PetFood PRO 2/2024

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums. We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums.

We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

International Magazine May <strong>2024</strong> ISSN 2628-5851<br />

Technology & Marketing 2/24<br />

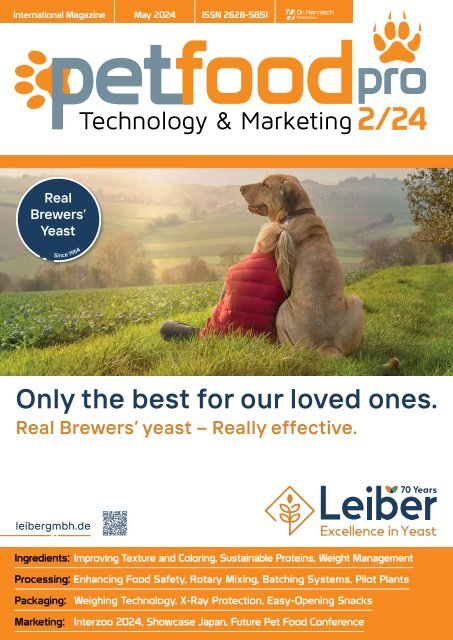

Only the best for our loved ones.<br />

Real Brewers’ yeast – Really effective.<br />

leibergmbh.de<br />

Ingredients: Improving Texture and Coloring, Sustainable Proteins, Weight Management<br />

Processing: Enhancing Food Safety, Rotary Mixing, Batching Systems, Pilot Plants<br />

Packaging: Weighing Technology, X-Ray Protection, Easy-Opening Snacks<br />

Marketing: Interzoo <strong>2024</strong>, Showcase Japan, Future Pet Food Conference

Collaboration + Innovation:<br />

How Can Food Science and Technology<br />

Transform the Food System?<br />

Join your colleagues at the leading global science<br />

of food event focused on innovation, thought<br />

leadership, and intentional networking.<br />

Register at<br />

iftevent.org.

EDITORIAL<br />

Everything for your Pet<br />

Having a pet changes your perspective on<br />

life. At first glance this might mean limiting<br />

your activity, needing to be home to care<br />

for the fur baby. On the other hand it can<br />

broaden your horizons, taking walks in<br />

all weathers to new places, getting more<br />

exercise and fresh air. Which ever way you<br />

look at it, the rewards of companionship<br />

and new experiences are beneficial for<br />

both sides.<br />

As the largest and most important meeting<br />

place for pets and supplies this year,<br />

the Interzoo international exhibition in<br />

Nuremberg, Germany, is fast approaching.<br />

The Interzoo will again offer the most<br />

comprehensive product overview in all<br />

respective sectors in the ever expanding<br />

pet industry, including the introduction of<br />

new products and trends.<br />

Just recently the Interzoo organizer WZF<br />

(Wirtschaftsgemeinschaft Zoologischer<br />

Fachbetriebe GmbH) announced a new<br />

record, with the number of exhibitors<br />

exceeding the 2,000 mark. Due to the<br />

consistently high demand, the remaining<br />

exhibition space has now also been<br />

allocated. Well over 2,000 companies from<br />

about 70 countries will showcase their<br />

products and solutions in 14 exhibition<br />

halls that cover an overall exhibition space<br />

of more than 140,000 square metres.<br />

“The sold-out Interzoo halls that break<br />

records with regard to exhibitor numbers,<br />

exhibition space and internationality<br />

show the huge pulling power of Interzoo<br />

for the gradually growing international<br />

pet supplies industry,” says Gordon<br />

Bonnet, Managing Director of WZF<br />

and ZZF (German Pet Trade & Industry<br />

Association, the institutional sponsor<br />

of Interzoo). “For trade visitors, there is<br />

no better opportunity on the globe to<br />

experience first-hand the incredible array<br />

of new products and exciting companies,<br />

to build networks, and to gain inspiration!”<br />

There will be the usual strong international<br />

presence, including 15 national pavilions<br />

and a total overseas exhibitor contingent<br />

of 86% giving an unrivalled overview<br />

of the global market. “The stronger<br />

demand across all continents shows<br />

how important Interzoo is as a showcase<br />

for innovation and a gathering place for<br />

industry decision-makers from all around<br />

the world,” says Dr Rowena Arzt, Director<br />

Exhibitions at Interzoo organizer WZF.<br />

Ian D. Healey, Editor-in-Chief<br />

These record breaking figures underline<br />

the importance of Interzoo as the central<br />

point of the worldwide pet supplies<br />

industry and as a creative force for ideas<br />

and insights in the months ahead. As<br />

the number of domestic pets continues<br />

to grow, so the need to feed, house and<br />

entertain them also increases. Interzoo<br />

gives plenty of input – and a whole range<br />

of new choices and ideas to further expand<br />

the benefits of the special companionship<br />

and joint experiences with our existing<br />

and maybe new pets.<br />

Sincerely<br />

If you like it subscribe!<br />

Issue 2 <strong>2024</strong><br />

3

CONTENTS<br />

International Magazine May <strong>2024</strong> ISSN 2628-5851<br />

Only the best for our loved ones.<br />

Real Brewers’ yeast – Really effective.<br />

leibergmbh.de<br />

Technology & Marketing 2/24<br />

Ingredients: Improving Texture and Coloring, Sustainable Proteins, Weight Management<br />

Processing: Enhancing Food Safety, Rotary Mixing, Batching Systems, Pilot Plants<br />

Packaging: Weighing Technology, X-Ray Protection, Easy-Opening Snacks<br />

Marketing: Interzoo <strong>2024</strong>, Showcase Japan, Future Pet Food Conference<br />

Issue 2 May <strong>2024</strong><br />

Leiber YeaFi® products combine brewers’ yeast benefits with the functional<br />

properties of fibers. In practical use in dry kibbles and vegan or vegetarian<br />

applications a positive impact on coloring, smell and texturization were seen.<br />

Fiber content is important also from an economic point of view. Pet food products<br />

compete more and more often with food products for natural fiber sources which<br />

