food Marketing - Technology 2/2024

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

food Marketing & Technology is the international magazine for executives and specialists in the food industry.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2/24<br />

Vol. 38 • 31377<br />

ISSN 0932-2744<br />

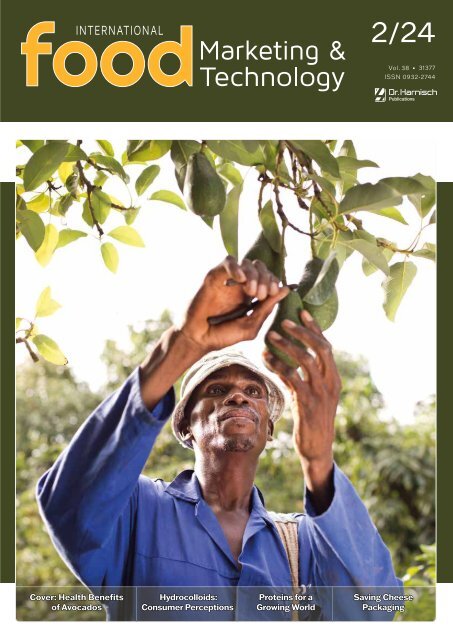

Cover: Health Benefits<br />

of Avocados<br />

Hydrocolloids:<br />

Consumer Perceptions<br />

Proteins for a<br />

Growing World<br />

Saving Cheese<br />

Packaging

One. Stop. Shop.<br />

Set up with your<br />

customers in mind.<br />

From plant-to-plate or field-tofork.<br />

With the new Protein Application<br />

Center at our headquarters in<br />

Switzerland you can now run trials to<br />

create new plant-based <strong>food</strong>s such<br />

as delicious meat and fish substitues<br />

or dairy alternatives starting<br />

anywhere along the protein value<br />

chain.<br />

Harness the unique infrastructure of<br />

the Grain Innovation Center and the<br />

Protein and Extrusion Application<br />

Centers combined with the<br />

experience of our technicians and<br />

technologists to create, optimize and<br />

scale the process for your product.<br />

Interested?<br />

Scan the code and<br />

connect to our experts<br />

right away.<br />

Innovations for a better world.

Editorial<br />

Clean Eating for a Healthy Future?<br />

A phrase has been buzzing around<br />

in the USA for a while now and which<br />

is finding a larger following in Europe.<br />

“Clean Eating“ is a <strong>food</strong> fad somewhere<br />

between a complete return to nature<br />

and a demonisation of all things<br />

processed. There are variations to the<br />

definition, but basically, Clean Eating<br />

means staying as close to nature as<br />

possible, including the preparation of<br />

meals from scratch, using local and<br />

regional ingredients.<br />

Of course there are many reasons for<br />

this, starting with health. Supporters<br />

claim that Clean Eating nourishes your<br />

body with healthy and nutrient-dense<br />

<strong>food</strong>s. Clean <strong>food</strong>s fill your body with<br />

plentiful vitamins and minerals, highquality<br />

protein and healthy fats, which<br />

improve heart and brain health, assist<br />

with weight management, build a<br />

stronger immune system and increase<br />

energy levels, among other benefits.<br />

How nice this would be.<br />

Because there is no science<br />

background to Clean Eating, the<br />

variations to the theme are sometimes<br />

unclear, and without a sound basis. For<br />

example, it’s often recommended that<br />

dairy and wheat are excluded from<br />

the diet, even for those who have not<br />

been diagnosed with an intolerance or<br />

allergy. Coconut oil is often promoted,<br />

despite being high in saturated fat,<br />

which is linked to high cholesterol.<br />

Butter is avoided by some clean eaters,<br />

but not by others, while most who<br />

eat it suggest it should be organic<br />

and grass-fed – attributes that don’t<br />

change the fact it is high in saturated<br />

fat. There is inconsistency over sugar.<br />

Although white sugar is definitely not<br />

viewed as ‘clean’, honey, maple syrup<br />

and juices, which are also sources of<br />

free sugars, are usually included and<br />

even encouraged by some clean eating<br />

gurus.<br />

What is often forgotten, in some extreme<br />

circles, is that processed <strong>food</strong>s grew<br />

from a need for convenience, as well<br />

as the wish for increased <strong>food</strong> safety<br />

and variety – and here there is plenty of<br />

scientific proof. It is unquestionably true<br />

that there are some <strong>food</strong>s we should be<br />

eating less of and others we should eat<br />

more of, but it is not helpful to define a<br />

world of <strong>food</strong> in terms of clean and dirty.<br />

The Clean Eating community would<br />

present an image of perfection that<br />

isn’t realistic. The majority of families<br />

(including families of one or two) simply<br />

do not have the time or money to spend<br />

in the garden or kitchen and being given<br />

a feeling of inferiority or guilt is not a<br />

good association.<br />

Ian Healey<br />

Editor-in-Chief<br />

In real life, some days there will be<br />

time to cook and being flexible in your<br />

diet is important if there is going to be<br />

a pattern of eating for the long term,<br />

rather than a continuous cycle of ups<br />

and downs.<br />

Nowadays people simply need to find<br />

what is right for themselves. Food can<br />

be fun, preparation and cooking can<br />

be a communal experience. And, as<br />

always, there needs to be a balance.<br />

And respect for others who choose<br />

differently.<br />

Cheers<br />

If you like it – subscribe!<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong> 3

Contents<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> April <strong>2024</strong><br />

3 Editorial<br />

42 Impressum<br />

Ingredients<br />

6 Avocados: Health Benefits and Sustainable Cultivation<br />

10 Molding and Demolding Consumer Perceptions of<br />

Hydrocolloids<br />

13 Continued Growth in the Food Supplements<br />

14 How to make High Fat Foods Healthier with Fat Layers<br />

and Marbling<br />

18 Study Reveals Pomegranate’s Potential to Slow<br />

Progression of Age-related Frailty<br />

Processing<br />

20 The Evolution of the Protein Value Chain –<br />

Sustainable Protein Systems for a Growing World<br />

24 Angle Grinder for Fresh and Frozen Meat Blocks with<br />

Well Thought-out <strong>Technology</strong><br />

26 Real-time Monitoring Solution for Food Processing<br />

<strong>Technology</strong> Launched at Anuga FoodTec<br />

28 Sustainable, Efficient Process Security with ‘Just Clip It’<br />

System<br />

Key No. 102163<br />

Your<br />

Ingredient<br />

Ideas.<br />

Packaging<br />

30 Going Digital for Greater Efficiency<br />

33 Safe, Attractive, and Resource-Saving Packaging<br />

Solutions in the Cheese Industry<br />

Departments<br />

37 New White Paper Examines How Processing <strong>Technology</strong><br />

Can Improve Food Sustainability and Nutrition<br />

38 Discover the Latest in Nutraceutical Innovation at<br />

Vita<strong>food</strong>s Europe <strong>2024</strong> in Geneva<br />

40 Calendar of Events<br />

42 Index

10/30/23 1:57 PM<br />

Vol. 38 • 31377<br />

ISSN 0932-2744<br />

2/24<br />

Cover:<br />

Avocado consumption is increasing<br />

worldwide by around 3% every year. In the<br />

EU, growth of as much as 15% is expected<br />

over the next five years. This makes<br />

Europe the second largest growth market<br />

for avocados after the USA. Avocados are<br />

healthy and versatile, they are easy to prepare<br />

and can be enjoyed on any occasion.<br />

Whether in salads, as dips or traditionally<br />

on bread - there are many ways to integrate<br />

them into our daily diet.<br />

uty parts<br />

ficult-to-cut<br />

ucts.<br />

tting <strong>Technology</strong><br />

ur product.<br />

rschel.com<br />

Cover: Health Benefits<br />

of Avocados<br />

Hydrocolloids:<br />

Consumer Perceptions<br />

Proteins for a<br />

Growing World<br />

Saving Cheese<br />

Packaging<br />

Our Cover Story starts on page 6.<br />

Photo: WAO - World Avocado Organisaton<br />

Ingredients: Hydrocolloids, A Consumer Perspective<br />

There are many forces and influences generating consumer<br />

perceptions about <strong>food</strong> ingredients including hydrocolloids. Social<br />

