food Marketing - Technology 2/2023

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2/23<br />

Vol. 37 • 31377<br />

ISSN 0932-2744<br />

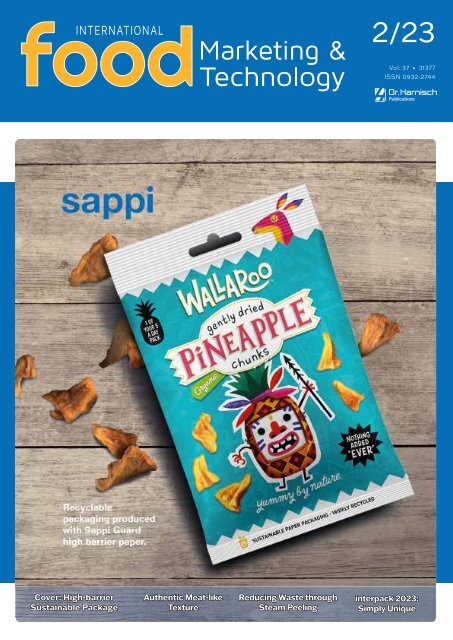

Cover: High-barrier<br />

Sustainable Package<br />

Authentic Meat-like<br />

Texture<br />

Reducing Waste through<br />

Steam Peeling<br />

interpack <strong>2023</strong>:<br />

Simply Unique

We understand how you strive for constant<br />

product quality and optimized costs.<br />

CONSISTENT<br />

+ CONFIDENT<br />

You are poised to meet your safety and quality requirements<br />

while optimizing resources and securing process repeatability.<br />

Endress+Hauser helps you to improve your processes:<br />

• With a hygienic, robust product portfolio that meets international standards<br />

• With access to traceable, reliable and real-time data<br />

• With a network of industry application experts that help you ensure greater<br />

plant availability throughout the product life cycle<br />

Key No. 103856<br />

Do you want to learn more?<br />

www.eh.digital/3G9EUcK

Editorial<br />

Many sides to sustainable <strong>food</strong> packaging<br />

Food packaging today is about more<br />

than protecting the product. This may<br />

still be the most important function.<br />

However, design and material also have<br />

a large influence on buying decisions,<br />

because more consumers want <strong>food</strong><br />

that comes in a sustainable package.<br />

Without any packaging, however, most<br />

<strong>food</strong>s cannot be transported, stored<br />

or sold, and in their unpackaged state<br />

they would prematurely spoil. The<br />

protective wrapping keeps harmful<br />

influences like light, oxygen or humidity<br />

away and prevents soiling or damage.<br />

But packaging is not only there to<br />

extend freshness and shelf-life.<br />

Consumers are increasingly demanding<br />

environmentally friendly packaging. It is<br />

supposed to be recyclable or made from<br />

sustainable materials, yet offer optimal<br />

protection for perishable products. And<br />

this means that especially today <strong>food</strong><br />

packaging is a real high-tech product.<br />

For aroma-proof <strong>food</strong> packaging,<br />

suitable materials are polyamide films<br />

with so-called bi-axial orientation,<br />

used for example to package oily, fatty<br />

<strong>food</strong>s or frozen <strong>food</strong>s. The demand for<br />

these films, which owe their special<br />

properties to a certain stretching<br />

process, continues to rise and so does<br />

the demand for relevant film stretching<br />

lines.<br />

Packaging manufacturers in the <strong>food</strong><br />

industry are obliged to follow strict<br />

legal regulations which among other<br />

things demand a high level of hygiene.<br />

But hygiene is more than just cleaning<br />

and disinfecting. Many applications,<br />

for example in the <strong>food</strong> sector, use<br />

compressed air. If this comes into<br />

direct contact with <strong>food</strong> or is used for<br />

cleaning, it must not be contaminated<br />

with germs, either.<br />

The upcoming interpack event in<br />

Dusseldorf, Germany, will cover all<br />

these packaging topics and many more!<br />

interpack is an important building block<br />

in the innovation cycle of the packaging<br />

and related process industries. After a<br />

six-year break, numerous innovations<br />

for all user areas will be on display,<br />

including <strong>food</strong>, beverage, confectionery<br />

and bakery products.<br />

Megatrends such as sustainability and<br />

digitalization, numerous economic<br />

and ecological, but also political and<br />

social changes and challenges are of<br />

concern for companies and provide<br />

a boost to innovation this year. The<br />

circular economy will be a top issue:<br />

seemingly a simple model but also<br />

all-encompassing and posing major<br />

challenges in many areas. In the<br />

age of climate change, the goal is to<br />

Ian Healey<br />

Editor-in-Chief<br />

produce as little unrecyclable waste<br />

as possible. Hand in hand with this<br />

goes the need to conserve resources.<br />

When it comes to transformation<br />

processes, little can be done<br />

without digital technologies. Big<br />

data, augmented reality and remote<br />

machine maintenance have long since<br />

found their way into assembly shops<br />

and machine fleets.<br />

Whatever your special focus, the<br />

interpack is a must for industry leaders.<br />

We look forward to seeing you there!<br />

Photo: GS<br />

Cheers<br />

If you like it – subscribe!<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

3<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

<strong>Technology</strong> & <strong>Marketing</strong><br />

International Magazine September 2022 ISSN 2628-5851<br />

your easy way to stay updated<br />

Contents<br />

<strong>Technology</strong> & <strong>Marketing</strong> 3/22<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> April <strong>2023</strong><br />

1 Editorial<br />

58 Impressum<br />

Ingredients<br />

8 Black Swan Hydrocolloid Events<br />

11 Bespoke Solutions for Soothing Colic<br />

12 Easy Way to an Authentic, Meat-Like Texture<br />

15 Variety of Chilies: Something for Every Taste<br />

Ingredients: Plant-Based Food, Black Soldier Flies, Fibers and Cellulose, Grain Acceptability<br />

Processing: Wet Pet<strong>food</strong> Processing, Quality Control, Heat Exchangers, Mixing<br />

Packaging: Pouches and Alutrays, No Waste, Weighing Investment<br />

Free trial issue at <strong>food</strong>@harnisch.com<br />

PetFood PRO magazine<br />

wants to emphasize the<br />

high level of quality and<br />

care in the production of pet<br />

<strong>food</strong> through the choice of<br />

ingredients, the choice of<br />

technology and the choice<br />

of packaging materials.<br />

Processing<br />

24 Behind the Scenes of Your Favorite Sweets: The<br />

Intricate Process to Create Classic Desserts<br />

28 How the Best Steam Peelers can Significantly Reduce<br />

Food Waste on Vegetable Processing Lines<br />

34 New Micropilot Radar Level Sensor: Designed for<br />

Special Demands<br />

38 Bag Intake and Control Screening Machine Vib &<br />

Press – New Generation Even More Efficient<br />

39 New Advanced Benchtop Meter Series Extended with<br />

3 New Models<br />

Packaging<br />

ine March 2022 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong><br />

1/22<br />

International Magazine May 2022 ISSN 2628-5851<br />

<strong>Technology</strong> & <strong>Marketing</strong> 2/22<br />

6 A ‘Fruitful’ Collaboration to Sustainably Package<br />

Healthy Organic Snacks New High-Barrier Paper<br />

Delivers Great Impact for Wallaroo Foods<br />

44 The Pinnacle of Food Packaging<br />

52 Consolidated Competence for the Process Industry<br />

54 Baked Goods: Automated Packaging for Sensitive<br />

Goods<br />

Departments<br />

Ingredients: Insect Proteins, More Sustainable BARF, Pet Nutrition, Plant-Based Food<br />

Processing: Healthy Kibbles, Hygienic Cooking, Modular and Flexible Solutions<br />

Packaging: Recyclable Packaging and Bags, Inline Tray Sealer<br />

<strong>Marketing</strong>: Vet's Corner, Pet Food Competence Network, Anuga FoodTec, IFFA, Interzoo<br />

Ingredients: Trusting Suppliers, Stress Relief, Humic Acids for Gut Health, Wheat Textures<br />

www.pet<strong>food</strong>pro-mag.com<br />

Processing: Customized Solutions for BARF, Safe Processing, Cutting, Grinding and Mixing<br />

