National Hardwood Magazine - Christmas 2023

Look back on 2023 and look forward to 2024 with the Christmas issue of National Hardwood Magazine. The issue also features stories on Lauzon Hardwood Flooring, Wolverine Hardwoods, the RTA Annual Symposium & Technical Conference, and much more.

Look back on 2023 and look forward to 2024 with the Christmas issue of National Hardwood Magazine. The issue also features stories on Lauzon Hardwood Flooring, Wolverine Hardwoods, the RTA Annual Symposium & Technical Conference, and much more.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LAUZON HARDWOODS Continued<br />

customers, suppliers and partners.”<br />

At Lauzon <strong>Hardwood</strong>, commitment to the environment<br />

is at par with its people. Since its inception in 1985, Lauzon<br />

<strong>Hardwood</strong> has recognized the importance of the forest<br />

as a natural and sustainable resource. “We always<br />

had the philosophy to show respect to nature and protect<br />

the environment by using a sustainable methodology,”<br />

David said. “Any development must be done with the<br />

least impact on the environment and its sustainability.<br />

As such, we are a carbon-neutral company,” he added.<br />

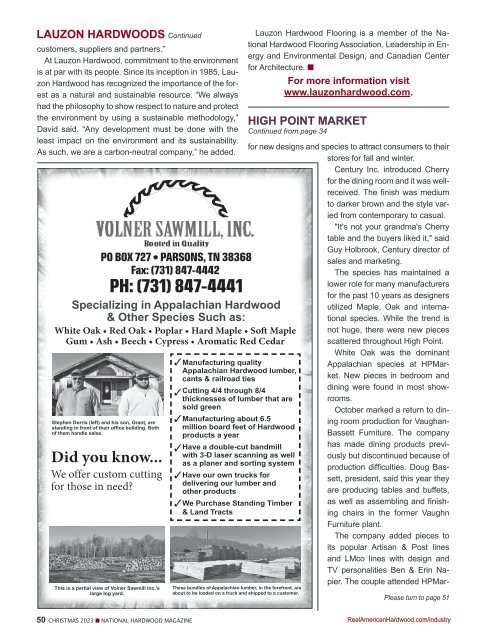

PO BOX 727 • PARSONS, TN 38368<br />

Fax: (731) 847-4442<br />

PH: (731) 847-4441<br />

Specializing in Appalachian <strong>Hardwood</strong><br />

& Other Species Such as:<br />

White Oak • Red Oak • Poplar • Hard Maple • Soft Maple<br />

Gum • Ash • Beech • Cypress • Aromatic Red Cedar<br />

Stephen Dorris (left) and his son, Grant, are<br />

standing in front of their office building. Both<br />

of them handle sales.<br />

Did you know...<br />

We offer custom cutting<br />

for those in need?<br />

This is a partial view of Volner Sawmill Inc.’s<br />

large log yard.<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

Manufacturing quality<br />

Appalachian <strong>Hardwood</strong> lumber,<br />

cants & railroad ties<br />

Cutting 4/4 through 8/4<br />

thicknesses of lumber that are<br />

sold green<br />

Manufacturing about 6.5<br />

million board feet of <strong>Hardwood</strong><br />

products a year<br />

Have a double-cut bandmill<br />

with 3-D laser scanning as well<br />

as a planer and sorting system<br />

Have our own trucks for<br />

delivering our lumber and<br />

other products<br />

We Purchase Standing Timber<br />

& Land Tracts<br />

These bundles of Appalachian lumber, in the forefront, are<br />

about to be loaded on a truck and shipped to a customer.<br />

Lauzon <strong>Hardwood</strong> Flooring is a member of the <strong>National</strong><br />

