Finishing - March-April 2022

Who knew that after coming out of a pandemic, the world could get any worse, but how wrong was everybody. The effects of the war are going to be be huge for industry. Industry that was already under price pressure, but fuel costs now are going to be astronomical. I truly hope that your business survives this latest onslaught. Fair play to all those people volunteering to look after refugees. They have my undying respect and it shows the people of the UK to be a country full of sympathy and humanity. I hope this message is seen from the outside world as I fear that sometimes our leaders may distort how UK citizens really feel. Good luck in the coming months, I think we might need it.

Who knew that after coming out of a pandemic, the world could get any worse, but how wrong was everybody.

The effects of the war are going to be be huge for industry. Industry that was already under price pressure, but fuel costs now are going to be astronomical. I truly hope that your business survives this latest onslaught.

Fair play to all those people volunteering to look after refugees. They have my undying respect and it shows the people of the UK to be a country full of sympathy and humanity. I hope this message is seen from the outside world as I fear that sometimes our leaders may distort how UK citizens really feel.

Good luck in the coming months, I think we might need it.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>March</strong>/<strong>April</strong> <strong>2022</strong><br />

MH0610_MHEL_PressAd_AutomotiveIssue_JUNE11 15/6/11 10:11 Page 1<br />

THE PREMIER UK JOURNAL FOR SURFACE TECHNOLOGY<br />

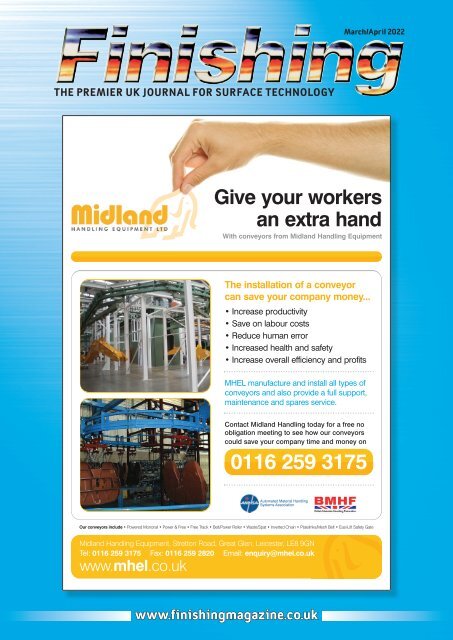

Give your workers<br />

an extra hand<br />

With conveyors from Midland Handling Equipment<br />

The installation of a conveyor<br />

can save your company money...<br />

• Increase productivity<br />

• Save on labour costs<br />

• Reduce human error<br />

• Increased health and safety<br />

• Increase overall efficiency and profits<br />

MHEL manufacture and install all types of<br />

conveyors and also provide a full support,<br />

maintenance and spares service.<br />

Contact Midland Handling today for a free no<br />

obligation meeting to see how our conveyors<br />

could save your company time and money on<br />

0116 259 3175<br />

Automated Material Handling<br />

Systems Association<br />

Our conveyors include • Powered Monorail • Power & Free • Free Track • Belt/Power Roller • Waste/Spat • Inverted Chain • Platelinks/Mesh Belt • Easi-Lift Safety Gate<br />

Midland Handling Equipment, Stretton Road, Great Glen, Leicester, LE8 9GN<br />

Tel: 0116 259 3175 Fax: 0116 259 2820 Email: enquiry@mhel.co.uk<br />

www.mhel.co.uk<br />

www.finishingmagazine.co.uk

THE POWER<br />

OF MEMBERSHIP<br />

ADVANCED<br />

ENGINEERING<br />

SHOW <strong>2022</strong><br />

JOINING THE SEA<br />

WILL HELP YOU...<br />

Save money<br />

Save time<br />

Keep a step ahead with<br />

industry updates<br />

Enhance your reputation<br />

Gain political clout and<br />

expertise<br />

Following on from the success of the show and<br />

as a result of the positive feedback, we have<br />

booked the SEA pavilion for <strong>2022</strong> taking place<br />

on 2nd and 3rd November at NEC, Birmingham.<br />

Take a look at the video testimonials from<br />

exhibitor’s within the SEA pavilion at<br />

https://www.sea.org.uk/blog/advancedengineering-2021-2/<br />

If you wish to join us and exhibit in the SEA<br />

pavilion, please contact us at info@sea.org.uk<br />

or on 0121 237 1123. Pods within the pavilion will<br />

be priced at £1500 for a standard pod and £2000<br />

for a corner pod (Member rates).<br />

MORE INFO:<br />

+44 (0)121 237 1123<br />

www.sea.org.uk<br />

For further details of how the Surface Engineering Association<br />

can support you, please contact Michaella Mais on 0121 237 1123<br />

or email michaella.mais@sea.org.uk<br />

Visit the members’ directory<br />

today to find a supplier or<br />

get help with your surface<br />

treatment requirements:<br />

https://www.sea.org.uk/<br />

member-directory/

www.finishingmagazine.co.uk CONTENTS 3<br />

Editor<br />

John Hatcher<br />

Tel: 01923 432705<br />

E.mail: j.hatcher@turretgroup.com<br />

Display Advertising<br />

Stewart Freshwater<br />

Tel: 01923 432705<br />

Mob: 07746 373 545<br />

E.mail: s.freshwater@turretgroup.com<br />

Classified Advertising<br />

Stewart Freshwater<br />

Tel: 01923 432705<br />

E.mail: s.freshwater@turretgroup.com<br />

Production Manager<br />

Carol Baird<br />

Tel: 01923 432705<br />

E.mail: c.baird@turretgroup.com<br />

Managing Director<br />

Ian Garmeson<br />

Circulation<br />

Tel: 0141 370 3883<br />

circulation@dimensionsmail.co.uk<br />

Published by<br />

Turret Group Ltd<br />

Cardinal Point<br />

Park Road<br />

Rickmansworth,<br />

WD3 1RE<br />

Tel: +44 (0) 1923 432705<br />

Web: www.turretgroup.com<br />

Annual Subscription Rates<br />

United Kingdom: £144.00<br />

Overseas: £168.00 (Airmail)<br />

Printed by Stephens & George<br />

All members of the SEA<br />

automatically receive <strong>Finishing</strong> Magazine<br />

<strong>March</strong>/<strong>April</strong> <strong>2022</strong> – Volume 46 Number 2 – ISSN no. 0264 2506<br />

In this issue...<br />

Who knew that after coming out of a pandemic, the world could get any worse, but<br />

how wrong was everybody.<br />

The efffects of the war are going to be be huge for industry. Industry that was already<br />

under price pressure, but fuel costs now are going to be astronomical. I truly hope that<br />

your business survives this latest onslaught.<br />

Fair play to all those people volunteering to look after refugees. They have my<br />

undying respect and it shows the people of the UK to be a country full of sympathy and<br />

humanity. I hope this message is seen from the outside world as I fear that sometimes<br />

our leaders may distort how UK citizens really feel.<br />

Good luck in the coming months, I think we might need it.<br />

News<br />

Newsdesk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Features<br />

Expanded line-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

Weld efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

A simple plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

Blast cleaning of springs prior to coating . . . . . . . . .20<br />

Top 5 sustainability tips . . . . . . . . . . . . . . . . . . . . . . .22<br />

Keep your workplace secure . . . . . . . . . . . . . . . . . . .28<br />

New specification . . . . . . . . . . . . . . . . . . . . . . . . . . . .30<br />

A whole new world . . . . . . . . . . . . . . . . . . . . . . . . . .32<br />

Twin extrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34<br />

© Copyright Turret Group Ltd <strong>2022</strong><br />

All Rights Reserved<br />

All rights reserved. No part of this publication<br />

may be produced in any material form (including<br />

photocopying it or storing it in any medium by<br />

electronic means and whether or not transiently<br />

or incidentally to some other use of this<br />

publication) without the written permission of<br />

the copyright owner except in accordance with<br />

the provisions of the Copyright, Designs and<br />

Patents Act 1988. Applications for the copyright<br />

owner's written permission to reproduce any<br />

part of this publication should be addressed to<br />

the info@turretgroup.com<br />

Regulars<br />

Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Workshop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46<br />