media, personal friends, family members, health concerns,<br />

environmental awareness, nutritional magazines and many<br />

others. In some cases there is a mystery over what caused the<br />

perception (or misperception) in the first place. Take a look at<br />

page 10 for a full analysis of this complex challenge.<br />

Our<br />

Extrusion Cooking<br />

and Drying<br />

Expertise.<br />

The Possibilities are Endless.<br />

Processing: <strong>Technology</strong> for New Proteins<br />

Over the past five years, the protein value chain has undergone<br />

significant transformation with plant-based proteins rising<br />

in popularity and consumer acceptance. Despite this progress,<br />

formidable challenges remain to further advance the industry.<br />

The <strong>food</strong> industry is tasked with designing more efficient processes<br />

that use less energy and water to extract and purify<br />

plant-based proteins. The full story can be found on page 20.<br />

Wenger pioneered twin screw extrusion for <strong>food</strong> applications<br />

nearly 40 years ago. Today, our leading-edge technology is<br />

used to create diverse <strong>food</strong> products and ingredients such as<br />

protein crisps, textured proteins, cereals, breadings, starches,<br />

snacks, and many more.<br />

And our world-class process<br />

experts can help you develop<br />

whatever shape, size, color,<br />

fi brous structure, or moisture<br />

level required.<br />

Packaging: Reduced Packaging for Cheese<br />

Whether it concerns a technical improvement of the packaging<br />

process at an artisan Swiss cheese factory, which gives its valuable<br />

skilled workers more time for cheese production, or global<br />

branding at a Portuguese cheese manufacturer that wants<br />

to significantly boost its export business, the high-tech traysealers<br />

and thermoformers from a leading packaging specialist<br />

support the goals of these companies. Two success stories<br />

from the world of dairy are shown on page 33.<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • February 2016<br />

Key No. 102163<br />

Wenger.com

Cover Story<br />

Avocados: Health Benefits and<br />

Sustainable Cultivation<br />

Avocados are healthy and versatile, they are easy to prepare and can be enjoyed on any occasion. Whether<br />

in salads, as dips or traditionally on bread - there are many ways to integrate them into our daily diet. The<br />

avocado offers a special sensory experience due to its slightly nutty flavor, creamy texture, aroma and<br />

appearance and is a nutritionally balanced <strong>food</strong>. The nutritional benefits are quite clear: avocados contain<br />

almost no sugar, but lots of vitamins, important minerals and healthy fats. They are part of a balanced diet<br />

and are available throughout the year. The cultivation of avocados is becoming increasingly sustainable and<br />

their reputation is growing in all cases.<br />

eggs. Avocados are mainly eaten for<br />

their healthiness, but also for their flavor<br />

and enjoyment. As a nutritious suby<br />

Sabine Straka<br />

Attractive growth segment<br />

In only a few years, the avocado has developed<br />

from being a rather exotic fruit<br />

into a real <strong>food</strong> trend and has become<br />

an integral part of modern cuisine and<br />

in restaurants throughout Europe and<br />

beyond. More and more nutritionconscious<br />

consumers integrate this<br />

popular fruit into their daily diet. Particularly<br />

during the last four to six years,<br />

the consumption of avocados in the<br />

EU has increased significantly. According<br />

to the World Avocado Organization<br />

(WAO), around 150,000 tonnes of<br />

avocados were consumed in France<br />

last year, 110,000 tonnes each in Germany<br />

and the UK, 60,000 tonnes in<br />

Scandinavia and 45,000 tonnes in Italy.<br />

The cultivation and trade of avocados<br />

is an attractive growth sector. Avocado<br />

consumption is increasing worldwide<br />

by around 3 % every year. In the EU,<br />

growth of as much as 15 % is expected<br />

over the next five years. This makes Europe<br />

the second largest growth market<br />

for avocados after the USA.<br />

High-demanding consumers<br />

For around 50 years, avocados have<br />

been available in supermarkets. In Germany,<br />

40 % of households regularly eat<br />

avocados, with 1.3 kg per capita consumed<br />

last year. This puts Germany in<br />

the second place after France in terms<br />

of avocado consumption. In Europe,<br />

Millennials and Generation Z are particularly<br />

fond of avocados, a discerning<br />

target group with a conscious lifestyle<br />

who like to share their dietary preferences<br />

on social media. Avocados are<br />

popular in salads and are mostly eaten<br />

for breakfast, often with bread and<br />

Zac Bard, President World Avocado Organization<br />

6 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Cover Story<br />

per<strong>food</strong>, avocados are an alternative to<br />

animal products. Avocados are available<br />

all year round. Most avocados come<br />

from countries such as Peru, Mexico,<br />

Colombia, Chile, South Africa, Kenya,<br />

Spain and Israel. More and more consumers<br />

are therefore concerned about<br />

the carbon footprint and whether they<br />

can eat avocados with a clear conscience.<br />

We asked Zac Bard, Chairman of the<br />

World Avocado Organization (WAO)<br />

some of these specific questions.<br />

Founded in 2016 as a non-profit organization,<br />

the WAO is made up of the<br />

largest avocado producers, exporters<br />

and importers from around the world.<br />

The aim of the organization is to educate<br />

people about the health benefits of<br />

avocados, to raise awareness of avocados<br />

in selected international markets,<br />

especially in Europe, and thus promote<br />

the consumption of avocados. It also<br />

provides information on the sustainable<br />

cultivation of avocados and supports<br />

retailers with sales. For this purpose,<br />

WAO runs large-scale marketing and<br />

communication campaigns.<br />

Nutritious super<strong>food</strong><br />

Most avocados are eaten for health<br />

reasons. In various educational campaigns,<br />

the WAO informs about the<br />

nutritional and physiological benefits<br />

of avocados. They hardly contain any<br />

sugar, but many essential vitamins<br />

and minerals, including magnesium,<br />

copper, potassium, vitamins C, E, K<br />

and some B vitamins, as well as other<br />

essential nutrients that are important<br />

for a healthy immune system and for<br />

the prevention of many diseases. The<br />

health benefits of avocados have also<br />

been proven in numerous clinical studies.<br />

With their high content of monounsaturated<br />

fatty acids, avocados can<br />

help to lower the LDL cholesterol level<br />

in the blood and thus reduce the risk of<br />

a stroke. A study in the „Journal of American<br />

Heart Association“ found that<br />

eating just two portions of avocado a<br />

week can reduce the risk of cardiovascular<br />

disease. With their high proportion<br />

of unsaturated fatty acids, avocados<br />

are also a healthy alternative to<br />

animal-based <strong>food</strong>s. Replacing saturated<br />

fats with unsaturated fats can also<br />

improve insulin sensitivity and reduce<br />

the risk of type 2 diabetes. Avocados<br />

have a high satiety value and contain<br />

few calories (approx. 250 calories per<br />

avocado). They can help losing weight<br />

and reducing the risk of obesity. Avocados<br />

are rich in fiber, which regulates<br />

appetite and is important for intestinal<br />

health and digestion. The nutrients and<br />

bioactive compounds in avocados can<br />

reduce the risk of metabolic syndrome<br />

(high cholesterol, high blood pressure,<br />

obesity). In older people, eating avocados<br />

can have a positive effect on brain<br />

function and eye health. The carotenoid<br />

lutein contained in avocados can<br />

protect the eye from damage caused<br />

by ultraviolet light from the sun and<br />

reduce the risk of macular degeneration.<br />

Finally, avocados can also be used<br />

externally. The combination of monounsaturated<br />

fatty acids, carotenoids,<br />

vitamins with the antioxidants vitamin<br />

C and E and phenolic compounds can<br />

improve skin firmness. The WAO is running<br />

various information campaigns<br />

about the health benefits of avocados.<br />

Precise irrigation systems<br />

The cultivation of avocados is mainly criticized<br />

for its high water consumption.<br />

However, in the past ten years much has<br />

been achieved in the irrigation of avocados.<br />

Producers throughout the World<br />

Avocado Organization have also been<br />

able to reduce their water consumption<br />

significantly. Irrigation primarily depends<br />

on the amount and frequency of<br />

precipitation in the growing area. Avocados<br />

grow in tropical and Mediterranean<br />

climates. Countries such as Ethiopia<br />

and Tanzania, for example, have almost<br />

ideal climatic conditions for cultivation.<br />

In areas with high rainfall, avocados can<br />

obtain almost all of their water requirements<br />

directly from the rain. The use<br />

of rainwater is a sustainable method of<br />

irrigation allowing farmers a certain degree<br />

of self-sufficiency so that they can<br />

water their crops regularly even when<br />

water is scarce. Rainwater harvesting<br />

systems consist of a network of collection<br />

mechanisms, filtration processes<br />

and storage facilities. In countries such<br />

as Kenya, Colombia, Mexico, Brazil and<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