Packaging: Perfect Packs, Fastening Solutions, Bags and Pouches, Sustainable Sealing<br />

<strong>Marketing</strong>: Interzoo 2022, Insect Breeding, Competence in Packaging, Too Much Protein?<br />

18 Vita<strong>food</strong>s Europe<br />

22 CFIA<br />

40 Firms<br />

44 Interpack

1/20/23 1:31 PM<br />

Vol. 37 • 31377<br />

ISSN 0932-2744<br />

ting <strong>Technology</strong><br />

ur product.<br />

rschel.com<br />

Cover: High-barrier<br />

Sustainable Package<br />

Authentic Meat-like<br />

Reducing Waste through<br />

Texture<br />

Steam Peeling<br />

2/23<br />

interpack <strong>2023</strong>:<br />

Simply Unique<br />

Cover:<br />

Wallaroo Foods was driven by its conviction<br />

to being sustainable in every respect<br />

and to package its products using only<br />

paper-based material. “We’ve seen other<br />

small brands attempt to master the<br />

transition, but they soon run out of steam<br />

on their quest to find paper-based packaging<br />

material. However, going down<br />

the plastic route was never an option for<br />

us,” remembers Abhisek Kanoi. The OPM<br />

Group, Wallaroo’s label and packaging<br />

partner, introduced the company to<br />

Sappi’s Guard Gloss 4-OHG paper-based<br />

high-barrier product.<br />

Our Cover Story starts on page 6.<br />

Photo: SAPPI Europe<br />

Ingredients: Meat-free texture<br />

There’s no denying that the market for plant-based meat<br />

alternatives is booming. Entering the segment may still feel like<br />

a huge step for meat-processing companies, or <strong>food</strong> manufacturers.<br />

That’s because, the ease with which plant-based<br />

alternatives can be produced may not be immediately obvious.<br />

However, it’s entirely possible for the processing of meatalternative<br />

ingredients to closely resemble that of conventional<br />

meat mixtures. See page 12<br />

Processing: Steam peeling success<br />

Food waste is financial waste, yet when processing lines peel<br />

vegetables, they often throw away huge amounts of raw material.<br />

Food losses can be as high as 30% during mechanical<br />

peeling and 20% with low-tech steam peelers – and much of<br />

this lost revenue is preventable. Rather than accepting this,<br />

vegetable processors can do something about it. There are<br />

four compelling reasons to do this. Eamonn Cullen shares his<br />

experience on page 28<br />

Packaging: Simply Unique<br />

The <strong>food</strong> sector is among the most favored target groups of<br />

visitors to interpack, and this shows in the breadth of their<br />

presentation. The global demand for packaged <strong>food</strong>s is increasing.<br />

In saturated markets with strong incomes, conscious<br />

consumption and consumer behavior also shifts towards<br />

sustainability, regional produce, organic <strong>food</strong> or fair trade,<br />

and this includes packaging. Find out what the Exhibition<br />

Director, <strong>food</strong> Thomas <strong>Marketing</strong> Dohse, & <strong>Technology</strong> has to say, • on February page 46 2016<br />

Key No. 102163

Cover Story<br />

A ‘Fruitful’ Collaboration to Sustainably<br />

Package Healthy Organic Snacks<br />

New High-Barrier Paper Delivers Great<br />

Impact for Wallaroo Foods<br />

One hundred percent product-safe packaging, meeting high consumer expectations in terms of sustainability<br />

and the need for appealing, high-impact design were the challenges Oxfordshire-based Wallaroo Foods<br />

was up against. Sappi, the leading manufacturer of packaging and specialty papers, contributed to an ideal<br />

solution with its Guard Gloss 4-OHG high-barrier paper.<br />

Sustainable through and through<br />

“To encourage young people to make<br />

better <strong>food</strong> choices by questioning<br />

where their <strong>food</strong> comes from, what<br />

it is made of and its impact on our<br />

environment,” is Wallaroo Foods’ stated<br />

mission. The producer of organic<br />

tropical fruit snacks creates tasty, fun<br />

<strong>food</strong> for kids that is healthy, nutritious<br />

and guilt-free.<br />

Since it was established in 2018,<br />

Wallaroo has focused on sustainability<br />

throughout its entire production<br />

process. The company works with<br />

small community producers in Africa to<br />

ensure that their organic fruit is grown<br />

with respect for the environment, and<br />

to guarantee a fair and sustainable<br />

livelihood for growers. Only perfectly<br />

ripe fruit is harvested and moved<br />

directly to a certified drying facility<br />

located right next to the fields. This<br />

ensures that only the freshest fruit<br />

is used and that <strong>food</strong> waste during<br />

transportation is reduced to a minimum.<br />

The fruit is cut and then dried using<br />

solar power in state-of-the-art drying<br />

facilities. No sugar, salt, preservatives<br />

or sulphites are added and consumers<br />

can enjoy the pure taste of fruit. To keep<br />

the company’s carbon footprint as low<br />

as possible, the dried and packed fruit<br />

is forwarded by ship.<br />

Sustainability in content and<br />

packaging<br />

Wallaroo had been searching for a<br />

packaging solution for its dried fruit<br />

snacks to meet its exceptionally high<br />

standards. This turned out to be<br />

quite a challenge. Wallaroo wanted<br />

Abhisek Kanoi, Co-Founder of Wallaroo<br />

Foods<br />

an affordable recyclable solution<br />

avoiding the use of any synthetic<br />

materials. “It was a difficult process for<br />

us,” says Abhisek Kanoi, Co-Founder of<br />

Wallaroo Foods. “In the UK, there are<br />

no common standards and so many<br />

differences between the many options<br />

After three months of trials, the quality offered by the 91 g/m² grammage proved to be the perfect choice. The pouches demonstrated excellent stability<br />

while filling. Sappi’s Guard Gloss also excelled in terms of barriers and sealing.<br />