directly increases the price of the pure natural fiber ingredients.<br />

Our cover story starts on page 6<br />

Cover photo: Leiber GmbH<br />

Ingredients<br />

Processing<br />

6 New Functional Ingredients to Improve Texture and<br />

Natural Coloring<br />

12 Functional Ingredients as a Natural Support for Weight<br />

Management in Pets<br />

16 New Production of Flours and Fats from Dried Black Soldier<br />

Fly Larvae Starts in Galicia, Spain<br />

21 New Omega-3 Range to be Showcased at Petfood Forum<br />

<strong>2024</strong><br />

22 Protein Choices to Lower Your Pet's 'Paw Print'<br />

23 Botanical Extracts: The Next Generation of Antioxidants<br />

25 Emsland Group at Interzoo<br />

30 Enhancing Pet Food Safety with Cutting-Edge Magnetic<br />

Separation Technologies<br />

32 HANDTMANN and MULTIVAC host the Future Pet Food<br />

Conference <strong>2024</strong><br />

34 Pilot Plant Innovation for Food and Petfood Industry<br />

36 Batching Systems in the Pet Food Industry: Precision and<br />

Efficiency<br />

38 Earth Animal is Top Dog in Product Quality<br />

Decreasing the impact on the environment is a hot topic, no<br />

less so than in the pet food industry, especially as the number<br />

of individual pets is still continuing to grow. This explains<br />

the growing market demand for trends like natural, organic,<br />

vegetarian or even vegan pet food. Ultimately, as the pet food<br />

industry, it is important for us to find sustainable alternatives<br />

to animal-derived ingredients for pet food. The full story is on<br />

page 22.<br />

Metallic impurities jeopardize the integrity of pet food,<br />

necessitating the rejection of affected batches. These<br />

contaminants can originate from various sources, including<br />

transportation vehicles used for product delivery. Internal<br />

contamination may occur during processing, grinding, or<br />

abrasion within the manufacturing plant. The application of<br />

magnetic separation equipment proves instrumental in reducing<br />

ferrous metal contamination issues. See page 30 for more.<br />

4<br />

Technology & Marketing

Departments<br />

3 Editorial<br />

52 Upcoming Events<br />

52 Impressum<br />

Automated ingredient handling<br />

Dosing, storing and transfer<br />

Events / Marketing<br />

26 Food Ingredients Goes Pet<br />

28 Japanese Pet Food Sector Moves Towards Premiumization<br />

Going Forward into <strong>2024</strong><br />

46 Interzoo <strong>2024</strong>: The Petfood Industry Meets in Nuremberg<br />

49 Flexible Production Solutions at the Interzoo <strong>2024</strong><br />

50 Clean Machine Technology for Outstanding Pet Food<br />

Quality<br />

BULK MINORS FLOUR RECLAIM LIQUIDS CONTROLS COMPONENTS<br />

SITE SERVICES<br />

SILOS<br />

From 6 to 120 tons<br />

Flour, sugar, salt<br />

Pressure safety<br />

High Hygienic<br />

Packaging<br />

40 Weighing in Rough Environments: Capacitive Load Cells in<br />

Meat Processing<br />

42 Innovative Packaging with Easy-Opening Assistance for<br />

Sausage Snacks and Small Portions<br />

MINOR<br />

INGREDIENTS<br />

Bag dumping station<br />

ROTARY<br />

SIFTER<br />

From 1 to 20 tons<br />

Healthy snacking is a growing trend. Nutritionists confirm that<br />

consumers increasingly value high-quality snacks with natural<br />

ingredients. Producers are adapting their product portfolios<br />

and packaging to meet this demand. A new seal-clip machine<br />

is an excellent solution for the production of innovative snack<br />

packaging of sausage products and other small portions. This<br />

packaging solution can be made from PVDC-free materials,<br />

while still delivering maximum performance. More on page 42.<br />

Confidence<br />

Built in<br />

BIG BAG<br />

STATION<br />

Any kind of<br />

ingredient<br />

Issue 2 <strong>2024</strong><br />

SHICK ESTEVE FRANCE<br />

4 Place des Noyers -18220 RIANS - 02 48 66 60 60<br />

www.shickesteve.com -<br />

5

COVER STORY<br />

New Functional Ingredients to<br />

Improve Texture and Natural<br />

Coloring<br />

by Maike Rakebrandt, Senior Product Management Companion Animals (Equine & Pet), Leiber GmbH (<strong>2024</strong>)<br />

Leiber YeaFi® products combine brewers’<br />

yeast benefits with the functional<br />

properties of fibers o. a. from spent grain<br />

and sugar beet pulp. In practical use<br />

in dry kibbles and vegan or vegetarian<br />

applications a positive impact on coloring,<br />

smell and texturization were seen. Leiber<br />

YeaFi® were also used as dilutatant<br />

of spray dried hydrolyzed liver or as<br />

substitute for pure dried brewer´s yeast<br />

because it is less hygrosgopic. The fiber<br />

content in Leiber YeaFi® are important<br />

also from an economic point of view. Pet<br />

food products compete more and more<br />

often with food products for natural fiber<br />

sources which directly increases the price<br />

of the pure natural fiber ingredients.<br />

The snack category is the second most<br />

sold, right after dry food. The market share<br />

for semi-moist and baked snacks has<br />

been rapidly increasing. In oven-baked<br />

snacks the moisture level is reduced to<br />

10%. Semi-moist snacks are products that<br />

Table 1: Leiber YeaFi® nutrition and fiber profiles in %<br />

contain 14-30% moisture. Therefore, it<br />

is important to explore ingredients that<br />

have impact on the texture and quality,<br />

and such that are naturally contribute to<br />

prevent microbiological spoilage.<br />

Material and Methods<br />

Leiber YeaFi® is rich in dietary fiber and<br />

brings at the same time the brewers’<br />

yeast with a high level of protein into the<br />

formulations. Using blended products at<br />

the 3-4% inclusion levels can contribute<br />

to the 1,2-1,6% of brewers’ yeast in the<br />

formulation while at the same time could<br />

replace use of fiber up to 2%. For this test<br />

we used different types of Leiber YeaFi®.<br />

Leiber YeaFi® BTR based on brewers‘ yeast,<br />

spent grain and beet pulp and Leiber<br />

YeaFi® AB-F with brewers’ yeast, apple<br />

pomace and beet pulp. Both contain a<br />

high soluble fiber fraction (Table 1).<br />

After a technical pre-test in the lab Leiber<br />

YeaFi® BTR and Leiber YeaFi® AB-F were<br />

tested in semi-moist functional snacks<br />

included at 5 and 10%.<br />

The semi-moist snacks were formulated<br />

with the following declaration: poultry<br />

meal, potato starch (pregeled), pea<br />

starch (pregeled), glycerin, pea fiber,<br />

preservatives. In test samples with 5%<br />

test product, pea fiber was completely<br />

exchanged. In the test samples with<br />

10% test product the pea fiber was fully<br />

replaced and 5% of pea starch was reduced.<br />

The nutritional analysis showed that when<br />

Leiber YeaFi® products were added to the<br />

formulations, crude fiber were decreased,<br />

but protein content and soluble fiber were<br />

increased in the snacks.<br />

The technical analyses of the test and<br />

control snacks were done in three periods,<br />

immediately, seven days and a month after<br />

the production. Following parameters<br />

were analysed: moisture, pH, aW, texture,<br />

firmness, energy, adhesiveness and<br />

stickiness. Texture analyses are important<br />

for both impacts on physical quality but<br />

also on sensory analyses like palatability.<br />

Additional to the semi-moist snack, vegan<br />

oven-baked snacks were produced in a<br />

two-step baking/drying, to imitate the<br />

commercial baking process. The moisture<br />

level was reduced to 10%. Reduction of<br />

moisture is important for shelf-life and<br />

prevention of microbial growth, also in<br />

baked snacks. Leiber YeaFi® BTR and Leiber<br />

YeaFi® AB-F were formulated by adding<br />

10% into the test recipes, which were based<br />

on potatoe flakes, oil and pea meal. Leiber<br />

YeaFi® products substituted 10% of the pea<br />

meal. Moisture, pH, aW, texture, baking loss<br />

and shrink percent were measured.<br />

The baking loss is the weight of the snacks<br />

before and after baking. The difference<br />

indicates the loss of evaporation. In<br />

addition, the weight change before<br />

6<br />

Technology & Marketing

COVER STORY<br />

Photo 1: Leiber YeaFi® products increased the shininess and natural coloring in semi-moist snacks<br />

Photos: Leiber GmbH<br />

and after baking indicates the shrink<br />

percentage.<br />

Results<br />

In the semi-moist test Leiber YeaFi® BTR,<br />

followed from Leiber YeaFi® AB-F showed<br />

high water absorption properties and<br />

moisture holding capacity after cooking<br />

and retorting. This is due to the higher<br />

level of the soluble fibers. Increasing the<br />

concentration of the Leiber YeaFi® BTR<br />

and Leiber YeaFi® AB-F samples caused<br />

an increase in the viscosity/hot water<br />

absorption.<br />

Photo 2: Leiber YeaFi® products increased the shininess and natural coloring in oven-baked snacks<br />

