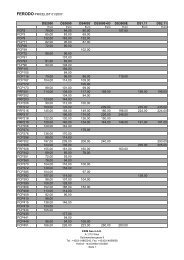

CP7372 - OE 80 - SF

CP7372 - OE 80 - SF

CP7372 - OE 80 - SF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

102<br />

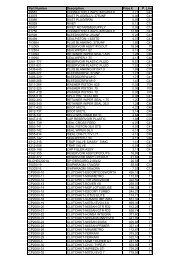

CP7223.<br />

Ø140mm Pull Type.<br />

GENERAL INFORMATION<br />

APPLICATIONS.<br />

- GT.<br />

- Endurance racing.<br />

FEATURES.<br />

- 10 Bolt, One piece cover and<br />

lugs.<br />

- machined from solid billet, for<br />

rigidity and strength.<br />

- Pull type confi guration.<br />

- increased effi ciency in terms of clamp and release loads.<br />

- Flat fl ywheel fi xing.<br />

- Cushion fl ywheel system available.<br />

- Long Life.<br />

- Durable and abuse resistant.<br />

- If maintained correctly life expectancy can be 10 times that<br />

of a sintered race clutch.<br />

- Factory reconditioning service available.<br />

- Heavy duty option available, CP7923 See page 104.<br />

PART NUMBERS.<br />

- 3 Plate, Flat Flywheel.<br />

CP7223-OH02-FN.<br />

- 3 Plate, Flat Flywheel with CFS.<br />

CP7223-OH02-FC.<br />

Note: Full Installation Drawing available at<br />

www.apracing,com<br />

INSTALLATION DRAWING<br />

(RECOMMENDED FOR<br />

CP4703 STUDS)<br />

#10 MOUNTING HOLES<br />

Ø6.012/6.000<br />

EQUISPACED ON A<br />

Ø152.00 P.C.<br />

Clutch - Carbon/Carbon<br />

OPTIONAL STARTER<br />

RING GEAR SUPPLIED<br />

BY CUSTOMER<br />

Ø73.70<br />

30.48 MAX<br />

6.60 MAX<br />

3.90 MAX<br />

1.65 MAX<br />

Ø34.25 MAX<br />

44.50° MIN 44.50° MIN<br />

R6.30<br />

6.20<br />

## BEARING POSITION<br />

TO ENSURE ADEQUATE RELEASE<br />

TRAVEL AND CLUTCH LIFE THESE<br />

LIMITS HAVE BEEN CALCULATED USING<br />

AN ADDITIONAL 20% RELEASE TRAVEL AND 50%<br />

MORE WEAR IN THAN SPECIFIED.<br />

(CALCULATED FROM THE FRICTION FACE)<br />

60.00°<br />

REF<br />

GER RING<br />

FORM<br />

##41.90<br />

##25.90<br />

R5.75 MIN<br />

RECOMMENDED CLUTCH<br />

MOUNTING:<br />

FOR ALL TYPES OF ASSEMBLY.<br />

M6x1.0, Cp4703 FAMILY<br />

STUD AND KLOCK NUT. NUTS<br />

TO BE TIGHTENED IN A<br />

DIAMETRICALLY-OPPOSITE<br />

SEQUENCE,HALF A TURN AT<br />

A TIME TIGHTENING TORQUE<br />

10Nm (7.5lb/ft) LENGTH OF<br />

STUD REQUIRED TO BE<br />

CALCULATED THUS: DIMENSION<br />

‘C’ + ‘F’ + (‘R’ OPTIONAL)+ NUT.<br />

10 COVER<br />

MOUNTING HOLES<br />

Ø6.15/6.05<br />

EQUISPACED ON A<br />

Ø152.00 P.C.<br />

Ø39.00<br />

RELEASE<br />

FULCRUM<br />

#R0.25<br />

MAX<br />

#1.00 MIN<br />

Ø161.98<br />

161.93<br />

REF.<br />

DIRECTION OF<br />

RELEASE TRAVEL<br />

Ø162.08<br />

162.04<br />

0.75 x 44.50 MIN<br />

Ø140mm Clutch<br />

Torque<br />

Capacity.<br />

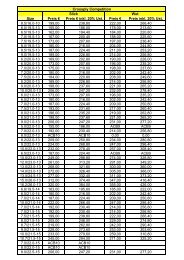

TECHNICAL SPECIFICATIONS<br />

1142Nm (842lb/ft)<br />

“Wear In”<br />

between P/Plate changes.<br />

1.50mm<br />

Total allowable carbon stack<br />

wear.<br />

6.0mm<br />

Release Loads.<br />

Max peak<br />

worn.<br />

At<br />

travel.<br />

540daN<br />

250daN<br />

Set-up Height. (New) 36.48mm<br />

Set-up Height. (Worn) 26.26mm<br />

Weight. 1.8Kg<br />

Complete<br />

Assembly Inertia.<br />

0.006438Kgm²<br />

Driven Plate &<br />

Hub Interia.<br />

0.001219Kgm²<br />

Ratio.<br />

MAIN PRESSURE PLATES.<br />

HiR<br />

Material. Stainless Steel<br />

.5mm to 4.5mm (0.5mm Steps) =<br />

Pressure Plate<br />

CP6504-7<br />

Kits.<br />

.25mm to 4.25mm (0.5mm Steps) =<br />

CP6504-8<br />

HUB OPTIONS.<br />

Material. Steel<br />

1.16” x 26 CP5143-104S<br />

1.00” x 23 CP5143-102S<br />

More hubs are available with other spline sizes, contact AP Racing.<br />

SLAVE CYLINDER.<br />

Recommended Slave Cylinder. CP6245-8<br />

R1.75 MAX<br />

AROUND<br />

FULL<br />

PROFILE<br />

www.apracing.com +44 (0)24 7663 9595<br />

DIM ‘F’<br />

49.50 MAX<br />

45.60<br />

45.10<br />

DIM ‘C’<br />

Ø97.00<br />

THIS ASSEMBLY IS SUPPLIED NEW WITH AN INSTALLATION<br />

PLATE AS SHOWN, THIS IS TO ALLOW THE ASSEMBLY TO BE<br />

BOLTED TO THEFLYWHEEL WITHOUT DAMAGING ANY OF<br />

THE CLUTCH COMPONENTS. AFTER BOLTING THE CLUTCH<br />

TO THE FLYWHEEL REMOVE THE CIRCLIP AND INSTALLATION<br />

PLATE AND RETAIN FOR USE WHEN REMOVING THE<br />

ASSEMBLY FROM THE FLYWHEEL<br />

15.50<br />

15.44<br />

1.74<br />

1.60<br />

AXIAL<br />

FLOAT<br />

Ø33.00<br />

32.75<br />

Ø34.975<br />

34.960<br />

DIAPHRAGM SRPINS<br />

TO BE FITTED WITH<br />

COATING FACES<br />

TOGETHER.<br />

DIM ‘R’<br />

OPTIONAL<br />

NOTE WHEN REMOVING A WORN CLUTCH ASSEMBLY<br />

THE INSTALLATION PLATE IS TO BE FITTED WITH THE WOR<br />

CONDITION - THIS SIDE-UP INSTRUCTION ON THE OUTSI<br />

WHEN RETURNING THIS CLUTCH ASSEMBLY BACK TO A<br />

RACING FOR RECONDITIONING PLEASE RETURN WITH<br />

INSTALLATION PLATE FITTED.<br />

RELEASE<br />

FULCRUM<br />

AND<br />

CIRCLIP<br />

SUPPLIED<br />

Ø82.90 MIN<br />

Ø161.98<br />

161.93