Classified listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46<br />

<strong>Finishing</strong> (formerly <strong>Finishing</strong> Industries) was established in 1947 and incorporates Metal<br />

<strong>Finishing</strong> journal, Electroplating & Metal <strong>Finishing</strong>, The Plant Journal, Surface Coatings, and<br />

Industrial <strong>Finishing</strong> & Surface Coatings. <strong>Finishing</strong> is a member of the Metal <strong>Finishing</strong><br />

Association, a sustaining member of the Institute of Metal <strong>Finishing</strong> and the UK representative<br />

of the Groupement International des Revues de Traitements de Surfaces.<br />

<strong>Finishing</strong> – <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

4 NEWS www.finishingmagazine.co.uk<br />

New opportunities on the horizon<br />

One of Shropshire’s oldest<br />

manufacturers is targeting more<br />

than £2.5m of new<br />

opportunities in <strong>2022</strong>, as more<br />

companies tap into the firm’s<br />

unprecedented lead times and<br />

quality.<br />

Corbetts the Galvanizers,<br />

which celebrated its 160th<br />

birthday in 2020, has seen<br />

significant growth from the<br />

transport, street furniture,<br />

agriculture and construction<br />

sectors during the last twelve<br />

months, with orders expected to<br />

jump a further 20% going<br />

forward.<br />

Despite taking on 30 new<br />

staff, the Telford-based firm is<br />

still looking to bolster its<br />

workforce with a further 39<br />

employees and is embarking on<br />

another strong recruitment<br />

campaign that will include<br />

flexible working, retention<br />

bonuses and organised<br />

transport.<br />

The company has also<br />

launched the Iron Duke<br />

Academy, a new training school<br />

that will help all individuals<br />

develop new skills and a clear<br />

progression route within the<br />

business.<br />

This could include offering to<br />

pay for Class 1 licences for<br />

potential HGV drivers and<br />

specialist training to integrate<br />

new lean manufacturing<br />

techniques and management<br />

qualifications/skills.<br />

Sophie Williams, finance<br />

director and general manager,<br />

commented: “2021 started with<br />

a £multi-million manufacturing<br />

agreement with Fastline to<br />

galvanise 15,000 tonnes of<br />

perimeter steel fencing every<br />

year.<br />

“This was the sign of things<br />

to come with our top accounts<br />

all growing by 20% during the<br />

following twelve months and<br />

we’ve had to respond to this by<br />

investing in new processes, new<br />

manufacturing technology and<br />

staff - the latter has been a<br />

constant challenge, but one we<br />

feel we are now getting on top<br />

of.”<br />

She continued: “We’re now<br />

hitting industry-leading delivery<br />

times alongside the quality<br />

standards Corbetts is renowned<br />

for…that is helping us to boost<br />

revenue with existing accounts<br />

and <strong>2022</strong> will focus on how we<br />

convert some of our pipeline<br />

activity. If plans go as expected,<br />

we’ll need to introduce 3<br />

rotating shifts in both plants!”<br />

Galvanizing Awards <strong>2022</strong> open for entry<br />

Galvanizers Association Galvanizing Awards <strong>2022</strong> are open for entry. After having been held virtually at the<br />

start of the pandemic and after a brief hiatus in 2021, the awards are back and Galvanizers Association are<br />

excited to hold the lunchtime event at the traditional London venue, the Royal Aeronautical Society in July<br />

this year.<br />

Judges will award the innovative use of hot dip galvanizing across six categories:<br />

Galvanizing in Architecture, Galvanizing in Engineering, Galvanizing in Detail, Sustainable Galvanizing<br />

and the Duplex Award, plus the Galvanizing in Art award.<br />

Marketing Manager Iqbal Johal believes the <strong>2022</strong> awards will be a chance to showcase the sector’s<br />

creativity and resilience but is also an opportunity to reflect a growing understanding of sustainability: “Apart<br />

from ongoing challenges with supply chains, UK and Irish Construction have bounced back fairly well from<br />

the pandemic. However, the sector now finds itself operating in very different conditions. Whilst the balance<br />

sheet appears healthy, promises around public spending are not iron clad and in addition, the sector finds<br />

itself being asked to find solutions to the demands of green growth and climate change. So, much has<br />

changed and there is a very different context to this year’s awards.”<br />

“At Galvanizers Association, we believe that the current environment, whilst being hugely challenging, will<br />

bring about largescale innovation. We anticipate projects offering up new ways to use our buildings and<br />

public spaces, with designs that embrace the circular economy, keep precious resources in use and which<br />

prize longevity. For a number of years now, we have promoted the sustainable use of galvanized steel, we<br />

look forward to seeing how the construction community is harnessing the manifold benefits of galvanized<br />

steel to meet the challenging needs of our time.”<br />

The GAGAs are open to all within the construction supply chain within the UK and Ireland, from clients,<br />

architects, engineers, to contractors and fabricators. Artists and craftspeople at all stages of their career are<br />

also invited to enter. Entries must be submitted by 29th <strong>April</strong> and require just a short project description and<br />

photographs. Any new building, refurbishment or art project completed after 1st January 2020 is eligible.<br />

Further details can be found at https://www.galvanizing.org.uk/construction-awards. For<br />

more information, please contact Iqbal Johal at: i.johal@hdg.org.uk<br />

New key<br />

moves<br />

One of the UK’s leading paint<br />

and powder coating companies<br />

has strengthened its leadership<br />

team with two key<br />

appointments.<br />

Thomas Howse Ltd has<br />

recruited long-standing industry<br />

figures Andrew Adkins and<br />

Garry Plant.<br />

They bring more than 75<br />

years’ sector expertise to the<br />

historic company, which was<br />

acquired by the Sheibani Group<br />

two years ago.<br />

Andrew, whose track record<br />

in the sector spans more than<br />

40 years, takes up the role of<br />

head of operations. He will<br />

spearhead the company’s inhouse<br />

production and process<br />

improvements programme<br />

across both powder coatings<br />

and liquid paints.<br />

Meanwhile, Garry has been<br />

appointed the company’s new<br />

general manager. He has been<br />

involved in paint production and<br />

sales since 1986, both in the UK<br />

as well as overseas, and has<br />

worked for the group for many<br />

years. He will be working closely<br />

with its sales team as well as its<br />

customer services and after-sales<br />

technical support departments.<br />

Group chairman, Abubaker<br />

Sheibani, said: “Andrew and<br />

Garry join us at an exciting time,<br />

and we look forward to drawing<br />

upon their expertise to propel us<br />

into a new era.<br />

“Our research and<br />

development lab has been<br />

upgraded to enable it to support<br />

all of the group's coatings<br />

business both in the UK and<br />

overseas, ensuring our in-house<br />

teams stay at the very forefront<br />

of innovation. We have<br />

ambitious plans to expand this<br />

internal asset throughout <strong>2022</strong><br />

and beyond.<br />

“We have also started a<br />

rolling programme of<br />

investment in our plants and in<br />

the latest technology. This will<br />

equip us with the internal<br />

capacity and capability to extend<br />

and diversify our in-company<br />

product range to meet customer<br />

needs.”<br />

<strong>Finishing</strong> – <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