Both test products performed as great<br />

texturizers improving the texture and<br />

shape and reducing the stickiness of<br />

the snacks and knives had a better cut.<br />

The 10% inclusion of Leiber YeaFi® BTR<br />

and Leiber YeaFi® AB-F decreased the<br />

use of energy (SME) and significantly<br />

improved capacity. All test ingredients<br />

improved the snacks’ appearance,<br />

coloring and shine. Leiber YeaFi® BTR<br />

and Leiber YeaFi® AB-F had the most<br />

positive impact on the snacks. Increased<br />

inclusion (10%) increased the impact.<br />

The shape was more distinctive. In<br />

addition, both products increased the<br />

shininess of the snack and gave more<br />

brown color (Photo 1). The variation<br />

in shape and natural coloring were<br />

significant.<br />

Also in the vegan oven–baked snacks<br />

the color change was significant<br />

when changing 10% of pea meal with<br />

the blended brewers’ yeast products<br />

(photo 2).<br />

Leiber YeaFi® BTR and YeaFi® AB-F had<br />

the tendency to reduce water activity<br />

(Figure 1). Inclusion of 10% significantly<br />

decreased water activity of the snacks<br />

Figure1: Water activity (aW), after a month storage in semi-moist snacks<br />

despite the added moisture during the<br />

extrusion.<br />

The water activity after LT (low temperature)<br />

in vegan, ovenbaked snacks was naturally<br />

high for all test samples (Figure 2). After<br />

the HT (high temperature) treatment, the<br />

test products reduced the water activity<br />

and moisture content more efficiently<br />

compared to the control biscuits. Due<br />

Issue 2 <strong>2024</strong><br />

7

COVER STORY<br />

Figure 2: Water activity (aW), in vegan, ovenbaked<br />

snacks, with low temperature (LT) and high<br />

temperature (HT) baking.<br />

Figure 4: pH values for vegan, oven-baked snacks, with low<br />

temperature (LT) and high temperature (HT) baking.<br />

to the higher moisture reduction during<br />

baking the weight loss and shrinkage were<br />

higher for the Leiber products.<br />

Increasing the inclusion level of Leiber<br />

YeaFi® products decreased significantly<br />

the pH of the semi-moist snacks (Figure 3)<br />

during the whole test period. Decreasing<br />

pH in semi-moist snacks has a positive<br />

impact on the preservation of the product.<br />

In vegan oven-baked snacks the pH was<br />

analyzed for both high (HT) and low (LT)<br />

temperature treatments (Figure 4). The<br />

addition of 10% Leiber YeaFi® significantly<br />

decreased the pH of the biscuits also. This<br />

indicated again a preservation potential<br />

of the test products.<br />

Leiber YeaFi® products also had an impact<br />

on the textural properties of the semimoist<br />

snacks. The firmness of the snacks<br />

decreased with the reduction of the pea<br />

starch in the control kibbles.<br />

This was expected as starch is one of the<br />

main factors to increase the hardness<br />

in the snacks. When used Leiber YeaFi®<br />

BTR and Leiber YeaFi® AB-F firmness<br />

increased with inclusion level (Figure 5).<br />

The inclusion level (5 or 10%) didn’t have<br />

Figure 3: pH values, analyses after a month storage<br />

period in semi-moist snacks<br />

Figure 5: Firmness values, analyses are taken over<br />

a month storage period<br />

8<br />

Technology & Marketing

INGREDIENTS<br />

Pet Food<br />

Cutting<br />

Solutions<br />

As the #1 Global Leader in Food Cutting Technology,<br />

successful processors depend on Urschel’s expertise<br />

to deliver optimal cutting solutions for pet food<br />

ingredients to produce high-quality fish, chicken, beef,<br />

and vegetable dices and shreds and coarse to smooth<br />

applications such as mousse, pastes, and liquids.<br />

Explore Urschel cutting solutions<br />

to achieve your processing goals.<br />

Issue 2 <strong>2024</strong><br />

#1 Best selling provider of<br />

industrial cutting machinery<br />

throughout the world.<br />

®Urschel, Urschel logo symbol, and The Global Leader in Food Cutting Technology<br />

