”<br />

His company sells to cabinet manufacturers. “Some of<br />

my customers have noted that their sales are starting<br />

to slow down as well,” he said. “People are just building<br />

less.”<br />

In North Carolina a lumberman said that his Red and<br />

White Oak sales have been stable, while his Poplar<br />

sales have not. “Whether you are selling into Asia or any<br />

other country, it’s all about the price on Poplar. You can<br />

always sell it but in a lot of cases it is going to have to be<br />

cheap,” he stated.<br />

While West Coast lumber providers fluctuated on the<br />

current state of <strong>Hardwood</strong>s, one source summed up the<br />

market in one word – “mediocre.”<br />

“We are doing OK,” he noted. “There is still some money<br />

out here from the tech industries.<br />

“But things are worse than they were six months ago,”<br />

he added.<br />

The Washington based buyer and seller handles “the<br />

usual suspects,” like Cherry, White Oak, and Maple,<br />

most of which are from Appalachia and the upper Mid-<br />

West. He noted that the company uses all thicknesses of<br />

wood, like 10/4, 12/4 and 16/4.<br />

“Everybody had a full order file a year ago,” he reflected.<br />

“That’s just not the case now.”<br />

At the time of this writing, a California lumber source<br />

reported that the market for cabinets, moulding and<br />

floors has been a “little quiet.”<br />

“Anything going into a new home is slow,” he noted.<br />

“I’d like to say that our sales are half off but it almost<br />

feels like it’s a little more than half.<br />

“The first of 2023 was good,” he continued, “but the<br />

last half was a struggle.”<br />

The lumber source said the sale of first and second<br />

grade (FAS) lumber has “been good,” along with FAS<br />

wides and rustics.<br />

The company has also been doing well with 8”-and-wider<br />

and 9”-and-wider lumber.<br />

“We’ve been doing some Walnut on the high-end stuff,”<br />

he said. “We’re doing NHLA Oak Grade Rule Walnut.”<br />

While some woods like Red Oak and Cherry are not<br />

currently being sought by buyers, the lumber provider<br />

said that White Oak sales are up.<br />

“We have been fortunate with White Oak,” he acknowledged.<br />

“That seems to be pretty dominant, except<br />

the low-grade stuff.”<br />

With the soaring demand of White Oak, the distributor<br />

said it is becoming challenging to find.<br />

The Washington lumber source echoed these sentiments.<br />

Please turn to page 41 Please turn to page 42<br />

6 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 7

CANADIAN TRENDS<br />

News from suppliers about prices, trends, sales and inventories<br />

Learn More<br />

<br />

ONTARIO<br />

QUEBEC<br />

Heading into a new year, we wonder how businesses<br />

will fare in the <strong>Hardwood</strong> sector and elsewhere. Production<br />