6<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Cover Story<br />

we investigated. Even some of the<br />

best recyclable solutions we examined<br />

contained a large share of plastics –<br />

something we wanted to pare down to<br />

the absolute minimum.”<br />

Wallaroo was driven by its conviction<br />

to being sustainable in every respect<br />

and to package its products using only<br />

paper-based material: “Four years ago,<br />

this was a rarity in the UK,” remembers<br />

Abhisek Kanoi. “We’ve seen other small<br />

brands attempt to master the transition,<br />

but they soon run out of steam on their<br />

quest to find paper-based packaging<br />

material. However, going down the<br />

plastic route was never an option for<br />

us.” The OPM Group, Wallaroo’s label<br />

and packaging partner, introduced the<br />

company to Sappi’s Guard Gloss 4-OHG<br />

paper-based high-barrier product.<br />

Impeccable printing, processing<br />

and sealing results<br />

Arnie Ellison, New Business Development<br />

Director at OPM, was<br />

immediately impressed with Sappi’s<br />

Guard Gloss: “We were surprised to<br />

experience outstanding runnability<br />

using normal inks or matt finish. With<br />

its glossy premium look and feel,<br />

Sappi’s one side single-coated paper<br />

made quite an impression on us.”<br />

Guard Gloss’ processing properties<br />

are also exceptional. The small,<br />

irregularly shaped fruit pieces proved<br />

difficult to process and it took some<br />

time to adjust the machines. Wallaroo<br />

never lost sight of its goal and finally<br />

succeeded in packaging the fruit<br />

snacks in paper at a processing<br />

speed of 40 bags a minute. “Initially,<br />

Oxfordshire-based Wallaroo Foods had<br />

been searching for an affordable recyclable<br />

packaging solution for its dried fruit snacks to<br />

meet its exceptionally high standards.<br />

we tested only one line with dried<br />

fruit such as mango and pineapple,”<br />

remembers Abhisek Kanoi. “After<br />

three months of trials, the quality<br />

offered by the 91 g/m² grammage<br />

proved to be the perfect choice.” The<br />

pouches demonstrated excellent<br />

stability while filling. Sappi’s Guard<br />

Gloss also excelled in terms of sealing.<br />

“The high-barrier paper is significantly<br />

better than all other materials we<br />

tested. It not only prevents the<br />

package from popping open, it can<br />

also be sealed using less heat, which<br />

saves energy during the process,”<br />

confirms Parminder Singh, Director<br />

of Complete Packaging Solutions<br />

Ltd., carrying out the packaging for all<br />

Wallaroo products.<br />

An Aha moment for consumers<br />

with Guard Gloss<br />

Wallaroo’s customers, who can now<br />

purchase the fruit snacks in selected<br />

organic supermarkets in the UK and<br />

Switzerland, online, in cafes, offices and<br />

hotels, as well as in venues targeted to<br />

The OPM Group, Wallaroo’s label and<br />

packaging partner, introduced the company to<br />

Sappi’s Guard Gloss 4-OHG paper-based highbarrier<br />

product.<br />

children such as zoos, were initially<br />

sceptical about the sustainability of the<br />

solution due to the glossy premium look<br />

of the packaging: “They were surprised<br />

to find out that the package is entirely<br />

paper-based. They literally experienced<br />

an Aha moment – especially when<br />

tearing open the package,” remembers<br />

Abhisek Kanoi.<br />

After successfully deploying the<br />

high-barrier paper for its fruit snacks,<br />

Wallaroo now has ambitious plans<br />

to use it for even more challenging<br />

applications: “We are currently<br />

testing Guard Gloss with naturally oily<br />

products such as roasted corn, beans<br />

and nuts, which usually leave greasy<br />

spots on paper. If everything works<br />

out as planned, we will be introducing<br />

a new generation of pouches to our<br />

customers by early next year,” confirms<br />

Abhisek Kanoi. A promise Wallaroo<br />

Foods is confident it can keep thanks<br />

to Sappi’s Guard Gloss paper-based<br />

solution featuring a heat-sealable, highbarrier<br />

coating that also guarantees<br />

effective grease barrier properties.<br />

grease barrier properties.<br />

fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

7

Ingredients<br />

Black Swan Hydrocolloid Events<br />

by Dennis Seisun & Nesha Zalesny<br />

Some developments in hydrocolloids<br />

are hard to believe even if there is no<br />

question that we are living them. Some<br />

prices have reached levels unheard or<br />

undreamt of. There is tightness if not<br />

outright shortage in supply of some<br />

key hydrocolloids. The pandemic and<br />

other factors have resulted in delivery<br />

delays of many months, not to mention<br />

shipping charges increased by a factor<br />

of 10 or more in 2020-2021. Regulatory<br />

issues combined with political<br />

actions have resulted in nightmarish<br />

documentation and compliance<br />

requirements. These were a fact<br />

of life over several recent years for<br />

both, a supplier of hydrocolloids and<br />

a user/buyer of hydrocolloids. They<br />

can be considered black swan events<br />

which, until they happened would have<br />

been deemed highly improbable if<br />

not impossible. For those not familiar<br />

with the term, swans were believed<br />

to be ONLY white. Black swans were<br />

thought to be non-existent until they<br />

were discovered in Australia. What<br />

was deemed impossible for many<br />

hydrocolloids became reality. The<br />

years 2020-2022 are the peak of ‘covid<br />

19’ years with special considerations.<br />

The covid pandemic itself, cannot<br />

really be called a Black Swan event.<br />

Similar if not worse pandemics<br />

have been experienced and a future<br />

one has been forecast with some<br />

certainty. The pandemic, however, did<br />

enable and accelerate the advent of<br />

several hydrocolloid Black Swans. An<br />

interesting book on the subject of Black<br />

Swans is titled, “The Black Swan: The<br />

Impact of the Highly Improbable” by<br />

Nassim Taleb. Let us consider in more<br />

detail now, some Black Swan events in<br />

hydrocolloids.<br />

Pricing is a key factor of interest to<br />

buyers and producers of hydrocolloids.<br />

Producers wonder, “How much can<br />

I get for my hydrocolloid….” And<br />

buyers think, “How little can I offer to<br />

get the hydrocolloid I need?”. Several<br />

years ago at one of IMR’s hydrocolloid<br />

conferences, the theme of “Open<br />

Innovation” was the buzz phrase du jour.<br />

Closer co-operation between supplier<br />

and buyer would not only result in a<br />

better business model for both parties,<br />

it would offer stability in supply and<br />

price. Most important, it would foster<br />

an environment of innovation on both<br />

sides of the transaction. Dynamics of<br />

today’s supply chain have changed this<br />

short lived philosophy. Negotiations<br />

are back to more traditional adversarial<br />

negotiations. Of course, contracts<br />

continue to be negotiated but they are<br />

not set in stone and indeed are not set<br />

at all in cases of force majeur. Annual<br />

contracts and multi-year contracts<br />

were common in the past. Now many<br />

Table 1: Source: IMR Quarterly Review of Food Hydrocolloids – Tableau Analysis<br />

contracts, if offered are for 6 months<br />

or 3 months only.<br />

A few black swans in pricing have<br />

appeared for several hydrocolloids<br />

including for example, LBG, xanthan<br />

gum and some of the more popular<br />

starches. LBG is used nearly exclusively<br />

in <strong>food</strong> and pet <strong>food</strong> applications.<br />

Xanthan gum and starches, however,<br />

have very large industrial and oilfield<br />

applications. The historical pricing<br />

of these three key hydrocolloids was<br />

relatively steady until a few years ago.<br />

Nothing in past pricing trends could<br />

have allowed a supplier or user to<br />

envision the dramatic changes which<br />

occurred in 2020-2022 and continue<br />

into <strong>2023</strong>.<br />

Each hydrocolloid ‘Black Swan’ is<br />

discussed below:<br />

There was an LBG crisis in 1994-1995<br />

which was a first in the history of LBG<br />

until then. Previous prices tripled<br />

and quadrupled. In Q1-1993 LBG enduser<br />

prices were about US$6.50/kg<br />

(roughly 2 ½ kg of seeds are needed<br />

per kg of LBG). By Q1-1994, the price<br />

of LBG had more than quadrupled to<br />

US$12.75/kg. (Source IMR’s Quarterly<br />

Review of Food Hydrocolloids). There<br />

was a dramatic drop by 1996 and<br />

then a continued price drop. By early<br />

1999, market pressures had driven<br />

LBG prices back down to $6.60/kg<br />

and even a little below the pre-crisis<br />

levels of 1993. Things remained<br />

steady for several years. Although<br />

there was some fluctuation, LBG<br />

prices never exceeded US$10.00/kg.<br />

Never until 2020 that is. Starting in<br />

2017-2018 a steady price increase led<br />

to a crescendo of increases in 2020<br />

through 2022. The LBG situation of<br />

2020-2022 made the prior “crisis”<br />

of 1994-1995 seem like a blip. The<br />

situation for LBG became so dire in<br />

2020-2022 that spot prices reached<br />

a peak of €100.00/kg ($105/kg) IF one<br />

could get it. Of course prices have<br />

since crashed albeit remaining well<br />

above the $6.60/kg of decades ago. A<br />

black swan event which no producer<br />

8 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

The world’s most successful IBC system.<br />

Now with double protection.<br />

FOODCERT + DUALPROTECT<br />

Dual leakage protection through liner and inner bottle<br />

Delivered “ready to fill” for the highest<br />

degree of user friendliness<br />

The liner automatically unfolds as the container is filled<br />

The irradiated liner protects the filling product<br />

against contact with oxygen or condensate<br />

Prevents oxidation, vitamin depletion<br />

and microbial contamination<br />

Extends product shelf life – without<br />

the need for preservatives<br />

Secure protection of the filling product quality<br />

Key No. 104139<br />

BAUCH & MÜLLER WERBEAGENTUR GMBH<br />

4 – 10 MAY <strong>2023</strong><br />

DÜSSELDORF<br />

HALL 10<br />

BOOTH D22|E34<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

Discover the new SCHÜTZ packaging with dual filling product protection<br />

for your <strong>food</strong> applications. ECOBULK FOODCERT + DUALPROTECT are supplied<br />

ex-works with a high-quality LDPE liner including an oxygen barrier. Filling can take<br />

place through the top opening or the outlet valve. Your filling product is hermetically<br />

sealed in the liner and completely protected against ambient conditions. The robust<br />

outer bottle provides the highest level of safety and dependability – even for the<br />

most tough transportation conditions – UN hazardous goods approval included.<br />