are registered trademarks of Urschel Laboratories, Inc. U.S.A.<br />

The Global Leader in Food Cutting Technology<br />

Set up a free test-cut of your product.<br />

www.urschel.com<br />

9

COVER STORY<br />

significant effect on the firmness as did<br />

the source of the fibers.<br />

After technical tests, the semi-moist<br />

snacks were given to a dog home panel<br />

(n=10). Taste preference was organized<br />

in the form of first-choice testing for<br />

two days and then statistically grouped<br />

and analyzed (Figure 6). All Leiber YeaFi®<br />

snacks were tastier then the controls, and<br />

dogs were keen on consuming them. The<br />

highest preference was shown towards<br />

Leiber YeaFi® BTR. Also the vegan ovenbaked<br />

biscuits were tested with the<br />

dogs. All biscuits were accepted well.<br />

Here Leiber YeaFi® AB-F had the highest<br />

preference.<br />

Conclusion<br />

Leiber YeaFi® products are an interesting<br />

concept for application in semi-moist<br />

and vegan oven-baked snacks. They have<br />

a positive impact on production as they<br />

effiiciently reduce stickiness, and improve<br />

texture, appearance, pH, coloring, shiness<br />

and taste of the semimoist snacks. From<br />

an economic point of view the production<br />

capacity was significantly higher<br />

compared to the controls. The inclusion<br />

of Leiber YeaFi® products in vegan ovenbaked<br />

snacks also resulted in a significant<br />

change of the color and reduction of the<br />

pH. The baking process reduced moisture<br />

more compared to control. The reduction<br />

of pH and water activity in both snacks<br />

indicating that Leiber YeaFi® products give<br />

a sort of natural preservation effect and<br />

the baking time can be reduced therefore<br />

the energy consumption can be lower.<br />

Technology & Marketing<br />

For more information<br />

www.leibergmbh.de<br />

Figure 6: Heatmap presented as preference<br />

map for the semi-moist snacks, where more<br />

intensive red color shows higher preference<br />

compared to blue colors.<br />

10<br />

Technology & Marketing

PALATANTS.<br />

SOLUTIONS.<br />

SERVICES.<br />

AFB is more than just palatants. We provide custom solutions to<br />

improve pet food palatability. Our services are tailored to the<br />

specific needs of each customer. We can partner to meet their<br />

objectives while making pet food taste great!<br />

STAND 6-321<br />

To learn how AFB brings value to pet food companies through<br />

research expertise, technical support and unparalleled<br />

customer service, visit afbinternational.com or<br />

contact your AFB account manager.<br />

© <strong>2024</strong> AFB International

INGREDIENTS<br />

Functional Ingredients as a Natural<br />

Support for Weight Management<br />

in Pets<br />

Photo: Beneo<br />

For many years, being overweight or obese<br />

was a human concern. These days however,<br />

more and more companion animals are<br />

struggling with this condition. Here Dr<br />

Maygane Ronsmans, Product Manager<br />

Animal Nutrition at BENEO, explores how<br />

functional ingredients can help as a natural<br />

support for weight management in pets<br />

and why the choice of carbohydrate and<br />

fiber matters when it comes to long-term<br />

health.<br />

Pets are increasingly overweight<br />

or obese<br />

Numbers of overweight and obese<br />

companion animals have steadily increased<br />

over the last few decades and now exceed<br />

50% in Western countries. i Recent statistics<br />

from the US have even classified 6 in 10<br />

dogs and cats as overweight or obese. ii<br />

As with humans, there are many serious<br />

health consequences for overweight or<br />

obese pets. These include cardiovascular<br />

and metabolic diseases (e.g., glucose<br />

intolerance, diabetes), or skeletal<br />

associated disorders, leading to a negative<br />

impact on the pet’s - and owner’s - quality<br />

of life.<br />

Pet owners are well aware of the dangers<br />

surrounding having overweight or obese<br />

companion animals, and many like to opt<br />

for a preventive approach when it comes<br />

to managing their pet’s weight. A recent<br />

global survey conducted by FMCG Gurus<br />

on behalf of BENEO showed that 3 in 4<br />

pet owners worldwide were concerned<br />

with their pet’s weight iii and around 4<br />

in 5 agreed that an on-pack claim about<br />

helping to control their pet’s weight<br />

naturally affects their purchase intention<br />

of a pet food product to some extent. iv<br />

There is therefore a market opportunity for<br />

functional ingredients that can help with<br />

weight and blood glucose management.<br />

Functional ingredients as part of<br />

the solution<br />

Like in humans, prevention of obesity is<br />

always better than cure, and a balanced<br />

diet should remain the ‘gold standard’.<br />

Nevertheless, when weight loss is<br />

required, a multi-pronged approach that<br />

combines exercise along with energyrestricted<br />

diets is often key. In the context<br />

of obesity, the choice of nutrients in pet<br />

food can also make a difference, and<br />

12<br />

Technology & Marketing

INGREDIENTS<br />

including functional ingredients in a pet’s<br />

diet - such as slow-release carbohydrate<br />

isomaltulose and prebiotic chicory root<br />

fibers - can help with weight and blood<br />

glucose management.<br />

Carbohydrate choice matters<br />

Carbohydrates are an inherent part of our<br />

pets’ diet nowadays. Though, carbohydrates<br />

have not been created equal and they<br />

differ in composition, digestive properties<br />

and therefore glycaemic effects. A case in<br />

point is that high glycaemic carbohydrates,<br />

such as sucrose or cooked starches, are<br />

rapidly digested and absorbed in the first<br />

part of the small intestine, resulting in a<br />

fast and high blood glucose response.<br />

Low glycaemic carbohydrates on the other<br />

hand, are digested more slowly and lead<br />

to a lower blood glucose response. Having<br />

a slower blood glucose supply results in<br />

more balanced glycaemia, lower insulin<br />

peaks and overall better metabolic health.<br />

A 2012 study with dogs has further shown<br />

that low glycaemic diets can support<br />

weight loss. v<br />

For pet food producers looking for low<br />

glycaemic carbohydrates, isomaltulose<br />

can become a key part of their ingredient<br />

toolbox. Isomaltulose is a disaccharide of<br />

glucose and fructose derived from sugar<br />

beet that is characterised by a stronger<br />

glycosidic bond than that of standard<br />

sugar. Due to this specific linkage, it is<br />

more resistant to enzymatic hydrolysation<br />

in the intestine, therefore inducing lower<br />

glycaemic and insulin responses than<br />

regular sucrose as demonstrated in many<br />

species (e.g., humans, rodents and pigs).<br />

A scientific publication from 2023 about<br />

three studies from Corbee et al vi , has<br />

confirmed that isomaltulose is a suitable<br />

low glycaemic ingredient for use in dog<br />

food, triggering a lower blood glucose rise<br />

after consumption. The trials evaluated<br />

the digestion of isomaltulose as well as<br />

its glycaemic and insulinaemic effects<br />

in dogs, compared to other relevant<br />

carbohydrate sources. An in-vitro study of<br />

small intestinal tissue samples from three<br />

dogs showed that isomaltulose can be<br />

digested by canine intestinal enzymes,<br />

with a lower enzyme activity compared to<br />

high glycaemic carbohydrates, indicating a<br />

slower rate of hydrolysis.<br />

In addition, two in-vivo studies compared<br />

the effects of isomaltulose, sucrose and<br />

maltodextrin in dogs. The results showed<br />

that isomaltulose significantly lowered<br />

blood glucose and insulin responses,<br />

compared to maltodextrin or sucrose –<br />

even after continuous feeding. All in all, this<br />

property makes isomaltulose a particularly<br />

interesting solution with the potential<br />

to support metabolic health and weight<br />

management in dogs.<br />

Plant-Based Innovations<br />

MADE FROM POTATOES AND PEAS<br />

Our plant-based ingredients include starches,<br />

flakes, special derivatives, proteins, and fibers,<br />

which can be applied to a wide range of<br />

products in the pet food industry.<br />

We are driven by sustainable innovation, in<br />

harmony with nature. Experts at our Innovation<br />

Center are constantly developing and optimizing<br />

concepts, including gluten or grain free, and<br />

added protein and fiber, to meet the evolving<br />

demands of the industry.<br />

VISIT US AT<br />

EMSLAND-GROUP.COM<br />

7-10 MAY, <strong>2024</strong> • NÜRNBERG, GERMANY<br />

BOOTH #4-420<br />

Issue 2 <strong>2024</strong><br />

13

INGREDIENTS<br />

The power of chicory root fibers<br />

Other functional ingredients that enable<br />

vii, viii, ix,<br />

blood sugar management in dogs<br />

x , as well as weight management in pets<br />

xi, xii, xiii<br />

are BENEO’s natural chicory root<br />

fibers Orafti® Inulin and Oligofructose.<br />

These inulin-type fructans belong to the<br />

very few scientifically proven prebiotics ,<br />

that support a pet’s intestinal health and<br />

are linked with nutritional benefits that<br />

go beyond the gut. For example, studies<br />

show that including Orafti® Inulin and<br />

Oligofructose in a pet’s diet can curb<br />

their appetite, improve satiety and hence<br />

xv, xvi, xvii<br />

decrease voluntary food intake. In<br />

doing so, chicory root fibers can help to<br />

maintain the healthy condition of a pet’s<br />

body.<br />

Additionally, since inulin-type fructans<br />

are non-digestible carbohydrates and<br />

dietary fibers, they do not trigger a rise<br />

in postprandial blood glucose or insulin<br />

concentrations. As a result, they support<br />

blood sugar management in dogs. What’s<br />

more, studies in dogs have shown that<br />

feeding them with chicory prebiotics can<br />

allow for a lower blood sugar response<br />

after a meal , and this benefit can extend<br />

to a subsequent meal taken hours later,<br />

even if that meal doesn’t include chicory<br />

root fibers; xx, xxi which is called the second<br />

meal effect.<br />

Quality production<br />

BENEO produces its functional<br />

carbohydrates, including isomaltulose, and<br />

chicory root fibers in state-of-the-art and<br />

food-certified processing plants, which<br />

enables the highest product quality to be<br />

continuously guaranteed. Also, the non-<br />

GMO sugar beets and chicory roots are<br />

sourced from farmers in close proximity to<br />

the production sites. Isomaltulose as well as<br />

Orafti® Inulin and Oligofructose are natural<br />

ingredients which are acknowledged as<br />

feed materials in the EU xxii . They are suitable<br />

for use in both dry and wet pet foods, or in<br />

snacks.<br />

With more and more companion animals<br />

struggling with being overweight or obese,<br />

it is no wonder that pet food producers are<br />

turning to functional ingredients, such<br />

as BENEO’s, to help owners resolve these<br />

issues. By choosing the right ones, it is<br />

now possible to support weight and blood<br />

sugar management in pets more naturally,<br />

whilst supporting their long-term health.<br />

Technology & Marketing<br />

BENEO source references for this article are<br />

available on request.<br />

For more information<br />

www.beneo.com<br />

14<br />

Technology & Marketing

INGREDIENTS<br />

New Production of Flours and<br />

Fats from Dried Black Soldier Fly<br />

Larvae Starts in Galicia, Spain<br />

The dried black soldier fly larvae used to produce the first batches come from the Bioflytech Group's other<br />

plant in Fuente Alamo, Murcia<br />

The company has recently obtained authorization for the production of flour, a milestone that marks a before<br />

and after in the production of this type of insect-derived products, where the Bioflytech group is a pioneer<br />

The products are aimed at animal feed, mainly pet food and the aquaculture sector<br />

Once the works have been completed and the necessary authorization has been obtained, the facilities in<br />

Galicia will produce 12,000 tonnes of larvae per year and will consolidate Bioflytech as one of the world leaders<br />

