PetFood PRO 1/2024

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums. We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums.

We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

International Magazine March <strong>2024</strong> ISSN 2628-5851<br />

Technology & Marketing<br />

1/24<br />

Ingredients: Insect Proteins, Plant Extracts for Pets, Digestive Health, Science in Pet Food<br />

Processing: Heat Pump Drying, Texture Analysis, Rotary Mixing, Butchery Perfection<br />

Packaging: High Technology Packaging, Food Safety, Flexible and Recyclable Films<br />

Marketing: Global Trends in Pet Care, Anuga FoodTec - Pet Food Zone, Interzoo

EDITORIAL<br />

Invitation to the Pet Food Zone<br />

At first glance the Anuga FoodTec in<br />

Cologne, Germany, this month is a trade<br />

fair for the food and dairy industry.<br />

However, since the last edition two years<br />

ago, there have been major developments<br />

for our branch in pet food manufacturing.<br />

For the first time there is now a separate<br />

Pet Food Zone, which features the<br />

companies who are specifically focussed<br />

on reaching out to our furry and feathered<br />

friends.<br />

Why is this so important and why now?<br />

I asked Matthias Schlüter, Exhibition<br />

Director of the Anuga FoodTec, for his<br />

comments:<br />

“The Pet Food Zone will present innovative<br />

and sustainable solutions, which reflect<br />

the growing standards in the pet food<br />

industry sector. It is our aspiration to be<br />

a pioneer in shaping the future of food<br />

production, especially for our domestic<br />

animals, with a clear focus on improving<br />

quality and protecting the environment.<br />

“At the Anuga FoodTec almost 400<br />

exhibitors offer solutions for the pet food<br />

industry, so the existing commitment<br />

is already very high. There are also<br />

traditionally many visitors from this sector.<br />

The Pet Food Zone is an opportunity<br />

to bring those with mutual interests<br />

together. This is why we have set up this<br />

dedicated area this year.“<br />

Our team at <strong>PetFood</strong> <strong>PRO</strong> magazine is<br />

proud to partner with Kölnmesse for the<br />

Pet Food Zone. We will have a central<br />

booth in the Boulevard and are happy to<br />

meet up with visitors and to answer any<br />

questions and discuss future articles and<br />

topics for upcoming issues.<br />

Since the market for pet food is growing<br />

steadily and recorded annual growth is<br />

more than three percent, with sales of<br />

around 30 billion euros in 2022 in Europe<br />

alone, we are responding to this high<br />

demand by offering the pet food market<br />

its own space, both in these pages and as<br />

a part of the Pet Food Zone.<br />

A growing focus on sustainability is<br />

particularly evident in the increased use<br />

of alternative proteins, such as plantbased,<br />

insect-based and cultured feeds.<br />

Consumers are placing more emphasis<br />

on where ingredients come from and how<br />

well our animals are doing. At the same<br />

Ian D. Healey, Editor-in-Chief<br />

time manufacturers of equipment and<br />

packaging are more aware than ever of<br />

their responsibilities in reducing energy<br />

usage and the wise use of resources.<br />

The Pet Food Zone will showcase a<br />

cross-section of suppliers to the petfood<br />

industry. Come and see us at Stand A048,<br />

Boulevard Central in Cologne, March 19-<br />

22.<br />

Sincerely<br />

If you like it subscribe!<br />

Issue 1 <strong>2024</strong><br />

3

CONTENTS<br />

International Magazine March <strong>2024</strong> ISSN 2628-5851<br />

Technology & Marketing<br />

1/24<br />

Ingredients: Insect Proteins, Plant Extracts for Pets, Digestive Health, Science in Pet Food<br />

Processing: Heat Pump Drying, Texture Analysis, Rotary Mixing, Butchery Perfection<br />

Packaging: High Technology Packaging, Food Safety, Flexible and Recyclable Films<br />

Marketing: Global Trends in Pet Care, Anuga FoodTec - Pet Food Zone, Interzoo<br />

Issue 1 March <strong>2024</strong><br />

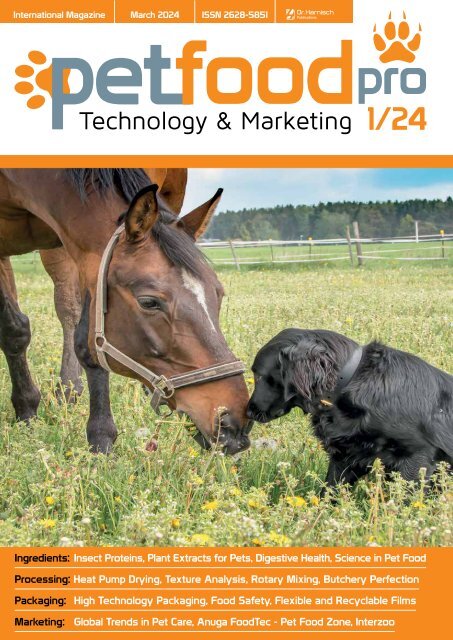

Sometimes among the non-stop everyday hectic which surrounds us, it is important<br />

to stop, share friendships and enjoy the moment. The photographer Sarah<br />

Brückmann together with Marat and Kira the dog has specialized in such pictures<br />

and has captured the scene for us this month. Sarah is a passionate photographer<br />

and animal lover, who has made her hobbies into a profession. Ponder, refresh and<br />

then delve into this issue of <strong>PetFood</strong> <strong>PRO</strong>.<br />

Cover photo: www.SarahBfotos.de<br />

Ingredients<br />

Processing<br />

6 Global Pet Care Trends in 2023<br />

8 Globe Buddy Introduces New Sustainable Dog Food with<br />

Insect Protein<br />

10 Natural Symbiosis: Plant Extracts Beneficial for Owners and<br />

for Pets<br />

14 Demand for Quality, Nutritional and Healthy Pet Food<br />

Remains High Despite Inflation<br />

16 Science-Backed Insect Proteins Gain Traction in Pet Food<br />

21 Expanding Capacity with a Heat Pump Dryer<br />

24 The Application of Texture Analysis on the Latest<br />

Developments<br />

28 Dr. Harvey's Ups Output of Natural Pet Foods with<br />

Rotary Batch Mixer<br />

34 K+G Wetter at the Anuga: Butcher's Machines for<br />

Perfection also for Pet Food<br />

36 Boosting Productivity and Maximizing Profit in Pet Food<br />

Production<br />

The black soldier fly (Hermetia illucens) offers many advantages<br />

as an environmentally conscious alternative source of amino<br />

acids and fatty acids for pet diets. These flies are powerful<br />

upcyclers, efficiently turning low-quality feedstock into<br />

premium-quality ingredients. See page 16 for more details.<br />

The right technology in food production ensures the best quality<br />

when it comes to food for our four-legged friends. K+G Wetter<br />

will be exhibiting at Anuga FoodTec to show customers from<br />

pet food production how meat processing machines can play a<br />

significant role in animal food quality. More on page 34.<br />

4<br />

Technology & Marketing

Departments<br />

3 Editorial<br />

52 Upcoming Events<br />

52 Impressum<br />

Events/Showcase<br />

30 Anuga FoodTec Preview: International, Innovative, Successful<br />

48 Interzoo <strong>2024</strong> Supporting Programme: Concise Overview of<br />

Key Topics in the Pet Industry<br />

50 IFT: Processing Improves Food Sustainability and Nutrition<br />

Automated ingredient handling<br />

Dosing, storing and transfer<br />

BULK MINORS FLOUR RECLAIM LIQUIDS CONTROLS COMPONENTS<br />

SITE SERVICES<br />

SILOS<br />

From 6 to 120 tons<br />

Flour, sugar, salt<br />

Pressure safety<br />

High Hygienic<br />

Packaging<br />

41 High Technology Packaging Solutions<br />

42 Safe Food for Faithful Fido<br />

46 World First with Recyclable Flexible Packaging Film<br />

made from More than 50% Recycled Plastic Waste<br />

MINOR<br />

INGREDIENTS<br />

Bag dumping station<br />

ROTARY<br />

SIFTER<br />

From 1 to 20 tons<br />

Products such as stand-up pouches already provide a<br />

convenient, low carbon solution for transporting every-day<br />

goods. A new development has seen an ultra-thin, rigid film<br />

used for recyclable flexible packaging products made from<br />

more than 50% recycled plastic for the first time. The full story<br />

is on page 46.<br />

Confidence<br />

Built in<br />

BIG BAG<br />

STATION<br />

Any kind of<br />

ingredient<br />

Issue 1 <strong>2024</strong><br />

SHICK ESTEVE FRANCE<br />

4 Place des Noyers -18220 RIANS - 02 48 66 60 60<br />

www.shickesteve.com -<br />

5

INGREDIENTS<br />

Global Pet Care Trends in 2023<br />

by Kate Kehoe, Marketing Executive at FMCG Gurus<br />

In recent years, the pet care industry has witnessed a notable transformation, driven<br />

by various trends and shifts in consumer preferences. One of the prominent changes<br />

is the increasing demand for natural and organic products for pets. Pet owners<br />

are becoming more conscious of the ingredients and chemicals used in pet care<br />

items, leading them to seek out options that are free from artificial additives and<br />

unnecessary preservatives. This shift towards natural and organic products reflects<br />

a broader trend seen within the health and wellness industry.<br />

Additionally, there is a growing demand for pet care products that cater to specific<br />

pet needs. Issues such as digestive problems are common among pets, and pet<br />

owners are actively seeking out products that can address these concerns effectively.<br />