Specialists In Surface Treatment Solutions<br />

CELEBRATING 75 YEARS OF SERVICE<br />

1947-<strong>2022</strong><br />

CELEBRATING 75 YEARS OF SERVICE<br />

1947-<strong>2022</strong><br />

CELEBRATING 75 YEARS OF SERVICE<br />

1947-<strong>2022</strong><br />

CELEBRATING 75 YEARS OF SERVICE<br />

1947-<strong>2022</strong><br />

Renowned in multiple specialised processes including:<br />

• Non Destructive Testing<br />

Fluorescent Penetrant Inspect,<br />

Magnetic Particle Inspect.<br />

• Etch Inspection<br />

Titanium Etch, Steel components,<br />

Nickel alloys, Nital etch.<br />

• Conversion coatings<br />

Alocrom 1200, SurTec 650<br />

& many more.<br />

• Anodising<br />

Including Chromic anodise,<br />

Sulphuric anodise, Hard anodise &<br />

Tartaric Sulphuric Anodise processes.<br />

Please call us on 01455 637 284<br />

Or email us at Quotes@amfin.co.uk & see how we can help you<br />

www.amfin.co.uk<br />

• Electroplating<br />

Silver plate, Copper plate<br />

• Plasma<br />

Amfin holds many accreditations for<br />

plasma, get in touch to find out more.<br />

• Painting<br />

Dry Film Lubricants, Epoxy coating systems,<br />

Polyurethane systems, Sermetel & many more<br />

• Bonding<br />

Extensive knowledge of many products<br />

including attrition coatings, silicon bonds<br />

& many more.<br />

Did you know Amfin is a PRI qualification approved training provider?<br />

Get in touch to find out how we can help you with your training needs.<br />

DISPLAYING THE MARK OF<br />

CONFORMITY<br />

CERTIFIED<br />

When using the Mark of<br />

Conformity (Mark), it shall appear<br />

only as shown.<br />

1. Do not change the font of the<br />

Mark<br />

2. Do not change the size of the<br />

globe or descriptor<br />

Beneath the line, insert the applicable process(es). It is recommended to use Arial font.<br />

PROCESS TITLES<br />

NonDestructiveTesting<br />

Chemical Processing<br />

Coatings

6 NEWS www.finishingmagazine.co.uk<br />

Cutting edge<br />

Colour of the year<br />

Axalta Coating Systems has announced its Global Automotive Colour<br />

of the Year <strong>2022</strong> – Royal Magenta.<br />

The selection for the eighth edition of the exclusive Global<br />

Automotive Colour of the Year, Royal Magenta, is a deep cherry<br />

colour that brings a luxurious finish to the market. The robust design<br />

has a majestic dark finish engrained with merlot and garnet hues. The<br />

colour appears berry red in sunlight yet reveals a dark, mysterious<br />

look in the midnight hours.<br />

“Royal Magenta delivers a new luxury look that is optimised for<br />

future mobility,” said Hadi Awada, senior vice president, global<br />

mobility coatings at Axalta. “With innovative mobility-sensing and<br />

environmentally-optimised waterborne technologies, we’re helping the<br />

mobility industry transition toward increasingly sustainable solutions,<br />

electric vehicles and autonomous driving.”<br />

Royal Magenta is formulated for all vehicle types and enriches the<br />

mobility palette with alluring colour. Royal Magenta is stylish and<br />

functional and is engineered to work with radar systems used on<br />

autonomous vehicles of all sizes. The sophistication of Royal Magenta<br />

is derived from Axalta’s track record of providing luxury finishes to the<br />

mobility market and ties into global colour trends that convey elegance<br />

with an indulgent and festive colour offering. Burgundy, violet and<br />

cherry-like hues are becoming more fashionable in the market. The<br />

premium colour creates an opulent finish appearing lush with faceted<br />

jewel accents.<br />

“This year, we have designed a complex-looking colour that can be<br />

applied in a simplified manner,” said Nancy Lockhart, global product<br />

manager of colour at Axalta. “The design process began by tinting<br />

waterborne paints with various layering systems to provide depth and<br />

colour. With sustainability in mind, the end colour was achieved with a<br />

conventional basecoat – clearcoat layering. It’s as easy on the eyes as it<br />

is to apply.”<br />

New in R&D<br />

Indestructible Paint Ltd. has<br />

strengthened its research and<br />

development services with a new<br />

senior appointment. Steve Berry<br />

has become the company’s<br />

technical manager and brings<br />

with him extensive experience in<br />

this highly specialist sector of<br />

industry.<br />

“My main focus will be on<br />

playing a key role in our<br />

laboratory operations with<br />

particular emphasis on helping to<br />

meet the research and<br />

development needs of a wide<br />

range of customers,” says Steve<br />

Berry. “I will be able to draw on a<br />

comprehensive background in the<br />

sector which has seen me<br />

undertake a range of technical<br />

roles for organisations in the field<br />

since the start of the 1980’s.”<br />

“A commitment to research and<br />

development, particularly through<br />

working closely with customers to<br />

identify requirements and then<br />

provide solutions, has always been<br />

at the heart of our approach,”<br />

says Brian Norton, managing<br />

director at Indestructible Paint.<br />

A leading British coatings<br />

manufacturer to the wood<br />

finishing industry has just<br />

released a totally new cuttingedge<br />

product that is greener<br />

than anything else on the<br />

market.<br />

Intercoat Paint’s AQ400 is a<br />

2K water-based replacement for<br />

conventional 2K solvent-based<br />

In the spotlight<br />

finishes primarily aimed at the<br />

kitchen, bedroom, contract<br />

furniture and shopfitting industry.<br />

AQ400 has FIRA Gold<br />

Certification, the quality mark<br />

recognised across the furniture<br />

industry, and complies with the<br />

relevant FIRA 6222-3<br />

specification which meets the<br />

highest of quality standards.<br />

HMG Paints has been featured in the latest Spotlight by Made in<br />

Britain. Made in Britain brings together the British manufacturing<br />

community and highlights the best of British manufacturing with its<br />

members products carrying its iconic mark.<br />

Made in Britain CEO John Pearce: "We were delighted to visit<br />

HMG Paints for this video, as the company embodies several of our<br />

organisation's core values - British provenance, innovation and<br />

longevity. HMG is one of many family businesses within the Made in<br />

Britain community, and we play a vital role in bringing more public<br />

awareness to the stories of how these companies evolve as they pass<br />

from generation to generation."<br />

The Made in Britain feature explores HMG and the Manchester<br />

home of the fifth-generation family-run business that has coined the<br />

catchy phrase ‘One name that covers everything'. Not only does the<br />

showcase discuss the world of paint, it highlights the values of the<br />

business in interviews with Jonathan and Rebecca Falder whose greatgrandfather<br />

founded the company in 1930.<br />

The report shows consumers feel it’s important to buy British<br />

In the third annual report into “Buying British”, 90% of respondents<br />

believed it is important to buy British Made products. Additionally,<br />

forty-six per cent believe that their purchasing habits will change post-<br />

Covid-19 and they will look to buy more British made products, the<br />

2021 'Buying British' Survey was conducted by Made in Britain and<br />

OnePoll.<br />

“2021 saw us working with a number of companies and customers<br />

who’ve been impacted by the pandemic and Brexit. Many have<br />

struggled to acquire paints and coatings which were previously<br />

imported from abroad due to supply chain disruptions” commented<br />

Paddy Dyson, HMG Marketing Manager. “We’re exceptionally proud<br />

to be a British paint manufacturer in an industry dominated by Multi-<br />

National Enterprises. All of our products are made right here in<br />

Manchester, and this allows us to quickly service our customers paint<br />

and coatings requirements.”<br />

<strong>Finishing</strong> – <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