7

Cover Story<br />

the Dominican Republic, the additional<br />

irrigation for 1 kilogram of avocados<br />

requires less than 10 liters, approximated.<br />

Where additional irrigation is<br />

required, water consumption has been<br />

significantly reduced thanks to modern,<br />

precise irrigation methods. This also<br />

happened at Three Farms in South Africa,<br />

for example, which exports around<br />

half of its 3,500 tonnes of avocados to<br />

Europe. Here, the water is channelled<br />

directly into the soil in the right quantity<br />

and at the right time using a new drip irrigation<br />

system, so that each plant gets<br />

exactly what it needs without wasting<br />

water. “Drip irrigation does not only reduce<br />

water consumption, but also improves<br />

crop yields. Thanks to intelligent<br />

irrigation systems, the average global<br />

water footprint of avocados is much lower<br />

than that of other everyday <strong>food</strong>s,<br />

such as beef, chocolate, coffee or butter,“<br />

explains Zac Bard.<br />

Smart agriculture<br />

Innovative technologies for digital agriculture<br />

use agronomic algorithms,<br />

sensors and artificial intelligence to<br />

monitor plants and to deliver the exact<br />

amount of water required. With<br />

the help of new agricultural technology,<br />

water consumption on smaller<br />

farms in Chile has been reduced by<br />

30 % and in Spain by up to 50 %. Intelligent<br />

sensors monitor soil moisture<br />

and ensure that water is only<br />

applied where it is needed. This minimizes<br />

waste through evaporation<br />

and prevents overwatering. Soil<br />

moisture monitoring systems provide<br />

precise data in real time and enable<br />

well-founded decisions to be made<br />

about irrigation systems. Fertigation<br />

systems are also frequently used, allowing<br />

fertilizer to be applied at the<br />

same time as irrigation. The nutrient<br />

mixture can be tailored precisely according<br />

to the needs of the individual<br />

avocado plant and delivered directly<br />

to the roots of the trees. In this way,<br />

the nutrients can be used more efficiently<br />

and excess fertilizer can be<br />

avoided. The use of new technologies<br />

can reduce water consumption,<br />

improve plant health, increase yields<br />

and make avocado cultivation more<br />

sustainable.<br />

Carbon footprint significantly<br />

lower than other <strong>food</strong>s<br />

Many consumers are also concerned<br />

about the long transport distances.<br />

With over 300,000 tonnes, Peru is the<br />

largest supplier of avocados to Europe,<br />

followed by Colombia, Chile, Kenya and<br />

South Africa. “Most of the avocados<br />

consumed in Europe are transported<br />

by ship from Latin America and Africa.<br />

This is more environmentally friendly<br />

and produces fewer CO 2<br />

emissions<br />

compared to air and road transport.<br />

These avocados therefore perform<br />

even better than avocados produced in<br />

Europe, which are usually transported<br />

by car or plane,“ Zac Bard adds. The CO 2<br />

emissions of avocados are significantly<br />

lower than those of other everyday<br />

<strong>food</strong>s such as milk, cheese or eggs and<br />

are comparable to those of other fruits<br />

such as apples. Avocados grow on perennial<br />

trees that can absorb up to 20 kg<br />

of carbon per year from the atmosphere<br />

and produce 2.4 kg of CO 2<br />

equivalents<br />

per kilogram. Compared to many other<br />

<strong>food</strong>s, avocados have a smaller ecological<br />

footprint overall.<br />

Economic impact on the growing<br />

countries<br />

Avocado production is often associated<br />

with negative economic impacts<br />

in the countries where they are grown.<br />

In various projects supported by the<br />

WAO, however, the cultivation of avocados<br />

has helped to improve the living<br />

conditions of people in the respective<br />

regions. In the Olmos Valley in Peru, for<br />

example, water intended for the Atlantic<br />

Ocean was diverted through the Andes<br />

to an automatic irrigation system. This<br />

turned a former desert into 24,000 hectares<br />

of fertile land for growing fruit and<br />

vegetables, including avocados. This<br />

project has created over 25,000 jobs<br />

in agriculture and many other indirect<br />

jobs, securing the livelihoods of many<br />

people. Avocado cultivation thus makes<br />

an important contribution to the<br />

8 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Cover Story<br />

economy in many growing countries, where the majority of<br />

production still takes place on small farms. In Peru, growth<br />

in the agricultural sector has helped to reduce poverty significantly,<br />

particularly in rural communities. The example<br />

of Three Farms also shows that sustainable avocado cultivation<br />

can have a positive impact on local communities.<br />

The farm pays competitive wages to its 300 employees and<br />

also promotes vocational skills and training.<br />

Photo: Three Farms<br />

In recent years, the cultivation of avocados has also increased<br />

significantly in other countries with suitable climatic<br />

conditions, such as Kenya, Ethiopia and Tanzania, where<br />

the up-coming avocado industry benefits small local<br />

farmers and boosts the local economy. In Chile, the third<br />

largest avocado supplier to Europe, the avocado industry<br />

has created around 35,000 new jobs and reduced poverty,<br />

particularly in rural regions. Here, there are programs to<br />

support organic avocado cultivation as well.<br />

The cultivation of avocados is becoming more and more<br />

environmentally friendly and the ecological CO 2<br />

footprint<br />

is already reduced compared to other products. Farmers<br />

are continuing to improve production methods. This makes<br />

avocados - together with their high nutritional value - to sustainable<br />

and healthy alternative to animal products. As Zac<br />

Bard says: “Transport distance, retail, packaging or special<br />

cultivation methods per kilo are very small compared to<br />

their high nutritional value.“<br />

More information:<br />

The WAO expects a worldwide increase in avocado consumption<br />

in the coming years, especially in Europe and Asia,<br />

particularly in India, where the avocado is still a very new<br />

fruit.<br />

fmt<br />

The Author:<br />

Sabine Straka, Editorial Team, Food <strong>Marketing</strong> & Technoloy<br />

For more information:<br />

www.avocadofruitoflife.com<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Ingredients<br />

Molding and Demolding Consumer<br />

Perceptions of Hydrocolloids<br />

There has been a quantum leap if not a paradigm shift in the level of detail and complexity in <strong>food</strong> label<br />

declarations. Consumer perceptions and label interpretations now have an immense effect on <strong>food</strong> choices.<br />

Understanding consumer perceptions is essential in addressing their concerns. How do consumers make up<br />

their minds? What has molded these perceptions (or mis-perceptions)? Can they be “De-molded and remolded”?<br />