This has prompted pet care companies to develop specialized formulas and remedies to<br />

provide targeted solutions for these issues.<br />

Ingredients<br />

Pet owners have become more conscious<br />

of the ingredients in pet care products<br />

for various reasons. For instance, FMCG<br />

Gurus’ consumer insights reveal that 70%<br />

of global consumers think the quality<br />

of ingredients used in dog and cat care<br />

food and drink makes the product more<br />

premium. This highlights an increasing<br />

awareness of the health risks associated<br />

with certain ingredients. For example,<br />

the most important formulation claims<br />

global consumers like to see on dog<br />

care products are non-GMO (59%) and<br />

no artificial flavors (43%) or colors (42%).<br />

This demonstrates that just as humans are<br />

more mindful of the ingredients in their<br />

own products, pet owners are recognizing<br />

that the ingredients used in pet care items<br />

can also impact their pets' well-being.<br />

Artificial additives, preservatives, and<br />

chemicals have the potential to trigger<br />

allergies, digestive issues, and other<br />

health problems in pets. By being more<br />

conscious of ingredients, pet owners<br />

aim to provide their pets with safer and<br />

healthier options.<br />

Natural and Organic<br />

Pet owners are looking to align their<br />

pets' diets and care practices with their<br />

own lifestyle choices. The rise in organic<br />

and natural products for humans has<br />

influenced pet owners to seek out similar<br />

choices for their pets. For example, FMCG<br />

Gurus’ market research highlights that<br />

43% of global consumers like to see<br />

natural ingredient claims on dog care<br />

products. This trend is driven by a desire<br />

for holistic approaches to pet care that<br />

emphasize overall well-being and quality<br />

of life. Therefore, pet owners are seeking<br />

products that are free from artificial<br />

ingredients and pesticides, and that are<br />

produced using sustainable and ethical<br />

practices.<br />

As a result, pet owners are willing to invest<br />

more time and effort in understanding<br />

the nutritional needs of their pets and<br />

ensuring that they are providing them<br />

with the best possible care. This includes<br />

being mindful of the ingredients used<br />

in pet care products and seeking out<br />

options that promote their pets' health<br />

and well-being.<br />

Digestive Health<br />

Pet products that have various health<br />

claims are of high appeal to consumers.<br />

Such claims include aiding digestive<br />

health, free-from claims, and streamlined<br />

ingredients, as consumers want maximum<br />

transparency over product formulation.<br />

The most appealing claim on both dog<br />

(56%) and cat care (54%) products is the<br />

aiding of digestive health. This indicates<br />

that pet owners deem digestive health<br />

a crucial area of wellness, due to it being<br />

interlinked with for long-term health<br />

maintenance. As pet owners become<br />

more proactive in their pets' care, they are<br />

seeking out products that address specific<br />

health concerns. The pet care industry<br />

must continue innovating to meet these<br />

needs, by providing specialized solutions<br />

that enhance pets' quality of life.<br />

Plant-based alternatives<br />

Across the last decade, the growth<br />

of Flexitarian diets has resulted in an<br />

increased number of consumers seeking<br />

Kate Kehoe, Marketing Executive, FMCG<br />

Gurus<br />

out plant-based alternatives that they<br />

deem healthier, more sustainable, and<br />

cruelty-free. This trend is being reflected<br />

in the pet food market, with one in<br />

five pet owners saying they like to see<br />

plant-based or vegan claims on pet care<br />

products. Similarly to the human plantbased<br />

market, brands must provide<br />

reassurance over the taste of products<br />

and the nutritional value of such products.<br />

Sustainability and eco-friendliness are also<br />

gaining traction in the pet care sector.<br />

Technology & Marketing<br />

Pet owners are becoming increasingly<br />

conscious of the environmental impact<br />

of pet care products and packaging.<br />

They are actively seeking out companies<br />

that prioritize eco-friendly practices in<br />

their manufacturing processes, utilize<br />

sustainable ingredients, and offer<br />

recyclable or biodegradable packaging<br />

options. This focus on sustainability<br />

aligns with the broader global movement<br />

towards environmental responsibility and<br />

conservation.<br />

This article is based on FMCG Gurus: The<br />

Humanization of Pets – Global Report 2023.<br />

For more information, please contact info@<br />

fmcggurus.com.<br />

For more information<br />

www.fmcggurus.com<br />

6<br />

Technology & Marketing

Pet Food<br />

Cutting<br />

Solutions<br />

As the #1 Global Leader in Food Cutting Technology,<br />

successful processors depend on Urschel’s expertise<br />

to deliver optimal cutting solutions for pet food<br />

ingredients to produce high-quality fish, chicken, beef,<br />

and vegetable dices and shreds and coarse to smooth<br />

applications such as mousse, pastes, and liquids.<br />

Explore Urschel cutting solutions<br />

to achieve your processing goals.<br />

#1 Best selling provider of<br />

industrial cutting machinery<br />

throughout the world.<br />

The Global Leader in Food Cutting Technology<br />

Set up a free test-cut of your product.<br />

www.urschel.com<br />

®Urschel, Urschel logo symbol, and The Global Leader in Food Cutting Technology<br />

are registered trademarks of Urschel Laboratories, Inc. U.S.A.

INGREDIENTS<br />

Globe Buddy Introduces New<br />

Sustainable Dog Food with Insect<br />

Protein<br />

Danish pet food company Globe Buddy has introduced a super-premium dog food based on a novel and<br />

sustainable source of protein – insects. The brand wants to inspire a positive change and help dog owners live a<br />

greener pet life.<br />

Bjarne Gravesen Jensen, CEO and co-founder of the<br />

Danish pet food company Globe Buddy.<br />

The carbon footprint of the ingredients in Globe Buddy's new product is just over half that of the<br />

ingredients used in the market's average dog food, according to calculations performed by the<br />