<strong>Hardwood</strong> Flooring Association, Leadership in Energy<br />

and Environmental Design, and Canadian Center<br />

for Architecture. n<br />

For more information visit<br />

www.lauzonhardwood.com.<br />

HIGH POINT MARKET<br />

Continued from page 34<br />

for new designs and species to attract consumers to their<br />

stores for fall and winter.<br />

Century Inc. introduced Cherry<br />

for the dining room and it was wellreceived.<br />

The finish was medium<br />

to darker brown and the style varied<br />

from contemporary to casual.<br />

"It's not your grandma's Cherry<br />

table and the buyers liked it," said<br />

Please turn to page 51<br />

WOLVERINE HARDWOODS<br />

Continued from page 27<br />

Guy Holbrook, Century director of<br />

sales and marketing.<br />

The species has maintained a<br />

lower role for many manufacturers<br />

for the past 10 years as designers<br />

utilized Maple, Oak and international<br />

species. While the trend is<br />

not huge, there were new pieces<br />

scattered throughout High Point.<br />

White Oak was the dominant<br />

Appalachian species at HPMarket.<br />

New pieces in bedroom and<br />

dining were found in most showrooms.<br />

October marked a return to dining<br />

room production for Vaughan-<br />

Bassett Furniture. The company<br />

has made dining products previously<br />

but discontinued because of<br />

production difficulties. Doug Bassett,<br />

president, said this year they<br />

are producing tables and buffets,<br />

as well as assembling and finishing<br />

chairs in the former Vaughn<br />

Furniture plant.<br />

The company added pieces to<br />

its popular Artisan & Post lines<br />

and LMco lines with design and<br />

TV personalities Ben & Erin Napier.<br />

The couple attended HPMarple,<br />

Hickory, Poplar, Red and White Oak, Walnut and a little bit<br />

of imported exotic woods. We have a Newman Planer, so we<br />

plane almost all of our lumber.”<br />

The company sells 12 million board feet of lumber each year,<br />

mainly sourced from Michigan and the surrounding states.<br />

“Most of our lumber comes from Michigan and the northern<br />

midwest – Indiana, Ohio, Illinois, Wisconsin, and Ontario. We<br />

will go a little bit further out for some species that are less<br />

abundant in our area. We get some<br />

White Oak and Poplar from further<br />

away and we do also carry some<br />

Alder that comes out of the Pacific<br />

Northwest,” Mallery commented.<br />

Wolverine <strong>Hardwood</strong>s operates<br />

on a 15-acre site with a 120,000<br />

square-foot facility, where they employ<br />

a skilled team of 30 employees.<br />

Their impressive equipment lineup<br />

is comprised of a Newman planer,<br />

automatic stacker, automatic trimmer,<br />

Weima wood waste grinder,<br />

600hp Hurst wood waste boiler, and<br />

a Johnson gas boiler. In addition to<br />

these, they also use Yardmaster by<br />

Forestry Systems Inc. for their inventory<br />

software.<br />

With eight SII Dry Kilns, two of<br />

which were added in <strong>2023</strong>, boasting<br />

a monthly capacity of 400,000 board<br />

feet, Wolverine <strong>Hardwood</strong>s is at the<br />

forefront of kiln-drying expertise. Notably,<br />

they can also store up to 1.5<br />

million board feet of kiln-dried lumber<br />

and 2.5 million board feet of air-dried<br />

lumber. Quality is their utmost priority,<br />

reinforced by a dedicated team of<br />

five trained lumber inspectors who<br />

meticulously ensure that each board<br />

meets their standards. Additionally,<br />

they have installed fans in their<br />

sheds allowing them to reduce staining<br />

in their white woods. “In 2021 SII<br />

Dry Kilns installed fans in the back of<br />

one of our T-Sheds and it has really<br />

worked well to help us minimize stain<br />

in our white woods. It paid for itself<br />

within the first summer, so I recom-<br />

Please turn the page<br />

Pictured are SII Dry Kilns, kiln 7 and kiln 8 installed<br />

June, <strong>2023</strong> with 50,000-foot capacity each.<br />

Appalachian Kiln Dried<br />

<strong>Hardwood</strong> Lumber<br />

Turman Mercer-Sawmills<br />

Hillsville, VA<br />

lee.daugherty@theturmangroup.com<br />

wil.brush@theturmangroup.com<br />

Turman Tye River, LLC<br />

Arrington, VA<br />

barry.largen@theturmangroup.com<br />

rc.conley@theturmangroup.com<br />

Turman Lumber-Salem<br />

Salem, VA<br />

ross.frazier@theturmangroup.com<br />

Appalachian Shipping Dry<br />

Lumber and Logs<br />

Turman Forest Products, Inc.<br />

Bedford, VA<br />

tfp@theturmangroup.com<br />

josh.bond@theturmangroup.com<br />

HILLSVILLE, VA<br />

BEDFORD, VA<br />

SALEM, VA<br />

ARRINGTON, VA<br />

www.theturmangroup.com<br />

50 CHRISTMAS <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE RealAmerican<strong>Hardwood</strong>.com/industry RealAmerican<strong>Hardwood</strong>.com/industry CHRISTMAS <strong>2023</strong> n NATIONAL HARDWOOD MAGAZINE 51