Find out more at www.schuetz-packaging.net<br />

Schütz GmbH & Co. KGaA<br />

Schützstraße 12<br />

D-56242 Selters<br />

Phone +49 2626 77 0<br />

info1@schuetz.net<br />

www.schuetz.net<br />

9

Ingredients<br />

or user of LBG would have forecast<br />

the 2020-2022 scenario for LBG. LBG<br />

prices are heading back down as<br />

shown in table 1.<br />

Another Black Swan event was the<br />

case of guar gum in 2011-2013 when<br />

it’s use in fracking combined with<br />

horizontal drilling resulted in undreamt<br />

of prices. Tara gum has always been<br />

viewed as a lower priced cousin of LBG.<br />

The guar crisis, however, seemed to<br />

have caused a temporary inversion<br />

between LBG and tara prices during<br />

2011-2013. Tara is now back at its<br />

trailing LBG position as shown in table<br />

2 below.<br />

Xanthan prices have been through<br />

strong cycles since its introduction to<br />

<strong>food</strong> users in the early 1970’s. Prices<br />

were very firm in the 1970’s and ‘80’s<br />

when there was only one supplier in the<br />

world and it’s use started to become<br />

ubiquitous. Then came European<br />

competition in the 1980’s and then<br />

came Chinese competition in the<br />

late 1990’s which drove prices down<br />

even further. Prices plummeted from<br />

over $13.00/kg in the 1980’s to about<br />

$4.00/kg in mid-2000’s. One Chinese<br />

producer had a ‘xanthan special’<br />

sign at an FIE exhibition around that<br />

time, offering xanthan at $2.00/KG!!<br />

By 2020 xanthan prices had slowly<br />

edged back up to around $10.00/kg<br />

before starting a rapid increase to the<br />

current $20.00/kg, again, IF supply<br />

can be found. Different reasons for<br />

this difficult situation to those which<br />

caused the LBG scenario. The net<br />

result, however, is the same, very high<br />

prices and poor availability, neither of<br />

which was expected or forecast by any<br />

of the players in this market.<br />

In the case of starches and to<br />

quote past IMR reports, “There are<br />

hydrocolloid of cyclic availability<br />

and price, and those with assured<br />

availability and steady price.”<br />

Starches of all types have always,<br />

until now, been in the latter category<br />

i.e. no problem in availability and<br />

steady in price. Indeed, starches and<br />

starch supply was so reliable that<br />

some contracts were established on<br />

verbal agreements based on historical<br />

past use. This is no longer the case<br />

for several workhorse starches, a<br />

shortage of which would have been<br />

unthinkable until it happened, another<br />

Black Swan event in hydrocolloids.<br />

The reasons for these unpredictable<br />

scenarios are varied, and now in<br />

hindsight may seem evident, but then<br />

hindsight is always much clearer than<br />

the hazy future. In the case of LBG<br />

an increase in demand in plant based<br />

beverages, poor raw material harvests<br />

and production issues which caused<br />

a reduction in supply. For xanthan<br />

gum the explanation is primarily<br />

related to Chinese supply issues<br />

combined with regulatory and political<br />

considerations. Lack of investment<br />

in capacity by Western producers left<br />

them ill prepared to satisfy a rapid<br />

increase in demand. The reason(s) for<br />

Table 2: Source: IMR Quarterly Review of Food Hydrocolloids – Tableau Analysis<br />

Dennis Seisun and Nesha Zalesny are partners<br />

with IMR International LLC and authors of the<br />

Quarterly Review of Food Hydrocolloids, as well<br />

as hosts of the annual Global Food Hydrocolloid<br />

Conference, this year in Malta<br />

the tight situation in some starches<br />

is more difficult to explain. Lack of<br />

capacity increases perhaps. A strong<br />

demand in industrial packaging, the<br />

Amazon effect. Poor crop harvests.<br />

Reduced raw material from Ukraine.<br />

The net result is a tightness which has<br />

forced some supply agreements to be<br />

cancelled or re-negotiated.<br />

These events in hydrocolloids over<br />

the last few years, have taken a<br />

market estimated at about $7.0-8.0<br />

billion in value to over $15.0 billion. Of<br />

course, much of this value increase is<br />

directly related to price and is likely to<br />

decline as sky high prices abate. There<br />

are, however, dynamics of volume<br />

increases that have contributed to this<br />

unpredictable growth in market value.<br />

With this brief look at a few hydrocolloid<br />

Black Swans, is it possible to look to<br />

the future and predict any other similar<br />

events that could upend the status<br />

quo? One can try but the very concept<br />

of Black Swans is that they are deemed<br />

improbable or impossible, until that is,<br />

they happen. A safer strategy would be<br />

a closer and more trusting association<br />

between supplier and buyer whereby<br />

the pain AND the gain, when Black<br />

Swans arrive, are shared equitably. An<br />

idyllic concept but worth aspiring to. Do<br />

you have any Black Swan hydrocolloid<br />

stories? Please share.<br />

fmt<br />

10 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Bespoke Solutions for Soothing Colic<br />

Laïta Nutrition are putting their expertise to good use<br />

New-born babies have very specific<br />

nutritional requirements, in order to<br />

help them grow and develop. Parents<br />

are increasingly demanding when it<br />

comes to the quality and <strong>food</strong> safety<br />

credentials of the products they give to<br />

their children. They are looking for real<br />

solutions capable of soothing the most<br />

common ailments suffered by babies,<br />

such as reflux and colic. Studies<br />

show that between 20% and 25% of<br />

babies suffer from colic in their first<br />

four months, with 66% experiencing<br />

problems with regurgitation. Acutely<br />

aware of the impact these conditions<br />

can have on babies and their families,<br />

the experts at Laïta Nutrition has a<br />

range of special recipes designed to<br />

help reduce colic in infants.<br />

Chief among these solutions is<br />

Laïta’s AC milk, available in a range<br />

of formulation options. The formula<br />

may include FOS and GOS for their<br />

prebiotic properties, Omega 3 oils,<br />

not always found in baby formula and<br />

a low-lactose formula, which helps<br />

limit fermentation and gas production<br />

in the intestine, another common<br />

symptom of colic.<br />

Laïta Nutrition’s breadth of expertise<br />

is also reflected in the company’s<br />

anti-reflux solutions. Laïta’s AR<br />

powdered milk (FSMP) is designed<br />

for infants displaying symptoms<br />

of gastro-oesophageal reflux or<br />

regurgitation. This product uses<br />

carob as a thickening agent, and can<br />

be combined with starch to delay the<br />

onset of hunger between feeds. It can<br />

be customized as required, with the<br />

addition of probiotics, FOS and GOS.<br />

• Reduced-lactose formulations are<br />

available, with the option to include<br />

partially hydrolysed whey protein.<br />

All in all, Laïta Nutrition offers a wide<br />

range of products designed to help<br />

reduce regurgitation and colic and<br />

improve the digestive comfort of infants.<br />

The many customization options on<br />

offer ensure that clients can choose the<br />

right forms, textures and compositions<br />

to suit their exact requirements. fmt<br />

Take your Gummy<br />

to the Next Level<br />

Beauty gummies<br />

Sugar reduction and<br />

protein enrichment<br />

Starch-free gelatin<br />

gummy production<br />

Laïta also help industrial partners to<br />

create specialized products such as<br />

milk formulas thickened with starch.<br />

Laïta has the flexibility and knowhow<br />

to tailor formulations to clients’<br />

precise requirements, incorporating:<br />

• DHA, EPA, ARA, Vitamins A, C<br />

and D, plus Iron, FOS/GOS to help<br />

reduce reflux and ensure maximum<br />

digestive comfort.<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong><br />