consultancy firm Viegand Maagøe on behalf of Globe Buddy.<br />

“We have made it easy to feed your furry<br />

friend a healthy and tasty diet while doing<br />

some good for the planet, simply by<br />

reducing the climate impact of dog food,”<br />

said Bjarne Gravesen Jensen, CEO and cofounder<br />

of Globe Buddy.<br />

The insect-based dog food Globe Buddy<br />

Brown features protein from the black<br />

soldier fly larvae, which is good for all<br />

dogs, especially those with sensitive<br />

digestion or intolerances to traditional<br />

meats.<br />

It is also a win for the climate. Using<br />

insect protein in pet food reduces carbon<br />

emissions. The carbon footprint of the<br />

ingredients in Globe Buddy's new product<br />

is just over half that of the ingredients<br />

used in the market's average dog food,<br />

according to calculations performed by<br />

the consultancy firm Viegand Maagøe on<br />

behalf of Globe Buddy.<br />

The insect-based product comes with<br />

a third-party verified carbon footprint,<br />

something that is still rarely seen in the<br />

pet food industry.<br />

“While many companies have brought<br />

what are claimed to be green pet foods<br />

to market, we saw a need among petparents<br />

for increased transparency in<br />

the environmental sustainability of their<br />

dog’s food. Our brand aims to address<br />

this unmet need,” said Bjarne Gravesen<br />

Jensen.<br />

Besides the climate-friendliness, insect<br />

larvae are a pet food ingredient that<br />

advances the circular economy and<br />

minimises waste because insects are fed<br />

on by-products from the food industry.<br />

Globe Buddy’s commitment to<br />

sustainability also extends to their<br />

packaging, with a fully recyclable and<br />

perfectly-sized box designed for directto-consumer<br />

distribution.<br />

Technology & Marketing<br />

For more information<br />

www.globebuddy.dog<br />

8<br />

Technology & Marketing

INGREDIENTS<br />

Collaboration + Innovation:<br />

How Can Food Science and Technology<br />

Transform the Food System?<br />

Join your colleagues at the leading global science<br />

of food event focused on innovation, thought<br />

leadership, and intentional networking.<br />

Register at<br />

iftevent.org.<br />

Issue 1 <strong>2024</strong><br />

9

INGREDIENTS<br />

Natural Symbiosis: Plant Extracts<br />

Beneficial for Owners and for<br />

Pets<br />

by David Daguet, Scientific Director<br />

Photo: shutterstock_2156779707<br />

We have all seen dogs dressed in eccentric<br />

outfits, wearing hats, wearing glasses in<br />

photos or videos. By making them look<br />

like little people, some owners please<br />

themselves without worrying about<br />

the well-being of their companions.<br />

Anthropomorphism means attributing<br />

to pets, behavior, reactions, and feelings,<br />

specific to humans. But attributing<br />

human faculties and feelings to our cats<br />

or dogs can distort the understanding of<br />

their real emotions and needs, and lead<br />

to errors of interpretation. Sometimes<br />

anthropomorphism can even lead to<br />

involuntarily mistreating pets.<br />

Even without anthropomorphism, pets<br />

may suffer from health troubles or illnesses<br />

that their owners also suffer from.<br />

But anthropomorphism can be extended<br />

to turning to natural treatments used by<br />

humans for years now through healthy<br />

diets, food supplements and cosmetics,<br />

and applied to pets. It is also real that<br />

our cats, dogs, and other pets, like their<br />

owners, may be affected by the “side<br />

effects” of the “modern” way of life.<br />

These can generate health troubles and<br />

sometimes more serious diseases. In<br />

fact, pets, like their owners, can present<br />

metabolic, liver, immune, locomotor,<br />

fertility disorders and diseases.<br />

Natural alternatives that help humans,<br />

can also be considered for our companions.<br />

Vidya Europe, a world leader<br />

in natural solutions, is also concerned<br />

with pet’s well-being. Vidya Europe, by<br />

combining tradition and strong modern<br />

science, develops and offers natural<br />

solutions.<br />

The following GMP+ certified plant<br />

extracts have been scientifically researched<br />

and proven to be beneficial for<br />

cats and dogs.<br />

Cats<br />

Artichoke and milk thistle<br />

As indicated in the introduction, our cats<br />

can suffer from metabolic disorders, and<br />

the main manifestation can be linked to<br />

the health of the liver. As an example,<br />

acute and chronic hepatobiliary diseases<br />

are quite commonly reported for both<br />

dogs and cats. There are many different<br />

causes for these conditions, as well as<br />

many different treatment options. The<br />

treatments reported for these conditions<br />

include anti-inflammatory molecules,<br />

immunosuppressants, antifibrotics,<br />

antioxidants, dietary management,<br />

and management of any possible<br />

complications. Dealing with natural<br />

solutions, artichoke (Cynara scolymus)<br />

and milk thistle (Silybum marianum)<br />

extracts should be considered. Artichoke<br />

leaf extract has been associated with<br />

antioxidant, hepatoprotective, bileexpelling,<br />

and lipid-lowering effects.<br />

Silymarin, the major active component of<br />

milk thistle, exerts immunomodulatory,<br />

anti-inflammatory, regenerative, antifibrotic,<br />

antioxidant, choleretic, and<br />

hepatoprotective actions directly<br />

benefiting to liver.<br />

Curcumin<br />

Curcumin, composed of mainly three<br />

curcuminoids, is the active principle<br />

10<br />

Technology & Marketing

of turmeric (Curcuma longa). Because<br />

its anti-inflammatory, antimicrobial,<br />

antioxidant, hepatoprotective, and<br />

immunomodulatory properties, curcumin<br />

is of interest 1,2 , and has been<br />

used in a combined natural formulation<br />

to help in the treatment of feline<br />

hyperthyroidism by Methimazole 3 .<br />

β-carotene<br />

Even if the conversion ratio of β-carotene<br />

into retinol is not clearly established in<br />

feline, cats readily absorb β-carotene.<br />

Domestic cats absorb β-carotene from<br />

their diet, which is then absorbed by<br />

their reproductive tissues and can act as<br />

an antioxidant to maintain the functional<br />

integrity of these tissues, increasing<br />

plasma progesterone, oestradiol concentrations,<br />

and the total amount of uterine<br />

protein 4 .<br />

Dogs<br />

Artichoke and milk thistle<br />

Like for cats, artichoke and milk thistle<br />

are friendly natural remedies for dog’s<br />

livers. But for dogs, milk thistle can also<br />

help to modulate the immune response<br />

to improve their health condition 5 .<br />

Curcumin<br />

Like for humans, diabetes mellitus is a<br />

common endocrine disorder that causes<br />

hyperglycaemia in dogs. Curcuminoid<br />

supplementation with standard treatment<br />

has been demonstrated to significantly<br />

reduce oxidative stress and<br />

can be used as a targeted antioxidant<br />

strategy in adjunctive therapy to<br />

minimise the complications of diabetes<br />

in dogs 6 .<br />

Due to its anti-inflammatory effects,<br />

curcumin may also improve animal<br />

health, with emphasis on the stimulation<br />

of the antioxidant system 7 . Like for<br />

humans, curcumin has a real application<br />

in relieving locomotor disorders by<br />

managing pain and inflammation 8,9 .<br />

β-carotene<br />

Immunity modulation can be very<br />

important, and we know that advanced<br />

age has a negative impact<br />

on various immune variables. Older<br />

dogs that have lower immunological<br />

responses in comparison with younger<br />

ones may benefit from β-carotene<br />

supplementation which can significantly<br />

restore their immune responses 10 . It<br />

has also been demonstrated in female<br />

Beagle dogs that immune response was<br />