and demand of <strong>Hardwood</strong>s is changing, and is<br />

keeping one on their toes to make a profit, or stay afloat.<br />

As statistics have reported both in the U.S. and Canada,<br />

production has been in a downward trend since 2022<br />

and continued throughout 2023. Those producing Red<br />

and White Oak, and Hard and Soft Maple are struggling<br />

to get logs, and buyers’ needs for many grades and<br />

thicknesses are not being met. Also, secondary manufacturers<br />

who use these species are controlling their inventories<br />

as consumers curb their purchases for finished<br />

goods, and due to inflation and higher interest rates.<br />

Some contacts noted having ample supplies, however,<br />

such as for Basswood and Aspen.<br />

Certain areas contacted stated that Ash supplies are<br />

barely adequate to meet demand. Prices are firm. Some<br />

say that kiln-dried business is not strong but is keeping<br />

inventories down for many grades and thicknesses.<br />

Demand is reported as slow but steady for kiln-dried<br />

Aspen. Inventories are sufficient to meet the market’s<br />

demand for most grades and thicknesses. Green production,<br />

noted some contacts, is not very high, but demand<br />

is on the slow side as well. Some sawmills struggle<br />

to find customers for total Aspen production.<br />

It was commented that certain sawmills limited Basswood<br />

log purchases and so production for this species<br />

was down. Green Basswood supplies outpaced needs<br />

for most grades and thicknesses.<br />

Birch demand, a species often used in <strong>Hardwood</strong><br />

products such as furniture, millwork and moulding, flooring<br />

and cabinets, has been down due to slower housing<br />

construction and renovation markets. Activity has slowed<br />

for businesses in these sectors and so it has affected<br />

Birch sales. Green lumber markets are not strong either.<br />

Mill output is controlled, and is closely balanced between<br />

developing supplies and market needs. Contacts noted<br />

that kiln-dried Birch inventories are sufficient to meet demand.<br />

Prices have also gone down for most grades.<br />

The U.S. Thanksgiving holiday, hunting season and<br />

Christmas holiday disrupted production and business<br />

activity for those in the <strong>Hardwood</strong> industry. Businesses<br />

were busy preparing their log decks and making operational<br />

plans as to production schedules, and planning<br />

orders of supplies needed for their particular business<br />

needs. Several contacts were seeking new sources of<br />

supply to work around species shortages of various<br />

grades and thicknesses. Items identified in short supply<br />

were Hard and Soft Maple, White Oak and upper grade<br />

Red Oak for green stocks. Some end users stated they<br />

had ample supplies of Basswood and Aspen for their<br />

needs.<br />

It is customary at this time of year for markets to soften.<br />

Wholesalers and secondary manufacturers reported<br />

weak sales as we come out of the holiday period. Their<br />

inventories were sufficient to meet current and shortterm<br />

needs. Pallet manufacturers expect sales to decline<br />

for finished goods at this time.<br />

Production was lower for Ash, but decent. Thus, demand<br />

held up well with mills shipping developing supplies.<br />

Prices edged higher for the No. 1 Common and<br />

Better grades. Kiln-dried business was also decent, but<br />

inventories were not high, with pricing steady.<br />

Depending on regions contacted, Aspen was getting<br />

mixed reviews. For some it was not doing so well with<br />

demand being weak for some time with prices responding<br />

accordingly. Sawmills processed Aspen at a reduced<br />

rate, thus prices eased pressure on green stocks to a<br />

certain extent.<br />

Basswood sales were down as this species is in less<br />

demand from secondary manufacturers whose business<br />

has also seen a slowdown, and also due to competition<br />

of other wood species and non-wood material products<br />

being substituted in finished goods rather than using<br />

Basswood. Contacts say it is hard to find new orders for<br />

this species. Sawmills are also limiting their production,<br />

however, in certain areas, supplies are outpacing market<br />

demand.<br />

The regionally important species Hard Maple is see-<br />

Boost Efficiency and Profits<br />

Heat Recovery Vents<br />

• Saves Up To 80% Of Lost Heat<br />

• Consistent Drying<br />

• Ensures Your Kiln Runs At<br />

Peak Efficiency<br />

NDKR Kiln Controls<br />

• Enhanced Sensor Technology<br />

Please turn to page 43 Please turn to page 44<br />

• Felxible Control Modes<br />

• Can Be Retrofitted To Any Kiln<br />

Regardless of Manufacturer.<br />

8 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 9

INDUSTRY NEWS<br />

AN UPDATE COVERING THE LATEST NEWS ABOUT<br />

HARDWOOD SUPPLIERS/VENDORS<br />

Clark <strong>Hardwood</strong>s LLC Makes Capital<br />

Improvements<br />

Clark <strong>Hardwood</strong>s LLC, located in Erin, TN, recently<br />

put in a Cleereman combination optimized edger. The<br />

mill is undergoing some other capital improvements regarding<br />

material handling that should be complete late<br />

spring/early summer <strong>2024</strong>, according to Brandon Clark,<br />

Vice-President of Clark Lumber Company.<br />

The mill’s annual production is 10 million board feet,<br />

producing Red and White Oak, Hard Maple, Poplar, Ash,<br />

Cherry, Hickory and Walnut. The operation provides<br />

planing services and has 125,000 board feet of drying<br />

Brandon Clark<br />

capacity. The company, headquartered<br />

in Red Boiling Springs, TN,<br />

produces 50 million board feet of Appalachian<br />

<strong>Hardwood</strong>s in thicknesses<br />

ranging from 4/4-8/4.<br />

For more information, visit<br />

www.clarklumbercompany.com.<br />

link’s system while remaining with Robinson as Vice<br />

President. Tradelink is pleased to welcome Jacqueline<br />

Monteilh, a dedicated nine-year Robinson employee,<br />

who has joined the Tradelink Sales Team and is now part<br />

of the Tradelink family.<br />

Robinson Lumber Company and Tradelink Wood<br />

Products are both family-owned businesses with extensive<br />

histories in the wood products<br />

industry. The two companies have<br />

shared numerous professional relationships<br />

since the 1980s, serving<br />

as customers, suppliers and competitors<br />

across various markets.<br />

Through years of collaboration,<br />

mutual admiration has grown within<br />

both organizations and among the<br />

individuals who drive them.<br />

This strategic transaction stands<br />

as a mutually beneficial step forward<br />

for both companies and their customers<br />

and suppliers.<br />

For more information visit,<br />

www.roblumco.com.<br />

Dura Supreme’s New<br />

Manufacturing Facility<br />

Begins Production<br />

Production has officially begun<br />

at Dura Supreme Cabinetry’s new<br />

manufacturing facility in Statesville,<br />

NC.<br />

In March of this year, the company<br />

announced its plans to expand its<br />

manufacturing operations with a new<br />

multi-million dollar manufacturing facility<br />

to accommodate the increasing<br />

demand for its cabinetry products.<br />

Over the last few months, the<br />

company has been hard at work<br />

setting up all the new state-of-theart<br />

equipment, fine-tuning the layout<br />

of the building, as well as recruiting<br />

and training the first of the new North<br />

Carolina production team. The new<br />

facility is designed to mirror the same<br />

state-of-the-art cabinet-making processes<br />

and quality craftsmanship<br />

practices that are already in action at<br />

Robinson Lumber Finalizes<br />

Sale of U.S. Flooring<br />

Business to Tradelink Wood<br />

Products<br />

Robinson Lumber Company<br />

and Tradelink Wood Products are<br />

pleased to announce they have<br />

completed a transaction to sell<br />

Robinson’s U.S. Flooring Business<br />

to Tradelink including Robinson’s<br />

U.S. flooring inventory, their flooring<br />

brand, associated Goodwill and the<br />

transfer of related supplier, customer<br />

and service provider relationships.<br />

Under the terms of the agreement,<br />

Robinson will provide Transition Services<br />

to Tradelink Wood Products.<br />

Guiding the transition of Robinson’s<br />

flooring business is Dan Lennon who<br />

will ensure the integration of Robinson’s<br />

valued customers, suppliers<br />

and service providers into Tradetheir<br />

headquarters in Howard Lake, MN, while providing<br />

the ability to increase their manufacturing capabilities to<br />

keep up with the demand for their highly requested cabinets,<br />

which they offer in Cherry, Maple, Red Oak, Quarter-sawn<br />

White Oak, Knotty Alder and Hickory in grades<br />

Please turn to page 47<br />

10 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 11

HMA UPDATE<br />

What Are Your Company’s Pathways To Success?<br />

What’s in store for your business in<br />

<strong>2024</strong>? Are you looking to improve your operations<br />

with new equipment? How are you<br />

going to pay for it? Is there a generational<br />

gap in your workforce making communication<br />

difficult? And what’s going on with the<br />

economy this year?<br />

If you’re asking yourself any of these<br />

questions, then you’ll want to make plans<br />

to attend HMA’s <strong>2024</strong> <strong>National</strong> Conference and Expo,<br />