PosiTector ® Inspection<br />

Unrivaled probe interchangeability<br />

for all of your inspection needs.<br />

Coating Thickness Probes<br />

n Ferrous n Non-Ferrous n Combination n Ultrasonic<br />

Surface Profile Probes<br />

n Depth Micrometer n Replica Tape Reader<br />

Environmental Conditions Probes<br />

n Integral n Cabled Magnetic Probe n Anemometer Probe<br />

n 1/2” NPT n Infrared<br />

Hardness Probes<br />

n Shore n Barcol<br />

Salt Contamination Probe<br />

n Bresle Method<br />

Ultrasonic Wall Thickness Probes<br />

n Corrosion n Multiple Echo Thru-Paint n Precision<br />

n Low Frequency n Xtreme<br />

NEW<br />

Design and Features<br />

Design and Features<br />

NEW<br />

Customized Inspection Kits...<br />

Build your own kit from a selection of gauge<br />

bodies and probes to suit your needs.<br />

Coating<br />

Thickness<br />

Surface<br />

Profile<br />

Environmental<br />

Conditions<br />

Hardness<br />

Salt<br />

Contamination<br />

Ultrasonic<br />

Wall Thickness<br />

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness<br />

(6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness<br />

(SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.<br />

DFT DFT Instruments UK UK LTD LTD<br />

16A 16A Long Long Drive, Meadway, Berkhamsted, Herts HP4 HP4 2PN 2PN<br />

t: t: 01442 879494 f: f: 01442 879595<br />

www.dftinstruments.co.uk e: e: sales@dftinstruments.co.uk<br />

Proud supplier of of DeFelsko Inspection Instruments

8 NEWS www.finishingmagazine.co.uk<br />

All materials when exposed to<br />

the elements will age in some<br />

form and change in appearance<br />

over time. Materials like stone<br />

and brickwork tend to age very<br />

well and offer an aesthetic look<br />

for many years with virtually no<br />

maintenance. Other materials<br />

such as copper take on a patina,<br />

a bright green colour in the case<br />

of copper, as the surface<br />

weathers and builds up a<br />

protective surface oxidisation.<br />

The effects of UV radiation and<br />

pollutants in rain can also have<br />

deleterious effect on many<br />

building materials often leading<br />

to premature failure. These<br />

finishes are often coated finishes<br />

and require careful specification.<br />

First of all, it is important to<br />

consider the design of any<br />

facade or roof. It is important to<br />

consider run-off of rain, as, if<br />

allowed to concentrate in any<br />

area, this can lead to localised<br />

staining, even on brickwork. An<br />

example of a run-off detail is the<br />

use of drip cills under windows<br />

which allow rainwater to run off<br />

the facade rather than run down<br />

the facade.<br />

Window and facade longevity<br />

starts with a high quality<br />

aluminium substrate<br />

pretreatment and powder coat<br />

finish as provided by a licensed<br />

QUALICOAT applicator. To<br />

identify a licensed QUALICOAT<br />

applicator in the UK or Ireland,<br />

simply go to the website<br />

www.qualicoatuki.org which is<br />

kept up to date with current<br />

licence holders.<br />

Often overlooked in the<br />

specification process is the choice<br />

of pretreatment system on the<br />

aluminium substrate, this is<br />

crucial as it needs to completely<br />

seal the aluminium surface whilst<br />

offering a good key for the<br />

powder coating to adhere too.<br />

Despite the powder coating<br />

being of a consistent thickness,<br />

coatings are air permeable and<br />

as a result, if the pretreatment is<br />

poorly applied, oxidisation of the<br />

aluminium substrate over time<br />

could cause the finish to lift. UK<br />

and Ireland QUALICOAT<br />

applicators are routinely<br />

inspected by independent test<br />

house, IFO, to ensure that the<br />

latest QUALICOAT Standard is<br />

being adhered to which ensures<br />

that a robust pretreatment has<br />

Angus Mackie - QUALICOAT UK & Ireland Chair looks at<br />

minimising the effects of weathering.<br />

been applied.<br />

Prior to handover of any new<br />

installation or building, coated<br />

aluminium fenestration will be<br />

cleaned down professionally to<br />

ensure that the finish is not<br />

damaged. It is crucial at this time<br />

to have any areas of impact or<br />

abrasion damage repaired,<br />

should it be present. During<br />

cleaning, all the protective tape<br />

must be removed from the<br />

inside and outside of powder<br />

coated surfaces as if this is left on<br />

for an extensive time, the tape<br />

low-tack adhesive can often<br />

degrade, especially in UV light,<br />

and become firmly attached to<br />

the powder coating.<br />

Once handed over to the<br />

client, in normal use such as in<br />

cities, the powder coat finish<br />

should simply be washed down<br />

at yearly intervals with clean<br />

water or with a ph neutral mild<br />

detergent solution in water. This<br />

should be enough to protect<br />

the visible surface of the<br />

powder coat for many years<br />

and can simply be done during<br />

the cleaning of windows. The<br />

powder coat finish wash down<br />

is especially important where<br />

squeegee bars are used to<br />

clean the glass, as their use<br />

tends to place the residue of<br />

the airborne contaminants<br />

directly on the powder coated<br />

frame which could begin to<br />

etch into the surface finish of<br />

the coating. Window cleaners<br />

must ensure that all powder<br />

coated surfaces are wiped clear<br />

of cleaning residue on every<br />

window clean.<br />

The original colour of the<br />

powder coating can be affected<br />

over time by contaminants in the<br />

atmosphere and possible UV<br />

degradation. Ensuring that the<br />

regular cleaning cycles wash<br />

down and remove any<br />

atmospheric deposits, especially<br />

acids that can be present in<br />

precipitation, will certainly help<br />

reduce possible staining of the<br />

powder coating. Elevations in full<br />

sun could be affected by UV<br />

degradation where there may be<br />

evidence of chalking, which<br />

appears as a whitening of the<br />

surface. Chalking is caused by<br />

UV radiation which brings the<br />

binder in the powder coat to the<br />

surface and is not an indication<br />

that the powder coating has<br />

failed but is an indication that<br />

cleaning has been neglected.<br />

Again, regular cleaning cycles<br />

should keep any chalking to a<br />

minimum. Should a product or<br />

facade be allowed to fall into this<br />

state, there are specialist cleaning<br />

companies who may be able to<br />

clean and restore the coating to<br />

its original colour.<br />

On all building projects, any<br />

powder coated finishes will come<br />

with a cleaning and maintenance<br />

regime from the company who<br />

coated the aluminium profiles,<br />

this may be an independent<br />

coater or a systems company.<br />

The cleaning regime will offer a<br />

minimum cleaning cycle which<br />

will need to be adhered to as<br />

well as being regularly recorded.<br />

This will ensure the coated finish<br />

is maintained within the<br />

applicators warranty and will<br />

help, should there be any claim<br />

in the future. Powder coat<br />

warranties vary in length and are<br />

dependent on the powder coat<br />

finish used and the location of<br />

the installation. For example,<br />

where the coating is close to the<br />

sea, a marine grade or<br />

QUALICOAT ‘Seaside’<br />

specification for the coating<br />

should be specified and the<br />

cleaning regime will often be<br />

increased to at least three<br />

monthly intervals as the<br />

atmosphere is much more<br />

corrosive.<br />

Crucial to any maintenance<br />

regime is preventative<br />

maintenance and powder<br />

coating is no exception, if the<br />

coating has become damaged,<br />

exposing the aluminium, it<br />

should be repaired as soon as<br />

possible. For repair, either<br />

contact the original coater, or<br />

approach any QUALICOAT<br />

approved application who can<br />

normally offer guidance. If you<br />

have mislaid cleaning advice<br />

QUALICOAT UK & Ireland offer<br />

a basic guide which can be<br />

downloaded from their website.<br />

Futura<br />

is now<br />

AkzoNobel Powder Coatings has<br />

launched its much-anticipated<br />

Interpon Futura Collection for<br />

<strong>2022</strong>-2025, revealing three<br />

brand new, on-trend colour<br />

palettes – Merging World,<br />

Healing Nature and Soft<br />

Abstraction – helping designers<br />

connect to the latest<br />

developments in the built<br />

environment.<br />

The new collection is the<br />

result of rigorous testing and<br />

scientific research by<br />

AkzoNobel’s trend and color<br />

specialists across multiple<br />

industries, and particularly those<br />

involved in the building and<br />

construction sector. It is also the<br />

result of more than two decades<br />

of evolution, during which time<br />

the collections have inspired<br />

innovative designs all over the<br />

world.<br />

Launched with the promise to<br />

‘Futura your world’, the new<br />

range delivers a superdurable<br />

performance with a warranty up<br />

to 25-years, enabling<br />

architectural creations to stand<br />

the test of time. With a<br />

building’s legacy determined by<br />

its ability to withstand its<br />

surroundings, the durability<br />

provided by Interpon powder<br />

coatings reflects the brand’s<br />

proven commitment to<br />

sustainability and the<br />

environment.<br />

As a powder coating, the<br />

collection uses no solvent<br />

emissions or volatile organic<br />

compounds and supports<br />

AkzoNobel’s broader<br />

sustainability programme:<br />

People. Planet. Paint.<br />

<strong>Finishing</strong> – <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