impaired in animals classified as low<br />

β-carotene absorbers, in comparison<br />

with similar females fed with the same<br />

amount of β-carotene 11 . Like for feline, it<br />

is possible that dietary β-carotene may<br />

improve reproductive function in the<br />

canine 12 .<br />

Green tea<br />

Green tea (Camellia sinensis) is not only<br />

a healthy beverage, but it also offers<br />

health benefits for dogs. Active in oral<br />

health, epigallocatechin gallate, the<br />

main active ingredient in green tea,<br />

interacts with the bacterial membrane to<br />

inhibit biofilm formation and to damage<br />

the biofilms 13 . As for humans, it can<br />

help manage metabolic disorders, and<br />

has been assessed on obese dogs with<br />

insulin resistance and dyslipidaemia,<br />

demonstrating that nutritional doses of<br />

green tea extract may improve insulin<br />

sensitivity and lipid profile. It also<br />

modifies the expression of genes involved<br />

in glucose and lipid homeostasis 14 .<br />

Owners and pets: the same<br />

remedies<br />

Pets are essential to human’s equilibrium.<br />

Pets help humans cope with solitude;<br />

they are part of a healthier way of<br />

life. Plant extracts beneficial for both<br />

owners and pets reinforce their common<br />

relationship. Like for humans, artichoke,<br />

green tea, milk thistle, curcuma, and<br />

natural β-carotene can help maintain or<br />

improve cats and dogs’ health. A natural<br />

symbiosis between owners and their<br />

pets, using the same natural remedies.<br />

References<br />

Technology & Marketing<br />

1. Marchegiani A, Fruganti A, Gavazza<br />

A, Mangiaterra S, Candellone A, Fusi<br />

E, Rossi G, Cerquetella M. Evidences on<br />

Molecules Most Frequently Included<br />

in Canine and Feline Complementary<br />

Feed to Support Liver Function. Vet<br />

Med Int. 2020 May 9;2020:9185759.<br />

doi: 10.1155/2020/9185759. PMID:<br />

32454964; PMCID: PMC7232710.<br />

2. Leray V, Freuchet B, Le Bloc'h J,<br />

Jeusette I, Torre C, Nguyen P. Effect<br />

of citrus polyphenol- and curcuminsupplemented<br />

diet on inflammatory<br />

state in obese cats. Br J Nutr. 2011<br />

Best INGREDIENTS in<br />

bioavailability!<br />

CeF i<br />

®pro<br />

–<br />

Autolysed yeast!<br />

Technology & Marketing<br />

| free amino acids &<br />

nucleotides<br />

| promotes intestinal<br />

integrity<br />

| stimulates metabolism<br />

| enhances palatability<br />

Visit our website:<br />

leibergmbh.de<br />

Issue 1 <strong>2024</strong><br />

11<br />

Leiber GmbH | Franz-Leiber-Straße 1 | 49565 Bramsche<br />

Germany | info@leibergmbh.de

INGREDIENTS<br />

Oct;106 Suppl 1:S198-201. doi:<br />

10.1017/S0007114511002492. PMID:<br />

22005428.<br />

3. Candellone A, Badino P, Gianella<br />

P, Girolami F, Raviri G, Saettone V,<br />

Meineri G. Evaluation of Antioxidant<br />

Supplementation on Redox Unbalance<br />

in Hyperthyroid Cats Treated with<br />

Methimazole: A Blinded Randomized<br />

Controlled Trial. Antioxidants (Basel).<br />

2019 Dec 23;9(1):15. doi: 10.3390/<br />

antiox9010015. PMID: 31877998;<br />

PMCID: PMC7022672.<br />

4. Chew BP, Weng BB, Kim HW, Wong<br />

TS, Park JS, Lepine AJ. Uptake of betacarotene<br />

by ovarian and uterine tissues<br />

and effects on steroidogenesis during<br />

the estrous cycle in cats. Am J Vet Res.<br />

2001 Jul;62(7):1063-7. doi: 10.2460/<br />

ajvr.2001.62.1063. PMID: 11453481.<br />

5. Sgorlon S, Stefanon B, Sandri M,<br />

Colitti M. Nutrigenomic activity of<br />

plant derived compounds in health<br />

and disease: Results of a dietary<br />

intervention study in dog. Res Vet Sci.<br />

2016 Dec;109:142-148. doi: 10.1016/j.<br />

rvsc.2016.10.005. Epub 2016 Oct 13.<br />

PMID: 27892863.<br />

6. Suemanotham N, Photcharatinnakorn<br />

P, Chantong B, Buranasinsup S,<br />

Phochantachinda S, Sakcamduang<br />

W, Reamtong O, Thiangtrongjit<br />

T, Chatchaisak D. Curcuminoid<br />

supplementation in canine diabetic<br />

mellitus and its complications using<br />

proteomic analysis. Front Vet Sci.<br />

2022 Dec 23;9:1057972. doi: 10.3389/<br />

fvets.2022.1057972. PMID: 36619946;<br />

PMCID: PMC9816143.<br />

7. Campigotto G, Alba DF, Sulzbach<br />

MM, Dos Santos DS, Souza CF,<br />

Baldissera MD, Gundel S, Ourique AF,<br />

Zimmer F, Petrolli TG, Paiano D, Da<br />

Silva AS. Dog food production using<br />

curcumin as antioxidant: effects of<br />

intake on animal growth, health<br />

and feed conservation. Arch Anim<br />

Nutr. 2020 Oct;74(5):397-413. doi:<br />

10.1080/1745039X.2020.1769442.<br />

Epub 2020 Jun 30. PMID: 32602378.<br />

of the efficacy of a diet supplemented<br />

with curcuminoids extract, hydrolyzed<br />

collagen and green tea extract in<br />

owner's dogs with osteoarthritis. BMC<br />

Vet Res. 2017 Dec 20;13(1):395.<br />

Photo: shutterstock_1919383028<br />

8. Comblain F, Barthélémy N, Lefèbvre<br />

M, Schwartz C, Lesponne I, Serisier<br />

S, Feugier A, Balligand M, Henrotin<br />

Y. A randomized, double-blind,<br />

prospective, placebo-controlled study<br />

of the efficacy of a diet supplemented<br />

with curcuminoids extract, hydrolyzed<br />

collagen and green tea extract in<br />

owner's dogs with osteoarthritis. BMC<br />

Vet Res. 2017 Dec 20;13(1):395. doi:<br />

10.1186/s12917-017-1317-8. PMID:<br />

29262825; PMCID: PMC5738810.<br />

9. Știrbu, Mara & Mariana, Grecu &<br />

Henea, Mădălina & Mihai, Iuliana<br />

& Savuţa, Gheorghe. (2022). THE<br />

ANTI-INFLAMMATORY EFFECTS<br />

OF TURMERIC IN LOCOMOTOR<br />

DISORDERS: A SHORT REVIEW. Journal<br />

of Veterinary Medicine Series A. 64. 59<br />

- 62.<br />

10. Massimino S, Kearns RJ, Loos KM, Burr<br />

J, Park JS, Chew B, Adams S, Hayek<br />

MG. Effects of age and dietary betacarotene<br />

on immunological variables<br />

in dogs. J Vet Intern Med. 2003 Nov-<br />

Dec;17(6):835-42. doi: 10.1111/j.1939-<br />

1676.2003.tb02523.x. PMID: 14658721.<br />

11. Dietary beta-carotene stimulates<br />

cell-mediated andhumoral immune<br />

response in dogs<br />

12. Weng BC, Chew BP, Wong TS, Park JS,<br />

Kim HW, Lepine AJ. Beta-carotene<br />

uptake and changes in ovarian<br />

steroids and uterine proteins during<br />

the estrous cycle in the canine. J<br />

Anim Sci. 2000 May;78(5):1284-90.<br />

doi: 10.2527/2000.7851284x. PMID:<br />

10834584.it<br />

13. Bai L, Takagi S, Ando T, Yoneyama<br />

H, Ito K, Mizugai H, Isogai E.<br />

Antimicrobial activity of tea catechin<br />

against canine oral bacteria and the<br />

functional mechanisms. J Vet Med<br />

Sci. 2016 Oct 1;78(9):1439-1445. doi:<br />

10.1292/jvms.16-0198. Epub 2016<br />

May 28. PMID: 27246281; PMCID:<br />

PMC5059371.<br />

14. Serisier S, Leray V, Poudroux W, Magot<br />

T, Ouguerram K, Nguyen P. Effects of<br />

green tea on insulin sensitivity, lipid<br />

profile and expression of PPARalpha<br />

and PPARgamma and their target<br />

genes in obese dogs. Br J Nutr. 2008<br />

Jun;99(6):1208-16. doi: 10.1017/<br />

S0007114507862386. Epub 2007 Dec<br />

6. PMID: 18053305.<br />

For more information<br />

www.vidyaeurope.com<br />

12<br />

Technology & Marketing

PALATANTS.<br />

SOLUTIONS.<br />

SERVICES.<br />

AFB is more than just palatants. We provide custom solutions to<br />

improve pet food palatability. Our services are tailored to the<br />

specific needs of each customer. We can partner to meet their<br />

objectives while making pet food taste great!<br />

BOOTH 1300<br />

STAND 6-321<br />

To learn how AFB brings value to pet food companies through<br />

research expertise, technical support and unparalleled<br />

customer service, visit afbinternational.com or<br />

contact your AFB account manager.<br />

© <strong>2024</strong> AFB International

INGREDIENTS<br />

Demand for Quality, Nutritional<br />

and Healthy Pet Food Remains<br />

High Despite Inflation<br />

Global survey reveals pet owners consider digestive health key for achieving holistic health and wellbeing<br />