Monday–Wednesday, March 25–27, at The Charleston<br />

Place Hotel in Charleston, SC. This year’s theme<br />

is Pathways to Success and the agenda is filled with<br />

learning sessions that will help your company navigate<br />

the challenges ahead. Here’s a brief overview of a few<br />

sessions.<br />

•Funding Improvements:<br />

Grant Opportunities<br />

What exactly is the USDA Forest Service’s Wood Innovations<br />

Grant (WIG) Program? How can a grant help<br />

your company make equipment and operational upgrades?<br />

What companies are eligible? How do you apply<br />

for a grant? Marcus Taylor, Wood Innovations coordinator<br />

for the Southern Region, will be with us to provide<br />

all the details and answer questions.<br />

•Effective Communication Panel<br />

Times have changed and communicating with workers<br />

from different generations can be challenging and frustrating<br />

for all involved. This panel discussion,<br />

moderated by Steve James—president and<br />

CEO of Frank Miller Lumber Company and<br />

a certified John C. Maxwell coach, trainer,<br />

and speaker—will bring together a Millennial,<br />

a Gen Xer, and a Boomer to provide insight<br />

into how to overcome communication<br />

issues and improve your company’s culture.<br />

•Economic Predictions: Hits and Misses<br />

Every year, attendees get to hear from an experienced<br />

economist who gives an update on the U.S. economy.<br />

HMA members have asked, “What did they get right<br />

and where were they wrong?” This year, we’re welcoming<br />

back our 2023 presenter, Dr. Christopher Kuehl,<br />

co-founder of Armada Corporate Intelligence. His presentation<br />

will give an honest critique of his assessment<br />

last year, as well as a current look at the U.S. economy<br />

and a forward-looking analysis of trends to watch. We’re<br />

looking forward to what he has to say!<br />

As a reminder, this event is open to all <strong>Hardwood</strong> industry<br />

stakeholders—members, non-members, industry<br />

suppliers, etc. All of the Conference details can be found<br />

online at www.HMAmembers.org. And while you’re there,<br />

take care of your registration, book your hotel room, see<br />

the full schedule, browse the list of exhibitors, and consider<br />

adding on a sponsorship! We’re looking forward to<br />

seeing you in Charleston! n<br />

BY IAN FAIGHT,<br />

CHIEF OPERATING OFFICER,<br />

HARDWOOD MANUFACTURERS ASSOCIATION<br />

WARRENDALE, PA<br />

412.244.0440<br />

www.HMAmembers.org<br />

Our industry has<br />

stories to tell.<br />

We’re telling them.<br />

Contribute Now to Build Your World<br />

Contribute Now to Build Your World<br />

Contribute Now to Build Your World<br />

The Real American <strong>Hardwood</strong> Coalition has launched its Build Your World<br />

campaign The Real American in partnership <strong>Hardwood</strong> with Magnolia Coalition Network. has launched The ads its Build are inspiring Your World a national<br />

audience campaign The Real American<br />

by in partnership educating <strong>Hardwood</strong><br />

them with on Magnolia Coalition<br />

the benefits Network. has<br />

of launched<br />

Real The American ads its Build are inspiring <strong>Hardwood</strong>® Your World a national products.<br />

audience campaign by in partnership educating them with on Magnolia the benefits Network. of Real The American ads are inspiring <strong>Hardwood</strong>® a national products.<br />

The audience campaign by educating was made them possible on the thanks benefits to of voluntary Real American contributions <strong>Hardwood</strong>® from the<br />

products.<br />

hardwood The campaign industry. was made Your continued possible thanks support to is voluntary critical to contributions advance the from initiative the and<br />

reclaim hardwood The campaign<br />

market industry. was<br />

share made Your for the continued possible<br />

benefit thanks support of all industry to is voluntary critical stakeholders.<br />

to contributions advance the from initiative the and<br />

reclaim hardwood market industry. share Your for the continued benefit support of all industry is critical stakeholders.<br />

to advance the initiative and<br />

Help reclaim Build market Your share World. for Learn the benefit more about of all industry the RAHC’s stakeholders.<br />

promotion efforts,<br />

see Help a Build list of Your supporters, World. Learn and make more a about voluntary, the RAHC’s tax-deductible promotion contribution efforts, at<br />

RealAmerican<strong>Hardwood</strong>.com/industry see Help a Build list of Your supporters, World. Learn and make more a about voluntary, the<br />

or RAHC’s<br />

scan tax-deductible the promotion<br />

QR code. contribution efforts, at<br />

RealAmerican<strong>Hardwood</strong>.com/industry see a list of supporters, and make a voluntary, or scan tax-deductible the QR code.<br />

contribution at<br />

RealAmerican<strong>Hardwood</strong>.com/industry or scan the QR code.<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.<br />

12 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 13<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.<br />

Real American <strong>Hardwood</strong> is a registered trademark, and Build Your World is a trademark of the Real American <strong>Hardwood</strong> Coalition.

AHEC REPORT<br />

AHEC Hosts European Journalists For<br />

Tour Of American <strong>Hardwood</strong> Forest<br />

HARDWOOD FEDERATION INFO<br />

Federation Advocacy 2023 –<br />

Key Federal Initiatives Impacting The <strong>Hardwood</strong> Industry<br />

American <strong>Hardwood</strong> forests stand as a<br />

compelling example of global reforestation<br />

in action, showcasing nature’s extraordinary<br />

capacity for regeneration. Over the<br />

last 50 years, the volume of standing timber<br />

in these forests has more than doubled,<br />

but unfortunately the success of forestry in<br />

America isn’t widely known outside of our<br />

industry. The American <strong>Hardwood</strong> Export<br />

Council (AHEC) hosted a week-long press<br />

trip to Pennsylvania in October 2023 to<br />

explore the relationship between the forest<br />

products industry and a healthy forest.<br />

The journalists from Germany, the UK, and<br />

Italy had an opportunity to engage directly<br />

with modern forest management and the production of<br />

<strong>Hardwood</strong> products and understand how our practices<br />

are continually evolving to ensure the future of this incredible<br />

resource. This collaborative project with support<br />

from local companies and the Pennsylvania Department<br />

of Agriculture has served to educate European writers,<br />

many of whom are focused on environmental policy and<br />

climate action, about the benefits of the American <strong>Hardwood</strong><br />