RELIABLE RESULTS<br />

FOR MULTI-COLOR<br />

COATINGS.<br />

2K Smart<br />

Mixing & dosing unit<br />

• Consistent mixing ratios<br />

• Homogeneous coating results<br />

• High process reliability<br />

wagner-group.com<br />

Contact<br />

Wagner Spraytech (UK) Ltd<br />

a Member of WAGNER GROUP<br />

Telephone: 01327 368410<br />

enquiries@wagner-group.com

10 AIR DRYERS<br />

Expanded line-up<br />

Hi-line Industries, an established and<br />

reputable UK manufacturer of highquality<br />

compressed air purification<br />

equipment, can today offer a fully featured<br />

range of desiccant air dryers. The company’s<br />

series of class-leading HPSA heatless dryers<br />

includes new standard models, the recently<br />

launched HPSA-CT (Carbon Tower) version,<br />

plus the bespoke HP-HPSA (High Pressure)<br />

model. As a result, Hi-line can fulfil the needs<br />

of any company that needs dry, clean<br />

compressed air or nitrogen, whatever the<br />

application.<br />

The Hi-line HPSA (Heatless Pressure Swing<br />

Adsorption) series of desiccant dryers features<br />

proven technology developed and<br />

manufactured in the UK by the company’s<br />

expert engineering team working to approved<br />

engineering standards. These ‘plug and play’<br />

units with digital control panels come skidmounted<br />

with their own filtration package<br />

(pre- and after-filtration). Available for next-day<br />

delivery, all standard HPSA dryers use Dri-<br />

Zorb 27 desiccant media that delivers<br />

constant low dewpoints while consuming the<br />

lowest possible quantity of regeneration air.<br />

In order to meet ongoing industry demand,<br />

Hi-line is constantly looking to expand its<br />

portfolio, recently enhancing the HPSA range<br />

with two smaller capacity models. The new<br />

HPSA 70 and HPSA 100 bring the total<br />

number of standard models to 12, with flow<br />

capacity from 75 to 1130 scfm (larger heatless<br />

dryers are available if required).<br />

Another recent introduction to the range is<br />

the HPSA-CT (Carbon Tower), a three-stage<br />

dryer with<br />

the Carbon Tower added after the<br />

adsorption dryer. Clean, dry air passes through<br />

the Carbon Tower and adsorbs gases and<br />

aerosols dependant on requirements and the<br />

zeolites selected. This capability makes the<br />

HPSA-CT extremely flexible and suitable for<br />

use in many specific applications. The Hi-line<br />

HPSA-CT features pre-filtration sub-micron oil<br />

removal and safety valves as standard, as well<br />

as an after-filter for particulate removal. A total<br />

of 12 standard HPSA-CT models are available<br />

with flow capacity from 80 to 1130 scfm.<br />

Larger HPSA-CT dryers are available upon<br />

request.<br />

Hi-line can also now offer its bespoke HP-<br />

HPSA (High Pressure) heatless dryer. This<br />

model features the same proven HPSA<br />

technology, just running at high pressure.<br />

Control air is at 7 bar, but with elevated<br />

pressures up to 450 bar for specific<br />

applications such as P.E.T. blowing and<br />

moulding, R&D applications, breathing<br />

air/diving applications, speciality gas blending<br />

and laser cutting.<br />

Every HPSA model in the extensive Hi-line<br />

range is a fully automatic, IP65-rated, selfcontained<br />

unit featuring HDC1 digital<br />

dewpoint controller, stainless steel pipework,<br />

independent switching valves, exhaust<br />

silencers and a one-year warranty on parts<br />

and labour. Options include the company’s<br />

AEMS - Automatic Energy Management<br />

System (with digital dewpoint readout, highhumidity<br />

alarm, and set and demand<br />

regeneration), dewpoint to -70°C, and<br />

automatic start/stop control.<br />

<strong>Finishing</strong> - <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

PYROLYSIS &<br />

BURN OFF OVENS<br />

UK’S LEADING MANUFACTURER<br />

Our Pyrolysis ovens provide you with a quick and highly effective<br />

process for the removal of plastic, paints and resins<br />

Longworth’s pyrolysis & burn off ovens are second to none in design and build quality, built to last and have the latest<br />

in technological features. Our ovens provide a quick and highly effective process for the removal of plastics, paints<br />

and resins from jigs, filters, shelving, food trays, motors, automotive parts and a multitude of other components.<br />

Accreditations<br />

BS EN ISO 9001:2008<br />

Call Longworth today for a no obligation meeting on how we can help you and your business<br />

call<br />

01254 680501<br />

email<br />

enquiries@bmlongworth.com<br />

visit<br />

www.bmlongworth.com

12 CLEANING<br />

Weld efficiency<br />

To avoid quality issues during the<br />

subsequent cathodic dip painting<br />

process, a renowned automobile<br />

manufacturer relies on Ecoclean's EcoCbooster<br />

technology for cleaning weld seams on<br />

integral subframes for electric vehicles. In<br />

contrast to the previously used method of<br />

solid media blasting, which requires an<br />

additional aqueous cleaning step, this virtually<br />

wear-free, fully automated process removes<br />

welding residues from the exterior and<br />

interior of parts in a targeted, resource-saving<br />

and cost-saving manner without the need for<br />

abrasives.<br />

Electric and hybrid vehicles are changing<br />

the way vehicles are built in ways that go far<br />

beyond the drive technology. For example,<br />

due to the weight of the battery, integral<br />

subframes now need a higher load-bearing<br />

capacity. The redesign of these axle<br />

components is also prompting many vehicle<br />

manufacturers to reconsider and reassess their<br />

production processes. One of these processes<br />

is the cleaning step to remove impurities such<br />

as silicate islands, scale and smoke residues<br />

formed during welding; these can cause<br />

major quality issues in the subsequent<br />

cathodic dip painting process and lead to<br />

corrosion damage. The cleaning technology<br />

generally used is blasting with a solid<br />

medium, for example corundum. To remove<br />

dust and abrasive residues from the parts<br />

prior to cathodic dip painting, another<br />

cleaning step in a separate machine is<br />

required.<br />

Focus on cost efficiency,<br />

sustainability and occupational<br />

health and safety<br />

These conventional blasting processes with<br />

an additional aqueous cleaning step are wearintensive<br />

and costly. Therefore, when<br />

designing a new production line for integral<br />

subframes, the project planner of a renowned<br />

German OEM sought information at<br />

parts2clean about ways to optimize this<br />

cleaning process. On the one hand, the aim<br />

was to clean weld seams with same or better<br />

results, but cheaper, with less maintenance,<br />

and saving on resources. On the other hand,<br />

the dust pollution occurring in the vicinity of<br />

the solid-state blasting machines due to<br />

fragmented abrasive needed to be eliminated<br />

in order to improve working conditions.<br />

Removing welding residues –<br />

parts cleaning included<br />

The planner found what he was looking for<br />

with Ecoclean's EcoCbooster technology. The<br />

patented process employs medium-pressure<br />

water jetting in the range between 300 and<br />

700 bar without addition of abrasives.<br />

Through the use of ultrasound, the prestressed<br />

column of water turns into an ultrahigh<br />

frequency pulsating water jet after<br />

exiting the nozzle. This imparts a much<br />

higher kinetic energy to the jet, such that it<br />

reliably and reproducibly eliminates silicate<br />

and weld spatter as well as scale and smoke<br />

<strong>Finishing</strong> - <strong>March</strong>/<strong>April</strong> <strong>2022</strong><br />