in the sector<br />

Bioflytech has started the production of<br />

flours and fats from dried black soldier fly<br />

larvae in its new facilities located in Palas<br />

de Rei, Galicia, north-western Spain. The<br />

company has started the activity after<br />

becoming the first Spanish company<br />

in this innovative sector to obtain the<br />

authorization to produce, transform and<br />

commercialize this type of product.<br />

The dried black soldier fly larvae, with<br />

which the rendering lines are being set<br />

up and the first batches of flours and<br />

fats produced, come from the company's<br />

other plant in Fuente Álamo, Murcia.<br />

These new facilities in Palas de Rei are<br />

now up and running after obtaining<br />

authorization for the production - by<br />

means of a drying process - of the<br />

products that make up the company's<br />

portfolio and which are mainly aimed at<br />

animal feed, especially pet food and for<br />

the aquaculture sector.<br />

Obtaining this authorization has been<br />

possible thanks to the hard work of the<br />

technicians involved in the project at all<br />

levels, from those who work at Bioflytech<br />

to those who are part of the national,<br />

regional and local administration. This has<br />

made it possible to achieve a milestone<br />

that marks a turning point in the<br />

production of protein meals from insects,<br />

where the Bioflytech group is a pioneer.<br />

After obtaining the necessary permits, it<br />

has been possible to start the production<br />

of flour and fat in the new facilities<br />

in Palas de Rei, which have state-ofthe-art<br />

technology to carry out the<br />

transformation of the dried larvae from<br />

Murcia. Thus, a rendering machine<br />

and a drying machine have come into<br />

operation, allowing the product to be<br />

transformed into flour, which is mainly<br />

used as a raw material for the production<br />

of pet food and aquaculture food. The fat<br />

is destined, on the one hand, for pig feed<br />

and, on the other, for the pharmaceutical<br />

and cosmetics industry, which uses it in<br />

the creation of soaps and moisturizing<br />

creams, among others.<br />

The facilities have also started up a second<br />

rendering machine of its own design and<br />

unique on the market, which will enable<br />

tailor-made flours to be manufactured<br />

with specific percentages of protein and<br />

fats according to the customer's demands,<br />

and which is set to revolutionize the<br />

production of protein flours from insects.<br />

These two rendering machines will be<br />

joined in the coming weeks by a third one<br />

that has already arrived in Palas de Rei and<br />

will be assembled in the next few days.<br />

In parallel to the start of the activity, work<br />

continues to complete the eight plants<br />

that make up the complex, which include<br />

the production plant, six larvae fattening<br />

plant and another for compost storage.<br />

16<br />

Technology & Marketing

INGREDIENTS<br />

Instalaciones Palas de Rei<br />

Photos: sBioflytech<br />

Palas de Rei, Lugo<br />

Find your solution<br />

Barentz is a leading provider of ingredients and solutions for dry and<br />

wet pet food as well as for pet treat manufacturers. With a strong<br />

network of partners, combined with our expertise in a wide range of<br />

areas, we are looking forward to finding a better solution, together.<br />

Antioxidants<br />

Plant-based<br />

proteins<br />

Insect<br />

proteins<br />

Yeasts<br />

Binders<br />

Natural<br />

colors<br />

barentz.com Always a better solution.<br />

Barentz<br />

Saturnusstraat 15<br />

2132 HB Hoofddorp<br />

The Netherlands Issue 2 <strong>2024</strong><br />

T + 31 (0) 23 5673456<br />

E petfoodinfo@barentz.com<br />

I www.barentz.com<br />

Visit us at<br />

Interzoo;<br />

Booth 7-632<br />

17

INGREDIENTS<br />

About Bioflytech<br />

Moira Capital Partners<br />

acquired a majority stake in<br />

Bioflytech, established in<br />

2012 as a biotech company,<br />

in 2018. A year later, the<br />

Fuente Álamo facility in<br />

Murcia was opened.<br />

The support of the Xunta de<br />

Galicia and the City Council<br />

of Palas de Rei for the project<br />

determined Bioflytech's choice<br />

of this autonomous community to<br />

undertake its expansion, for which<br />

different locations in the north of Spain<br />

and even Portugal were considered.<br />

Bioflytech obtains four main products<br />

from the black soldier fly: dried larva,<br />

which is obtained after almost complete<br />

drying of the fresh larvae and has highly<br />

digestible protein and all the necessary<br />

components for the diet of poultry,<br />

fish and other animals; high protein<br />

meals; fats, which are obtained from the<br />

larvae without using chemical agents<br />

or solvents; and compost, obtained<br />

as a result of the biodigestion of the<br />

vegetable material produced during the<br />

fattening process.<br />

Bioflytech's dried larvae is a product<br />

especially designed as a feed diet for<br />

laying hens and broilers, while the<br />

protein meals are aimed at the petfood,<br />

aquaculture and poultry industries,<br />

and also to a lesser extent at animal<br />

feed for the fur industry. Fats are mainly<br />

used in animal feed, but also in the<br />

pharmaceutical and cosmetics industry.<br />

Compost is used as fertilizer.<br />

The surroundings are also being adapted,<br />

as the total plot is 140,000 square meters<br />

in size.<br />

Challenges for the company<br />

Once the necessary authorization has<br />

been obtained, the fresh larvae fattening<br />

process will also begin in Palas de Rei,<br />

which will allow for the production<br />

of a total of 12,000 tonnes per year.<br />

Subsequently, a new phase of expansion<br />

of the facility will be undertaken to<br />

produce 100,000 tonnes of fresh larvae<br />

per year.<br />

Meanwhile, at the Fuente Álamo facility in<br />

Murcia, not only will the activity continue,<br />

but an investment of 2.8 million euros is<br />

planned for the second half of the year to<br />

increase the production capacity of the<br />

hatchery that supplies larvae eggs to the<br />

facility in Galicia. At present, the Fuente<br />

Álamo facility produce 180 kilos of eggs<br />

Left: Dried black soldier fly larvae<br />

Right: Flour<br />

per month, which is already a milestone<br />

in the sector worldwide, given the<br />

complexity of guaranteeing stable and<br />

continuous production throughout the<br />

year. The objective with this expansion, for<br />

which all the permits have already been<br />

requested, is to reach 350 kilos of eggs per<br />

month, something unprecedented in the<br />

sector.<br />

This first Bioflytech plant in Fuente Álamo<br />

currently produces 4,000 tonnes of fresh<br />

larvae per year.<br />

Technology & Marketing<br />

For more information<br />

www.bioflytech.com<br />

Photos: sBioflytech<br />

18<br />

Technology & Marketing

I SUCCESSFULLY <strong>PRO</strong>DUCE<br />

A WIDE VARIETY OF PET<br />

FOOD WITH HANDTMANN<br />

TECHNOLOGY.<br />

Visit us!<br />

Hall 5, stand 207<br />

Your partner for solutions with line and process expertise.<br />

You have ideas – we have just the right solution for them. From product preparation to filling<br />

and portioning technology and product handling – our process solutions to match your needs.<br />

Benefit from our many years of in-depth expertise, our process-reliable technology and our<br />

excellent service. Let us turn your ideas into solutions.<br />

Scan QR code and watch the video.<br />

Further information at:<br />

www.handtmann.com/petfood<br />

Follow us:

HANDTMANN LINE SOLUTIONS:<br />

FROM RAW MATERIAL THROUGH TO PACKAGING<br />

Perfectly coordinated technology from product preparation and portioning, forming or drying all the way<br />

through to packaging. Our process solutions are ideally suited for cold-extruded applications. Handtmann<br />

technology turns meat, plant-based or insect protein raw materials into bars and sticks of varying sizes<br />

and shapes. We stand for accurate-to-the-gram portioning and diverse process options ensuring precise<br />

product depositing onto conveyors or trays.<br />

<strong>PRO</strong>DUCT PREPARATION<br />

Mixing: Handtmann Inotec IM mixer<br />

2-shaft mixer for the quick and homogeneous thorough mixing of<br />

viscous to highly viscous products. Handtmann Inotec mixers also<br />

provide the optimum shaft configuration for any mixing material.<br />

Emulsifying: Handtmann Inotec iT<br />

The modular 1- to 5-stage cutting system with optimum adjustment of<br />

the cutting position and thus minimised wear, reliably grinds products<br />

of any viscosity and temperature into homogeneous products of<br />

particle sizes less than two millimetres.<br />

ACCURATE-TO-THE-GRAM PORTIONING<br />

Filling and forming: VF 800 vacuum filler and FS 510 forming system<br />

Handtmann vacuum filling technology with subsequent fully<br />

automatic, multi-lane forming stands representative for long-term<br />

stable portioning accuracy, minimal wear, needs-based performance,<br />

application variety, hygiene and ergonomics at the highest level.<br />

DOWNSTREAM <strong>PRO</strong>DUCT <strong>PRO</strong>CESSING<br />

Product depositing, drying and packaging<br />

Handtmann technology is perfectly coordinated with downstream<br />

process steps and the machines from our numerous partners required<br />

for depositing, drying and packaging. Everything from a single source<br />

for a seamless production process from A to Z.<br />

Albert Handtmann Maschinenfabrik GmbH & Co. KG<br />

Hubertus-Liebrecht-Str. 10-12 | 88400 Biberach | Germany<br />

sales.machines@handtmann.de | +49 7351 45-0<br />

www.handtmann.com/petfood |

New Omega-3 Range to be<br />

Showcased at Petfood Forum<br />

<strong>2024</strong><br />

INGREDIENTS<br />

Veramaris® Pets joins dsm-firmenich’s growing petfood portfolio – discover this and more at stand 1306,<br />