Let’s delve into the muddy waters of consumer decision making and strategize on how to possibly<br />

influence them at least in the world of hydrocolloids.<br />

by Dennis Seisun<br />

There are many forces and influences<br />

generating consumer perceptions<br />

about <strong>food</strong> ingredients including hydrocolloids.<br />

Social media, personal<br />

friends, family members, health concerns,<br />

environmental awareness, nutritional<br />

magazines and many others.<br />

In some cases there is a mystery over<br />

what caused the perception (or misperception)<br />

in the first place. Take gelatin,<br />

for example. Many consumers believe<br />

it comes from animal hoofs and/<br />

or horns. Few have any idea why or how<br />

they came to this conclusion. Try this<br />

little gelatin quiz on friends who are not<br />

in the <strong>food</strong> business and see what percentage<br />

believe it comes from hoofs<br />

and/or horns. What are the origins of<br />

that perception? As you know, virtually<br />

all <strong>food</strong> gelatin is produced from beef<br />

hide or pork skin and NOT from hoofs<br />

or horns. The gelatin industry has done<br />

a good job of pre-empting concerns<br />

about gelatin by associating it with human<br />

health and relating it to collagen<br />

which has a very positive consumer<br />

image. Let us consider now some consumer<br />

perception molding and de-molding<br />

strategies which could be applied<br />

to improve consumer acceptance of<br />

these unique ingredients. The science<br />

supporting their safety is there, but<br />

that is sadly and often, not enough.<br />

The list of hydrocolloids which IMR covers<br />

in its “Quarterly Review of Food<br />

Hydrocolloids” includes: Agar, Alginates,<br />

Acacia gum, Carrageenan (refined<br />

and semi-refined), Cassia Gum, Gelatin,<br />

Guar, Locust Bean Gum, Carboxy<br />

Methyl Cellulose (CMC), Methyl Cellulose<br />

(MC), Hydroxy Propyl Methyl<br />

Cellulose (HPMC), Micro-crystalline<br />

cellulose, Pectin, Xanthan, Tara Gum,<br />

Konjac and Starches. There are many<br />

ways in which these hydrocolloids can<br />

be grouped some of which are better<br />

than others. Three hydrocolloid grouping<br />

systems could be as follows:<br />

1) Classifying by raw material origin<br />

2) Classifying by stability of availability<br />

and price<br />

3) Classifying by “Pantry Friendliness”.<br />

1) Classifying them by raw material<br />

origin was used in the early days of<br />

analysing market value and size by hydrocolloid<br />

group or category.The main<br />

hydrocolloid groups are:-<br />

• seaweed extracts (agar, alginates,<br />

carrageenan, furcelleran)<br />

• seed gums (Locust bean gum/carob<br />

bean gum, guar, tara gum, fenugreek<br />

gum)<br />

• cellulosics (carboxy methyl cellulose,<br />

micro-crystalline cellulose,<br />

methyl cellulose/hydroxy propyl<br />

methyl cellulose.<br />

• plant exudates (gum acacia, karaya,<br />

tragacanth)<br />

• plant extracts (pectin, konjac)<br />

• biogums (xanthan gum, gellan<br />

gum, curdlan)<br />

• starches (corn, potato, wheat, rice,<br />

tapioca)<br />

This method of grouping is mainly for<br />

market analysis purposes. Consumers<br />

do not view and evaluate hydrocolloids<br />

by this type of grouping.<br />

2) From a B2B point of view, suppliers<br />

and buyers are more interested<br />

in the stability (or instability) of<br />

price and availability. For this purpose,<br />

IMR has categorized hydrocolloids<br />

in terms of cyclic vs non-cyclic<br />

availability and price. Starches, cellulosics<br />

and xanthan, for example,<br />

were traditionally categorized as<br />

steady in price and always available.<br />

Other hydrocolloids such as LBG,<br />

gum acacia, guar and tara were notoriously<br />

cyclic in price and availability<br />

depending on weather and annual<br />

rainfall. These old rules of cyclic vs<br />

non-cyclic differentiation no longer<br />

apply. Starch, xanthan and cellulosics<br />

have been through dramatic<br />

cycles of high price and low availability<br />

in recent years. In any case,<br />

these considerations are of little importance<br />

to consumers and to their<br />

perception of hydrocolloids. So, we<br />

can ignore this method of grouping<br />

hydrocolloids when considering consumer<br />

perceptions.<br />

10 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Ingredients<br />

A pantry friendly profile for a given hydrocolloid<br />

can be subject to regional consumer<br />

customs and preferences. Konjac<br />

for example is more widely known<br />

and accepted in China, Japan and Indonesia,<br />

than in most other parts of the<br />

world. Gum acacia is a standard of excellence<br />

in confectionery especially in<br />

Italy and France. In Egypt acacia gum<br />

is sold at the retail level for therapeutic<br />

teas. Some of the largest volumes of<br />

gracilaria agar are sold in single serve<br />

sachets in Indonesia to make therapeutic<br />

beverages. In Japan agar in powder<br />

or strips is widely sold at the retail<br />

level and is a staple of Japanese home<br />

cooking. In Ireland, Irish Moss contains<br />

carrageenan and has been sold at the<br />

retail level for centuries. Carrageenan<br />

is pantry friendly not only in Ireland but<br />

in other countries including Indonesia<br />

and the Philippines where much of the<br />

carrageenan raw material is grown. In<br />

India, guar is literally a staple crop for<br />

home use. Guar pods are sold at vegetable<br />

markets or in the frozen <strong>food</strong><br />

section of Indian supermarkets. Guar is<br />

very pantry friendly in these countries.<br />

In Germany, locust bean gum is declared<br />

as “Johannisbrotkernmehl” literally<br />

a biblical reference meaning “St. John’s<br />

3) A more recent hydrocolloid grouping<br />

method promoted by IMR is to<br />

consider hydrocolloids in terms of<br />

their “Pantry Friendliness”. Which hydrocolloids<br />

are likely to be found in a<br />

consumer’s pantry. If a hydrocolloid is<br />

commonly found in a consumer’s pantry<br />

and is used in home cooking, then<br />

it is “Pantry Friendly” and more likely<br />

to be accepted on a processed <strong>food</strong><br />

label. Pectin, starch and gelatin are all<br />

“Pantry Friendly” in Western homes.<br />

Consumers have a long history of using<br />

them in home cooking. “Grandma used<br />

pectin to make jam”. Gelatin is found<br />

in most home pantries with multiple<br />

home recipe applications. The healthy<br />

connotations of collagen are also associated<br />

with gelatin to increase its<br />

“Pantry Friendliness”. Corn starch is<br />

a standard ‘go-to’ thickener in homecooked<br />

sauces, gravies and even dairy<br />

desserts. Pectin is a complex chemical<br />

extraction but its consumer image is so<br />

positive that it is sometimes used simply<br />

because ‘it looks good on the label’.<br />

The faba fix for a greener, tasty future.<br />

Milk the texture opportunity of dairy-free.<br />

Make your applications future proof and dairy-free to answer both stricter nitrogen<br />

policies and changing consumers’ wishes. The ever-increasing percentage of consumers<br />

who believe that going dairy-free provides multiple health benefits must be acknowledged.<br />

Offering dairy alternatives that provide a luscious taste and airy texture is a challenge,<br />

but with BENEO’s ingredients it becomes a breeze. Discover our alternative solution with<br />

faba bean for a traditional whipping cream. It will have consumers mouth-watering over<br />

their favourite dessert with a piece of dairy-free heaven. Seize the moo-ment and go for<br />