New research results show that despite<br />

inflation and price increases on pet food,<br />

owners continue to want the best for<br />

their pets. As a consequence, delivering<br />

added value such as nutritional, health or<br />

sustainability benefits is key to retaining<br />

consumer interest in times of tighter<br />

budgets. This new global survey has been<br />

conducted by the market research agency<br />

FMCG Gurus, on behalf of BENEO, with<br />

2,500 dog and cat owners in the US, Brazil,<br />

UK, Germany, and China.<br />

Price versus value<br />

The research demonstrates that even<br />

though almost 9 in 10 surveyed pet owners<br />

feel that pet food prices have risen in the<br />

last year, only 1 in 6 pet parents globally has<br />

turned to cheaper products or brands as a<br />

result. Most are staying loyal to their brand<br />

of choice by taking greater advantage of<br />

promotional offers or bigger packs. In fact,<br />

price is considered less important when<br />

buying pet food compared to ingredient<br />

quality, nutritional value, taste and health<br />

claims. And over half of respondents are<br />

even willing to pay a price premium for pet<br />

food with health-promoting ingredients<br />

that have been scientifically proven.<br />

Prioritizing health<br />

Pet parents are very concerned about<br />

their pet’s health and the survey results<br />

reflect this, with more than 4 in 5 owners<br />

considering their pet’s health to be as<br />

important as their own. The link between<br />

their pet’s digestive health and overall<br />

health is also more widely recognised<br />

by pet owners, with over 3 in 4 cat and<br />

dog owners understanding that the<br />

digestive system has a positive influence<br />

on many aspects beyond the gut, such<br />

as bone condition, mental and physical<br />

wellbeing and the immune system. It is<br />

not surprising therefore that the on-pack<br />

claims most likely to influence purchasing<br />

of pet food products include “promotes<br />

digestive health naturally” and “easy-todigest”.<br />

Natural support for digestive<br />

health<br />

Most pet owners opt for a proactive and<br />

natural approach to nurturing their pet’s<br />

digestive health, with more than 1 in<br />

3 saying that they feed their pets food<br />

that features claims to support digestive<br />

health, showing the importance of<br />

highlighting specific benefits on pack. The<br />

digestive health claims with the biggest<br />

effect on pet owners’ purchase interests<br />

are: “digestive comfort and well-being”,<br />

“promotes digestive health naturally”<br />

14<br />

Technology & Marketing

INGREDIENTS<br />

and “supports a healthy and balanced<br />

digestive system”. In addition, almost half<br />

of pet owners associate prebiotics with gut<br />

health, making this a key ingredient in pet<br />

food manufacturers’ toolbox.<br />

Demand for proteins and<br />

sustainable credentials<br />

The survey also reveals that protein quality<br />

and content are important for 7 in 10<br />

respondents. Additionally, sustainability<br />

claims are considered to some extent by 4<br />

in 5 owners when choosing food for their<br />

pets. With more than half of cat and dog<br />

owners considering plant-based proteins<br />

to be better for the environment, it is no<br />

surprise that vegetal ingredient sources<br />

with sustainability credentials are of<br />

increasing relevance. For instance, more<br />

than 80% of pet owners associate faba<br />

beans with being sustainable. Natural and<br />

high-quality vegetal proteins are therefore<br />

a valuable resource for manufacturers,<br />

allowing them to cater to pet owners’<br />

interests, whilst formulating nutritious pet<br />

food recipes.<br />

Dr. Maygane Ronsmans, Product Manager<br />

Animal Nutrition at BENEO says: “The<br />

findings of this latest pet owner survey<br />

highlight that even in times of inflation,<br />

nutritional value and health remain<br />

a priority for pet food purchasers.<br />

Scientifically proven prebiotics, like<br />

BENEO’s Orafti® Inulin and Oligofructose<br />

from chicory root, are proving popular<br />

with pet food producers as they naturally<br />

support digestive health, whilst allowing<br />

for appealing on-pack communication.<br />

Also, with pet owners more attentive to<br />

sustainability, BENEO’s vegetal proteins,<br />

derived from faba bean, wheat or rice,<br />

are valuable assets in pet food producers’<br />

toolboxes. Thanks to a versatile range of<br />

plant-based ingredients with technical,<br />

nutritional and health-promoting benefits,<br />

as well as longstanding expertise in<br />

healthy nutrition, BENEO is well equipped<br />

to help manufacturers bring to market<br />

innovative and relevant pet food products<br />

that meet consumer demand, even in a<br />

tough economic climate.”<br />

Technology & Marketing<br />

For more information<br />

www.beneo.com<br />

<strong>PetFood</strong>Pro_1_3ad_210x99mm_f.pdf 1 16/01/<strong>2024</strong> 14:06:23<br />