GELITA AG · Uferstr. 7 · 69412 Eberbach · Germany · www.gelita.com<br />

Key No. 104787

Ingredients<br />

Easy Way to an Authentic, Meat-Like<br />

Texture<br />

How texturates made from wheat, soy and pea proteins can be used to produce authentic plant-based meat<br />

alternatives<br />

There’s no denying that the market<br />

for plant-based meat alternatives<br />

is booming. However, entering the<br />

segment may still feel like a huge<br />

step for meat-processing companies,<br />

butchers or other <strong>food</strong> manufacturers,<br />

who have not previously considered<br />

expanding their offerings to include<br />

vegan and vegetarian products. That’s<br />

because, the ease with which plantbased<br />

alternatives can be produced<br />

may not be immediately obvious to<br />

traditional processors. Yet, depending<br />

on the raw material, it’s entirely possible<br />

for the processing of meat-alternative<br />

ingredients to closely resemble that of<br />

conventional meat mixtures.<br />

Meat-like processing<br />

With GoodMills Innovation’s VITATEX®<br />

line of texturates made from wheat,<br />

soy and pea proteins, this process is<br />

particularly straightforward. That’s<br />

because the texturates have many<br />

similarities to a conventional meat<br />

mass, which means manufacturers<br />

can use machines commonly used in<br />

the meat industry to produce plantbased<br />

ground beef, patties, nuggets or<br />

cutlets as they do for meat processing.<br />

The texturates pre-swell with<br />

water. In a mixer, for example, the<br />

binding system, oil, flavoring and, if<br />

required, further water is added until<br />

a homogeneous and pleasant-tasting<br />

mass is obtained. In a similar manner<br />

to minced meat mass, the mixture is<br />

processed in a cutter or mincer until<br />

it is the appropriate size for the final<br />

application. The resulting basic mass<br />

is now ready to be formed.<br />

As VITATEX® can be used to produce<br />

vegetable products in meat processing<br />

plants, there’s no need to invest in<br />

new machinery and, in addition, the<br />

manufacturer benefits from the<br />

processing know-how of the product<br />

developers and application engineers<br />

at raw material stage. The range<br />

is suitable for various vegan and<br />

vegetarian applications, replicating<br />

the authentic sensory profile of<br />

conventional pork, beef, poultry and<br />

fish-based products.<br />

Why texture is key<br />

Consumers – especially flexitarians –<br />

still expect a realistic meat-like culinary<br />

experience from meat substitutes.<br />

The task for <strong>food</strong> manufacturers,<br />

therefore, is to authentically replicate<br />

the original product in terms of<br />

texture, sensory characteristics and<br />

appearance. This is called “meat<br />

mimicking”. Texture plays a vital<br />

role in this process, is crucial for<br />

an authentic meat alternative and<br />

decisive in consumer purchasing<br />

decisions: If the texture is not right,<br />

the product will not be perceived to<br />

be a realistic meat alternative and will<br />

have no ‘shelf appeal’ as a result. So<br />

there is no room for compromise and<br />

special attention to the fibrousness<br />

of the components used is therefore<br />

vital for processors.<br />

In the production of the VITATEX®<br />

range, GoodMills Innovation has drawn<br />

on more than 20 years of experience<br />

in the texturization of vegetable<br />

proteins. These insights are a crucial<br />

part of the company’s texturizing<br />

expertise, for example when it comes<br />

to authentically recreating a chicken<br />

nugget with long fibers or a burger<br />

patty with short fibers. The bite and<br />

mouthfeel are completely different<br />

for each product and so, accordingly,<br />

12 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Innovation in a<br />

Time of Crisis:<br />

Can We Future-Proof the Food System?<br />

IFT FIRST Registration Is Now Open!<br />

Be FIRST to<br />

Save Your Seat!<br />

Register today at iftevent.org.<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

13<br />

Key No. 104910

Ingredients<br />

carefully selected flavors and spices,<br />

convincing results can be achieved.<br />

the texturate used must be<br />

carefully selected. Its fibrousness is<br />

determined in part by the properties<br />

of the protein, which affect elasticity,<br />

structure-forming capabilities and<br />

general texture. Some texturates are<br />

particularly suitable for short-fibered<br />

masses such as minced meat, while<br />

others are perfect for fibrous end<br />

products such as poultry or cutlets.<br />

Long-fiber protein structures are best<br />

achieved with wheat and soy proteins.<br />

Nevertheless, it is not just the starting<br />

material that’s important, as expertise<br />

in the extrusion process determines<br />

bite, texture and mouthfeel, which are<br />

all vital too.<br />

Convincing results<br />

Even though VITATEX® texturates<br />

are particularly convincing with their<br />

texture and fiber-like mouthfeel, taste<br />

and appearance are also key. That’s<br />

why it’s important to realize that<br />

off-flavors of vegetable texturates<br />

can be a challenge. Depending on<br />

the raw material, cereal and earthy<br />

notes must be minimized or masked.<br />

VITATEX® texturates have a neutral<br />

to raw material-typical taste. However,<br />

depending on customer expectations<br />

and product concept, this can be<br />

masked.<br />

Careful pre-selection of raw materials<br />

enables higher product quality.<br />

GoodMills Innovation works with<br />

selected farmers across projects to<br />

source the best raw materials with<br />

defined quality characteristics. But an<br />

almost “real” imitation meat product<br />

will not work without flavor. Yet with<br />

Whether <strong>food</strong> manufacturers choose<br />

the wheat, soy or pea variety, or a<br />

mixture, depends largely on the<br />

product concept and positioning<br />

they are aiming for. Wheat and soy<br />

extrudates are already established,<br />

and the fact that the products are also<br />

available with EU origin brings obvious<br />

advantages. Peas combine regionality,<br />

sustainable cultivation and tradition,<br />

and are thus particularly suitable for a<br />

target group that makes its purchasing<br />

decisions very consciously. With all<br />

three raw materials, common meat<br />

and fish applications can be faithfully<br />

imitated.<br />

Recognizing demand, retaining<br />

customers<br />

Demand for alternative products<br />

based on vegetable proteins has<br />

been rising steadily in recent years,<br />

and further growth is foreseeable.<br />

The most relevant target group<br />

is “flexitarians” - people who want<br />

to reduce their meat consumption<br />

for health, ethical or environmental<br />

reasons, but do not follow a consistent<br />

vegan or vegetarian diet and<br />

are open to new product concepts.<br />

Accordingly, in multi-person households,<br />

statistically there are almost<br />

always people who prefer to reach for<br />

plant-based alternatives. So, in order<br />

to offer the right solution for everyone<br />

at the dinner table, <strong>food</strong> and meat<br />

manufacturing companies should<br />

seriously consider expanding their<br />

portfolios to include authentic plantbased<br />

concepts.<br />

fmt<br />

14 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Variety of Chilies:<br />

Something for Every Taste<br />

Anyone who enjoys spicy <strong>food</strong> likes to reach for chili peppers. But not all chilies are the same: there are<br />

countless chili varieties and offshoots. They differ in color, shape, taste and degree of spiciness. Hotness<br />

is measured on a scale of 0 to 10, or in Scoville units, which range from 0 to the millions. Chili peppers are<br />

therefore very rich in variation, and their range of application in the kitchen and in the <strong>food</strong> industry is also<br />

diverse. In dried form, chili peppers are used to spice up seasonings, frozen <strong>food</strong>s and convenience <strong>food</strong>s.<br />

In addition, chili peppers are an important ingredient in many sauces and pastes. Import Promotion Desk<br />

(IPD), a project of the German Federal Ministry for Economic Cooperation and Development, supports<br />

chili producers from South America in bringing their products to the European market. One of them is the<br />

company “Uchu Spice” from Ecuador, which specializes in the cultivation and production of a wide range of<br />

chili varieties.<br />

Hot peppers<br />

Both chili peppers and sweet peppers<br />

are descended from the bell pepper<br />

plant genus (Capsicum). Chili peppers<br />

grow on shrubby plants that can reach<br />

a height of up to one and a half feet. We<br />

usually call the fruit a pod, even though<br />

botanically it is a berry. Chili peppers<br />

are rich in vitamins – especially vitamin<br />

C and B1.<br />

The best known characteristic of the<br />

chili pepper is its spiciness. However,<br />

it not only dominates the taste, it also<br />

has an antibacterial effect. Capsaicin<br />

and other substances in the flesh of the<br />

fruit are responsible for the spiciness<br />

of chili. A particularly high proportion<br />

of capsaicin is found in the placenta, i.e.<br />

in the somewhat lighter flesh to which<br />

the seeds are attached. The seeds, on<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