continues on page 14

PMD Chemicals Limited<br />

401 Broad Lane • Coventry • CV5 7AX<br />

T: 024 76 920 168<br />

info@pmdchemicals.co.uk<br />

www.pmdchemicals.com<br />

PMD CHEMICALS ……Your trusted, reliable partner for all your Chemical<br />

processing requirements, in an industry where supplier choices have<br />

become limited, dependability really matters.<br />

PMD was formed as a limited company<br />

in 1959 and can boast over 60 years<br />

experience of research, development and<br />

supply of its own formulated products from<br />

its modern facilities in Coventry, England.<br />

Success has been achieved through<br />

continuous development of process<br />

chemistry and a consistent understanding<br />

of the ever changing requirements of the<br />

GMF Industry. Our focussed approach of<br />

dedicated customer service is unrivalled<br />

and our ability to work alongside our<br />

customers to solve problems and create a<br />

process that is technically advanced and<br />

cost effective makes PMD a reliable partner<br />

in today’s market.<br />

PRE-TREATMENTS<br />

Soak Cleaners<br />

Electrocleaners<br />

Dual Purpose Soak-Electrocleaners<br />

Activators - Inhibitors-Bright Dips<br />

Aluminium Treatment<br />

PLATING PROCESSES<br />

Chrome Plating<br />

Copper Plating<br />

Electroless Nickel<br />

Electrolytic Nickel<br />

Gold Plating<br />

Silver Plating<br />

Tin Plating<br />

Zinc Alloys<br />

Zinc Plating<br />

Speciality Finishes<br />

POST TREATMENTS<br />

Anti-Tarnish Corrosion Protection<br />

Electrophoretic Lacquers<br />

Passivates<br />

Topcoats Sealants<br />

Anodising<br />

ANCILLARIES/EQUIPMENT<br />

Ancillary Products<br />

Base Chemistry<br />

Equipment<br />

Contact a member of the team<br />

02476 920168 • info@pmdchemicals.co.uk

14 CLEANING<br />

residues from the surfaces in a clearly defined<br />

operating window. Feed rates of up to 800<br />

mm per second are possible, with a robot<br />

moving either the workpiece or the nozzle<br />

tool.<br />

The part is also cleaned at the same time<br />

the welding residues are removed, thus<br />

dispensing with the need for an additional<br />

cleaning step and the corresponding machine.<br />

This not only noticeably decreases investments<br />

related to the cleaning process, but also<br />

ensures more competitive unit costs because<br />

operating costs are significantly reduced.<br />

Another factor contributing to the high<br />

economic and resource efficiency of the<br />

process is the effective treatment of the<br />

process water, which is mixed with a corrosion<br />

protection medium so that it can be<br />

recirculated for a long time.<br />

Selectively cleaning external and<br />

internal geometries<br />

The effective range of the water jet can be<br />

precisely adapted to the application by using<br />

different nozzle geometries, for example fan<br />

and solid-jet nozzles as well as lances. Among<br />

other things, this enables not only the outer<br />

but also the inner contours of the integral<br />

subframes to be selectively cleaned, in contrast<br />

to conventional jet-cleaning processes with<br />

abrasives.<br />

Process engineering and<br />

validation in Technology Centre<br />

The process parameters, such as nozzle<br />

geometry, pressure and feed rate, were<br />

precisely adjusted using a special test set-up at<br />

the manufacturer's Technology Centre in<br />

Monschau. To validate the new water jetting<br />

process, integral subframes were coated in the<br />

cathodic dip painting line cleaning and then<br />

subjected to a lengthy salt spray test. The<br />

results were impressive: The weld seams were<br />

cleaner after treatment with the pulsating<br />

water jet than after blasting with abrasive<br />

media, and any discolouration from the<br />

welding process still visible on the surface had<br />

no effect on the quality of the paint finish. The<br />

high corrosion protection requirements had<br />

been met. The new cleaning solution also<br />

proved to be a good choice in terms of<br />

cost/benefit.<br />

Fully automatic jetting, cleaning<br />

and drying in 50-second cycles<br />

In order to implement the developed<br />

process in a fully automated machine concept,<br />

an integral subframe had to be jetted, cleaned<br />

and dried within 50 seconds. To meet this<br />

requirement, the cleaning machine has three<br />

independently functioning jetting modules<br />

with integrated manipulator, a hot air dryer,<br />

one robot each for loading and unloading,<br />

and a bath treatment unit for the process<br />

water.<br />

Pallet cages loaded with several integral<br />

subframes to be processed are transported to<br />

the machine. The machine’s loading robot<br />

picks up the parts and places them on the<br />

transfer stations of the jet modules. The<br />

manipulator of the respective module picks up<br />

the part and moves presents in a defined<br />

sequence it to the jet tool, treating the welding<br />

contours in a specific manner. After cleaning,<br />

the manipulator places the integral subframe a<br />

clean surface. From here, the loading robot<br />

takes it to the drying step. On exiting the<br />

dryer, the subframe is picked up by the<br />

unloading robot and hooked into the rack for<br />

painting.<br />

To eliminate the transport path between the<br />

welding and cleaning process, the<br />

EcoCbooster can also be connected directly to<br />

the welding cell.<br />

The vehicle manufacturer has been using<br />

the new cleaning system in series production<br />

since mid-2020. Due to the optimizations<br />

achieved, the company is now considering<br />

integrating the new cleaning solution into<br />

further production lines for integral subframes.<br />

<strong>Finishing</strong> - <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

The Choice for the Professional Powder Coater<br />

Gema UK<br />

01202 763942<br />

uk.sales@gema.eu.com

16 CLEANING<br />

A simple plan<br />

Now is a good time to review your<br />

existing cleaning processes or upgrade<br />

current equipment. In the autumn<br />

Budget 2021, the Chancellor, Rishi Sunak,<br />

announced an extension of the temporary<br />

increase in Capital allowances which allow the<br />

cost of capital assets to be written off against<br />

taxable income. The 130% super-deduction<br />

and 50% first-year allowance are very<br />

generous but only available for a short time.<br />

This will allow companies to not only lower<br />

their corporation tax bills but improve<br />

productivity and reduce operating costs for<br />

cleaning processes.<br />

Vapour degreasing is the simplest but most<br />

effective degreasing and cleaning process<br />

which, until recently, has been subject to little<br />

change since it was first invented in the early<br />

part of the last century. This is a very mature<br />

chemical technology which legislation is now<br />

effecting changes so fundamental that the<br />

more accurate name for the process<br />

“Condensation Cleaning” should be used to<br />

reflect the improvements in equipment<br />

design, chemistry, reduced emissions,<br />

economies in usage of solvents and the<br />

subsequent environmental acceptability<br />

compared to the open topped tanks so<br />

ubiquitous in factories and workshops<br />

worldwide. The alternatives in equipment<br />

design offer differences in technology, which<br />

guarantee the continuing use of this process<br />

in the future, need to be considered and<br />

understood.<br />

The cleaning tank in the corner of most<br />

engineering shops hides a very well<br />

researched process using sophisticated<br />

chemistry. Its popularity is in its simplicity. The<br />

tank sump is heated, fitted with cold coils<br />

around the internal surfaces at the top to<br />

retain the vapour. Fill to a few centimetres<br />

with a non-flammable solvent able to dissolve<br />

contaminants, boil to form a vapour 3 to 4<br />

times heavier than air to fill the tank. Hot<br />

solvent vapour condenses on the cooler target<br />

parts at workplace temperature. The hot liquid<br />

solvent dissolves oil and grease and other<br />

contaminants. Used solvent returned to the<br />

sump revaporises continuing the cycle until<br />

parts have achieved the same temperature as<br />

the vapour when, with no further<br />

condensation, the process is complete. Simple<br />

but perfect. Highly productive and<br />

economical, parts removed from the cleaning<br />

process are clean, warm, and dry in 5 to 10<br />

minutes.<br />

Historically chlorinated hydrocarbons have<br />

been the solvents of choice for the<br />

“Condensation Cleaning” process. Compatible<br />

with most materials of manufacture, stable in<br />

constant use, producing a non-flammable<br />

saturated vapour heavier than air at a<br />

temperature greater than ambient.<br />

In Europe, the United States and in other<br />

advanced industrialised economies<br />

increasingly stringent legislation to control<br />

emissions of VOCs, especially solvents, has<br />

led to new formulations for paints and other<br />

coatings where water replaces most of the<br />

solvent. In the early days the quality of waterbased<br />

paints was not as good as traditional<br />

solvent-based coatings, but innovation has<br />

driven the development of new polymers with<br />

results as good as, if not better than, the<br />

solvent-based originals.<br />

As with coatings, cleaning systems have had<br />

to change. With increasingly demanding<br />

<strong>Finishing</strong> - <strong>March</strong>/<strong>April</strong> <strong>2022</strong><br />