industry from a green perspective.<br />

Pennsylvania is recognized today as one of the most<br />

forested states in the Eastern US, but that’s not always<br />

been the case. The state was the focal point for timber<br />

extraction during the industrial development of the<br />

1800s, and in fact, Williamsport was the center of the<br />

global lumber industry during this time. By the beginning<br />

of the 1900s, most of the state and others along the<br />

eastern seaboard had been heavily deforested. However,<br />

120 years later those forests have grown back naturally<br />

and are now largely healthy and well managed.<br />

That’s not to say that there are no challenges. PA is an<br />

excellent example of how the <strong>Hardwood</strong> forests of the<br />

Eastern USA have regenerated with the help of a long-<br />

term strategy to ensure that they are protected<br />

for future generations. Rural communities<br />

and the people that live and work in these<br />

forests have played a central role in what<br />

they are today - a rich source of wildlife, biodiversity,<br />

clean water, food, recreation, and<br />

of course, timber.<br />

This short and intense trip across PA from<br />

Pittsburgh to Philadelphia explored the <strong>National</strong><br />

Forest, state forest, and private timberlands,<br />

all of which make up the composition<br />

of this resource. AHEC was able to introduce<br />

the journalists to private and state foresters,<br />

scientists, educators and researchers, loggers<br />

and sawmillers, and artisans who explained<br />

their work and gave insight into the complexity<br />

and resilience of these forests.<br />

The first stop for our team of journalists was the Kane<br />

Experimental Research Forest to meet with the US Forest<br />

Service and learn about forest regeneration, management<br />

strategies like natural selection, and how they<br />

address the challenges of invasive species and climate<br />

change. With this knowledge in mind, the group visited<br />

a <strong>Hardwood</strong> logging site to see these management<br />

strategies in action. The second day itinerary focused on<br />

carbon sequestration, and featured presentations from<br />

Penn State University on how using wood products is an<br />

active way to meet human needs while fighting climate<br />

change. In the afternoon the group visited a multigenerational<br />

sawmill team who talked about the history of<br />

the area as the “lumber capital of the world” in the late<br />

1800s and how things have changed since then. The<br />

next morning had an early start with a sawmill and logging<br />

site tour, then in the afternoon the group met with a<br />

local educator, forester, and musician, Van Wagner, for<br />

Please turn to page 54<br />

Approaching the end of a calendar<br />

year is always a good time for<br />

reflection. The <strong>Hardwood</strong> Federation<br />

team did just that as we look back<br />

on an eventful legislative year where<br />

lawmakers have addressed many of<br />

the industry’s top issues. This has<br />

also helped us look forward to <strong>2024</strong>,<br />

which promises to be equally action packed. Below are<br />

highlights of key developments to help you track where<br />

industry has focused its advocacy in 2023…and an indication<br />

of where we will go in the new year.<br />

Farm Bill 2023<br />

Front and center in this year’s advocacy has been inclusion<br />

of <strong>Hardwood</strong>-friendly provisions within the context<br />

of Farm Bill legislation. Political turmoil in the House<br />

squashed hopes for an on-time for 2023 Farm Bill reauthorization,<br />

but on November 15, Congress finally<br />

passed an extension on the expired bill through September<br />

30, <strong>2024</strong>. The one-year extension will guarantee<br />

funding for key <strong>Hardwood</strong> initiatives such as the Market<br />

Access and Foreign Market Development programs. It<br />

is unclear what the exact language of current Farm Bill<br />

draft language looks like as House Ag Chair GT Thompson<br />

(R-PA) has indicated that he won’t release legislative<br />

text on the Farm Bill until leadership schedules floor<br />

time. But we are confident that as the Farm Bill moves<br />

forward in <strong>2024</strong>, it will serve as a vehicle to capture other<br />

