You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

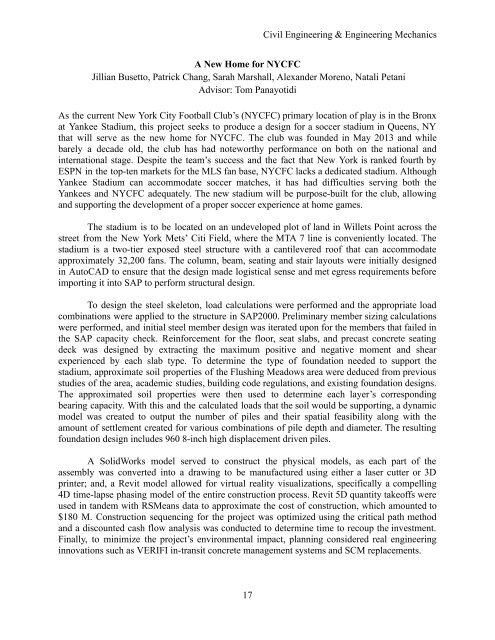

Civil Engineering & Engineering Mechanics<br />

A New Home for NYCFC<br />

Jillian Busetto, Patrick Chang, Sarah Marshall, Alexander Moreno, Natali Petani<br />

Advisor: Tom Panayotidi<br />

As the current New York City Football Club’s (NYCFC) primary location of play is in the Bronx<br />

at Yankee Stadium, this project seeks to produce a design for a soccer stadium in Queens, NY<br />

that will serve as the new home for NYCFC. The club was founded in May 2013 and while<br />

barely a decade old, the club has had noteworthy performance on both on the national and<br />

international stage. Despite the team’s success and the fact that New York is ranked fourth by<br />

ESPN in the top-ten markets for the MLS fan base, NYCFC lacks a dedicated stadium. Although<br />

Yankee Stadium can accommodate soccer matches, it has had difficulties serving both the<br />

Yankees and NYCFC adequately. The new stadium will be purpose-built for the club, allowing<br />

and supporting the development of a proper soccer experience at home games.<br />

The stadium is to be located on an undeveloped plot of land in Willets Point across the<br />

street from the New York Mets’ Citi Field, where the MTA 7 line is conveniently located. The<br />

stadium is a two-tier exposed steel structure with a cantilevered roof that can accommodate<br />

approximately 32,200 fans. The column, beam, seating and stair layouts were initially designed<br />

in AutoCAD to ensure that the design made logistical sense and met egress requirements before<br />

importing it into SAP to perform structural design.<br />

To design the steel skeleton, load calculations were performed and the appropriate load<br />

combinations were applied to the structure in SAP2000. Preliminary member sizing calculations<br />

were performed, and initial steel member design was iterated upon for the members that failed in<br />

the SAP capacity check. Reinforcement for the floor, seat slabs, and precast concrete seating<br />

deck was designed by extracting the maximum positive and negative moment and shear<br />

experienced by each slab type. To determine the type of foundation needed to support the<br />

stadium, approximate soil properties of the Flushing Meadows area were deduced from previous<br />

studies of the area, academic studies, building code regulations, and existing foundation designs.<br />

The approximated soil properties were then used to determine each layer’s corresponding<br />

bearing capacity. With this and the calculated loads that the soil would be supporting, a dynamic<br />

model was created to output the number of piles and their spatial feasibility along with the<br />

amount of settlement created for various combinations of pile depth and diameter. The resulting<br />

foundation design includes 960 8-inch high displacement driven piles.<br />

A SolidWorks model served to construct the physical models, as each part of the<br />

assembly was converted into a drawing to be manufactured using either a laser cutter or 3D<br />

printer; and, a Revit model allowed for virtual reality visualizations, specifically a compelling<br />

4D time-lapse phasing model of the entire construction process. Revit 5D quantity takeoffs were<br />

used in tandem with RSMeans data to approximate the cost of construction, which amounted to<br />

$180 M. Construction sequencing for the project was optimized using the critical path method<br />

and a discounted cash flow analysis was conducted to determine time to recoup the investment.<br />

Finally, to minimize the project’s environmental impact, planning considered real engineering<br />

innovations such as VERIFI in-transit concrete management systems and SCM replacements.<br />

17