continues on page 18

Unit 10, Southlink Business Park,<br />

Hamilton Street,<br />

Oldham, OL4 1DE

18 CLEANING<br />

standards of cleaning required for precision<br />

engineering, electronics, optics etc solvents are<br />

often first choice, for reasons outlined above,<br />

but these have been targeted by regulators<br />

and alternatives are encouraged by the<br />

relevant authorities and law makers often<br />

without serious consideration of unintended<br />

consequences.<br />

For example, water-based cleaning is<br />

encouraged as the obvious alternative, but this<br />

has many disadvantages compared to<br />

condensation cleaning as although the<br />

machines are simple and relatively cheap the<br />

processes require multiple heated tanks for<br />

immersion or spray processing or long<br />

programmed cycles in batch machines for<br />

cleaning, rinsing, and drying. Water based<br />

processes are slow, energy intensive and<br />

occupy more floor space than solvent-based<br />

condensation cleaning equivalents where only<br />

one tank with a small footprint is needed,<br />

delivering shorter process times and, most<br />

importantly for the environment, using<br />

minimal energy.<br />

The ideal cleaning process would be<br />

“Condensation Cleaning” using water but due<br />

to the physical characteristics of the water<br />

vapour/steam and the inability to carry onto<br />

the surface of the targeted parts surfactants to<br />

remove the oil, grease and soils and the<br />

difficulty and expense of rinsing and especially<br />

drying this can only ever be a dream.<br />

Historically chlorinated hydrocarbons have<br />

been the solvents of choice for the<br />

“Condensation Cleaning” process. Compatible<br />

with most materials of manufacture, stable in<br />

constant use, producing a non-flammable<br />

saturated vapour three to four heavier than air<br />

at a temperature greater than ambient.<br />

The traditional solvents such as<br />

trichloroethylene exhibits all these<br />

characteristics however concerns about its<br />

carcinogenic properties and the danger to<br />

operators by exposure, led to a continuing<br />

search for a safer alternative. 1,1,1<br />

trichloroethane based solvent formulations<br />

became popular in the mid part of the last<br />

century as a safer replacement. An excellent<br />

solvent, safer for users, it proved to be<br />

depleting the protective ozone layer around<br />

the Earth and was subsequently banned. With<br />

the development of the REACH legislation in<br />

Europe, trichloroethylene was again allowed<br />

with restrictions and stringent controls for use<br />

in authorised machines which control<br />

emissions to very low figures close to zero.<br />

EnviroTech have been supplying vapour<br />

degreasing solvent formulations for 40 years<br />

constantly responding to increasingly stringent<br />

regulatory requirements for environmental<br />

and safety laws and the need for improved<br />

cleaning standards.<br />

ProSolv®5408e is a new sustainable solvent<br />

blend with near zero OPD (Ozone Depletion<br />

Potential) and GWP (Global Warming<br />

Potential) for high performance degreasing<br />

and cleaning which ticks all the boxes with the<br />

perfect profile for a vapour degreasing solvent.<br />

Soft on the environment and safer for users<br />

with high performance, improved cleaning,<br />

and lower costs. Lower boiling point,<br />

economical with energy with low solvent<br />

losses, faster production, reduced costs, easy<br />

handling. Exceptionally low surface tension to<br />

penetrate micron sized holes and close contact<br />

surfaces. Sustainable and secure for future use<br />

as your ‘forever solvent’.<br />

As with all legislation for chemical use<br />

regulation and restrictions drive development<br />

of associated processes and equipment. Sealed<br />

tanks are now standard with many different<br />

designs available. The most common are<br />

discussed below.<br />

The single tank hermetically sealed<br />

machines favoured by some manufacturers<br />

uses a process tank to contain the solvent and<br />

a separate storage tank/vapour generator.<br />

Baskets loaded with parts to be cleaned are<br />

introduced from the top or through access<br />

points on the side of the tank. Lids or doors<br />

hermetically seal the tank. Solvent is pumped<br />

into the process tank where agitation,<br />

ultrasonics or pumped liquid is circulated<br />

through the parts. Used Solvent is removed to<br />

the vapour generator, condensing coils<br />

controlling the vapour are linked to coils<br />

located in the vapour zone which, when the<br />

cycle is complete, collapse the vapour. The<br />

process tank is emptied. Controlled air<br />

introduced to process tank is then recycled<br />

through carbon absorption units to remove<br />

traces of solvent until the concentration is<br />

within regulatory standards when the lid is<br />

released for the basket of parts, clean and dry,<br />

to be removed and replaced with a further<br />

basket.<br />

Variations of process within the hermetically<br />

sealed tank are possible using sprays of cold<br />

or hot condensed solvent, immersion with or<br />

without ultrasonics and revolving baskets to<br />

cover most of the problems experienced when<br />

processing machined and fabricated parts.<br />

Continuous external distillation of the contents<br />

of the vapour generator is also an option<br />

depending on contamination.<br />

The alternative technology is much simpler<br />

and uses well tried techniques not requiring<br />

the long recovery times of the hermetically<br />

vacuum sealed processes. The multilevel<br />

system uses a standard vapour degreasing<br />

tank design with a sealed loading section<br />

above the process tank. Components to be<br />

cleaned loaded in work baskets or jigs are fed<br />

to the load section by hand or conveyor, an<br />

internal platform raises and lowers the baskets<br />

in controlled cycles.<br />

Loading complete - the load enclosure is<br />

sealed to completely isolate the process. Then<br />

seal on the process tank is opened and the<br />

basket automatically lowered into the cleaning<br />

section which can be simple condensation<br />

cleaning or immersion cleaning with or<br />

without ultrasonics or power sprays. Revolving<br />

baskets can also be added to improve<br />

cleaning in blind or through holes or oil ways<br />

in castings and fabrications.<br />

On completion the basket rises to the area<br />

where the condensation coils are located, and<br />

parts allowed to drain and dry, basket raises<br />

into the load section when the process tank is<br />

sealed. A fan circulates air within the load area<br />

which can be recycled through carbon<br />

absorption systems if no external exhaust is<br />

preferred.<br />

As baskets entering the loading space<br />

contain parts drained and dried only very<br />

small amounts of solvent are carried in the<br />

exhausted air which is monitored to ensure<br />

compliance with appropriate legislation. When<br />

this is complete the seal opens fully for<br />

removal of cleaned components. The loading<br />

section can be fitted with top or side seals<br />

allowing baskets to flow through on conveyor<br />

systems or be removed by hand or hoist. No<br />

solvent enters the work area.<br />

Both processes will produce parts cleaned to<br />

the highest standards but the choice of which<br />

offers the best solution needs a little more<br />

consideration.<br />

The hermetically sealed vacuum process is<br />

complicated with the need to move liquids in<br />

the machine. It is relatively slow as the carbon<br />

adsorption process has to remove high levels<br />

of solvent from the recirculated airstream from<br />

the process tank. This is inefficient as<br />

adsorption rates for carbon fall rapidly with<br />

increasing saturation. Final levels of solvent in<br />

the tank when the lid or loading door opens<br />

will be dragged into the workshop and the<br />

area where the operator is working. Long<br />

process cycles reduce throughput.<br />

The simpler multilevel systems where<br />

movement of liquids is not required are more<br />

efficient and offer much faster process times.<br />

Cost of manufacture is also reduced as no<br />

liquid movement or vacuum is involved. The<br />

extracted loading section ensures no leakage<br />

of solvent into the work area giving complete<br />

safety for operators and factory staff.<br />

Both designs of process machines fully<br />

comply with the emission regulations of the<br />

EU and U.S authorities. Which to choose will<br />

depend on many factors which should be<br />

discussed with equipment and solvent<br />

suppliers who have the experience to advise<br />

on which offers the best process for the<br />

application. Equipment and solvent must work<br />

together, so it is advisable to ensure that the<br />

suppliers co-operate to offer a package with<br />

high levels of responsible care and product<br />

stewardship to ensure the best and safest<br />

installation. EnviroTech personnel and<br />

distributors are trained to work with our<br />

equipment suppliers to advise on the use of<br />

ProSolv®5408e for the most satisfactory<br />

outcome.<br />

The “Condensation cleaning” process still<br />

gives the highest levels of economical cleaning<br />

with minimum energy usage, low footprint on<br />

the factory floor, safety for the operator, and<br />

high production rates with low solvent usage<br />

and environmental impact. With the new<br />

generation of sealed cleaning machines its<br />

future as the process of choice is assured.<br />

<strong>Finishing</strong> - <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