Petfood Forum, April 29 - May 1, <strong>2024</strong>, Kansas City.<br />

dsm-firmenich, innovators in nutrition,<br />

health and beauty, will showcase its full<br />

range of ingredients at Petfood Forum<br />

<strong>2024</strong> including the latest addition to the<br />

company’s portfolio, Veramaris® Pets –<br />

the world’s most powerful and complete<br />

omega-3 solution for cats and dogs. At<br />

stand 1306, attendees can also discover<br />

DHAgold alongside innovative taste<br />

ingredients and gut health-supporting<br />

nutrients, to help pet nutrition brands<br />

create food, treats and supplements that<br />

are good for pets, good for producers and<br />

good for the planet.<br />

Photo: shutterstock_2290425993_ret_AI<br />

Ensuring the world’s access to<br />

omega-3s, sustainably<br />

Veramaris® Pets algal oil is the latest addition<br />

to dsm-firmenich’s petfood portfolio.<br />

Containing 60% eicosapentaenoic acid<br />

(EPA) and docosahexaenoic acid (DHA) –<br />

the highest of any solution on the market<br />

– it delivers more than double the potency<br />

of equivalent fish-oil while also providing<br />

enhanced taste and stability benefits.<br />

Around 930 billion fish are removed from<br />

the oceans each year, just to supply the<br />

pet food industry with fish oil and meal. 1<br />

Veramaris® Pets aims to change this as an<br />

infinitely consistent and scalable source<br />

of omega-3 that does not rely on fish<br />

stocks. With Veramaris® Pets joining dsmfirmenich’s<br />

growing petfood portfolio,<br />

producers will benefit from the company’s<br />

worldwide team of experts, global supply<br />

chain and access to a leading range of<br />

nutritional and taste products.2<br />

At Petfood Forum, dsm-firmenich will<br />

also showcase DHAgold, which offers<br />

petfood brands even more versatility<br />

in DHA fortification. This easy-to-use<br />

powder is made from fermented algae<br />

and is scientifically proven to support<br />

brain health in dogs. In one study, a group<br />

of 8- to 11-year-old dogs were fed food<br />

containing DHAgold for 6 months and<br />

displayed significantly improved memory<br />

and visual performance.3<br />

All bite, no bark<br />

Additionally, at Petfood Forum <strong>2024</strong><br />

dsm-firmenich will spotlight its flavorenhancing<br />

solutions for improving the<br />

taste in petfood applications with a<br />

Cheddar cheese flavor concentrate. Made<br />

using genuine Wisconsin Cheddar cheese<br />

and whey, this versatile spray-dried<br />

powder helps producers craft irresistible<br />

food for dogs.<br />

Petfood Forum <strong>2024</strong> attendees will also<br />

be able to learn more about Leva-Mos®<br />

– a convenient, spray-dried, prebiotic<br />

powder that supports healthy digestion,<br />

gastrointestinal health and immunity<br />

by stabilizing the gut microflora and<br />

strengthening intestinal barrier function<br />

in dogs.<br />

Discover your next petfood<br />

partner<br />

“It’s our ambition to create ingredients that<br />

are good for pets, good for producers and<br />

good for the planet,” says George B. Josef,<br />

Global Head Marketing & Nutritional Lipids<br />

for petfood at dsm-firmenich. “We have<br />

the same dedication to crafting delicious,<br />

nutritious and sustainable solutions as pet<br />

parents do to caring for their furry friends.<br />

And we combine this ethos with decades<br />

of science-based research and expertise,<br />

leading technology and substantial<br />

investment in innovation. The result is a<br />

range of high-quality, safe ingredients that<br />

pet parents want and their cats and dogs<br />

love. Stop by stand 1306 at Petfood Forum<br />

<strong>2024</strong> to discover how we can help you<br />

balance taste, health, sustainability and<br />

cost to engage today’s pet parents, and<br />

fuel happy, healthy pets at every life stage.”<br />

Technology & Marketing<br />

1FAO, 2018 2Veramaris® will continue as a joint venture between dsm-firmenich and Evonik<br />

Nutrition & Care GmbH focused on the aqua feed market. 3The oil-rich alga Schizochytrium<br />

sp. as a dietary source of DHA improves shape discrimination learning associated with visual<br />

processing in a canine model of senescence. [K.B. Hadley, J. Bauer, N.W. Milgram, Clinical<br />

Research Department, DSM Nutritional Products, Columbia, MD 21045, USA]<br />

For more information<br />

www.dsm.com/food-beverage/en_US/about-us/events/join-us-atpetfood-forum-<strong>2024</strong>.html<br />

Issue 2 <strong>2024</strong><br />

21

INGREDIENTS<br />

Protein Choices to Lower Your<br />

Pet's 'Paw Print'<br />

Reducing your environmental impact by selecting more sustainable alternatives<br />