15<br />

Key No. 102618

Ingredients<br />

the other hand, which mistakenly have<br />

the reputation of being “particularly<br />

hot”, contain no capsaicin.<br />

Wide range of varieties and<br />

flavors<br />

Chili peppers come in a variety of<br />

colors – e.g. yellow, orange, green,<br />

red – and in different color intensities.<br />

The shapes also vary – narrow or<br />

bulbous, short or long. Depending on<br />

the variety, there are also differences<br />

in taste, aroma and pungency. The<br />

spiciness is joined by different flavors,<br />

such as fruity, floral, sweet, tangy,<br />

smoky, etc.<br />

Spicy <strong>food</strong> makes you happy<br />

Capsaicin irritates the nerve cells<br />

of the oral mucosa. The cells also<br />

warn us if we burn our mouth<br />

with something too hot. This<br />

is where the burning sensation<br />

comes from when eating a chili<br />

pepper. The body reacts to<br />

capsaicin with increased blood<br />

flow and hot flashes. The pain<br />

stimulus can cause the release<br />

of the happiness hormone<br />

endorphin.<br />

The origin of peppers and chili<br />

peppers is in Central and South<br />

America, and Christopher Columbus<br />

is said to have brought the chili bell<br />

pepper to Europe. Today, there are<br />

a large number of varieties and new<br />

chilies are constantly being created<br />

through breeding. Most commonly<br />

used varieties are descended from<br />

five families of species: Sweet<br />

peppers, as well as “Cayenne” and<br />

“Jalapeño,” belong to the most<br />

common species, Capsicum anuum.<br />

Capsicum baccatum includes the<br />

citrus-flavored chili pepper “Lemon<br />

Drop”. The very hot chili peppers<br />

“Carolina Reaper”, “Scorpion” and<br />

“Habanero” are Capsicum chinense<br />

varieties. The “Tabasco” pod, known<br />

through the sauce of the same name,<br />

is of the Capsicum frutescens species.<br />

The fifth species Capsicum pubescens<br />

is rarely cultivated. “Rocota” is one of<br />

its varieties and very popular among<br />

chili connoisseurs.<br />

+ Markets. “This one-stop chili variety<br />

was met with great demand at recent<br />

trade shows to which we accompanied<br />

the company.”<br />

Developing a high-quality seed<br />

The richness of chili varieties is the<br />

result of cultivation and breeding.<br />

Accordingly, the production of highquality<br />

chili varieties begins with seeds.<br />

“Uchu Spice” puts special emphasis<br />

on seed production, handling and<br />

control in its development center.<br />

The company does not resort to<br />

hybrid seeds but has established<br />

its own seed bank and takes care of<br />

seed management itself. 68 different<br />

varieties of the five Capsicum species<br />

families are currently in the seed<br />

bank. Seed development is a lengthy<br />

process. Each variety goes through<br />

a special development process. For<br />

the development of the “Carolina<br />

Reaper”, for example, five seeds were<br />

available and the company needed<br />

2 ½ years. During the research and<br />

development process, the fruits with<br />

the best genotype and phenotype are<br />

selected to ensure that the chilies<br />

are bred that are the most flavorful,<br />

have the best shape and have the<br />

best organoleptic characteristics.<br />

“Many chili producers don’t pay<br />

enough attention not to mix varieties,”<br />

explains Imelda Echavarria, cofounder<br />

and CEO of Uchu Spice. “We,<br />

on the other hand, take special care<br />

to manage the gene bank so that we<br />

have the best ‘habanero’ or that the<br />

‘scorpion’ pod always has the shape of<br />

a scorpion. Our quality control starts<br />

with the seed.”<br />

The company “Uchu Spice” offers 15<br />

different chili varieties. Among them<br />

are the rather mild “Jalapeño” to the<br />

very hot “Habanero” pods. Many<br />

well-known and often used varieties<br />

are included, such as “Tabasco” and<br />

“Cayenne”, as well as specialties like<br />

“Rocota” and “Scotch Bonnet” chilies.<br />

For the European <strong>food</strong> industry, the<br />

chilies are available in dried form, in<br />

flakes, as powder, puréed or pickled,<br />

depending on their intended use. “The<br />

range of chili varieties, flavors, heat<br />

levels and processing options is very<br />

wide for ‘Uchu Spice’” explains Maria<br />

Paula Gomez, IPD expert for Sourcing<br />

16 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Ingredients<br />

Cultivating a diversity of varieties<br />

For cultivation, “Uchu” works with<br />

about 600 small farmers in Ecuador<br />

and also in Peru. The company itself<br />

has no cultivated land of its own. The<br />

model involves close cooperation with<br />

local growers. They are part of the chili<br />

network with long-term contracts. In<br />

addition to special seeds, the farmers<br />

receive ongoing training and technical<br />

support to further develop quality and<br />

yields - and thus also to secure and<br />

improve their livelihoods.<br />

Engagement of the Import Promotion Desk (IPD) in Ecuador.<br />

The IPD has been active in Ecuador since 2018 and is primarily<br />

involved in the rural and structurally weak regions of Ecuador.<br />

Ecuador's natural wealth holds great potential for the export industry.<br />

For example, pineapples, passion fruits, pitahayas, passion fruit,<br />

mangos, physalis, granadillas are grown in Ecuador. They are offered<br />

both as fresh fruit and in processed form, and the demand for tropical<br />

and subtropical fruits is high. The portfolio of natural ingredients also<br />

includes grains such as amaranth, quinoa and chia, which have found<br />

their way into European cuisine.<br />

By cultivating in different regions,<br />

the company ensures year-round<br />

production. In addition, differences<br />

in climate and soil conditions benefit<br />

varietal diversity and high quality: the<br />

“Escabeche” chili, for example, thrives<br />

well in the sandy soils of northern<br />

Peru, while the “Charapita” pod<br />

“prefers” the moist clay soils of the<br />

Amazon basin.<br />

fmt<br />

The goal is to work with small and medium-sized enterprises to<br />

harness the country's natural potential, as well as to open up Europe<br />

as a new sales market and win partners for sustainable business<br />

relationships. The IPD is supported by the German Federal Ministry for<br />

Economic Cooperation and Development (BMZ).<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

17<br />

Key No. 102979

Events<br />

Experience the World’s Nutraceutical<br />

Event: Registration is open for<br />

Vita<strong>food</strong>s Europe <strong>2023</strong><br />

The much-loved nutraceutical event returns both in person and online this May with an expanded offering<br />