priorities for the industry. In addition to authorizing resources<br />

that promote <strong>Hardwood</strong> exports, the Federation<br />

is also leveraging the debate to promote related industry<br />

objectives:<br />

<strong>Hardwood</strong> Access Program – In an important milestone<br />

for the <strong>Hardwood</strong> sector, Reps. Tom Tiffany (R-<br />

WI) and Annie Kuster (D-NH) have<br />

agreed to sponsor the <strong>Hardwood</strong><br />

Access Program (HAP) bill for introduction<br />

in the House. Although fiscal<br />

constraints will make it very difficult<br />

to move HAP as part of the Farm<br />

Bill, the legislation will serve as a<br />

high-profile vehicle to educate Congress<br />

on the benefits of <strong>Hardwood</strong> products, laying the<br />

groundwork for enactment in future years. Stay tuned<br />

for updates as the industry bill moves forward.<br />

Timber Innovation for Building Rural Communities Act<br />

– This bipartisan, bicameral bill, sponsored by Senators<br />

Wyden (D-OR) and Senator Crapo (R-ID) and Reps.<br />

Salinas (D-OR), Glusenkamp-Perez (D-WA) and Duarte<br />

(R-CA) could be folded into a final Farm Bill. The<br />

proposal includes several positive provisions for the<br />

industry including establishing a USDA platform measuring,<br />

collecting and sharing data related to the carbon<br />

benefits of wood products, and recognizing the value of<br />

carbon reduction and environmental benefits of wood<br />

in building design and furnishings in USDA grant programs.<br />

Through the Federation’s work with the Forest in<br />

the Farm Bill Coalition, several recommended changes<br />

to ensure that <strong>Hardwood</strong>s are eligible for the programs<br />

were incorporated into the bill language.<br />

Jobs In the Woods Act – This fall, Senate and House<br />

members introduced the bipartisan “Jobs in the Woods<br />

Act.” (H.R. 5344, S. 3063), a bill that would provide education<br />

grants ranging in size from $500,000 to $2 million<br />

to promote jobs in the understaffed timber industry<br />

and U.S. Forest Service. Legislative champions include<br />

Reps. Chavez-Deremer (R-OR) and Gluesenkamp-Perez<br />

(D-WA) on the House side and Sens. King (I-ME)<br />

Please turn to page 51<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

BY DANA LEE COLE,<br />

EXECUTIVE DIRECTOR,<br />

HARDWOOD FEDERATION,<br />

WASHINGTON, DC<br />

202-463-5186<br />

WWW.HARDWOODFEDERATION.WILDAPRICOT.ORG<br />

14 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 15

WCMA INSIGHTS<br />

NHLA: Why Knot...<br />

WCMA Looking Ahead To A Successful New Year<br />

Looking back on 2023, I am very<br />

proud of what the WCMA accomplished.<br />

We hosted our third European<br />

Plant Tour Event in northern Italy, and<br />

the individuals that attended had very<br />

positive things to say about the event,<br />

with one saying “I will remember this<br />

one as one of WCMA’s best events<br />

and encourage everyone to consider<br />

this opportunity when it comes around<br />

again. The camaraderie that grew<br />

amongst the group was special, and we all appreciated<br />

the opportunity to see state-of-the-art manufacturing<br />

plants.” Our two sponsors were exceptionally gracious<br />

and supportive, and they were very pleased with the<br />

turnout.<br />

The association also hosted an excellent Fall Conference<br />

event in the Canton, Ohio area. We were thrilled to<br />

have a full lineup of plant tours, with an excellent mix of<br />

manufacturing facilities. The companies that we toured<br />

included wood product manufacturing, lumber processing,<br />

and machinery technology. Attendees also enjoyed<br />

the opportunity to network with their colleagues in the<br />

<strong>Hardwood</strong> industry.<br />

And now, I am excited to look forward to <strong>2024</strong> and the<br />

variety of benefits WCMA has to offer.<br />

Educational and Networking Opportunities<br />

We’ve already started planning our <strong>2024</strong> Fall Conference<br />

which will be held in Iowa in the fall. There are<br />

many excellent manufacturing facilities<br />

that are open for tours, and we are excited<br />

to see the advancements made since<br />

we last visited in 2008.<br />

In addition, we are exploring opportunities<br />

to host one-day events that will<br />

allow us to see state-of-the-art facilities<br />

in locations that are not amenable to a<br />

fall conference. If your company is interested<br />

in hosting a tour, or you know of<br />

a company that you would love to visit,<br />

please let us know.<br />

You will also see us at the International Woodworking<br />

Fair in Atlanta, where we will help buyers of wood components<br />

find the perfect manufacturing company for their<br />

needs.<br />

Real Industry Promotion<br />

As a founding contributor to the Real American <strong>Hardwood</strong><br />

Coalition (RAHC), WCMA is invested in real promotion<br />

for domestic <strong>Hardwood</strong> manufacturers. The RAHC’s<br />

mission: “With widespread support, the Real American<br />

<strong>Hardwood</strong> Coalition (RAHC) unites the collective efforts<br />

and resources of the industry to advance American <strong>Hardwood</strong>s<br />

as the Naturally Authentic choice.”<br />

Because of the WCMA’s financial support, WCMA<br />

members are able and encouraged to download and<br />

use the RAH logo on all products that qualify, and help<br />

consumers start recognizing the brand and spread the<br />

word. This exciting program helps our members’ products<br />

stand out!<br />

Please turn to page 56<br />

Proselytize Employees, Family & Friends<br />

For Forestry & Wood Careers<br />

My dad was an engineer. I<br />

wanted to be an engineer. I applied<br />

to the University of British<br />

Columbia and put forestry as<br />

a backup at the last minute. I<br />

moved my family to Vancouver<br />

and started locksmithing before<br />

I knew if I was accepted. However, I ended up getting<br />

accepted to forestry but not engineering. It didn’t matter<br />

because I took prerequisites for engineering courses<br />

anyway. I wouldn’t be where I am today if a college<br />

counselor hadn’t told me there was a wood engineering<br />

program within forestry. All my credits transferred over,<br />

and I picked up Wood Products Processing like a grizzly<br />

picks up spawning salmon.<br />

Very few college students know and choose wood science<br />

and technology career paths. Very few universities<br />

offer forestry degrees and even fewer with wood tracks.<br />

Here are the university acronyms for North America: AU,<br />

CU, Laval, LSU, MSU, NCST, OSU, Purdue, UBC, UI,<br />

UK, UM, UNB, UT, UW, VT, WSU, WVU, and I am sure<br />

there are others. Some have complete wood programs;<br />

others have classes or other renewable material specialties.<br />

But no matter the studies, the point is all the same.<br />

They need more students.<br />

At the NHLA Inspector Training<br />

School graduation ceremony<br />

in November, a student’s parents<br />

asked me what was next<br />

for their teenage son. I offered<br />

two tracks. Work hard and take<br />

initiative at the plant to improve<br />

production and learn the process. A production supervisor<br />

and other roles would be available if he wants them.<br />

Apply for university, get a wood (processing, science, or<br />

engineering) degree, and advance into production supervisor<br />

and management roles. Both options are great<br />

careers.<br />

After I graduated with my Wood degree, I worked for<br />

Sauder Molding and was the production supervisor on<br />

the night shift for four months. I told them I was interested<br />

in a master’s degree, and they told me they would<br />

rather I worked there for two years. I told them I wanted<br />

them to guarantee me a day job within one year, but they<br />

didn’t want to put it in writing. I had seen sales guys get<br />

promoted over production guys and didn’t want to get<br />

stuck in 4 concrete walls, so I returned to school and<br />

received a master’s at UBC in Forests and Society. That<br />

opened even more career opportunities and put me on a<br />

course to NHLA.<br />

Please turn to page 57<br />

BY AMY K. SNELL, CAE,<br />

EXECUTIVE DIRECTOR,<br />

WOOD COMPONENT MANUFACTURERS ASSOC.,<br />

LINDSTROM, MN<br />

651-332-6332<br />

WWW.WCMA.COM<br />

BY DALLIN BROOKS,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD LUMBER ASSOCIATION,<br />