Innovation in Thru-Process<br />

Automotive Paint Monitoring<br />

Safe ATEX Certified Temperature Profiling<br />

Intrinsically Safe<br />

• 20 measurement<br />

channels<br />

• Paint & Powder coating<br />

• Includes Phoenix Factor<br />

cure index calculation<br />

New Optic Video Profiling System<br />

During Production<br />

• Detect paint runs, drips<br />

and defects<br />

• Spot transport problems<br />

• Identify oven damage<br />

Phoenix Temperature Measurement<br />

T:01353223100 E:sales@phoenixtm.com www.phoenixtm.com

20 CLEANING<br />

Blast cleaning of springs<br />

prior to coating<br />

The Baumann Springs Ltd., located in<br />

Ermenswil, Switzerland, is a global leader<br />

in the production of springs and all kinds<br />

of stampings. This family-owned company was<br />

founded in 1886 and ever since has been<br />

managed by the family, today in the fifth<br />

generation. Baumann Springs is specialized in<br />

the development and production of customengineered<br />

products with tight dimensional<br />

tolerances and high demands for process<br />

stability in the automobile industry, medical<br />

engineering and other markets. The products<br />

are manufactured in 11 plants in Europe, Asia<br />

and North-America.<br />

Shot blasting solution for a new<br />

production line<br />

In 2021 the plant in Stare Mesto in the<br />

Czech Republic established a new production<br />

line for different types of long compression<br />

springs made from spring steel EN 10270-2.<br />

For cleaning and texturing (roughening) the<br />

surface of the springs prior to coating, the<br />

company purchased a tumble belt blast<br />

machine, model RMBC 4.2-HD, from Rösler.<br />

Claudio Hertig, project manager global<br />

operations at Baumann Springs, explains: „For<br />

this challenging task we had discussions with<br />

several equipment manufacturers and<br />

requested quotes from three of the suppliers“.<br />

“The Rösler solution impressed us not only<br />

because of the design of the equipment but<br />

also its functionality. Another positive factor<br />

was the sturdy machine construction. To<br />

familiarize myself with the suppliers, I visited<br />

all three companies and prepared a detailed<br />

technical comparison. Last-but-not-least, our<br />

good experience with Rösler equipment<br />

already running at some of our facilities and<br />

the global presence of the company, also<br />

played a role in our decision for Rösler”,<br />

continues Mr. Hertig.<br />

Equipped for short cycle times<br />

and clean results<br />

The RMBC 4.2-HD was painted per<br />

customer specifications and is equipped with<br />

special technical features. It allows the blast<br />

cleaning of complete batches of loosely<br />

tumbling compression springs with batch<br />

weights of up to 1,000 kg. Two Gamma<br />

300G turbines, each equipped with a power<br />

of 11 kW, ensure a high shot blast intensity.<br />

These high performance turbines, developed<br />

by Rösler, are equipped with curved throwing<br />

<strong>Finishing</strong> - <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

CLEANING 21<br />

blades in “Y” design. Compared to<br />

conventional turbines the specially calculated<br />

blade curvature generates very high media<br />

throwing speeds resulting in an up to 20%<br />

higher blast performance and, consequently,<br />

shorter cycle times. All this is achieved with a<br />

lower energy consumption. Moreover, the<br />

special “Y” design of the throwing blades<br />

allows the use of both blade sides. This<br />

practically doubles the usable life of the<br />

throwing blades. A quick-change system<br />

permits a quick blade change without the<br />

need for dismounting the turbine from its<br />

housing.<br />

The blast process is further intensified and<br />

accelerated by the integrated blast media<br />

deflectors. These special compressed air<br />

nozzles are causing an additional blast media<br />

movement. The automatic blast media flow<br />

control allows not only the monitoring but also<br />

the precise adjustment of the media flow to<br />

the respective work pieces. The media<br />

replenishment takes also place fully<br />

automatically. An additional automatic dosing<br />

system allows the application of a powder<br />

cleaning compound in the blast chamber to<br />

catch and discharge any oil that may be<br />

carried into the shot blast machine by the<br />

work pieces. It should be noted that the<br />

powder compound does not affect the<br />

functionality of the blast media: In the air wash<br />

separator of the media cleaning system the<br />

powder is completely separated from the blast<br />

media. Since the machine was also intended<br />

for stripping the coating buildup from the<br />

work piece carriers used for the coating<br />

operation, the dry dust collector is equipped<br />

with explosion protection features.<br />

Optimum wear protection<br />

ensures long uptimes<br />

In order to minimize machine downtimes<br />

due to wear, the inside of the blast chamber is<br />

lined with easily replaceable 6 mm thick highly<br />

wear-resistant manganese plates. The left and<br />

right side of the media discharge opening of<br />

the turbines is equipped with additional wear<br />

plates. These bundle the media stream and<br />

prevent this section of the blast chamber to be<br />

attacked by the blast media. Finally, the barrel<br />

heads, also made from manganese steel, are<br />

equipped with a PU coating providing an<br />

additional wear protection in the primary blast<br />

zone. This helps to further extend the<br />

equipment uptime.<br />

Claudio Hertig concludes: „The<br />

comprehensive experience and know-how of<br />

Rösler with the production of such machines is<br />

an invaluable advantage that helps improve<br />

the overall efficiency of the equipment. In<br />

addition, the global Rösler technical service<br />

allows us to work in other plants with the<br />

same processes and machinery and have them<br />

maintained by local Rösler service engineers”.<br />

• Dedicated stand-alone unit is ready to measure right out of the box<br />

• Fast measurement speed—ideal for moving lines and swinging parts<br />

• Scan Mode continuously takes measurements—ideal for<br />

analyzing large areas<br />

Powder Checker<br />

Non-contact Uncured Powder Thickness Gauge<br />

Affordably measures uncured powder coatings using<br />

non-contact ultrasonic technology to predict<br />

a cured thickness<br />

• Storage of 999 readings with onscreen averaging. Stored readings<br />

can be downloaded to PosiSoft Desktop Software<br />

Powder Inspection Kits<br />

Complete solutions for measuring<br />

powder coating before and<br />

after cure are available<br />

£1950.00<br />

16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN<br />

t: 01442 879494 • www.dftinstruments.co.uk • e: sales@dftinstruments.co.uk<br />

<strong>Finishing</strong> – <strong>March</strong>/<strong>April</strong> <strong>2022</strong>

22 COMPRESSED AIR<br />

Top 5 sustainability tips<br />

In industry in general there’s been a lot of<br />

talk given to sustainability and carbon<br />

reduction over the years, but it’s more often<br />

than not been a welcome added benefit<br />

coming from reducing costs, rather than the<br />

goal itself. But times are changing. With<br />

COP26 making headline news across the<br />

world, climate change is being taken seriously.<br />

In line with the UK’s landmark Net Zero<br />

Strategy, from <strong>April</strong> <strong>2022</strong> new legislation will<br />

require Britain’s largest businesses to disclose<br />

climate-related financial information. The aim<br />

is to get businesses to consider the risks and<br />

opportunities they face as a result of climate<br />

change and encourage them to set out their<br />

emission reduction plans and sustainability<br />

credentials. But companies of all sizes and<br />

across all sectors are now examining their<br />

own strategies to achieve net zero by the<br />

earliest date possible.<br />

For many businesses this will require<br />

significant changes in the coming years, from<br />