Photos: Barentz<br />

Decreasing the impact on the<br />

environment is a hot topic, no less so<br />

than in the pet food industry, especially<br />

as the number of pets is still growing. This<br />

explains the growing market demand for<br />

trends like natural, organic, vegetarian or<br />

even vegan pet food. Premiumization and<br />

humanization continue to drive the petfood<br />

category, an increasing demand for<br />

plant-based proteins could also be a result<br />

of more flexitarians as pet owners, as pet<br />

parents want their pets eating habits to<br />

be similar to their own. Ultimately, as the<br />

pet food industry, it is important for us to<br />

find sustainable alternatives to animalderived<br />

ingredients for pet food.<br />

Plant-based proteins<br />

There is a broad variety of plant-based<br />

proteins, which can be used to reduce<br />

meat proteins in pet diets, however it is key<br />

to keep an eye on the amino acids profile<br />

of plant-based proteins. From the plantbased<br />

proteins, soy protein has the most<br />

complete amino acid profile. Nevertheless,<br />

soya is not always so popular to use. This<br />

is because its acceptance varies from<br />

country to country; the possible reason<br />

behind this could be related to GMO and<br />

deforestation, even when there is also<br />

GMO free soy on the market, produced in<br />

Europe, without deforestation. Another<br />

aspect could be that soya can contain<br />

anti-nutritional factors. Soya concentrates<br />

and isolates can be used to avoid those<br />

problems.<br />

Pea protein is very popular, although it<br />

has very low values of methionine and<br />

cystine. To overcome this deficiency, it can<br />

be used together with rice, which is rich<br />

in methionine and cystine. Also potato<br />

protein is quite often used, because of its<br />

balanced amino acid profile. On the other<br />

hand, corn protein (corn gluten meal) is an<br />

incomplete protein, it is lacking in arginine<br />

and tryptophan. To overcome this, corn<br />

can be supplemented with other plantbased<br />

proteins to make the list of essential<br />

amino acids complete.<br />

In all cases of using plant-based proteins,<br />

keep an eye towards the levels of taurine<br />

and carnitine in the diet, even when these<br />

are considered as non-essential, both are<br />

really key for healthy dogs and cats.<br />

Functionality<br />

Beside the nutritional aspects, plantbased<br />

proteins can also be used for their<br />

great functional properties. Different<br />

types of soya concentrates or isolates<br />

have different levels of water binding,<br />

emulsifying and gelling properties. Those<br />

concentrates or isolates can be used to<br />

retain the water and fat during the entire<br />

technological process, with securing<br />

shelf life of the final product. Next to<br />

soya, also other functional proteins from<br />

pea, chickpea or faba beans can be used.<br />

Those are typically used for products such<br />

as paté, terrine, chunks and also for meat<br />

alternatives.<br />

Insects – fully circular<br />

Another alternative to animal-derived<br />

proteins are insects, which are a highly<br />

valuable nutritional protein source.<br />

Insects are also more sustainable for<br />

several reasons. Firstly, insects can turn<br />

low value feed materials and related byproducts<br />

into high value insect protein<br />

and oil. They are fed with by-products,<br />

not suitable for other livestock, which<br />

otherwise would have gone to lower<br />

value productions such as bio-refineries.<br />

Secondly, insect breeding is a zero-waste<br />

and circular process. There are three<br />

final products produced from insects:<br />

insect protein, insect oil and organic<br />

fertilizer. Insect protein and oil are used<br />

as natural and sustainable alternative<br />

ingredients in livestock feed and pet<br />

food. The frass, which is the manure and<br />

the leftovers from the insect breeding, is<br />

used as an organic fertilizer to grow new<br />

crops, of which again the lowest value<br />

by-products are used for feeding new<br />

batches of insects. This is a full circular<br />

model! However sustainability of insectbased<br />

ingredients can even go beyond<br />

circularity and upgrading of low value byproducts.<br />

Barentz has a range of plant-based and<br />

alternative proteins. Their technical team<br />

is ready to find together with pet food<br />

manufacturers the best solution, to lower<br />

the pet food ‘paw print’.<br />

For more information<br />

www.barentz.com/<br />

animalnutrition/pet-food<br />

22<br />

Technology & Marketing

INGREDIENTS<br />

Botanical Extracts: The Next<br />

Generation of Antioxidants (Part 1)<br />

by Cristina Murcia<br />

Introduction<br />

Botanical extracts are natural ingredients<br />

that contain diverse polyphenol type<br />

molecules. Some are well known for their<br />

endogenous and exogenous antioxidant<br />

abilities. In the European Union's<br />

regulatory framework for feed and pet<br />

food, until recently, only mixed tocopherols<br />

were registered as antioxidants.1 However,<br />

in response to the EFSA's 2022 Scientific<br />

Opinion, the European Commission has<br />

now approved rosemary extract as feed<br />

additive for cats and dogs, in the category<br />

of antioxidants. 2<br />

This article will focus on the exogenous<br />

antioxidant capacity of rosemary and olive<br />

extracts and the main reaction mechanism<br />

of their active molecules with the highest<br />

antioxidant potential.<br />

Rosemary extract<br />

Rosemary extract contains different<br />

diterpene molecules with antioxidant<br />

activity, from these, the one with the<br />

highest antioxidant effect is carnosic<br />

acid. Other molecules such as carnosol,<br />

rosmanol or epirosmanol have also some<br />

antioxidant capacities but less significant<br />

than carnosic acid. The reason for that<br />

is that all the above are decomposition<br />

products of carnosic acid, as we will see<br />

while explaining the simplified chemical<br />

reaction mechanisms.<br />

Oxygen Scavenger Mechanism:<br />

To prevent oxidation rosemary extract, or<br />

specifically, carnosic acid can scavenge<br />

singlet oxygen, an excited form of oxygen,<br />

and free radicals. While doing this carnosic<br />

acid will oxidize itself to form a carnosic<br />

acid quinone that by action of temperature<br />

or other catalysts will be transformed into<br />

carnosol. The carnosol molecule will further<br />

follow this path and will oxidise itself to be<br />

transformed into epirosmanol or rosmanol,<br />

depending on the stereochemistry of the<br />

reaction. 3,4 See Figure 1.<br />

Hydrogen Transfer Mechanism:<br />

Carnosic acid can also neutralize free<br />

radicals by following a different mechanism,<br />

by donating hydrogen atoms to stabilize<br />

lipid molecules (in figure 2 represented as<br />

ROOH). This type of mechanism is called<br />

hydrogen transfer mechanism. Here<br />

carnosic acid can neutralize the free radical<br />

activity of two lipid radical molecules<br />

(ROO°) to form a carnosic acid quinone. Like<br />

in the previous mechanism the carnosic<br />

acid quinone can be transformed into<br />

carnosol to provide additional antioxidant<br />

activity. Or the mechanism can follow a<br />

different pathway and lipid radicals can be<br />

stabilized by forming an epoxy quinone. In<br />

summary, the key message here is that one<br />

molecule of carnosic acid can neutralize<br />

two lipid radical molecules. 3<br />

What we can learn from the chemistry<br />

explained here is that carnosic acid<br />

can generate a variety of secondary<br />

antioxidants. This unique cascade-type<br />

process is likely to amplify the antioxidative<br />

power of carnosic acid and hence of<br />

rosemary extract and to constitute an<br />

Cristina Murcia<br />

García, PhD<br />

Technical Service<br />

Manager, Kemin<br />

Nutrisurance EMEA<br />

Dr Cristina Murcia<br />

García gained her PhD in<br />

Chemistry with focus on redox<br />

reactions from the University<br />

of Bonn (Germany). Since then, she has specialized in<br />

managing oxidation in rendering and pet food products.<br />

She works as Technical Service Manager for Kemin<br />

Nutrisurance Europe where she provides solutions to<br />

improve raw materials and pet food safety and shelf-life.<br />

Besides, she develops tailor-made trials and protocols for<br />

customers and holds customer specific trainings on topics<br />

like oxidation, freshness, and food safety.<br />

effective defense mechanism.4 In sum,<br />

the main driver for the antioxidant activity<br />

of rosemary extract is carnosic acid.<br />

This means the higher the carnosic acid<br />

concentration in a rosemary extract, the<br />

better will be its antioxidant activity. The<br />

rest of the phenolic diterpenes will also have<br />

some antioxidant activity but lower than<br />

carnosic acid because, as we have seen, they<br />

are degradation products from the carnosic<br />

acid molecule. Besides, rosemary extracts<br />

contain also other antioxidants such as<br />

rosmarinic acid bringing more antioxidant<br />

power to the overall activity of this botanical<br />

extract.<br />

Olive extract<br />

Olive extract is another natural<br />

ingredient very well known for its health<br />

Figure 1. Proposed oxygen quenching mechanism of rosemary extract.<br />

Figure 2. Proposed hydrogen transfer mechanism of rosemary extract.<br />

Issue 2 <strong>2024</strong><br />

23<br />

Photos: Kemin

INGREDIENTS<br />

Figure 3. Chemical structure of oleuropein<br />

Photos: Kemin<br />

Figure 4. Proposed radical scavenging mechanism of hydroxytyrosol.<br />

benefits and widely used for centuries in<br />

the countries of the Mediterranean area.<br />

Apart from its health or endogenous<br />

antioxidant and antimicrobial properties,<br />

recent research has shown the potential<br />

benefit of using olive extract as an<br />

exogenous antioxidant to prevent<br />

oxidation of fats, oils and fat containing<br />

matrices.<br />

Since olives are a raw material extensively<br />

used in human nutrition, the question<br />

arose if it could be economically suitable<br />

as an ingredient for the feed and pet<br />

food industries. Not all parts of the olive<br />

tree are used at the moment for human<br />

consumption. Among others, there are<br />

the leaves and there is the waste of the<br />

olive fruit after production of olive oil.<br />

Both co-products are rich in polyphenols<br />

with potential antioxidant activity.<br />

In olive materials we can find two<br />

interesting molecules for our antioxidant<br />

purpose: oleuropein and hydroxytyrosol.<br />

These two catechols have shown<br />

endogenous and exogenous free radical<br />

scavenging activity.⁵<br />

Although we can find both active<br />

ingredients in olive leaf and fruit, olive<br />

leaves are rich in oleuropein while olive<br />

fruits main ingredient is hydroxytyrosol.<br />

Oleuropein has shown an important<br />

antimicrobial effect as well as some<br />

endogenous antioxidant activity.⁶<br />

Nowadays there are a number of<br />

supplements in the market for human<br />

