program time controller - events chart - Faraday

program time controller - events chart - Faraday

program time controller - events chart - Faraday

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

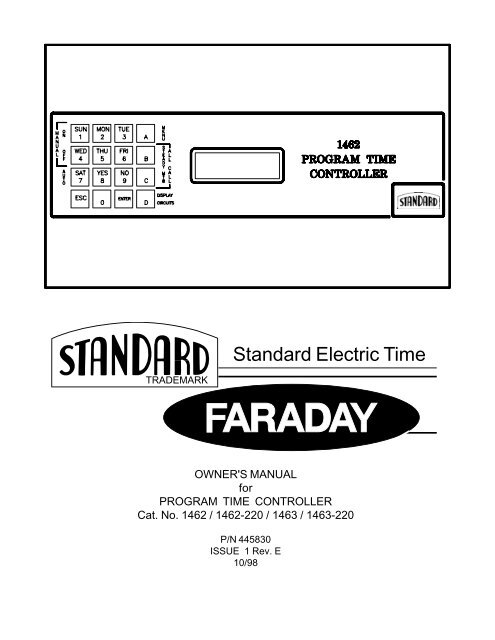

TRADEMARK<br />

Standard Electric Time<br />

OWNER'S MANUAL<br />

for<br />

PROGRAM TIME CONTROLLER<br />

Cat. No. 1462 / 1462-220 / 1463 / 1463-220<br />

P/N 445830<br />

ISSUE 1 Rev. E<br />

10/98

1462/63 INSTRUCTION MANUAL<br />

IMPORTANT INSTALLATION AND WARRANTY INFORMATION<br />

WARRANTY INFORMATION: <strong>Faraday</strong>, LLC (the Manufacturer) provides a limited warranty to the Original Purchaser<br />

of this product. The Original Purchaser is the party to whom the Manufacturer issued its Sales Order, generally the<br />

Manufacturer's distributor. In order to preserve this warranty, it is important that the product be serviced only by<br />

persons who have been properly trained and authorized by the Manufacturer.<br />

Other parties involved in the installation of this product may have also provided a warranty which may be different<br />

than that of the manufacturer. The Manufacturer will only be responsible to the Original Purchaser and only for<br />

the Manufacturer's own warranty. For further information regarding the Manufacturer's warranty, contact the<br />

Original Purchaser.<br />

OWNER'S MANUAL: The owner's manual does not purport to cover all the details or variations in the equipment<br />

described, nor does it provide for every possible contingency to be met in connection with installation, operation<br />

and maintenance. All specifications subject to change without notice. Should further information be desired or<br />

should particular problems arise which are not covered sufficiently, the matter should be referred to the Installer<br />

or Original Purchaser listed below.<br />

INSTALLER INFORMATION<br />

COMPANY:_________________________________INSTALLER:___________________________PHONE:______________<br />

ADDRESS:__________________________________CITY:__________________STATE:___________ZIP:____________<br />

DATE INSTALLED:____________________________INSTALLER'S SIGNATURE:____________________<br />

ORIGINAL PURCHASER INFORMATION<br />

COMPANY:_________________________________________________________PHONE:____________________<br />

ADDRESS:__________________________________CITY:__________________STATE:___________ZIP:____________<br />

PURCHASER'S PURCHASE ORDER NO.:____________________________________________________<br />

DATE PURCHASED:______________________________________________________________________<br />

FARADAY SALES ORDER ACKNOWLEDGMENT NO.:__________________________________________<br />

ORIGINAL PURCHASER'S SIGNATURE:_____________________________________________________<br />

NOTE: A copy of the above completed information may be required by the manufacturer for authorization of<br />

Warranty services.<br />

Page 1

1462/63 INSTRUCTION MANUAL<br />

FCC FCC FCC COMPLIANCE<br />

COMPLIANCE<br />

WARNING: WARNING: This equipment generates, uses, and can radiate radio frequency energy and if<br />

not installed and used in accordance with this instruction manual, may cause interference to<br />

radio communications. It complies with the limits for a Class A computing device pursuant to<br />

Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection<br />

against such interference when operated in a commercial environment. Operation of this<br />

equipment in a residential area is likely to cause interference in which case the user at his own<br />

expense will be required to take whatever measures may be required to correct the interference.<br />

ATTENTION<br />

OBSERVE PRECAUTIONS<br />

FOR HANDLING<br />

ELECTROSTATIC<br />

SENSITIVE<br />

DEVICES<br />

STATIC STATIC WARNING<br />

WARNING<br />

CAUTION: CAUTION: CAUTION: This equipment contains electronic devices that are sensitive to static electric<br />

charges. To guarantee protection for the circuitry of this unit, it is required that electrostatic<br />

handling precautions be observed when installing or repairing this equipment. Any technician<br />

or other personnel working on this unit must wear a static grounding wrist strap or similar device<br />

to provide protection of sensitive components.<br />

ELECTRIC ELECTRIC ELECTRIC SHOCK SHOCK HAZARD<br />

HAZARD<br />

WARNING:<br />

WARNING: Hazardous voltage in electrical equipment can cause severe personal injury or<br />

death. Inspection, installation, and preventive maintenance should only be performed on<br />

equipment to which power has been turned off, disconnected and electrically isolated so no<br />

accidental contact can be made with energized parts.<br />

Page 2

1462/63 INSTRUCTION MANUAL<br />

Table of Contents<br />

IMPORTANT INSTALLATION AND WARRANTY INFORMATION .................................................................. 1<br />

FCC COMPLIANCE .................................................................................................................... 2<br />

STATIC WARNING...................................................................................................................... 2<br />

ELECTRIC SHOCK HAZARD .......................................................................................................... 2<br />

TABLE OF CONTENTS ................................................................................................................ 3<br />

DESCRIPTION............................................................................................................................ 7<br />

GENERAL DESCRIPTION OF UNIT .............................................................................................. 7<br />

PROGRAM FEATURES ........................................................................................................... 7<br />

SYSTEM OPTIONS ................................................................................................................ 8<br />

SPECIFICATIONS ........................................................................................................................ 9<br />

INSTALLATION ......................................................................................................................... 10<br />

PARTS CHECKLIST ............................................................................................................. 10<br />

SURFACE MOUNT UNIT (1462, 1462-220) .......................................................................... 11<br />

PANEL MOUNTING ........................................................................................................ 11<br />

APPLYING POWER ........................................................................................................ 12<br />

ADJUSTING THE DISPLAY................................................................................................ 12<br />

CONNECTING FIELD DEVICES .......................................................................................... 13<br />

FINISHING THE INSTALLATION........................................................................................... 13<br />

LOCATION OF AC INPUT TERMINALS ON 1462 MAIN BOARD ................................................ 14<br />

WIRING A 1462 TO AC POWER ..................................................................................... 14<br />

EXPLODED VIEW OF 1462 CHASSIS ................................................................................ 15<br />

LOCATION OF JUMPERS ON CPU/DISPLAY BOARD OF THE 1462 .......................................... 15<br />

RACK MOUNT UNIT (1463, 1463-220) ................................................................................ 16<br />

PREPARING UNIT FOR EQUIPMENT RACK .......................................................................... 16<br />

GIVING UNIT A BENCH TEST .......................................................................................... 16<br />

ADJUSTING THE DISPLAY................................................................................................ 17<br />

INSTALLING THE UNIT INTO THE EQUIPMENT RACK .............................................................. 18<br />

CONNECTING FIELD DEVICES .......................................................................................... 19<br />

FINISHING THE INSTALLATION........................................................................................... 19<br />

LOCATION OF AC INPUT TERMINALS ON 1463 CHASSIS ...................................................... 20<br />

WIRING A 1463 TO AC POWER ..................................................................................... 20<br />

EXPLODED VIEW OF 1463 CHASSIS ................................................................................ 21<br />

LOCATION OF JUMPERS ON CPU BOARD OF THE 1463 ...................................................... 21<br />

OPERATION ............................................................................................................................ 22<br />

SYSTEM CONTROLS ........................................................................................................... 22<br />

HARDWARE RESET ....................................................................................................... 22<br />

KEYPAD ...................................................................................................................... 22<br />