plant-based alternatives with faba bean.<br />

Want to know more about BENEO?<br />

Scan here!<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> •<br />

www.beneo.com<br />

11

Ingredients<br />

Bread Seed Flour”. Pectin and starches<br />

don’t need an introduction at the retail<br />

consumer level.<br />

The not so Pantry Friendly hydrocolloids<br />

include the likes of methyl cellulose,<br />

carboxy methyl cellulose and xanthan<br />

gum. These hydrocolloids are unlikely<br />

to be found in consumer pantries with<br />

the exception of xanthan gum in the<br />

pantries of celiac and gluten intolerant<br />

consumers. Using these hydrocolloids<br />

in recipes is complicated and a small<br />

error in measurement gives a big error<br />

in the final product. Xanthan has recently<br />

come to be scrutinized by consumers,<br />

would you believe, because of<br />

how it is spelled; it starts with an X!!.<br />

Cellulosics are referred to as “They’re<br />

serving us wood pulp or wood chips” by<br />

less informed consumers. They don’t<br />

realize that cellulose is one of the most<br />

abundant raw material and they are<br />

eating it in every day <strong>food</strong>s. Admittedly<br />

<strong>food</strong> cellulosics are modified but they<br />

have passed the test of time and regulatory<br />

scrutiny.<br />

So what does the preceding have to<br />

do with molding and de-molding perceptions?<br />

Consumers are far less suspicious<br />

of things they are familiar with<br />

and which they use themselves. Familiarity<br />

overcomes fear of the unknown.<br />

One of the perception molding and demolding<br />

strategies could simply be to<br />

“Make the unfamiliar familiar”. Easier<br />

said than done of course, but the challenge<br />

is worth it. In fact, it is a ‘Do or<br />

die’ challenge in some cases. If consumer<br />

mis-perceptions are allowed to go<br />

rampant it could mean the end of a perfectly<br />

safe and suitable hydrocolloid.<br />

An effort should be made collectively<br />

by the hydrocolloid industry to counter<br />

some of the outlandish social media<br />

claims about the “dangers” of some hydrocolloids.<br />

There are opportunities to<br />

transfer “Pantry Familiarity” of a given<br />

hydrocolloid from one region/culture<br />

to another part of the world. Recipes<br />

that use hydrocolloids in one part of<br />

the world can be promoted in other<br />

parts of the world. In this age of <strong>food</strong><br />

experimentation, there is every opportunity<br />

to promote a novel <strong>food</strong> and recipe.<br />

For example, consumers could be<br />

enticed to make their own “Asian noodles”<br />

with konjac, topped with imitation<br />

surimi with curdlan and served with a<br />

dressing thickened with xanthan gum.<br />

All followed by a dessert made creamy<br />

with MCC. It is beyond the scope of this<br />

article to come up with specific recipes<br />

but the concept of ‘Breeding Familiarity’<br />

is worth pursuing.<br />

Another strategy to promote a positive<br />

image of many hydrocolloids could<br />

be based on the IMR concept of “Employment<br />

Factor”. A dollar’s worth of<br />

one hydrocolloid may well employ up<br />

to 300 or even 400 times as many individuals<br />

as the same dollar’s worth of<br />

another hydrocolloid. Consumers are<br />

increasingly sensitive to the social as-<br />

pects of the <strong>food</strong>s they purchase. Last<br />

but not least, the sustainability of all<br />

hydrocolloids is assured based on the<br />

renewable raw material source for all of<br />

them. Another tool for molding a positive<br />

image of hydrocolloids.<br />

Some industry observers advocate<br />

doing little, if anything, about consumer<br />

perceptions of hydrocolloids.<br />

“Don’t rock the boat” they say. “You<br />

may do more damage than good by<br />

raising awareness”. We at IMR, do not<br />

agree. Being proactive is a lot more efficient<br />

than being reactive. “A stitch in<br />

time….”.<br />

The topic of consumer perceptions of<br />

hydrocolloids is sure to be one of the<br />

many hot topics discussed at the forthcoming<br />

IMR conference on <strong>food</strong> hydrocolloids<br />

in Savannah, GA April 28-30,<br />

<strong>2024</strong>. More information about this gathering<br />

of “Who’s Who in Hydrocolloids”<br />

at www.hydrocolloid.com.<br />

fmt<br />

The Author:<br />

Dennis Seisun founded IMR International a hydrocolloid<br />

consulting company in 1984. Nesha<br />

Zalesny joined IMR in 2019 and brings a much<br />

needed, technical and scientific content to The<br />

Quarterly Review of Food Hydrocolloids. Together,<br />

Nesha and Dennis bring over 55 years<br />

of hydrocolloid expertise in their consulting<br />

and market research activities.<br />

For more information:<br />

www.hydrocolloid.com<br />

12 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Ingredients<br />

Continued Growth in the Food<br />

Supplements<br />

The French manufacturer Laboratoire<br />

PYC continues to grow in the European<br />

<strong>food</strong> supplements segment. At<br />

Vita<strong>food</strong>s Europe Stand M169 in the<br />

French Pavilion, the company will be<br />

showcasing new <strong>food</strong> supplement<br />

formulas. In May will also be the<br />

inauguration of its industrial site, which<br />

has been completely redesigned to<br />

support its growth.<br />

Discovery box of 10 <strong>food</strong><br />

supplements<br />

At Vita<strong>food</strong>s, Laboratoire PYC will<br />

showcase 10 <strong>food</strong> supplement concepts<br />

in a recyclable box. Each formula<br />

addresses a key promise of the<br />

<strong>food</strong> supplement market: sleep,<br />

stress, vitality, immunity, circulation,<br />

digestion, weight-management and<br />

nutricosmetics. These 10 <strong>food</strong> supplement<br />

formulas come in the form of<br />

powders packaged in stick-packs. 8<br />

formulas are intended to be rehydrated<br />

and 2 formulas are orodispersible.<br />

These formulas are ready for sale.<br />

Laboratoire PYC also develops tailormade<br />

<strong>food</strong> supplements. The contractmanufacturer<br />

supports brands in the<br />

production of their <strong>food</strong> supplements,<br />

from ingredient sourcing to packaging.<br />

“For this <strong>2024</strong> edition of Vita<strong>food</strong>s,<br />

Laboratoire PYC has chosen to<br />

focus on innovative formulas, French<br />

origin, naturalness and pleasure”,<br />

explains Aurélie DE SCHUYTENEER,<br />

<strong>Marketing</strong> and Communications<br />

Manager. “Each concept in the box<br />

is supported by clinical studies, and<br />

all the formulas are clean label. In<br />

addition, we monitor market trends<br />

and keep a close eye on ingredients<br />

to offer the most up-to-date and<br />

innovative formulas possible. On the<br />

flavor side, our R&D teams worked<br />

for several months to select new<br />

natural flavors and create pleasant<br />

combinations of fruit and floral notes.<br />

One of the strengths of Laboratoire<br />

PYC lies in formulating <strong>food</strong><br />

supplements that are very pleasant<br />

to consume. All our formulas are<br />

developed in our laboratory in Aix-en-<br />

Provence and manufactured in the<br />

French department of Ain.”<br />

New nutricosmetic concepts to<br />

taste<br />

The company is also the first French<br />

contract-manufacturer to have<br />

developed a complete range of<br />

nutricosmetics. “Our first nutricosmetic<br />

formula was developed in 2009.<br />

Laboratoire PYC is celebrating 15 years<br />