MEMPHIS, TN<br />

901-377-1082<br />

WWW.NHLA.COM<br />

16 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 17

“As a lumberyard and mill, we are part of a collective stewardship in a unique supply chain,<br />

from forest to finished product. We source quality lumber, wood products and services<br />

providing a palette of materials to fulfill residential and commercial project needs catering to<br />

architects, designers, builders and craftsmen.”<br />

– Steve Jackel, owner and president of Jackel Enterprises Inc.<br />

This home received a deck made of Teak from Jackel Enterprises.<br />

Just-In-Time At Jackel Enterprises Inc.<br />

Jackel Enterprises Inc., headquartered in Watsonville,<br />

CA, distributes <strong>Hardwood</strong>s, softwoods and imported<br />

woods. The operation also handles reclaimed woods,<br />

live edge slabs, urban woods and offers milled products<br />

such as box beams, sidings, ceiling treatments, flooring,<br />

moulding and trim packages.<br />

Jackel Enterprises Inc. purchases 150,000 board feet<br />

in <strong>Hardwood</strong>s, 100,000 board feet of imported lumber<br />

and 250,000 board feet in softwoods annually. <strong>Hardwood</strong><br />

species include Alder, Cherry, Maple, Red and<br />

Jackel Enterprises Inc., in Watsonville, CA, close to San Francisco,<br />

distributes <strong>Hardwood</strong>s, softwoods and imported woods. “The<br />

key word in our business is serve; we serve our customers,” said<br />

Owner and President Steve Jackel.<br />

By Michelle Keller<br />

White Oak, Poplar and Walnut (4/4, 8/4, 10/4, 20/4 FAS,<br />

Select and Better). In softwoods the operation carries<br />

and manufactures from western red cedar, redwood,<br />

Alaskan yellow cedar, ponderosa pine, sugar pine, hemlock<br />

and douglas fir (4/4, 6/4, 8/4, 10/4, Moulding and<br />

Better). Species available in imported woods include<br />

African Mahogany, Ipe, Sapele, Jatoba and Teak (FEQ,<br />

Select and Better).<br />

Owner and President Steve Jackel became involved<br />

in the forest products industry by making dulcimer instruments<br />

from Claro Walnut. The dulcimer is a fretted string<br />

instrument made from wood. It typically has three or four<br />

strings and was originally played in the Appalachian region<br />

of the United States. Jackel said after selling the instruments<br />

he began to get lumber requests. He sold both<br />

lumber and dulcimers for about 16 years before deciding<br />

to focus solely on selling lumber and manufacturing<br />

products. “I was a partner in what could only be called<br />

a folk business. We were in a barn and made dulcimers<br />

which we distributed around the United States. We were<br />

selling them mainly to music stores and, because of the<br />

nature of the wood we were purchasing, I got into selling<br />

From left, are Steve Jackel and his son Noah Jackel with<br />

live edge slabs.<br />

Sapele is one species of exotic woods handled by<br />

Jackel Enterprises.<br />

extra wood to the public. As time went on, I discovered<br />

my archetype was a merchant as opposed to an artisan.”<br />

Today the operation encompasses a two-acre,<br />

40,000-square-foot shop, mill and lumberyard purchased<br />

and expanded in 2016.<br />

“As a lumberyard and mill, we are part of a collective<br />

stewardship in a unique supply chain, from forest to finished<br />

product,” Jackel explained. “We source quality<br />

lumber, wood products and services providing a palette<br />

of materials to fulfill residential and commercial project<br />

needs catering to architects, designers, builders and<br />

craftsmen.<br />

“Our focus is on value-added production,” he continued.<br />

“We have two L200 Nyle dry kilns. So, if we have<br />

a job where we are using bigger timbers for smaller<br />

boards, we have the capacity to resaw, sticker and dry.<br />

The selling of lumber is greatly influenced by trends as<br />

opposed to actual functionality. As a consequence, western<br />

red cedar is in high demand worldwide. There is a<br />

limited supply. Our clients want it, although there might<br />

be woods that are similar in function but not in appearance.<br />

Alaskan yellow cedar is just as functional, but the<br />

appearance is significantly different along with the pricing.”<br />

Jackel Enterprises’ products and lumber have appeared<br />

in some high-profile and interesting places. However,<br />

Jackel said he’s not able to release any details.<br />

“We’ve signed non-disclosure agreements for most of<br />

these jobs. We aren’t allowed to take photos in some<br />

instances. Once we had a project that had 12,000 feet<br />

of color-selected hemlock and 25,000 square-feet of engineered<br />

8-inch wide, rift White Oak flooring in just one<br />

house.”<br />

He continued, “We did a fence that was hand-split redwood<br />

from salvaged trees for an equestrian horse ranch.<br />

That job required a lot of reclaimed redwood bridge timbers.<br />

That was also for a high-profile client. So, we get<br />

engaged in high-end projects that are architecturally demanding<br />

in the Bay Area.”<br />

When asked what sets Jackel Enterprises apart from<br />

his friendly competitors he indicated experience, quality<br />

and value-added services are at the top of the list. “I’ve<br />

been in the woodworking industry for 50 years. The primary<br />

goal at Jackel Enterprises is to supply lumber and<br />

value-added products at the highest standard. We place<br />

importance on our customers, meeting all of their needs.<br />

Please turn the page<br />

18 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 19

Jackel Enterprises encompasses a two-acre, 40,000-square-foot shop, mill and lumberyard purchased and expanded in 2016.<br />