DISPLAY ..................................................................................................................... 23<br />

USING THE SYSTEM CONTROLS TO OPERATE AND PROGRAM THE PROGRAM TIME CONTROLLER .23<br />

OPERATING THE PROGRAM TIME CONTROLLER ........................................................................ 25<br />

ACCESS CODE SECURITY .............................................................................................. 25<br />

DISPLAY CIRCUITS ........................................................................................................ 27<br />

FUNCTION KEYS ........................................................................................................... 27<br />

THE VIRTUAL ON/OFF/AUTO SWITCH .................................................................... 28<br />

MANUAL ON ..................................................................................................... 28<br />

MANUAL OFF .................................................................................................... 28<br />

AUTOMATIC ...................................................................................................... 29<br />

Page 3

1462/63 INSTRUCTION MANUAL<br />

Table of Contents<br />

ALL CALL .............................................................................................................. 29<br />

STEADY ALL CALL ............................................................................................. 29<br />

MTB ALL CALL ................................................................................................ 29<br />

PROGRAMMING THE PROGRAM TIME CONTROLLER .............................................................. 30<br />

LEVEL 1 PROGRAMMING ........................................................................................... 30<br />

SET SCHEDULE ................................................................................................. 30<br />

SET MAIN SCHEDULE.................................................................................... 30<br />

SET ALTERNATE SCHEDULE ........................................................................... 30<br />

LEVEL 2 PROGRAMMING ........................................................................................... 31<br />

PROGRAM EVENTS............................................................................................. 31<br />

WHAT IS AN EVENT AND WHY PROGRAM IT? .................................................... 31<br />

THE PROGRAM EVENTS / EDIT EVENTS MENU................................................... 32<br />

ADDING EVENTS .......................................................................................... 32<br />

SCANNING AND EDITING EVENTS ..................................................................... 33<br />

ALTERNATE DATES ............................................................................................ 36<br />

ADDING ALTERNATE DATES ............................................................................ 36<br />

SCANNING AND EDITING ALTERNATE DATES ...................................................... 37<br />

SET TIME......................................................................................................... 38<br />

SET DATE ........................................................................................................ 38<br />

MANUAL ADVANCE ............................................................................................. 39<br />

CLOCK ENABLE ................................................................................................. 39<br />

LEVEL 3 PROGRAMMING ........................................................................................... 40<br />

SET DEFAULTS.................................................................................................. 41<br />

SET TIME BASE ........................................................................................... 41<br />

TIME FORMAT.............................................................................................. 41<br />

SET LINE FREQ ........................................................................................... 42<br />

SET DAYLIGHT SAVINGS ................................................................................ 42<br />

ALL CALL FEATURE ...................................................................................... 42<br />

SERIAL PORT .............................................................................................. 42<br />

MASTER TO MASTER SYNC ............................................................................ 43<br />

PROGRAM CLOCKS ....................................................................................... 44<br />

FUNCTION KEYS........................................................................................... 44<br />

CLEAR MEMORY .......................................................................................... 45<br />

ACCESS CODE ................................................................................................... 45<br />

DIAGNOSTICS .................................................................................................... 46<br />

SPECIAL FUNCTIONS........................................................................................... 47<br />

TROUBLE SHOOTING GUIDE ...................................................................................................... 48<br />

TROUBLE SHOOTING GUIDELINES .......................................................................................... 48<br />

SECONDARY CLOCKS DON'T KEEP TIME ........................................................................... 48<br />

PROGRAM TIME CONTROLLER DOESN'T KEEP TIME ............................................................ 49<br />

BELL(S)/UTILITY DEVICE(S) WON'T OPERATE PROPERLY ........................................................... 49<br />

BELL(S)/UTILITY DEVICE(S) WON'T TURN OFF ........................................................................ 50<br />

Page 4

1462/63 INSTRUCTION MANUAL<br />

Table of Contents<br />

APPENDIX A: QUICK REFERENCE PROGRAMMING MENUS ........................................................... A-1<br />

PROGRAMMING MENU TABLE OF CONTENTS .......................................................................... A-1<br />

APPENDIX B: INSTALLATION OF SECONDARY CLOCKS ................................................................. B-1<br />

CLOCK CODE DESCRIPTIONS .............................................................................................. B-1<br />