in this sphere. Since then, we have<br />

developed a complete, specific range<br />

for the skin and hair,” says Aurélie DE<br />

SCHUYTENEER.<br />

To celebrate the occasion, the<br />

COLLAGEN BEAUTY BOOSTER®<br />

nutricosmetic formula will be available<br />

for free tasting at the TASTING BAR<br />

at Vita<strong>food</strong>s. This area is dedicated to<br />

discovering the latest developments<br />

in the nutraceuticals sector. The<br />

French collagen-based formula has<br />

been specifically developed for the<br />

event. Laboratoire PYC‘s R&D teams<br />

have created a fresh, fruity taste with<br />

natural strawberry and elderflower<br />

flavors. Strawberry is one of the TOP<br />

3 most popular and growing flavors in<br />

beauty supplements worldwide. The<br />

formula benefits from clinical studies<br />

on hydration, elasticity and wrinkles. Its<br />

composition is clean label.<br />

Laboratoire PYC‘s Manziat plant in the<br />

Ain region has undergone a complete<br />

makeover! After 18 months of work,<br />

the company will inaugurate its new<br />

production site at the end of May. It<br />

has been completely redesigned to<br />

meet the company‘s growing business<br />

and customer expectations. The plant<br />

occupies a new surface area of 4,600<br />

m2. It has been equipped with the<br />

latest generation equipment, including<br />

a new powder blending unit relocated<br />

on the existing site.<br />

This project is a major milestone in<br />

the company‘s history. More than 20<br />

new jobs have been created, including<br />

around 15 on the production site itself.<br />

Qualified operators, administrative staff<br />

and engineers are joining the existing<br />

teams. The production capacity has<br />

also been significantly expanded to<br />

support business growth.<br />

The teams took advantage of this<br />

industrial investment to modernize the<br />

infrastructure, meet CSR challenges<br />

and further improve employee safety<br />

and <strong>food</strong> safety. Laboratoire PYC is ISO<br />

22000 certified.<br />

fmt<br />

For more information:<br />

www.laboratoire-pyc.com<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

13

Ingredients<br />

How to make High Fat Foods Healthier<br />

with Fat Layers and Marbling<br />

by Jennifer Zamanifar<br />

Epidemiological data show a strong<br />

relationship between dietary fat intake<br />

and body weight, blood cholesterol<br />

levels, cardiovascular disease,<br />

and some cancers. High fat intakes<br />

are habitually accompanied by increased<br />

saturated fat, cholesterol and<br />

energy density.<br />

At a time when unhealthy eating habits<br />

and obesity are causing problems<br />

for both adults and children, choosing<br />

a diet with fewer sweet and fatty<br />

<strong>food</strong>s could be a battle at any age but<br />

is especially challenging for children.<br />

The more important it should be for<br />

the <strong>food</strong> industry to support a healthy<br />

lifestyle. To reduce dietary fat consumption<br />

of an average individual, it<br />

is important to identify factors that<br />

influence their <strong>food</strong> choices. A major<br />

determinant of <strong>food</strong> selection is the<br />

degree of liking of the <strong>food</strong>s. Raynor<br />

et al. (2004) suggested that liking, especially<br />

for high-fat <strong>food</strong>s, is a stronger<br />

predictor of dietary fat intake than<br />

the availability of high- and low-fat<br />

products in the home. High-fat <strong>food</strong>s<br />

in this study were defined mainly as<br />

meat products, cheeses, butter &<br />

margarine, ice cream and salty snack<br />

with fat contents more than 50%, lowfat<br />

<strong>food</strong>s were mostly vegetables and<br />

fruits, cereals and products made out<br />

of it. The author stated that a greater<br />

liking of high fat <strong>food</strong>s, regardless of<br />

environmental controls varying the<br />

availability of high- and low-fat <strong>food</strong>s<br />

in the household, is associated with<br />

greater fat intake.<br />

Thus he suggested interventions designed<br />

to reduce dietary fat intake<br />

should target changing the liking of<br />

high-fat <strong>food</strong>s means to reduce the<br />

liking and increase the liking of lowfat<br />

<strong>food</strong>s, because only if individuals<br />

living in a household containing many<br />

low-fat relative to high-fat <strong>food</strong>s leads<br />

to low-fat intake if these individuals<br />

have a greater liking for low-fat <strong>food</strong>s.<br />

But what if we can do low-fat <strong>food</strong>s<br />

such as delicious as high-fat <strong>food</strong>s?<br />

Should this not be the target of any<br />

<strong>food</strong> producing corporation?<br />

SANACEL® add 035 fibre blend<br />

as fat replacement (fat mimetic)<br />

Fibre blends can be used as an excellent<br />

fat substitute. Together with<br />

water, SANACEL® add fibre blends<br />

replace the functionality of fat and<br />

14 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Ingredients<br />

imitate its mouthfeel. From a chemical and nutritional<br />

point of view, however, the fibre blend remains a<br />

dietary fibre, including its positive effect on digestion.<br />

In contrast, conventional fat substitutes, which are<br />

chemically and physically similar to triglycerides, have<br />

half the calories of fat. As this fat substitute is not broken<br />

down by intestinal bacteria, it retains its physical<br />

properties. Excess fat substitute also forms an oily<br />

texture in the feces, which can lead to problems with<br />

bowel movements or atypical oily stool composition.<br />

In contrast, the calories for dietary fibre are calculated<br />

at only 2 kcal/g.<br />

SANACEL® add 035 is a complex fibre combination of<br />

bamboo, potato and a soluble fibre, which is very well<br />

able to imitate the properties of fat. Besides that it<br />

brings a natural color, tasty flavor and important dietary<br />

fibres into the <strong>food</strong> product.<br />

In comparison to other fat replacement systems it has<br />

some important advantages:<br />

• manufactured from natural raw materials<br />

• free from allergens<br />

• E- number free, clean label<br />

• easy to prepare, no activating by high<br />

shearing forces required<br />

SANACEL® add 035 in boiled sausages<br />

CFF GmbH & Co. KG developed a fat reduced and fibre<br />

enriched boiled sausage. The recipe for the sausage<br />

is based on 60 % pork meat, made of shoulder and<br />

knuckle meat, 18 % neck fat and 22 % ice. In the trial<br />

the standard basic recipe is modified by exchanging<br />

5/6 of the neck fat through a fat replacer made out of<br />

SANACEL® add 035.<br />

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

Go discover<br />

what’s new in<br />

nutraceuticals<br />

and take advantage of the latest innovations<br />

14-16 May <strong>2024</strong> Geneva<br />

vita<strong>food</strong>s.eu.com<br />

The aim is to produce a product with the same taste,<br />

texture and mouth feeling like the standard sausage<br />

with full fat. In the trial (V1) the fat is just replaced by<br />

the fibre blend SANACEL® add 035. The fibre concentrate<br />

SANACEL® wheat 200 was additionally added to<br />

reach the status of an fibre enriched product.<br />

1. Standard (without fat replacer)<br />

2. V1, fat reduced with SANACEL® add 035 and<br />

fibre enriched with SANACEL® wheat 200<br />

After their production the sausages are examined<br />

concerning their nutritional value, sensory properties<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