JACKEL ENTERPRISES INC. Continued<br />

We’re not car salesmen; we’re wood people. We want<br />

the job, but we want to be sure it’s the right material for<br />

the job. We have a significant ability to assure this because<br />

of our experience. The key word in our business<br />

is serve; we serve our customers.”<br />

He also noted that while the company is small with<br />

only 12 employees, it has the ability to compete on a<br />

larger scale. “For a small company, we have capacity for<br />

high volume. We can compete with anybody in terms of<br />

capacity.”<br />

Jackel Enterprises responded to the global pandemic<br />

by growing its just-in-time operations. “We’re very<br />

nimble,” Jackel said. “We’ve lowered our inventory and<br />

strengthened our trading partnerships where we can buy<br />

and sell per job. The jobs are of a size that enables us<br />

to do that even when the supply chain has been difficult.<br />

There was a period when we were selling projects and<br />

the price of inventory doubled in a period of a year. It<br />

would take 90 days to get a smaller purchasing number<br />

than we would normally buy. At one point a full truckload<br />

of Cedar went from $90,000 to $180,000. That wasn’t<br />

practical and it was difficult to operate under those circumstances.<br />

With our trading partners, we’ve been able<br />

to make adjustments and meet the needs faster.”<br />

Jackel initially set up shop in his own home. “It was<br />

just me, a pickup truck and a phone,” he recalled. Two<br />

years into his new venture, Jackel moved the company<br />

into a warehouse, then relocated again in 1998. The<br />

company finally moved into its new location in 2016.<br />

Jackel, who runs the company with his son, Noah<br />

(vice president), sells about 95 percent of the company’s<br />

products to other businesses. “We sell to cabinet shops,<br />

product manufacturers and high-end residential and<br />

commercial contractors,” said Jackel, whose firm also<br />

encompasses an urban forestry division (West Coast<br />

Woods) and a manufacturing firm dedicated to making<br />

real wood box beams. Through the former, the company<br />

salvages street trees, urban fall-downs and institutional<br />

tree removals, and converts the logs into lumber and<br />

live-edge slabs.<br />

Jackel Enterprises Inc. is Forestry Stewardship Council<br />

(FSC)-certified. n<br />

For more information visit www.JackelEnterprises.com.<br />

Class 204 Graduates From<br />

NHLA Inspector Training School<br />

Left to Right Standing: Jeremy Prosser, Billy Joe Blackburn, Eric<br />

Osborne, Dylan Maggert, Michael Janjigian<br />

Seated: Lucian Gratz, Roman Matyushchenko (Instructor), Freddy<br />

Guevara<br />

The <strong>National</strong> <strong>Hardwood</strong> Lumber Association, headquartered<br />

in Memphis, TN, celebrated the graduation of<br />

Class 204 from the Inspector Training School (ITS) recently.<br />

Geoff Webb, Dean of NHLA Inspector Training School,<br />

kicked off the celebration, saying, “It’s an honor to welcome<br />

this class into the ranks of lumber inspectors. This<br />

is just the start of your career, and it is essential to re-<br />

Roman Matyushchenko presented the individual achievement awards.<br />

Outstanding individual awards recipients were as follows:<br />

•Jeremy R. Prosser, ITS Educational Foundation Award for Highest Overall Average<br />

•Lucian H. Gratz, Howard Hanlon Award for Second Highest Overall Average<br />

•Jeremy R. Prosser, Westside <strong>Hardwood</strong> Club Award for Highest Board Run Average<br />

•Billy Joe Blackburn IV, Milt Cole Award for Best Attitude/Citizenship<br />

Enrollment is now open for Class 205 in Memphis, TN,<br />

beginning on <strong>January</strong> 8, <strong>2024</strong>. To enroll or learn more<br />

about the Program, please visit www.nhla.com.<br />

The NHLA Inspector Training School has a proud and<br />

rich 70-year history, graduating more than 7,500 students<br />

since its conception. The Program teaches the<br />

rules and applications of the NHLA grading system and<br />

prepares students for a career in the <strong>Hardwood</strong> industry.<br />

This unique Program has earned worldwide respect,<br />

attracting students from throughout the United States,<br />

member that the lumber inspector is a key employee and<br />

a vital part of the team at the sawmill, the concentration<br />

yard and the entire <strong>Hardwood</strong> lumber operation.”<br />

Nick Thompson, President and Co-Owner of Thompson<br />

Appalachian <strong>Hardwood</strong>s, gave the graduates an<br />

energizing keynote address. As a graduate of the NHLA<br />

Inspector Training School (Class 166), he told students,<br />

“I’m emotional about this School; it has been a cornerstone<br />

of my life since childhood; graduating from Inspector<br />

Training School was a foundational point for my career<br />

and allowed me to preserve my family’s legacy.”<br />

Thompson continued, “We sent our employee, Freddy<br />

Guevara, to the school. He graduates today. We paid<br />

for Freddy’s education because we know it’s essential to<br />

continue to develop quality talent, especially talent that is<br />

part of the next generation. Trust me, you will look back<br />

when you are my age and realize this was the best eight<br />

weeks you ever spent.”<br />

Class President Jeremy R. Prosser of Ontario <strong>Hardwood</strong><br />

Products spoke to his fellow students, saying,<br />

“This class has been a great experience for all of us; we<br />

all gained valuable knowledge to further our careers and<br />

have formed priceless memories at the school that will<br />

stay with us for the rest of our lives.”<br />

Graduates of the 204 class were:<br />

•Billy Joe Blackburn IV, D & T Sawmill, LLC<br />

•Lucian H. Gratz, Midwest <strong>Hardwood</strong> Company LLC<br />

•Freddy Guevara, Thompson Appalachian <strong>Hardwood</strong>s, Inc.<br />

•Dylan J. Maggert, Hartzell <strong>Hardwood</strong>s, Inc.<br />

•Jeremy R. Prosser, Ontario <strong>Hardwood</strong> Products, Ltd.<br />

•Eric V. Osborne, Connor Sports<br />

•Michael A. Janjigian, Independent<br />

Canada, Europe, Africa, South America, and Asia.<br />

The world’s largest and oldest <strong>Hardwood</strong> industry association,<br />