Pawsitively Beneficial<br />

Water Extracted Botanical Ingredients<br />

®<br />

®<br />

®<br />

® ®<br />

Pomegranate fruit extract<br />

Antioxidant Support<br />

Healthy Ageing<br />

Cucumber extract<br />

Joint Health<br />

Lemon fruit extract<br />

Naturally Bioavailable Flavonoids<br />

Artichoke bud extract<br />

Prebiotic and<br />

Digestive Health<br />

Olive fruit extract<br />

Powerful Antioxidant<br />

Technology & Marketing<br />

Discover our 40+ botanical extracts<br />

www.euromedgroup.com<br />

Issue 1 <strong>2024</strong><br />

15

INGREDIENTS<br />

Science-Backed Insect Proteins<br />

Gain Traction in Pet Food<br />

by Jennifer Adolphe<br />

Hermetia Illucens (black soldier fly)<br />

©Innovafeed<br />

Innovafeed vertical farm<br />

Innovafeed team<br />

Pet foods have traditionally relied on<br />

animal protein ingredients. Growing<br />

environmental concern is partly to thank<br />

for the surge in demand for alternative<br />

proteins that can supplement or replace<br />

animal derived ingredients that have<br />

traditionally been more resource intensive.<br />

Insect ingredients from black soldier<br />

fly larvae (BSFL) offer a more resource<br />

friendly alternative to go along with<br />

unique benefits for your furry friends.<br />

The Mighty Black Soldier Fly<br />

The black soldier fly (Hermetia<br />

illucens) offers many advantages as an<br />

environmentally conscious alternative<br />

source of amino acids and fatty acids<br />

for pet diets. These flies are powerful<br />

upcyclers, efficiently turning lowquality<br />

feedstock into premium-quality<br />

ingredients.<br />

Innovafeed is a biotechnology company<br />

and a leading producer of black soldier<br />

fly larvae ingredients. Innovafeed’s<br />

Hilucia Protein and Oil contain unique<br />

components, including lauric acid,<br />

bioactive peptides and chitin. Lauric acid<br />

is a medium chain triglyceride, a fatty<br />

acid prevalent in coconut oil, and is being<br />

studied for its potential benefits. The<br />

black soldier fly expresses over 50 unique<br />

bioactive peptides, which are small<br />

proteins with distinct properties. Chitin<br />

acts as a dietary fiber to support digestive<br />

health. These components are in addition<br />

to the highly digestive amino acids that<br />

help dogs and cats meet their essential<br />

amino acid requirements.<br />

By combining the most advanced<br />

knowledge of Hermetia illucens’ nutritional<br />

properties with Innovafeed’s circular<br />

and zero-waste insect breeding model<br />

and expertise in ingredient formulation,<br />

Hilucia aims to meet consumer demand<br />

for high-protein, sustainably sourced<br />

ingredients for pet foods, treats and<br />

supplements.<br />

Jennifer Adolphe, PhD, Pet Technical<br />

Services Manager, ADM<br />

Innovafeed and ADM have recently<br />

entered a partnership agreement for<br />

exclusive distribution rights of Innovafeed’s<br />

ingredients in North America. Additionally,<br />

ADM and Innovafeed have pursued joint<br />

research and development focused on<br />

BSFL and pet nutrition, such as palatability<br />

studies and protein performance.<br />

Innovations in Research &<br />

Development<br />

Before a novel ingredient can be<br />

incorporated in new product development,<br />

pet brands must evaluate a number<br />

of factors. Rigorous scientific research is<br />

crucial to uncovering viable sources of<br />

proteins and oils that will provide optimal<br />

nutrition for cats and dogs. For example,<br />

an animal must be able to digest the<br />

amino acids from a protein source to<br />

ensure their amino acid requirements are<br />

met.<br />

In collaboration with ADM and Innovafeed,<br />

a research study was conducted at the<br />

University of Illinois to investigate the<br />

protein quality of BSFL in dogs 1 .<br />

The goal was to determine the suitability<br />

of BSFL as a nutritious substitution for<br />

other commonly used protein ingredients<br />

in pet food. The research study included<br />

two feeding trials. First, three ingredients<br />

were evaluated: Hilucia Protein, whole<br />

powdered egg and chicken meal, to assess<br />

amino acid digestibility. A second trial<br />

was designed to evaluate macronutrient<br />

digestibility of Hilucia Protein in dog<br />

diets.<br />

16<br />

Technology & Marketing

PLANT<br />

EXTRACTS<br />

FOR PETS<br />

The first trial measured the digestible<br />

indispensable amino acid score (DIAAS),<br />

a score based on amino acid digestibility<br />

that is used to assess protein quality.<br />

DIAAS values for Hilucia Protein were<br />

compared to scores for chicken meal, a<br />

high-quality, very common ingredient<br />

in pet food, and powdered egg, which<br />

is considered the gold standard for<br />

protein quality. Results demonstrate that<br />

Hilucia Protein is a suitable substitute<br />

for chicken meal in pet foods 1 .<br />

• Turmeric<br />

• Capsicum<br />

• Rosemary<br />

• Black pepper<br />

• And more...<br />

In the second trial, dog diets were<br />

specifically formulated for this research<br />

and included a controlled diet made<br />

with chicken meal, a diet that included<br />

15% Hilucia Protein, and another<br />

test diet that included 30% Hilucia<br />

Protein. These levels represented using<br />

insect protein as a partial substitution<br />

for chicken meal and one that replaced<br />

chicken meal entirely. Findings indicate<br />

that the Hilucia Protein at both 15%<br />

and 30% inclusion was well accepted<br />

by the dogs 1 . Additionally, all the diets<br />

had average fecal scores between<br />

2 and 3, which is considered ideal 1 .<br />

Researchers also noted that macronutrient<br />

digestibility values were<br />

very similar between the three diets,<br />

again suggesting that Hilucia Protein<br />

performs similarly to chicken meal in dog<br />

diets 1 .<br />

VIDYAEUROPE.COM

INGREDIENTS<br />

Hermetia Illucens Larvae ©Innovafeed<br />

Consumer Perceptions Soar<br />

Understanding consumer perceptions<br />

of novel ingredients is another key<br />

component in new product development.<br />

ADM and Innovafeed recently<br />

conducted a study of U.S. pet owners<br />

who had at least one dog, at least one<br />

cat, or both. Participants were first asked<br />

how likely they were to feed their pet a<br />

food made with insect protein to get<br />

a baseline response. Other questions<br />

included some educational facts about<br />

insect ingredients, and then the initial<br />

question was repeated.<br />

Results suggest that with a bit of<br />

education, 42% of pet owners were<br />

more likely to feed their pet with insect<br />

protein 2 . It is essential for pet food to be<br />

tasty and nutritious, and other attributes<br />

may encourage pet owners to choose<br />

an insect-based pet food, such as the<br />

science behind specific ingredient<br />

inclusions 2 .<br />

The top-ranked wellness claims that<br />

are important to pet owners are high<br />

protein, digestive health and healthy<br />

aging 2 . Sixty-three percent of surveyed<br />

pet owners said having such priorities<br />

met would increase their likelihood<br />

of serving pet food made with insect<br />

protein2. And with additional education,<br />

35% of pet owners became comfortable<br />

or very comfortable with serving insect<br />

protein 2 .<br />

Environmentally Conscious<br />

Production<br />

Modern pet parents have a heightened<br />

focus on pet products that are good<br />

for their furry family members<br />

and for the planet. In fact, 42% of<br />

global pet owners say they want to<br />

purchase pet food with sustainably<br />

sourced ingredients 3 . Insect<br />

ingredients have exciting potential<br />

to support a circular economy and<br />

corporate environmental initiatives.<br />

Innovafeed insect farming<br />

Innovafeed’s innovative vertical insect<br />

farms are strategically located alongside<br />

grain processing facilities to enable an<br />

“industrial symbiosis” production model.<br />

ADM’s corn processing plant in Decatur,<br />

Illinois, will provide grain byproducts<br />

that Innovafeed will upcycle as feedstock<br />

to grow BSFL, eliminating the need for<br />

energy to dry the feedstock and trucks<br />

required for transport. This commitment<br />

to sustainably produced ingredients and<br />

ethical business practices has earned<br />

Innovafeed the distinction of becoming<br />

a B Corp-certified company.<br />

With more pets in the home than<br />

ever, there is a rising sense of urgency<br />

to provide high-performance pet<br />

nutrition products that can assist in<br />

supporting the circular economy.<br />

ADM’s partnership with Innovafeed and<br />

promising advancements in research and<br />

development are just a few examples of<br />

how the pet food industry is evolving to<br />

meet the needs of today’s discerning pet<br />

owners.<br />

Technology & Marketing<br />

1Maria R. C. de Godoy, Ph.D., Associate<br />

Professor at the Department of Animal<br />

Sciences, University of Illinois. Unpublished<br />

research.<br />

2ADM Outside Voice SM<br />

3FMCG Gurus, Pet Care Health, 2022<br />

For more information<br />

www.adm.com<br />

18<br />

Technology & Marketing

W300U<br />

■<br />

■<br />

■<br />

■<br />

Flexibility with fluctuating meat prices<br />

Separate or simultaneous processing of fresh meat and<br />

frozen meat blocks down to -25 °C<br />

Same cutting set for fresh meat and frozen<br />

meat blocks<br />

Easy control with programmes for respective<br />

raw materials to avoid operating errors<br />

■<br />

■<br />

■<br />

Frequency-controlled and continuously variable drives:<br />

No current peaks, low energy consumption<br />

Robust and reliable construction<br />

Hygienic design: polished surfaces, embedded covers,<br />

CIP-cleaning, removable bearing<br />

duction Lines<br />

nd-Hand M

Expanding Capacity with a Heat<br />

Pump Dryer<br />

<strong>PRO</strong>CESSING<br />

Investing in a new drying system a producer of pet food could increase output, cut energy cost, optimize<br />

product quality, and shorten the drying period. Let us look at an alternative dehumidification technology<br />

based on the use of a heat pump.<br />

The 8-chamber dryer is designed to process daily batches of about 1,500 kg of sausage meat placed on Intercarne’s existing trolleys.<br />

Intercarne of Upper Bavaria, Germany,<br />

is a producer of special dog food. The<br />

company founded in 1985 sells snacks<br />

and chews made from 100 percent<br />

natural, pluck and grain free raw<br />

materials, also organic, on international<br />

markets. Intercarne, as so many other<br />

manufacturers, used a dryer that did<br />

no longer work efficiently enough. The<br />

company based at lake Chiemsee also<br />

intended to expand their capacity. "We<br />

also wanted to find a solution that would<br />

allow the continued use of our existing<br />

drying trolleys," explains Philipp Hibler,<br />

Managing Director of Intercarne GmbH.<br />

So, it was time for an up-to-date, energy<br />

efficient technology and a versatile<br />

drying solution. Hibler found such a<br />

solution through an internet search –<br />

a heat pump assisted, chamber-type<br />

condensation drying system.<br />

Harter of Stiefenhofen, Germany,<br />

dev-eloped this drying technique<br />

more than 30 years ago. Nobody was<br />

interested in a heat pump at that time,<br />

it was the quality result that mattered.<br />

"Today, efficiency and saving of energy<br />

are of equal value as meeting the<br />

specified residual humidity requirement,"<br />

explains Stephan Ortmann of<br />

Harter Technical Sales. "Another plus<br />

of our heat pump assisted process<br />

is that its low drying temperatures<br />

have positive effects on the flavor, the<br />

ingredients, and the look and feel." Each<br />

manufacturer has, of course, their very<br />

special requirements.<br />

Tests and Solution<br />

The German drying system manufacturer<br />

normally runs tests in their in-house<br />

pilot plant station to establish the<br />

drying response of the relevant product.<br />

The station includes several dryers to<br />

determine the relevant parameters. For<br />

Intercarne, the tests were conducted<br />

using a loan system on site. Upon<br />

instruction by an engineer, the dog food<br />

producer tested samples of products from<br />

horse meat, strips of beef, turkey, venison,<br />

or salmon. Depending on their size and<br />

properties, some snacks showed a residual<br />

humidity below 10 percent after only a<br />

few hours, while others – with originally<br />

higher humidity – needed 30, 40 or more<br />

hours. Another factor is the desired final<br />

consistency – soft or rather firm to the<br />

Issue 1 <strong>2024</strong><br />

21

<strong>PRO</strong>CESSING<br />

started. Temperature and humidity<br />

sensors pick up the relevant parameters.<br />

Once the desired result is obtained, the<br />

drying system shuts down automatically.<br />

Snacks and chews are then forwarded for<br />

further processing.<br />

Heat Pump and Government<br />

Subsidy<br />

The core of each Harter dryer is the<br />

heat pump technology integrated in<br />

the dehumidification module. Where<br />

the module is installed depends on the<br />

space available on site – directly next<br />

to the drying chamber or, alternatively,<br />

in another room or on another level.<br />

Irrespective of its installation space<br />

the module is connected to the drying<br />

chamber through insulated piping.<br />

Ortmann explains: "The heat pump<br />

module conditions the process air and<br />

is also responsible for the condensation<br />

process." The process air is extremely<br />

dry and, thus, unsaturated. It is passed<br />

through or over the items to be dried. It<br />

perfectly absorbs any humidity present.<br />

Subsequently, the air is cooled, and<br />

the humidity condenses to form water.<br />

The air is reheated and returned to the<br />

drying chamber. Drying temperatures are<br />

normally between 20 °C and 75 °C. High<br />

temperature steps or cooling stations may<br />

easily be integrated if desired.<br />

Managing Director Philipp Hibler inspects dried material for conformity with defined quality<br />