15

Ingredients<br />

and texture. For analysing and comparing<br />

the boiled sausages there are<br />

different methods in use.<br />

Nutritional values<br />

First the nutritional value of the sausages<br />

is measured by the Food GmbH<br />

Jena Analytic-Consulting:<br />

• fat content according to<br />

method ASU §64 LFGB L<br />

06.00-6<br />

• fibre content according to<br />

method ASU §64 LFGB<br />

L 00.00-18<br />

• calorific value calculated<br />

according to Art. 31 Abs.<br />

1 EU regulation No. 1169/2011<br />

The results in table 1 show that the<br />

aim is reached by decreasing the fat<br />

content down to 10 % and increasing<br />

the fibre content up to 3 %. By replacing<br />

the fat, the whole calorific value<br />

is decreasing.<br />

Sensorial test & texture analysis<br />

Secondly the sensorial test “sensory<br />

preference test”, which is focussing<br />

on the evaluation of the consumers,<br />

has been performed. The consumers<br />

received the two different sausages<br />

marked with a code for a blind test.<br />

Afterwards the products were scored<br />

from 1 to 5 while 1 means “very good“<br />

and 5 “very bad“. At strong deviations<br />

a comment was added. Requirement<br />

for the blind test were healthy conditions<br />

of the test panel, since an infection<br />

could always have impacts on<br />

the sensory system of the test consumers.<br />

Figure 1 shows the results after 21<br />

consumers have tested the sausages<br />

and evaluated the texture, the taste,<br />

the odor and the look of the products.<br />

Odor and look are almost the same for<br />

both products - for the odor the result<br />

is at average 2,3 and for the appearance<br />

at 2,2. The taste of the Standard<br />

and V1 is nearly the same, at average<br />

2,25 and V1 has a taste with 2,28.<br />

The texture has been the attribute<br />

with a slight difference between the<br />

sausages. The Standard is at average<br />

2,1, V1 is a little higher.<br />

Hence the third test performed has<br />

been the texture analysis by using<br />

the TexturePro CT V1.8 Build 31<br />

from Brookfield. The bite becomes<br />

imitated by running the measuring<br />

body into the sausage with constant<br />

speed. When the sausage is breaking<br />

apart, the graph is showing a<br />

peak. The higher the peak, the more<br />

weight the TexturePro needs to break<br />

through. Figure 2 shows the results of<br />

the break through to imitate the bite.<br />

For the standard sausage up to 550 g of<br />

weight are necessary, for V1 a bit more<br />

than 550 g and for V2 around 525 g.<br />

Trial evaluation & conclusion<br />

The results of the analytical tests are<br />

displaying that the goal is reached, a<br />

healthy boiled sausage with a reduced<br />

fat content down to 10 % and an<br />

increased fibre content up to 3 % is<br />

accepted by consumers. This aim is<br />

easy to achieve by using SANACEL®<br />

add 035 instead of neck fat.<br />

Therefore SANACEL® add 035 is a<br />

perfect solution for the replacement<br />

of fat in sausages without losing the<br />

attributes that make the product delicious.<br />

Even the consumers who tested<br />

the boiled sausages during the<br />

sensory test could not find a difference<br />

between the products. The only<br />

deviation they found was the texture.<br />

But even the texture analyser could<br />

just measure small differences between<br />

the standard sausage and the<br />

V1- sausage with SANACEL® add 035.<br />

With regard to a healthy diet and good<br />

weight management, the replacement<br />

of fat is also possible in bakery<br />

products. Trials have shown that fat<br />

reduction in muffins or sponge cakes<br />

can easily be achieved with dietary<br />

fibre. With a fat reduction of 30 % without<br />

fibres and additional water, the<br />

muffin loses its shape and airy, fluffy<br />

texture. Using the fibre mixture SAN-<br />

ACEL® add and water, the volume and<br />

moistness is retained. The gel-like fat<br />

substitutes of the SANACEL® add fib-<br />

16 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Ingredients<br />

re mixtures are versatile. Further information<br />

on fat reduction with SANA-<br />

CEL® add can be found at: www.cff.de<br />

CFF GmbH & Co. KG, one of the<br />

world‘s largest manufacturers of dietary<br />

fibres, regularly supports the<br />

<strong>food</strong> industry with new ideas to improve<br />

the health and quality of <strong>food</strong>.<br />

The natural <strong>food</strong> fibres are produced<br />

from renewable raw materials<br />

in a gentle process. Sustainability<br />

is part of CFF‘s corporate philosophy.<br />

Responsible use of resources<br />

is therefore a matter of course, as is<br />

certification in accordance with DIN<br />

EN ISO 55001 for sustainable energy<br />

management.<br />

fmt<br />

The Author<br />

Jennifer Zamanifar; Nutritionist,<br />

Team Leader Food International Sales<br />

For more information:<br />

www.cff.de<br />

Come and see for yourself:<br />

www.harnisch.com<br />

Perfectly<br />

positioned.<br />

The international specialist magazines from Dr. Harnisch Publications<br />

In addition to the haptic charm of<br />

classic print magazines, we also<br />

offer newsletters, news, events and<br />

subscriptions on our magazine<br />

websites in addition to the digital<br />

editions that can be read free of charge.<br />

Take a look at www.harnisch.com<br />

for all relevant content.<br />

Our publications include:<br />

- <strong>Technology</strong> & <strong>Marketing</strong> -<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

17

Ingredients<br />

Study Reveals Pomegranate’s Potential to<br />

Slow Progression of Age-related Frailty<br />

Euromed extract reverses loss of motor coordination and prevents oxidative stress in ageing mice, according to<br />

independent research study conducted at the University of Valencia (Spain).<br />

A recently published study shows that Euromed’s pomegranate extract Pomanox® can promote healthy ageing in<br />

mice. 1 The substance was found to prevent frailty, improve motor skills and reduce oxidative stress in the cerebellum,<br />

the part of the brain responsible for coordination. Falling and subsequent bone fractures are one of the<br />

major health risks in elderly people. Therefore, the researchers of this model study looked at how to overcome<br />

the problem by addressing balance and stance, which are controlled by the cerebellum.<br />

The cerebellum is also responsible for<br />

coordination of voluntary movements,<br />

motor learning and cognitive tasks.<br />

During the ageing process, most of<br />

these functions deteriorate, resulting<br />

in falls and accidents. In the study,<br />

Pomanox® was able to maintain antioxidant<br />

levels in elderly mice after<br />

four months of supplementation. This<br />

effect was particularly evident in the<br />

cerebellum. Moreover, the standardised<br />

pomegranate extract influenced<br />

gene expression related to the apoptosis<br />

pathway, suggesting support for<br />

healthy ageing. Although no changes<br />

in grip strength and endurance were<br />

found, the results showed that pomegranate<br />

extract supplementation<br />

improved the motor skills in terms of<br />

coordination and neuromuscular function,<br />

and helped prevent age-related<br />

weight loss. Thus, the researchers<br />

believe that Pomanox® may provide<br />

practical nutritional support for common<br />

health problems, such as frailty,<br />

in later life.<br />

Pomegranate’s health benefits come<br />

from punicalagins, which are among<br />

nature’s strongest antioxidants. Po-<br />

18 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Ingredients<br />

manox® contains up to 30 per cent<br />

punicalagins and is a well-researched<br />

botanical ingredient from Euromed’s<br />

Mediterranean fruit and vegetable extracts<br />

range. It is obtained via a quality-controlled,<br />

transparent and sustainable<br />

local supply chain, and gently<br />

processed with an eco-friendly, proprietary<br />

technology.<br />

Andrea Zangara, Head of Scientific<br />

Communication and Medical Affairs at<br />

Euromed, says: “Pomanox® is already<br />

well known to provide benefits for cardiovascular<br />

and metabolic health, satiety,<br />

sports performance, mood, skin<br />

and cognitive health. The novelty of<br />

this work focuses on the fact that the<br />

pomegranate extract could be used to<br />

help prevent deterioration associated<br />

with normal ageing. The authors of this<br />

independently conducted study have<br />

observed for the first time that the<br />

cerebellum is the area where ageing<br />

is first noticed in a model without pathology.<br />

As Pomanox® acted efficiently<br />

here, it could be a helpful tool to reduce<br />

the risk of falls so common in ageing,<br />

and other functional impairments.”<br />

fmt<br />

1 Verdú, D. et al. Pomegranate Extract Administration<br />

Reverses Loss of Motor Coordination<br />

and Prevents Oxidative Stress in Cerebellum<br />

of Aging Mice. Antioxidants 2023, 12, 1991. https://doi.org/10.3390/antiox12111991.<br />