CLOCK CODE TABLE ......................................................................................................... B-4<br />

FIG. 1 TYPICAL WIRING FOR SYNCHRONOUS CLOCK MOVEMENTS (SINGLE VOLTAGE) .......................... B-5<br />

FIG. 2 TYPICAL WIRING FOR SYNCHRONOUS CLOCK MOVEMENTS (DUAL VOLTAGE) ............................ B-6<br />

FIG. 3 TYPICAL WIRING FOR 2 WIRE POLARITY REVERSAL CLOCKS W/1415 CLOCK POWER SUPPLY<br />

AND 1416 CLOCK BOOSTER .............................................................................. B-7<br />

FIG. 4 TYPICAL WIRING FOR 2 WIRE POLARITY REVERSAL CLOCKS ......................................... B-8<br />

FIG. 5 TYPICAL WIRING FOR 2362 AND 2364 DIGITAL SECONDARY CLOCKS............................. B-9<br />

FIG. 6 TYPICAL WIRING FOR AR2 & AR2A CLOCKS .......................................................... B-10<br />

FIG. 7 TYPICAL WIRING FOR AR3 CLOCKS........................................................................ B-11<br />

FIG. 8 TYPICAL WIRING FOR 2 WIRE POLARITY REVERSAL IMPULSE CLOCKS (CLOCK CODE 21)......B-12<br />

FIG. 9 TYPICAL WIRING FOR 3 WIRE IMPULSE CLOCKS ........................................................ B-13<br />

FIG. 10 TYPICAL WIRING FOR 2 WIRE, MINUTE IMPULSE CLOCKS<br />

WITH NO HOURLY OR 12 HOUR CORRECTION ...................................................... B-14<br />

APPENDIX C: TYPICAL SIGNAL CIRCUIT WIRING ....................................................................... C-1<br />

FIG. A TYPICAL AUXILIARY CIRCUIT WIRING FOR SIGNAL DEVICES ........................................... C-1<br />

FIG. B TYPICAL AUXILIARY CIRCUIT WIRING FOR UTILITY CONTROL DEVICES ............................. C-2<br />

APPENDIX D: GLOSSARY OF TERMS ...................................................................................... D-1<br />

APPENDIX E: OPTION MODULE INSTALLATION INSTRUCTION SHEETS<br />

1464 FOUR BELL/AUXILIARY CIRCUIT ADDER OPTION INSTALLATION INSTRUCTIONS ........ P/N 445734<br />

1464R FOUR BELL/AUXILIARY CIRCUIT ADDER OPTION INSTALLATION INSTRUCTIONS ..... P/N 445735<br />

1466 MASTER-TO-MASTER SYNCHRONIZATION OPTION INSTALLATION INSTRUCTIONS ...... P/N 445739<br />

1468A RS-232 PORT OPTION INSTALLATION INSTRUCTIONS ..................................... P/N 445796<br />

APPENDIX F: PROGRAMMING SHEETS<br />

PROGRAM TIME CONTROLLER DEFAULT SETTINGS CHART<br />

PROGRAM TIME CONTROLLER - EVENTS CHART<br />

APPENDIX G: CODE CARD ................................................................................................... G-1<br />

Page 5

1462/63 INSTRUCTION MANUAL<br />

Page 6

I.) General Description of Unit:<br />

1462/63 INSTRUCTION MANUAL<br />

DESCRIPTION<br />

The 1462/1463 Program Time Controller is a microprocessor based <strong>time</strong> management unit. It<br />

provides synchronized control of most analog and digital secondary clock systems via its clock<br />

circuit.<br />

The 1462/1463 contains two <strong>program</strong>mable signal circuits. Each signal circuit provides automatic<br />

and manual control of signaling or utility devices. To increase the number of signal circuits to six,<br />

simply add the Four Bell/Auxiliary Circuit Adder Option.<br />

A sixteen key, multiple-function keypad allows the user to <strong>program</strong> the 1462/1463. It is also how<br />

the user performs manual clock advance, manual operation of the signal circuits, and all call. The<br />

abbreviated names for the keys provide a helpful reference for <strong>program</strong>ming the 1462/1463.<br />