features including the defined residual humidity, the desired consistency, and a uniformly<br />

dry product.<br />

The drying period depends on the<br />

desired or required residual humidity to<br />

be achieved. For packaged food, where<br />

the wet package is to be dried, the drying<br />

period is often in the order of minutes to<br />

meet the specified cycle time. For direct<br />

product drying, the drying period is often<br />

longer and as required to obtain the<br />

desired residual humidity of the product.<br />

bite. This has, of course, an impact on the<br />

drying period. The temperatures used for<br />

test purposes were between 50 °C and<br />

55 °C. The data obtained from the tests<br />

was used to create individual recipes. The<br />

recipes are stored in the controller of the<br />

drying system built and may be called up<br />

by the operator.<br />

The tests are also used to establish the<br />

design of the drying system best suited<br />

for the product in question. Sensitive<br />

products, for example, are often<br />

dehumidified on trolleys whereas more<br />

robust material may also be dried in<br />

barrels. Continuous solutions, such as belt<br />

dryers, are rather used for semi or fully<br />

automatic processes.<br />

The solution for Intercarne was given<br />

from the beginning because they<br />

wanted to continue to use their existing<br />

drying trolleys. Harter designed and<br />

built an 8-chamber dryer to process the<br />

manufacturer’s 1,500 kg approx. batches<br />

of dog snacks. The dryer was sized to<br />

exactly accommodate the existing<br />

trolleys. The trolleys are manually moved<br />

into the drying chambers, the appropriate<br />

recipe is selected, and the drying process<br />

A critical factor for drying to be successful<br />

is air routeing because the air, by its very<br />

nature, always follows the path of least<br />

resistance. The method to force the air onto<br />

the desired path is one of Harter’s recipes<br />

for success. "Special system engineering<br />

is our strong suit because every customer<br />

has their own product and their own<br />

process," says Ortmann. "What counts at<br />

the end of the day is that the product is<br />

perfectly and uniformly dehumidified and<br />

the process is reproducible – and this goal<br />

we do achieve."<br />

The power rating of the 8-chamber dryer<br />

is only 45 kW. The closed air system<br />

contributes to even higher efficiency.<br />

22<br />

Technology & Marketing

<strong>PRO</strong>CESSING<br />

Residual humidities below 10 percent were obtained in<br />

tests at 50 °C to 55 °C. This corresponded to the desired<br />

consistency. Defined temperature limits enable exact<br />

dry matter contents to be achieved. Absolute process<br />

reliability is thus ensured.<br />

Our drying technique was classified by<br />

the government as future fit technology<br />

in 2017. So, Harter’s heat pump systems<br />

stand out by their high energy efficiency.<br />

"Constant quality, shorter drying periods<br />

through optimized air routeing, lower<br />

energy consumption - for us, this drying<br />

method has fulfilled more than we had<br />

desired. Consequently, we ordered<br />

another two large size Harter drying<br />

systems," summarizes Hibler contentedly.<br />

Technology & Marketing<br />

For more information<br />

www.harter-gmbh.de<br />

Defrosting<br />

Tumbling<br />

Pressing<br />

Slicing<br />

Mixing & Grinding<br />

Forming<br />

Separation<br />

provisur.com<br />

Anuga FoodTec 19. – 22. March <strong>2024</strong><br />

Hall 9.1 || Booth B040 C059<br />

HIGHER YIELD<br />

SEPARATION<br />

FOR PET FOOD<br />

The Beehive S-Series rotary separator<br />

• Very high yield and quantity in pet food<br />

• High-speed separation leads to reduced temperature rise<br />

on end product<br />

• Robust construction with simple design<br />

BEEHIVE S20<br />

Issue 1 <strong>2024</strong><br />

23<br />

BEEHIVE ®

<strong>PRO</strong>CESSING<br />

The Application of Texture<br />

Analysis on the Latest<br />

Developments<br />

by Jo Smewing, Business Development Director<br />

The soaring demand for protein poses a<br />

real challenge, because current available<br />

supplies just can't keep up. This gap<br />

between protein supply and demand<br />

is expected to continue to expand as<br />

the world population and global pet<br />

ownership increases. From alligator,<br />

kangaroo, buffalo and brushtail possum<br />

in dog and cat treats pet food companies<br />

are cleverly catering to growing consumer<br />

demand for ever more exotic and novel<br />

sources of protein. Just as people are<br />

seeking to try new types, and increase<br />

the levels, of protein in the foods they eat,<br />

they are doing the same for their pets'<br />

foods, thanks to ongoing humanization.<br />

Plant-based proteins<br />

Many plant-based proteins have been<br />

widely used in human and animal nutrition<br />

for years such as soybeans, peas, lupin<br />

beans, potatoes, wheat and corn. Other<br />

meat analogues and the development of<br />

e.g. vegan canine biscuits, are just now<br />

starting to become popular and widely<br />

available.<br />

Upcycling<br />

Upcycling is a new word for something<br />

the pet food industry has done for a long<br />

time, using human food products that<br />

would have otherwise gone to waste.<br />

Upcycled pet food ingredients use existing<br />

materials, especially otherwise discarded<br />

foods like misshapen vegetables or citrus<br />

by-products, to make a value-added item.<br />

Fortified and functional foods<br />

Fortified and functional foods are<br />

packaged foods and beverages that have<br />

been enhanced with additional health<br />

components and/or nutrients in order to<br />

provide a nutritional benefit. Pet treats<br />

are given to dogs to strengthen pet and<br />

owner bonds and as a reward but it is<br />

essential to understand the functionality<br />

of the raw materials, e.g. sorghum, and<br />

relate their impact on animal health and<br />

acceptance of the pet and the pet owner.<br />

Personalized doses for animals<br />

Currently, the number of approved<br />

veterinary medicines are limited, and<br />

Typical kibble compression test and resulting comparative graphs<br />

human medications are used off-label.<br />

These approved human medications<br />

are of too high potencies for a cat or a<br />

small dog breed. Therefore, there is a dire<br />

demand for smaller doses of veterinary<br />

medicines. 3D printing (PDF) could<br />

potentially be used to manufacture<br />

personalised doses for animals at the<br />

point-of-care and is the perfect example<br />

of where texture analysis is being<br />

applied.<br />

Insects<br />

One alternative protein source gaining<br />

attention is insects, and is already<br />

spilling over into pet food. For people<br />

who are not comfortable eating them<br />

directly, insects still have a role to play in<br />

addressing climate change and making<br />

agriculture more sustainable. Using<br />

insects as a feed source for farm animals<br />

has been happening already and is a<br />

lot less costly for the environment than<br />

traditional feeds.<br />

However, unlike our farm animals, our<br />

pets may be all too fussy to switch unless<br />

the palatability of the new pet food is<br />

up to their liking. As the purchaser of<br />

their food, consumers loyalty is affected<br />

when the pet finds their new food not to<br />

their liking. Whilst it would not be clear<br />

whether that was due to taste or texture,<br />

the right food texture should be high<br />

on a formulators list of priorities. This is<br />

when you need to compare the texture<br />

of original ‘well liked’ pet foods with their<br />

reformulated counterpart to see whether<br />

you have created a textural match.<br />

Using a Texture Analyser in<br />

pet food and animal feed<br />

development<br />

The integration of the Texture Analyser<br />

in pet food and animal feed product<br />

research and development (R&D) holds<br />

a diverse range of applications, playing a<br />

pivotal role in enhancing the quality and<br />

effectiveness of animal feed. Measuring<br />

kibble hardness for dry pet foods offers<br />

24<br />

Technology & Marketing

<strong>PRO</strong>CESSING<br />

Typical multiple puncture test<br />

and the resulting graph<br />

insights into chewability, allowing<br />

adjustments based on the target animal's<br />

size and age. Understanding moisture<br />

content and cohesiveness becomes<br />

vital for wet pet foods, influencing<br />

palatability. Adhesiveness assessment<br />

proves significant for pet treats or pastes,<br />

predicting how well they'll be accepted<br />

and handled by animals.<br />

All of these measurements and textural<br />

properties are possible by the correct<br />

choice of test for the Texture Analyser to<br />

perform. The sample is placed under the<br />

arm of the Texture Analyser and a suitable<br />

attachment selected in order to test the<br />

sample in a specific way by the choice of<br />

the following test types: compression,<br />

penetration, shearing, tension, bending,<br />

extrusion or adhesion. Examples of<br />

typical tests and their resulting graphs<br />

are shown.<br />

The Texture Analyser's contributions<br />

extend to ensuring the integrity of animal<br />

feed pellets, particularly in aquaculture<br />

settings where maintaining pellet<br />

structure in water is essential. Quality<br />

Safety and reliability are top priorities for pet owners when it comes to their<br />