For more information:<br />

www.euromedgroup.com<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

19

Processing<br />

The Evolution of the Protein Value Chain<br />

– Sustainable Protein Systems for a<br />

Growing World<br />

As the world’s population is on<br />

course to surpass ten billion by<br />

2050, our <strong>food</strong> systems face the<br />

challenge of providing sustainable<br />

nutrition without further harming<br />

the planet. Animal-based diets and<br />

the reliance on animal-derived proteins<br />

are significant contributors<br />

to environmental degradation and<br />

public health issues. Not only is the<br />

global population increasing, but<br />

the expanding middle class in developing<br />

nations is driving a surge<br />

in protein demand, intensifying the<br />

strain on our environment. Animal<br />

proteins are a principal factor in cliby<br />

Dr. Christian Kern<br />

mate change, biodiversity loss, and<br />

the draining of freshwater resources,<br />

with the agricultural <strong>food</strong> sector<br />

responsible for approximately 25%<br />

of all greenhouse gas emissions. To<br />

address these issues, we must diversify<br />

protein sources and reduce<br />

<strong>food</strong> loss and waste, ensuring that<br />

alternatives are not only accessible,<br />

but also desirable to consumers.<br />

Over the past five years, the protein<br />

value chain has undergone significant<br />

transformation with plant-based<br />

proteins rising in popularity and consumer<br />

acceptance. Despite this progress,<br />

formidable challenges remain<br />

to further advance the industry. The<br />

<strong>food</strong> industry is tasked with designing<br />

more efficient processes that use less<br />

energy and water to extract and purify<br />

plant- based proteins. Additionally,<br />

there is an urgent need for a new wave<br />

of protein concentrates and isolates<br />

to support specific market demands.<br />

This includes the development of specific<br />

fractionation processes crucial<br />

for preserving or enhancing protein<br />

functionalities for use in plant- based<br />

<strong>food</strong>s, where taste profiles and textural<br />

properties are vital for consumer<br />

acceptance.<br />

20 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Processing<br />

Bühler’s state-of-the-art Application<br />

Centers are hubs where research is<br />

conducted to enhance the protein<br />

value chain through advanced technologies.<br />

The transformation begins<br />

at the Grain Innovation Center, where<br />

raw materials such as pulses or grains<br />

undergo cleaning, de-hulling, and dry<br />

grinding, before being purified in process<br />

steps like dry fractionation.<br />

Dry fractionation, which capitalizes on<br />

physical properties to separate protein-rich<br />

from starch- rich fractions, is<br />

an eco-friendly method due to its low<br />

energy requirements and lack of wastewater<br />

generation. The starch-rich<br />

fractions, or side streams, from pulses<br />

or grains can be used in products<br />

including snack bars, baked goods,<br />

pasta, or pet <strong>food</strong>, thus, supporting<br />

the concept of a circular economy. By<br />

contrast, wet fractionation processes<br />

are employed to achieve high-purity<br />

protein concentrates or isolates that<br />

are vital for their versatility in the <strong>food</strong><br />

industry. The Protein Application Center<br />

is dedicated to wet fractionation<br />

processing, beginning with wet grinding<br />

and/or dispersion to initiate protein<br />

purification.<br />

In addition to well-known methods like<br />

solid-liquid separation and isoelectric<br />

precipitation using decanter centrifuges,<br />

the Protein Application Center<br />

provides the advanced option of using<br />

membrane filtration technology.<br />

Beyond purification, the membrane<br />

system fosters the development of<br />

sophisticated methods, such as the<br />

separation and purification of specific<br />

protein fractions, to customize the<br />

techno-functional properties of protein<br />

ingredients. After extraction, prote-<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

21

Processing<br />

in powders are produced using drying<br />

technologies such as spray drying<br />

to ensure stability. This is where the<br />

unique advantage of the Bühler Application<br />

Centers comes into play. If the<br />

protein obtained in the Protein Application<br />

Center is to be used in an extrusion<br />

process, the energy-intensive<br />

spray-drying process can be suspended<br />

and the purified protein slurry can<br />

be dosed directly into the extruder<br />

next door.<br />

Those described integrated approaches<br />

also include comprehensive application<br />

testing – ranging from meat<br />

analogs utilizing extrusion techniques<br />

to plant-based beverages and dairy<br />

alternatives – to guarantee that these<br />

plant-based proteins meet, and often<br />

exceed, market standards for taste,<br />

texture, and nutritional value. Through<br />

ongoing innovation and collaboration,<br />

Bühler is committed to scaling up sustainable<br />

protein production to meet<br />

the global demand while caring for our<br />

planet.<br />

fmt<br />

The Author<br />

Dr. Christian Kern is Process Engineer R&D<br />

with Bühler AG in Uzwil Switzerland. He specializes<br />

in Extrusion <strong>Technology</strong> for Human<br />

Nutrition.<br />

For more information:<br />

www.buhlergroup.com<br />

22 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Processing<br />

MOVE YOUR<br />

BUSINESS<br />

FORWARD<br />

AT THE WORLDWIDE<br />

FAIR FOR SAVOURY<br />

SNACKS<br />

XX International Trade Fair for Savoury Snacks & Nuts<br />

STOCKHOLMÄSSEN<br />

STOCKHOLM<br />

19-20 JUNE <strong>2024</strong><br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />

23<br />

Stockholmsmässan<br />

SNACKEX.COM<br />

TRENDS<br />

TASTES<br />

TECHNOLOGIES<br />

SUPPLIERS<br />

DECISION-MAKERS<br />

DISTRIBUTORS<br />

TRADE PARTNERS<br />

CUSTOMERS

Processing<br />

Angle Grinder for Fresh and Frozen Meat<br />

Blocks with Well Thought-out <strong>Technology</strong><br />

K+G Wetter spent four well-attended<br />

trade fair days at Anuga FoodTec in<br />

Cologne. "We are highly satisfied with<br />

Anuga. Our sales staff and technicians<br />

were in conversation from early to late<br />

- with long-standing customers from all<br />

over the world, but also with companies<br />

that do not yet work with our machines,"<br />

reports K+G Wetter Managing<br />

Director Andreas Wetter.<br />

The new WW 200 angle grinder was always<br />

surrounded by interested trade<br />

fair visitors - and impressed <strong>food</strong> industry<br />

professionals with its useful<br />

machine technology. "We always listen<br />

carefully to our customers when they<br />

talk about their work with the machines.<br />

Our team then devises technology<br />

that truly proves itself in practice," says<br />

Volker Schlosser, Sales Manager International<br />

at K+G Wetter. What makes<br />

the powerful Angle Grinder WW 200<br />

special is its ability to process not only<br />

fresh products but also frozen meat<br />

blocks without pre-cutting. This makes<br />

it unrivaled in flexibility and perfect<br />

for companies that work with a mix of<br />

fresh and frozen meat.<br />

This is made possible by well thoughtout<br />

technology: the 500-liter hopper of<br />

the WW 200 has a special, asymmetrical<br />

shape - this ensures that meat and<br />

other ingredients are fed evenly to the<br />

feeder worm after loading. The special<br />

frozen meat feeder worm with cutting<br />

edge cuts up the blocks during transportation<br />

to the meat worm: the meat<br />

is cut precisely from the block and not<br />

squashed. The temperature increase<br />

is also minimal due to the low product<br />

stress. This ensures a clear cut of the<br />

finished minced product.<br />

Thanks to clever hygienic-secure features,<br />

the WW 200 can be cleaned in a<br />

timesaving and perfectly hygienic manner,<br />

as is standard with all K+G Wetter<br />

machines. The expertly hand-polished<br />

stainless-steel surfaces are easy to<br />

keep clean, and the angled arrangement<br />

allows cleaning water to run off<br />

without forming puddles. The feeder<br />

and meat worms can be removed and<br />

replaced in a few simple steps without<br />

the need for tools. This also facilitates<br />

hygienically safe cleaning. The single-stage<br />

folding step makes the WW<br />

200's grinder hopper quickly and safely<br />

accessible with minimal space requirement<br />

– cleverly designed for both<br />

handling and hygiene.<br />

The cleaning chamber prevents a typical<br />

hygiene risk due to hidden contamination<br />

inside the machine behind<br />

the seals of the drive shaft and feeder<br />

worm. Daily cleaning is carried out<br />

from the outside by simply holding<br />

the standard cleaning lances or spray<br />

nozzles against the easily accessible<br />

rinsing ports. The seals that come into<br />

contact with the product are thus cleaned<br />

on both sides and do not provide<br />

a breeding ground for microorganisms.<br />

Thanks to this ingenious technology,<br />

the additional cleaning effort is negligible<br />

with maximum effectiveness.<br />

The loading options for the WW 200<br />

are extremely flexible, whether column<br />

loader or hydraulic loading device<br />

using meat trolleys: how and from<br />

which side the raw materials are loaded<br />

into the angle grinder can be individually<br />

adapted to the customer's space<br />

and workflow. A big plus thanks to a<br />

machine that is optimally adapted to<br />

the respective production.<br />

The optional large touch panel provides<br />

the operator with lots of practical<br />

information, clearly displayed in<br />

graphics and text: for example, about<br />

possible cutting set configurations or<br />

optimum machine settings for different<br />

applications. This makes operation<br />

simple and safe and ensures the best<br />

product quality.<br />

fmt<br />

For more information:<br />

www.kgwetter.de<br />

24 <strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong>

Processing<br />

GREEN EFFICIENT TECHNOLOGIES<br />

The independent media platform for<br />

energy supply, efficiency enhancement and<br />

alternative energy sources and storage<br />

Sustainable opportunities in process<br />

technology<br />

Circular economy in the industrial<br />

production process<br />

Topics H 2<br />

, Synthetic Fuels, Water,<br />

Solar & Photovoltaics, Wind Power,<br />

Bioenergy, Geothermal Energy, Battery<br />

<strong>Technology</strong>, System Integration and<br />

other alternative options<br />

<strong>food</strong> <strong>Marketing</strong> & <strong>Technology</strong> • April <strong>2024</strong><br />