but also for petfood claiming immune<br />

system boost thanks to the properties<br />

of oleuropein (just type on your web<br />

browser pet food supplement with<br />

oleuropein and you will find several<br />

companies offering such products).<br />

Unfortunately, as technological additive<br />

to control oxidation of fats and oils,<br />

oleuropein as such has shown a poor<br />

antioxidant activity in comparison<br />

with hydroxytyrosol and other known<br />

antioxidants.⁷<br />

On the contrary, hydroxytyrosol has been<br />

demonstrated to be an ideal candidate to<br />

be considered as exogenous antioxidant<br />

to prevent the oxidation of feed and pet<br />

food relevant matrices.⁸,⁹ A few studies<br />

have proposed the mode of action of<br />

hydroxytyrosol, mainly by using radical<br />

scavenging reaction mechanism in<br />

which the hydroxytyrosol molecule can<br />

neutralized lipid radicals (ROO°). See<br />

figure 4.<br />

Kemin internal results have shown that<br />

the antioxidant activity of olive fruit<br />

extract can be enhanced by combination<br />

with known natural antioxidant<br />

molecules and that contrary to rosemary<br />

extract and carnosic acid, higher<br />

amounts of hydroxytyrosol in an olive<br />

extract do not necessarily mean better<br />

antioxidant activity.10<br />

Several studies have shown that olive<br />

fruit extract containing hydroxytyrosol<br />

but not only shows antioxidant<br />

activity comparable to that of pure<br />

hydroxytyrosol, perhaps due to the<br />

presence of active derivatives of<br />

hydroxytyrosol and other phenolic<br />

compounds which promote synergistic<br />

effects in the extract that are not<br />

available when using the pure molecule.<br />

Further research is needed to elucidate<br />

the mode of action of the antioxidants<br />

present in the olive extract.<br />

1https://ec.europa.eu/food/food-feed-portal/<br />

screen/feed-additives/search accessed on<br />

11th November 2023<br />

2https://eur-lex.europa.eu/eli/reg_<br />

impl/<strong>2024</strong>/1068/oj - Commission<br />

Implementing Regulation (EU) <strong>2024</strong>/1068 of<br />

12 April <strong>2024</strong>.<br />

3T. Masuda, Y. Inaba, Y. Takeda, J. Agric. Food<br />

Chem, 2001,49,5560-5565;; S. L. Richheimer,<br />

M. W. Bernart, G. A. King, M. C. Kent, D. T. Bailey,<br />

J. Am. Oil. Chem. Soc. 1996, 73, 507-514;<br />

4 M. Loussouarn, L. Krieger-Liszkay, A. Bily,<br />

S. Birtić, M. Havaux, Plant Physiol. 2017<br />

Nov;175(3):1381-1394<br />

⁵ M. Fiorini, V. Crognaletti, O. Sabry, P. Fattori,<br />

Processes 2021, 9, 433.<br />

⁶ D. Borjan, M. Leitgeb, Molecules 2020, 25,<br />

5946<br />

⁷ M.H. Gordon, F. Paiva-Martins, M. Almeida, J.<br />

Agric. Food Chem., 2001, 49, 2480-2485<br />

⁸A.Y. V. Theah, T. O. Akanbi, Antioxidants 2023,<br />

12, 929<br />

⁹ L. Martínez-Zamora, R. Peñalver, G. Ros, G.<br />

Nieto, Foods. 2021 Oct 28;10(11):2611<br />

10 Kemin R&D internal results<br />

Technology & Marketing<br />

For more information<br />

www.kemin.com<br />

24<br />

Technology & Marketing

Emsland Group at Interzoo<br />

INGREDIENTS<br />

Interzoo <strong>2024</strong><br />

May 7-10<br />

Nuremberg<br />

Hall 4 Booth 4-420<br />

The Emsland Group will be exhibiting for<br />

the first time at the Interzoo in Nuremberg<br />

from May 7 to 10. The Emsland Group is an<br />

international company that manufactures<br />

innovative products based on plant-based<br />

raw materials for the pet food processing<br />

industry, among others.<br />

The plant-based ingredients of the<br />

Emsland Group are made from peas<br />

and potatoes. In line with their guiding<br />

principle — “using nature to create”<br />

— the company has developed the<br />

innovative Empet® products for domestic<br />

and commercial animal nutrition. The<br />

components of potatoes and peas are<br />

ideal to support the market trends. These<br />

materials offer the possibility to produce<br />

non-GMO, natural and gluten- and grainfree<br />

products. The portfolio of the Emsland<br />

Group for animal nutrition consists of<br />

proteins, fibers, potato flakes and starches.<br />

Pet food should contain various amino<br />

acids. Although pets are capable<br />

of producing the majority of these<br />

themselves, there are 10 (essential)<br />

amino acids which they cannot generate.<br />

Peas and potatoes are excellent sources<br />

of easily digestible vegetable proteins<br />

and therefore our Empet® protein<br />

ingredients supplement the daily diet.<br />

These ingredients are rich in essential<br />

amino acids such as lysine, methionine,<br />

cysteine, valine, and arginine. Empet® pea<br />

and potato proteins offer many appealing<br />

qualities such as a low ash content as<br />

well as a lack of GMOs, allergens, grains<br />

and gluten. In terms of sustainability,<br />

these plant-based proteins are also more<br />

sustainable than their animal-based<br />

counterparts.<br />

Fibers can play a very important role in a<br />

pet’s diet. Insoluble fibers are responsible<br />

for creating a feeling of fullness without<br />

adding any calories. A higher fiber content<br />

in everyday animal feed increases the<br />

quantity of feed without increasing its<br />

energy content, meaning that the animal<br />

feels full without overeating. Especially<br />

for overweight animals, this can make it<br />

easier to implement a weight loss diet; it<br />

can also improve the feeling of fullness for<br />

animals that are constantly hungry, aiding<br />

in the prevention of obesity. The Emsland<br />

Group’s Empet® E 5 ingredients play what<br />

could be called a “mechanical” role in<br />

the digestive tract. Fibers have proven<br />

effective in relieving the symptoms of<br />

various diarrheal diseases. Fibers even<br />

can be helpful for diseases of the liver and<br />

kidneys. They lower the pH value in the gut<br />

and thus reduce the amount of ammonia<br />

released, which in turn provides relief<br />

to the metabolism through the positive<br />

effect of fibers’ strong ability to absorb<br />

water on diarrheal diseases.<br />

Potato flakes produced from fresh<br />

potatoes are applicable in a wide range<br />

of wet and dry pet food products, for<br />

example in products made by an extrusion<br />

process. In animal nutrition, potato flakes<br />

are used as a cold water functional binder,<br />

dough improver or for optimizing process<br />

viscosity for extrusion.<br />

Meet the Emsland Group at the Interzoo<br />

at booth 4-420 and discover their plantbased<br />

ingredients made from potatoes<br />

and peas.<br />

Technology & Marketing<br />

For more information<br />

www.emsland-group.de/en<br />

Photos: Emsland Group<br />

Issue 2 <strong>2024</strong><br />

25

MARKETING<br />

Food Ingredients Goes Pet<br />

The Fi Europe exhibition has been running for many years and is a important fixed point in the annual calendar. The world's leading<br />

suppliers attend and meet with the biggest food manufacturers. The focus has been on innovation and ingredients for food and<br />

beverages for human consumption and has both followed and created the trends in recent years. Until now. Ian Healey talked to<br />

Yannick Verry, Brand Manager of the international Food Ingredients Exhibitions organizer Informa Markets about a surprising new<br />

initiative for <strong>2024</strong>.<br />

Simultaneously, a growing number of our visitors are seeking<br />

solutions around pet food manufacturing, whether it is all-inone<br />

contract manufacturing or specific needs, such as a novel<br />

ingredient or new equipment that safeguards nutritional value<br />

during processing. We’re talking about more than 15% of our<br />

visitors who come to the show for pet nutrition, which is amazing<br />

if you think we’ve never promoted the event specifically to the<br />

pet food manufacturing community. It’s a best kept secret until<br />

today, for those who’ve been attending the show in the past few<br />

years.<br />

But this is not surprising because consumers are more demanding<br />

than ever, making continuous innovation in this dynamic market<br />

a necessity. And Fi Europe is at the forefront of F&B innovation -<br />

it’s the place to see and feel the products that we will enjoy on<br />

our plates tomorrow. That’s why the show takes place every year<br />

unlike most of the events in our industry, and it allows pet food<br />

makers to get ahead of their competition.<br />

Photo: FI Global<br />

chnology & Marketing<br />

chnology & Marketing<br />

Yannick Verry, Brand Manager, Food Ingredients Europe &<br />

Americas<br />

Technology & Marketing<br />

Hi Yannick, please introduce yourself and<br />

Informa Markets to our readers.<br />

Hello Ian. I am the Event Director for Food ingredients Europe,<br />

organized by Informa Markets. Fi Europe was launched in 1986<br />

and is the world’s largest event for ingredients and innovation<br />

in the food and beverage industry. Fi Europe is an annual show<br />

and alternates between Paris and Frankfurt, where 1500+<br />

suppliers of food ingredients and manufacturing solutions<br />

present their latest products and innovative solutions to<br />

manufacturers of finished F&B and pet food products.<br />

Technology & Marketing<br />

Why is a food ingredient event now interested<br />

in reaching pet food suppliers?<br />

Prior to my role at Informa Markets, I worked for 12 years in Asia<br />

on one of the largest exhibitions for pet supplies and developed<br />

a strong interest in the sector. After joining Fi Europe last year,<br />

I identified that suppliers of pet food solutions already had a<br />

huge presence at the event: about one third of our exhibitors<br />

are proactively promoting their pet food innovations at the<br />

show. With around 450 companies fitting this profile, this<br />

makes Fi Europe the largest annual gathering of suppliers for<br />

the pet food industry in Europe.<br />

How do you see the pet food market developing<br />

in the next 5 to 10 years? How does this compare<br />

to food for humans?<br />

According to research from Mordor Intelligence, the global pet<br />

food market is growing at 8.54% CAGR over the period <strong>2024</strong>-<br />

2029, faster than F&B – growing at roughly 6% annually over the<br />

same period.<br />

On the one hand, the premiumization of pet food products<br />

alongside the humanization of our furry friends drives the<br />

market value up. And on the other hand, budget constraints<br />

among consumers add to the challenge of manufacturing good<br />

products at reasonable prices. If you add sustainability objectives<br />

or the competition over usage of resources (fatty acids in pet<br />

food vs biofuels for instance), brands will need to rely on the<br />

most innovative suppliers to stay relevant and grow in the next<br />

10 years.<br />

What is the plan to offer a pet food zone and how<br />

would this look?<br />

The Petfood Suppliers Hub will be located at the heart of Fi<br />

Europe near some of our largest exhibitors, offering maximum<br />

exposure to pet food innovations. The area will gather suppliers<br />

of equipment, technology, contract manufacturing and services<br />

alongside the large contingent of ingredients manufacturers and<br />

premix solutions already available at Fi Europe.<br />