including new, premium content<br />

Registrations are now open for<br />

Vita<strong>food</strong>s Europe <strong>2023</strong>, the leading<br />

global platform for nutraceutical,<br />

functional <strong>food</strong> and beverage, and<br />

dietary supplement professionals.<br />

The event, which features Title<br />

Sponsor KSM-66 Ashwagandha, is<br />

set to welcome over 15,000 attendees<br />

from around the globe to the Palexpo<br />

Convention Centre in Geneva (9-11<br />

May) and online (1-12 May). Visitors<br />

can experience exclusive expertled<br />

content on consumer trends,<br />

market opportunities and scientific<br />

innovations, as well as connect with<br />

like-minded peers and suppliers<br />

to inspire new collaborations and<br />

finished products.<br />

In addition to returning favorites,<br />

this year’s event will offer brand new<br />

show features – such as the new<br />

Sustainability Resource Centre and<br />

the Startup Innovation Challenge –<br />

plus premium content offerings via the<br />

Future of Nutrition Summit (8 May)<br />

and the Vita<strong>food</strong>s Europe Conference<br />

(9-10 May) which are designed to keep<br />

businesses at the leading-edge of the<br />

industry.<br />

Speaking on the return of the event<br />

and the addition of new premium<br />

content offerings, Andy Mather,<br />

Brand Director of Vita<strong>food</strong>s Europe<br />

at Informa Markets, said, “Vita<strong>food</strong>s<br />

Europe <strong>2023</strong> aims to create a unique<br />

experience that visitors will not<br />

just find valuable, but that they will<br />

also really enjoy. This year, we are<br />

introducing a host of new content,<br />

designed to inspire, engage and<br />

provide the spark to propel the<br />

industry forward.<br />

The new Sustainability Resource<br />

Centre will feature innovations and<br />

insights from passionate experts<br />

dedicated to driving sustainable<br />

change in the nutrition industry.<br />

Meanwhile, the Startup Innovation<br />

Challenge provides an opportunity<br />

for upcoming nutraceutical stars to<br />

make their mark on the industry and<br />

develop their innovative projects<br />

through a through a specialized<br />

support programme. We are excited<br />

to welcome everyone in the Vita<strong>food</strong>s<br />

community back for <strong>2023</strong> both<br />

in Geneva and online – including<br />

those joining us for the first time<br />

– to experience the creativity and<br />

collaborations on offer.”<br />

Show highlights<br />

Offering a huge range of new and<br />

returning content for visitors to<br />

18 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Events<br />

explore, including a mix of premium<br />

paid-for and free-to-attend sessions,<br />

the Vita<strong>food</strong>s Europe <strong>2023</strong> agenda<br />

will explore everything from market<br />

trends, sustainability, women in<br />

nutraceuticals, and more. Highlights<br />

of this year’s event include:<br />

• NEW: Future of Nutrition Summit (8<br />

May, Marriott Hotel, Geneva) – join<br />

a diverse range of C-suite industry<br />

leaders and futurist thinkers for<br />

an exclusive, paid-for one-day<br />

summit discussing the trends and<br />

technologies that will shape the<br />

nutrition industry in 5+ years’ time<br />

– from precision nutrition and the<br />

digitalization of health management<br />

to sustainable supply chain<br />

solutions.<br />

• NEW: Vita<strong>food</strong>s Europe Conference<br />

(9-10 May) – this premium, two-day<br />

conference returns in a new format,<br />

focused on current challenges and<br />

opportunities in sports and active<br />

nutrition; cognitive and emotional<br />

health; metabolic and immune<br />

health; life stages and healthy<br />

ageing. Now located in a purposebuilt<br />

theater on the Vita<strong>food</strong>s<br />

Europe show floor, visitors can<br />

easily combine attending the<br />

conference alongside their regular<br />

show floor and expo experience.<br />

• The Vita<strong>food</strong>s Insights Theater –<br />

returning for <strong>2023</strong>, the Vita<strong>food</strong>s<br />

Insights Theater offers free-toattend<br />

expert sessions diving into<br />

current global consumer trends,<br />

updates on regulatory and supply<br />

chain issues, as well as insights into<br />

delivery formats and packaging.<br />

• NEW: Startup Innovation Challenge<br />

– discover cutting-edge innovations<br />

from the most exciting health and<br />

nutraceutical startups as they<br />

pitch their ideas live. Together<br />

with the popular Startup Pavilion,<br />

this challenge provides a unique<br />

opportunity for companies to<br />

find innovative ingredients,<br />

technologies, services, and finished<br />

products to help their businesses<br />

grow.<br />

• NEW: Sustainability Resource<br />

Center – dedicated to driving<br />

sustainable change in the nutrition<br />

industry, this resource center<br />

offers expert presentations and<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April<br />

insights into the full spectrum of<br />

sustainability issues, including<br />

supply chain traceability, regulatory<br />

compliance, certifications, carbon<br />

offsetting, alignment with the UN<br />

Sustainable Development Goals,<br />

and gender and LGBTQ+ inclusivity.<br />

Experience innovations, ideas<br />

and insights yourself<br />

“Standing still simply isn’t an option<br />

in this industry; people return to<br />

Vita<strong>food</strong>s Europe year-after-year to<br />

drive their businesses forward and<br />

be inspired.” says Mather. “This year,<br />

we are offering another lively agenda,<br />

packed full of exciting opportunities to<br />

Key No. 104845<br />

Vita<strong>food</strong>s Europe is<br />

connect and gather knowledge. This<br />

includes both new and re-imagined<br />

premium, paid-for events that will dive<br />

deeper into current trends and future<br />

industry predictions; the Vita<strong>food</strong>s<br />

Europe Conference and the Future of<br />

Nutrition Summit. The latter joins the<br />

Vita<strong>food</strong>s Europe <strong>2023</strong> family after<br />

being a huge success at previous<br />

Food Ingredients Europe events. We<br />

truly believe that Vita<strong>food</strong>s Europe<br />

<strong>2023</strong> in Geneva, Switzerland, has<br />

something for everyone, and that this<br />

year’s attendees will experience the<br />

very best in industry innovations and<br />

insights to keep their businesses at<br />

the leading-edge of nutrition.” fmt<br />

Every year, thousands of nutraceutical experts look forward to joining friends,<br />

colleagues and suppliers at Vita<strong>food</strong>s Europe. They love tasting new<br />

products, listening to world-class speakers, discovering new ingredients and<br />

connecting with fantastic people from across our industry.<br />

Experience it for yourself<br />

9-11 May Geneva<br />

1-12 May Online<br />

Register now at vita<strong>food</strong>s.eu.com

Events<br />

Supporting both Human Health and that<br />

of the Planet<br />

AstaReal at Vita<strong>food</strong>s Europe <strong>2023</strong>, booth H100<br />

AstaReal continues its mission to<br />

be a planet-friendly and sustainable<br />

business by launching Astaxin®<br />

VEGAN. The new product containing<br />

natural algal astaxanthin aims to<br />

promote good health while alleviating<br />

environmental concerns.<br />

With its scientifically proven<br />

antioxidant and anti-inflammatory<br />

properties, natural microalgaederived<br />

AstaReal® astaxanthin is well<br />

positioned to satisfy current consumer<br />

demands: supporting health via<br />

effective and sustainable solutions.<br />

Demand for vegetarian- and vegancompliant<br />

supplements is increasing<br />

globally. To complement daily diets<br />

and maintain well-being, many people<br />

seek plant-based supplements that<br />

promote both physical and mental<br />

health. Meanwhile, consumers are<br />

increasingly concerned about the<br />

origins of their purchases and their<br />

impact on climate and ecosystems.<br />

At Vita<strong>food</strong>s Europe, AstaReal will<br />

exhibit its extended product range,<br />

and demonstrate how supplement<br />

manufacturers can better address the<br />

current consumer concerns.<br />

An innovative finished formulation will<br />

also be launched at the show. Astaxin®<br />

VEGAN, an antioxidant formula that<br />

taps into the plant-based market,<br />

with the content mirroring Astaxin®<br />

Original – including vitamin C and<br />

natural vitamin E – but in a vegan<br />

softgel made of carrageenan and<br />

modified starch. Astaxin® VEGAN will<br />

be available in bulk from June and as a<br />

retail product from October <strong>2023</strong>.<br />

In addition, expo visitors can try<br />

samples of the next-generation vegan<br />

starch-based astaxanthin gummies<br />

that are sugar-free. Moreover, they<br />

will get to know about AstaReal’s bulk<br />

products that are registered with the<br />

Vegan Society and that are applicable<br />

in various supplement dosage forms,<br />

including but not limited to, hard<br />

capsules, softgels, sachet/stick<br />

powder mixes and gels, gummies, and<br />

liquid shots.<br />

AstaReal is a global pioneer in<br />

microalgae cultivation, and the<br />

first producer of human nutritional<br />

supplements containing natural<br />

astaxanthin. The company believes<br />

in transparency that better enables<br />

informed choices, especially with<br />

regards to sustainability. Peter Ahlm,<br />

Head of <strong>Marketing</strong> and Sales at<br />

AstaReal, says: “Sustainability is not<br />

only a core value for us at AstaReal,<br />

but also one of the key considerations<br />

among today’s consumers. This is<br />

reflected in the supplements market,<br />

with environmentally sound products<br />

growing in popularity. Also, in terms<br />

of ecosystem preservation, natural<br />

astaxanthin is a promising ingredient,<br />

as it is derived from fast-regrowing<br />

microalgae which are planet-friendly,<br />

natural resources. Our mission is to<br />

offer the carotenoid in its natural,<br />

purest and most stable form to pave<br />

the way for truly healthy products with<br />

proven sustainability credentials.” fmt<br />

Gut Health Innovations<br />

FrieslandCampina Ingredients at Vita<strong>food</strong>s Europe <strong>2023</strong>, booth H270<br />