beloved animals. The increasing demand for premium quality, high flexibility<br />

and limitless reliability is constantly presenting pet food producers with new<br />

challenges!<br />

Whether wet food in cups, cans, jars and thermoformed packaging or clipped<br />

products, such as dog sausage and fresh pet food filled to the exact gram,<br />

or snacks, such as filled and unfilled chews, treats, sticks or stripes:<br />

VEMAG offers reliable solutions with flexible machine systems!<br />

VEMAG: Boundless passion for YOUR solution!<br />

vemag.com/pet-food · e-mail@vemag.de<br />

VISIT US<br />

19. – 22.03.<strong>2024</strong><br />

Hall 9 | Stand C-10<br />

Issue 1 <strong>2024</strong><br />

25

<strong>PRO</strong>CESSING<br />

Typical three-point bend test and<br />

the resulting graph<br />

control is upheld as the Analyser aids in<br />

maintaining consistent texture across<br />

feed batches, impacting palatability for<br />

pets and feed efficiency for livestock. In<br />

formulation testing, understanding how<br />

the introduction of new ingredients or<br />

changes in ratios affects the resulting<br />

texture is of paramount importance.<br />

Shelf-life studies, vital for monitoring<br />

textural changes over time, especially in<br />

the presence of moisture, ensure feed<br />

quality over its lifespan. Furthermore, the<br />

Texture Analyser serves as an indicator of<br />

digestibility, as certain feeds' hardness<br />

and texture can correlate with digestibility<br />

levels, thus aiding in optimising animal<br />

health. While true palatability tests<br />

involve animals' responses, texture<br />

analysis offers quantitative data that,<br />

when combined with palatability tests,<br />

guides formulation decisions. In the<br />

realm of animal feed product R&D,<br />

the Texture Analyser emerges as an<br />

indispensable tool, enabling precise<br />

analysis and contributing to the creation<br />

of high-quality feeds that meet animal<br />

preferences and nutritional requirements.<br />

The combination of innovative ingredients,<br />

sustainable practices, and instruments<br />

like Texture Analysers ensures the<br />

pet food and animal feed industry can<br />

create products that are beneficial for<br />

animal health, accepted by animals, and<br />

environmentally sustainable.<br />

New ingredient and product<br />

ideas in pet food and animal<br />

feed product research,<br />

development and production<br />

• Alternative proteins: There's a<br />

growing interest in sustainable<br />

protein sources for pet food, such<br />

as insect-based proteins, fungibased<br />

proteins, and plant-based<br />

proteins. These sources are seen as<br />

environmentally friendly alternatives<br />

to traditional meat.<br />

• Functional ingredients: Incorporating<br />

health-beneficial ingredients into pet<br />

food, such as probiotics, prebiotics,<br />

antioxidants, omega-3 fatty acids,<br />

and joint supplements.<br />

• Grain-free and limited ingredient<br />

diets: Many pet owners are looking<br />

for grain-free options or foods with<br />

limited ingredients to address allergy<br />

concerns or dietary sensitivities.<br />

• Human-grade and premium ingredients:<br />

As pet owners increasingly<br />

view pets as family members, there's<br />

a demand for high-quality, humangrade<br />

ingredients in pet food.<br />

• Customisable pet foods: Offering<br />

tailor-made pet food blends based<br />

on the specific needs, age, breed, or<br />

health concerns of individual pets.<br />

• Sustainability: Sustainable sourcing<br />

of ingredients, upcycling ingredients<br />

(using food by-products), and ecofriendly<br />

packaging.<br />

• Clean label movement: Just as in<br />

human foods, there's a trend toward<br />

simpler ingredient lists and avoiding<br />

synthetic additives in pet foods.<br />

• Alternative animal feed additives: Use<br />

of seaweeds or specific botanicals<br />

that can reduce methane emissions<br />

from ruminants, helping to combat<br />

climate change. Use of novel petfood<br />

supplementary ingredients can<br />

add beneficial nutrients to existing<br />

compositions.<br />

• Aquaculture feeds: With the growth<br />

of the fish farming industry, there's<br />

research into more sustainable and<br />

efficient feed for farmed fish.<br />

• Fermented and processed feeds:<br />

Fermentation or specific processing<br />

techniques can improve the<br />

digestibility and nutrient availability<br />

of animal feeds.<br />

The market is exciting and opportunities<br />

abound but loyalty is key and quick to<br />

change so you’ll want to make sure that<br />

the product quality is optimally measured<br />

and monitored to minimize failure<br />

and that is where texture analysis is an<br />

invaluable tool.<br />

Technology & Marketing<br />

For more information<br />

www.stablemicrosystems.com<br />

26<br />

Technology & Marketing

BAKE<br />

DRY & COOK & BAKE SOLUTIONS<br />

HEALTHIER TREATS<br />

H A P P<br />

I E R<br />

P E T S<br />

· New All-in-One technology:<br />

Dehydrating, cooking and baking<br />

by forced convection<br />

· Acceleration of Innovation:<br />

Allows to develop new foods<br />

and treats for pets<br />

· Great Versatility:<br />

Possibility to dry & cook & bake<br />

any type of product and format<br />

· Process Optimization:<br />

Continuous system, with superior<br />

performance and lower energy consumption<br />

· Full Connectivity 4.0:<br />

Full control of the process<br />

www.metalquimia.com

<strong>PRO</strong>CESSING<br />

Dr. Harvey's Ups Output of<br />

Natural Pet Foods with<br />

Rotary Batch Mixer<br />

Operators weigh and empty ingredients into bowls<br />

which are emptied into a 0.56 m3 (20 cu ft) hopper<br />

that feeds the Rotary Batch Mixer.<br />

Proprietary mixing flights impart a tumble-turn-cutfold<br />

mixing action that causes particles to recombine<br />

288 times per minute, yielding uniform blends in<br />

about five minutes.<br />

One receiving hopper containing a blended batch is<br />

rolled away from the mixer (foreground) as another<br />

fills a packaging machine surge hopper (rear left).<br />

Dr. Harvey’s produces all-natural food<br />

products for dogs and birds, each of which<br />

is a blend of 15 to 30 dry ingredients<br />

ranging from seeds, dried vegetables,<br />

fruits and organic grains, to protein<br />

powder and freeze-dried meat.<br />

The company's previous 836 m2 (9000 sq<br />

ft) plant and 57 liter (2 cu ft) ribbon blender<br />

limited growth, prompting Dr. Harvey’s to<br />

move to a 2787 m2 (30,000 sq ft) facility in<br />

Eatontown, New Jersey, and install a 566<br />

liter (20 cu ft) Munson Rotary Batch Mixer,<br />

which is “the central and fastest part of<br />

the process,” says General Manager Cesar<br />

Salazar.<br />

Achieving uniform distribution<br />

of disparate ingredients<br />

Each food product begins with a base<br />

mixture of grains and dry vegetables to<br />

which herbs, protein powders, and other<br />

ingredients are added. Canine products<br />

contain between 20 and 25 ingredients,<br />

versus about 30 for bird feed products<br />

containing seeds, nuts, dehydrated<br />

protein, and fruit. Ingredient particles<br />

are powder-sized up to a quarter inch–or<br />

about 6 millimeters.<br />

Ingredients for batches of up to 363<br />

kg (800 lb) are manually weighed and<br />

dumped into a plastic hopper, which is<br />

then forklifted above the mixer's inlet to<br />

be gravity discharged through a manual<br />

slide gate into the Rotary Batch Mixer.<br />