NHLA represents companies and individuals<br />

that produce, use, and sell North American <strong>Hardwood</strong><br />

lumber or provide equipment, supplies, or services to the<br />

<strong>Hardwood</strong> industry. It was founded in 1898 to establish<br />

a uniform system of grading rules for the measurement<br />

and inspection of <strong>Hardwood</strong> lumber. Since 1979, its<br />

headquarters have been in Memphis. n<br />

To learn more about NHLA, please visit www.nhla.com.<br />

20 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 21

New Year, New Business:<br />

How The <strong>Hardwood</strong> Industry<br />

Can Continue Growing In <strong>2024</strong><br />

The remodel and repair segment of the lumber niche<br />

has boomed in recent years. This portion of the <strong>Hardwood</strong><br />

space has not always been sizable, but in the past<br />

few years, the industry has seen rapid growth in the remodel<br />

and repair segment.<br />

What is driving this growth? During the pandemic, we<br />

experienced a massive societal reconsideration of home<br />

and office spaces. Remodeling became commonplace<br />

as people sought new ways to use and, in some cases,<br />

show off their homes and commercial buildings. As<br />

we have moved past the pandemic and interest rates<br />

have continued to rise, we have seen this trend continue<br />

as homeowners look to add value to their homes with<br />

wood-based products.<br />

While there is much to celebrate in the <strong>Hardwood</strong><br />

space today, as we head into <strong>2024</strong>, there are a few<br />

headwinds to consider. Supply chain shortages, talent<br />

challenges and inflation still loom large as threats to<br />

business. Weather-related claims, auto claims and insure-to-value<br />

issues are rising in frequency. Heading<br />

into the new year, <strong>Hardwood</strong> businesses should take<br />

time to examine the obstacles ahead and properly prepare<br />

for the risks on the horizon.<br />

Examining The Challenges In The New Year<br />

As has been the case for several years, supply chain<br />

shortages remain. Whether renovating or replacing<br />

By Sean Briscoe,<br />

assistant vice president of underwriting at PLM<br />

equipment, the downtime to find new parts and machinery<br />

is much more extreme. What used to be a one-year<br />

turnaround now can take around two to three years.<br />

<strong>Hardwood</strong> businesses used to be able to turn to the<br />

refurbished market for additional options, but those resources<br />

have been largely exhausted in the wake of the<br />

pandemic.<br />

Inflation and employment issues have raised additional<br />

challenges. Due to the supply chain and talent crises,<br />

it is more expensive today to rebuild a structure than two<br />

years ago, or even six months ago. This has created<br />

some significant gaps in insurance to value. <strong>Hardwood</strong><br />

businesses are finding their buildings and equipment are<br />

not valued at the proper level. This has caused some<br />

sticker shock, where insureds are often unprepared for<br />

the significant cost to replace and rebuild in the event of<br />

a loss.<br />

Talent has also impacted the claims side. We are<br />

seeing more auto claims caused by staffing issues.<br />

<strong>Hardwood</strong> businesses have had a hard time hiring and<br />

maintaining good drivers, leading to an increase in costly<br />

claims. Hot works safety protocols continue to be a<br />

concern in the niche too. Though the number of fire losses<br />

are down this year, ensuring that staff are properly<br />

trained and practicing sound hot works/welding safety<br />

controls is imperative to avoiding fires and other costly<br />

losses.<br />

Perhaps the largest rise in claims we have seen has<br />

involved weather-related losses. We are seeing a major<br />

uptick, most notably in areas where we do not traditionally<br />

see storms. For example, this year, a hurricane hit<br />

the coast of California while wildfires spread in New Jersey.<br />

Areas inexperienced in these types of catastrophes<br />

have suffered major losses with long rebuild times as a<br />

result.<br />

Addressing Business And Safety Concerns<br />

While these are certainly major challenges for <strong>Hardwood</strong><br />

businesses, there are several safety and business<br />

planning practices business owners can take to prepare<br />

and maintain safe operations. These include:<br />

•Plan ahead: Planning equipment and part purchases<br />

far ahead of necessity is an important step to ensure<br />

downtimes are not too long in the event of an equipment<br />

breakdown. Whenever possible, staying ahead<br />

of supply chain shortages is critical.<br />

•Establish a hot works program: <strong>Hardwood</strong> businesses<br />

are a frequent source of fire related incidents with<br />

the high amount of sawdust and wood present. Establishing<br />

a comprehensive hot works program similar<br />

to what PLM requires, with strict requirements<br />

for regular cleaning, fire watch, fire extinguish placement<br />

and management of potentially combustible<br />

and flammable materials is critical. Staff should be<br />

trained regularly regarding these requirements too.<br />

•Housekeeping: Routine housekeeping is critical to<br />

limiting losses. Management should enforce a written<br />

program with routine equipment and machinery<br />

maintenance. Staff should be trained to perform daily<br />

dust clean ups across all surfaces and supervisors<br />

should conduct a weekly dust inspection to confirm<br />

staff is following the program.<br />

•Look at your coverage: Business owners should review<br />

the amount of coverage they have and ensure<br />

they have adequate limits. Consider worst case scenarios<br />

with longer wait times for replacing equipment<br />

and plan your limits accordingly. Make sure inventory<br />

and equipment have the right value as of today to<br />

avoid sticker shock when a loss occurs.<br />

•Pay attention to driver safety: Hiring the right staff and<br />

continuously monitoring their behavior behind the<br />

wheel is critical to driver safety. Thoroughly vet potential<br />

staff and implement continuous motor vehicle<br />

record (MVR) monitoring program to confirm they are<br />

practicing safe driver behavior. Consider implementing<br />

telematic devices in all vehicles to best ensure<br />

drivers are performing to the company’s standards of<br />

care behind the wheel. Using forward and rear facing<br />

cameras within that suite of telemetric controls can<br />

also help determine fault in the event of an incident.<br />

•Get back to weather basics: With claims on the<br />

rise, going back to the basics is important. Examine<br />

your roof and make sure you have practiced proper<br />

roof maintenance and upkeep. Clean any shrubs<br />

or growth on buildings as well. Keep an emergency<br />

supply kit on site as well and develop an emergency<br />

response plan in the event of a weather incident.<br />

<strong>2024</strong> could be another year of major growth for the<br />

<strong>Hardwood</strong> industry, provided these businesses take the<br />

right steps forward. Implementing comprehensive safety<br />

practices, considering your current coverage portfolio,<br />

and following basic housekeeping and training schedules<br />

can make a major difference. n<br />

About The Author<br />

Sean Briscoe, Pennsylvania Lumbermens Mutual Insurance Company, is assistant vice president of<br />

underwriting. Sean can be reached at sbriscoe@plmins.com or by phone at (267) 825-9262<br />

22 JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry<br />

RealAmerican<strong>Hardwood</strong>.com/industry<br />

JANUARY <strong>2024</strong> n NATIONAL HARDWOOD MAGAZINE 23

Equipment And Services Providers<br />

Accept The Challenges That<br />

The Market Brings<br />

Across the forest products industry, equipment and<br />

services providers that accommodate the <strong>Hardwood</strong> industry<br />

came to a general consensus that while budgets<br />

have begun to tighten, there is a growing need for advances<br />

in AI and automation technologies to meet the<br />

demand that sawmills have with the changing work force.<br />

One company leader noted, “The current trend in the<br />

sawmill industry both in <strong>Hardwood</strong> and softwood mills is<br />

to be as efficient as possible.”<br />

Casey Miller<br />

A.W. Stiles Contractors Inc.<br />

McMinnville, TN<br />

At A.W. Stiles we work with<br />

both the <strong>Hardwood</strong> and softwood<br />

industries.<br />

We have noticed that<br />

the <strong>Hardwood</strong> industry has<br />