Finishing Yearbook 2024

Welcome to the 46th edition of the Finishing Industries Yearbook – the essential guide for everyone involved in the UK surface treatment industry. Each year I write a little note about the events of the past year, and how they have affected the industry. Like most my age we only seem to recall the difficulties faced over the past year. However, it is always good to read how the industry circumnavigates each situation. We hope that you find this edition an invaluable aid to sourcing suppliers to provide the solution to your specific needs. It is used by the whole buying chain from trade finishing houses to manufacturers of a wide variety of products from white goods to automotive. We would like to take this opportunity to thank all the businesses that have contributed to the compilation of this yearbook. If you have any comments, suggestions or would like to be included in the next edition, please email me at b.williams@turretgroup.com. The Buyers’ Guide categories have been updated this year with the new headings of “Lubricants/Grease” and “Solvent Recovery’. In the Regional Guide, there is the new category of “Chemical Etching & Etch Inspection”. The Finishing Industries Yearbook Team & Finishing Industries Magazine Team wish you all the very best for 2024!

Welcome to the 46th edition of the Finishing Industries Yearbook – the essential guide for everyone involved in the UK surface treatment industry.

Each year I write a little note about the events of the past year, and how they have affected the industry. Like most my age we only seem to recall the difficulties faced over the past year. However, it is always good to read how the industry circumnavigates each situation.

We hope that you find this edition an invaluable aid to sourcing suppliers to provide the solution to your specific needs. It is used by the whole buying chain from trade finishing houses to manufacturers of a wide variety of products from white goods to automotive.

We would like to take this opportunity to thank all the businesses that have contributed to the compilation of this yearbook. If you have any comments, suggestions or would like to be included in the next edition, please email me at b.williams@turretgroup.com. The Buyers’ Guide categories have been updated this year with the new headings of “Lubricants/Grease” and “Solvent Recovery’. In the Regional Guide, there is the new category of “Chemical Etching & Etch Inspection”.

The Finishing Industries Yearbook Team & Finishing Industries Magazine Team wish you all the very best for 2024!

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

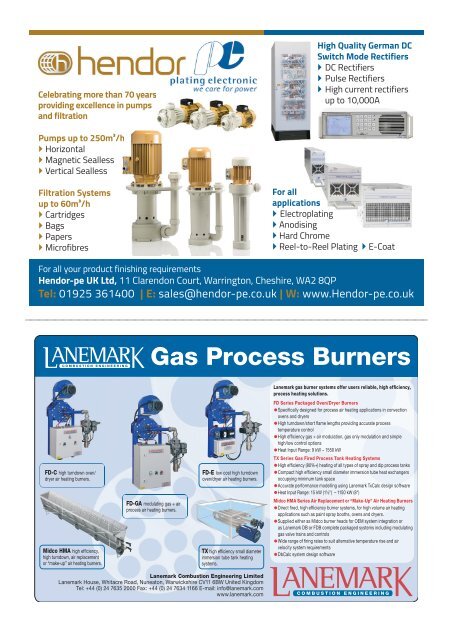

Celebrating more than 70 years<br />

providing excellence in pumps<br />

and filtration<br />

High Quality German DC<br />

Switch Mode Rectifiers<br />

DC Rectifiers<br />

Pulse Rectifiers<br />

High current rectifiers<br />

up to 10,000A<br />

Pumps up to 250m³/h<br />

Horizontal<br />

Magnetic Sealless<br />

Vertical Sealless<br />

Filtration Systems<br />

up to 60m³/h<br />

Cartridges<br />

Bags<br />

Papers<br />

Microfibres<br />

For all<br />

applications<br />

Electroplating<br />

Anodising<br />

Hard Chrome<br />

Reel-to-Reel Plating E-Coat<br />

For all your product finishing requirements<br />

Hendor-pe UK Ltd, 11 Clarendon Court, Warrington, Cheshire, WA2 8QP<br />

Tel: 01925 361400 | E: sales@hendor-pe.co.uk | W: www.Hendor-pe.co.uk<br />

Gas Process Burners<br />

Lanemark gas burner systems offer users reliable, high efficiency,<br />

process heating solutions.<br />

FD-C high turndown oven/<br />

dryer air heating burners.<br />

Midco HMA high efficiency,<br />

high turndown, air replacement<br />

or “make-up” air heating burners.<br />

FD-GA modulating gas + air<br />

process air heating burners.<br />

FD-E low cost high turndown<br />

oven/dryer air heating burners.<br />

TX high efficiency small diameter<br />

immersion tube tank heating<br />

systems.<br />

FD Series Packaged Oven/Dryer Burners<br />

• Specifi cally designed for process air heating applications in convection<br />

ovens and dryers<br />

• High turndown/short flame lengths providing accurate process<br />

temperature control<br />

• High effi ciency gas + air modulation, gas only modulation and simple<br />

high/low control options<br />

• Heat Input Range: 9 kW – 1550 kW<br />

TX Series Gas Fired Process Tank Heating Systems<br />

• High effi ciency (80%+) heating of all types of spray and dip process tanks<br />

• Compact high effi ciency small diameter immersion tube heat exchangers<br />

occupying minimum tank space<br />

• Accurate performance modelling using Lanemark TxCalc design software<br />

• Heat Input Range: 15 kW (1½") – 1150 kW (8")<br />

Midco HMA Series Air Replacement or “Make-Up” Air Heating Burners<br />

• Direct fired, high effi ciency burner systems, for high volume air heating<br />

applications such as paint spray booths, ovens and dryers.<br />

• Supplied either as Midco burner heads for OEM system integration or<br />

as Lanemark DB or FDB complete packaged systems including modulating<br />

gas valve trains and controls<br />

• Wide range of firing rates to suit alternative temperature rise and air<br />

velocity system requirements<br />

• DbCalc system design software<br />

Lanemark Combustion Engineering Limited<br />

Lanemark House, Whitacre Road, Nuneaton, Warwickshire CV11 6BW United Kingdom<br />

Tel: +44 (0) 24 7635 2000 Fax: +44 (0) 24 7634 1166 E-mail: info@lanemark.com<br />

www.lanemark.com<br />

COMBUSTION ENGINEERING<br />

X4620 Lanemark Ad SDAW.indd 1 31/08/2016 09:04