FrieslandCampina Ingredients, a<br />

global leader in protein and prebiotics,<br />

will return to Vita<strong>food</strong>s Europe (9 – 11<br />

May) in Geneva, Switzerland. The<br />

company is launching a brand-new<br />

ingredient at the New Product Zone,<br />

with details to be revealed closer<br />

to the show, as well as showcasing<br />

its latest prebiotic and sustainable<br />

ingredient innovations.<br />

In <strong>2023</strong>, people overwhelmingly<br />

see living and eating well as a top<br />

priority and gut health remains high<br />

on the consumer agenda for <strong>2023</strong>.<br />

But with increasingly busy schedules,<br />

consumers are looking for convenient<br />

gut health applications to meet their<br />

health goals with ease.<br />

To inspire brands to create convenient<br />

gut health solutions,<br />

FrieslandCampina Ingredients will<br />

showcase its recently launched<br />

Biotis® GOS-OP High Purity, including<br />

its new gummy concept. Designed<br />

to help manufacturers overcome<br />

common challengers associated with<br />

formulating prebiotic supplements,<br />

this ingredient is efficacious in doses<br />

as low as two grams, opening up a<br />

range of new opportunities for brands<br />

to develop effective and convenient<br />

holistic health solutions.<br />

Sustainably feeding the future<br />

Health and planet-conscious consumers<br />

are actively looking for more<br />

environmentally-friendly products –<br />

and reducing carbon is a top priority,<br />

with 63% of consumers having taking<br />

action to reduce their personal carbon<br />

footprint.<br />

FrieslandCampina Ingredients is<br />

committed to helping brands create<br />

sustainably nutritious solutions and<br />

will be showcasing its new suite of<br />

20 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong>

Events<br />

carbon-neutral solutions at Vita<strong>food</strong>s<br />

Europe – including its new carbonneutral<br />

protein powder.<br />

Vicky Davies, Global Senior <strong>Marketing</strong><br />

Director, Performance and Active<br />

Nutrition at FrieslandCampina<br />

Ingredients, said:<br />

“This year’s Vita<strong>food</strong>s Europe is going<br />

to be a big one for FrieslandCampina<br />

Ingredients! We’ll be launching a<br />

brand-new ingredient at the show<br />

and it’s one that breaks new ground<br />

for us and the industry. We can’t wait<br />

for brands to discover our newest<br />

offering, as well as our wider portfolio<br />

of nutritious and sustainable proteins<br />

and prebiotics. I’m looking forward<br />

to collaborating with our customers<br />

in person. Vita<strong>food</strong>s Europe gives us<br />

a great opportunity to work together<br />

with our customers and partners to<br />

create tasty, efficacious and sustainable<br />

solutions, so that people can<br />

get the most out of life, always.” fmt<br />

Solutions for Well-being Benefits and<br />

Innovative Delivery<br />

Rousselot at Vita<strong>food</strong>s <strong>2023</strong>, booth I114<br />

Darling Ingredients’ Health Brand<br />

Rousselot®, a global leader in collagen<br />

peptides and gelatin solutions, invites<br />

Vita<strong>food</strong>s <strong>2023</strong> attendees to discover<br />

the ‘game-changing’ benefits and<br />

trending applications of its full range of<br />

collagen and gelatin solutions.<br />

Maintaining a healthy lifestyle remains<br />

a priority for consumers worldwide and<br />

the use of supplements for enhancing<br />

health and wellness is becoming<br />

an increasingly popular solution to<br />

achieve this goal. As a more holistic<br />

view of health and well-being gains<br />

momentum, brands are placing a<br />

greater emphasis than ever before<br />

on adding ingredients with multiple<br />

benefits into their products.<br />

Among the key solutions Rousselot<br />

will spotlight, collagen peptides brand<br />

PEPTAN® is the ingredient to watch<br />

to tap into this trend. From helping<br />

shoppers stay active and mobile at<br />

every stage of life, to boosting beauty<br />

from within, or improving sports<br />

recovery, this premium ingredient<br />

combines multiple science-backed<br />

benefits with versatile formulation<br />

properties.<br />

COLARTIX®, a unique hydrolyzed<br />

cartilage matrix for joint health, made of<br />

naturally occurring collagen peptides<br />

and glycosaminoglycans (GAGs) will<br />

also be a key highlight at the event.<br />

In a recently published consumer<br />

study, performed in a real-life setting,<br />

Colartix was shown to decrease joint<br />

discomfort across gender, age and<br />

sport intensity.<br />

Attendees will experience the endless<br />

versatility of these ingredients firsthand<br />

thanks to a range of samples from<br />

Rousselot’s application center. These<br />

include a peach-flavored “Beyond<br />

Beauty” drink featuring Peptan and<br />

probiotics, as well as mobility gummies<br />

featuring Colartix.<br />

In addition to the collagen products<br />

on display, Rousselot will showcase<br />

its world-class gelatin solutions;<br />

Stabicaps, specifically designed<br />

to achieve more stable softgels and<br />

SiMoGel, a unique gelatin technology<br />

solution which enables the production of<br />

nutraceutical gummies in a starch-free<br />

environment. Rousselot’s formulation<br />

experts will be available to discuss with<br />

supplement, capsule, and confectionery<br />

manufacturers how these solutions<br />

unlock the innovative delivery forms<br />

needed to meet the ‘pillars’ of consumer<br />

experience: good taste, convenience,<br />

new shapes and naturalness.<br />

fmt<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2023</strong><br />

21

Events<br />

Sobriety and Performance on the Menu,<br />

at CFIA - Food Exhibition in France<br />

The CFIA is a major <strong>food</strong> fair in France, the crossroads of suppliers to the <strong>food</strong> industry. It takes place every<br />

year in Rennes, Brittany, core region of French agricultural <strong>food</strong> production. But this has become a major<br />

meeting place, gathering 1600 exhibitors and nearly 20,000 visitors. For its 26th edition, on everyone’s lips,<br />

there was talk of sobriety, frugality and innovation in manufacturing processes as well as in ingredients and<br />

packaging. This report from Dominique Huret, Cape Decision, who was on the spot for Food <strong>Marketing</strong> &<br />

<strong>Technology</strong>.<br />

“Essentially manufacturers who come<br />

here are looking for either the recipe of<br />

tomorrow, the machine that will allow<br />

them to improve their production while<br />

saving energy, or a better package<br />

for their products or to finalize their<br />

projects”, explains Sébastien Gillet<br />

CFIA director.<br />

Between hygiene constraints and<br />

growing environmental challenges,<br />

suppliers of solutions for the quality<br />

department are stepping up their<br />

efforts to reconcile sobriety and <strong>food</strong><br />

safety. This is evidenced by about 100<br />

new products put forward by exhibitors<br />

at this <strong>2023</strong> edition.<br />

Innovations in process , quality<br />

and with sobriety<br />

The specialist in industrial water<br />

treatment ChemDoc Water is<br />

deploying a project to recycle wash<br />

water. In <strong>food</strong> production processes,<br />

tanks and lines are washed with<br />

softened water. This water is then<br />

loaded with organic matter and sent<br />

for biological purification before<br />

being discharged into the natural<br />

environment. ChemDoc offers a<br />

process that allows total recycling (or<br />

zero liquid discharge) of manufacturing<br />

washing water. Two processes are<br />

combined: a recycling unit for the salt<br />

(up to 85% recovery) and a membrane<br />

separation unit of the effluents which<br />

allows a reuse of the water for cleaning<br />

with <strong>food</strong> contact guarantee.<br />

Cabinplant automates the dosing of<br />

sticky or even liquid products. Called<br />

MHW SF Extreme, this multi head<br />

weigher weighs and packages products<br />

that are still often added manually,<br />

such as mixed salads, coleslaw, tuna<br />