A 16 character by 2 line LCD allows the user to monitor the 1462/1463’s status and response to<br />

<strong>program</strong>ming. Included is a backlight that either remains on continuously, or turns off after a short<br />

<strong>time</strong>, depending on the user’s requirements.<br />

Password security protects the system from unauthorized operation. Three levels of password<br />

security allow selective access to the 1462/1463’s features. The ability to enable or disable<br />

password security to some basic features, such as all call, provides even more flexibility.<br />

The 1462/1463’s <strong>time</strong> keeping synchronizes to either AC line frequency or a quartz controlled <strong>time</strong><br />

base. The <strong>time</strong> of day and date, as well as unit <strong>program</strong>ming, are stored in a non-volatile memory<br />

(NVRAM). The NVRAM saves this information in the event of a power failure.<br />

II.) Program Features:<br />

A.) NON-VOLATILE MEMORY (NVRAM) - The NVRAM stores all <strong>time</strong>, date, and <strong>program</strong>ming<br />

information. The NVRAM has an internal lithium battery. This pr<strong>events</strong> <strong>time</strong> keeping and data<br />

from being lost during AC power failures for up to ten years. The internal lithium battery<br />

requires no battery charging.<br />

B.) DAYLIGHT SAVINGS TIME - The 1462/1463 automatically changes the <strong>time</strong> of day for itself<br />

and the secondary clocks during a change to or from Daylight Savings Time. This feature can<br />

be “disabled” during <strong>program</strong>ming if not required.<br />

C.) LEAP YEAR - Event and calendar changes for leap year are done automatically.<br />

D.) ALTERNATE SCHEDULE - Any one of the available 10 schedules can be implemented on a<br />

per day basis for holidays, exam days, pep rallies, etc. The 1462/1463 will automatically return<br />

to the main schedule the next day.<br />

E.) ALTERNATE DATES - Up to 32 dates can be <strong>program</strong>med into the 1462/1463 in advance to<br />

automatically run alternate schedules for holidays, exam days, pep rallies, etc.The 1462/1463<br />

will automatically return to the main schedule the next day.<br />

Page 7

1462/63 INSTRUCTION MANUAL<br />

II.) Program Features (Cont'd)<br />

F.) EVENTS - The 1462 allows up to 300 <strong>events</strong> per day to be entered into memory. This is<br />

equivalent to 2100 possible <strong>events</strong> per week. Programmed <strong>events</strong> can be “start”, “stop”, or<br />

“duration” <strong>events</strong>. “Duration” <strong>events</strong> are normally used to operate signals. “Start” and “stop”<br />

<strong>events</strong> are usually used to turn utility devices on and off. Each “start” or “stop” event is<br />

considered a separate event.<br />

G.) DATE AND EVENT SCANNING - The alternate dates and <strong>events</strong> <strong>program</strong>med into the<br />

1462/1463 can be viewed and altered. The user can choose to scan all <strong>program</strong>med <strong>events</strong>,<br />

or just those connected with a certain schedule or signal circuit.<br />

III.) System Options:<br />

DESCRIPTION<br />

The standard 1462/1463 Program Time Controller can be enhanced by the following options:<br />

1464/1464R Four Bell/Auxiliary Circuit Adder Option expands the number of available signal<br />

circuits from two to six. With this option, all six signal circuits are independently <strong>program</strong>mable.<br />

1466 Master-to-Master Synchronization Option allows the 1462/1463 to synchronize or be<br />

synchronized by another device (usually another master clock).<br />

1468A RS-232 Port Option provides the 1462/1463 with an RS-232 serial port. The user can<br />

enable or disable this serial port, and select its baud rate. When enabled, once a minute it will<br />

transmit <strong>time</strong> and date to another RS-232 compatible device.<br />

Page 8

GENERAL<br />

1462/63 INSTRUCTION MANUAL<br />

SPECIFICATIONS<br />

Weight: 1462/1462-220 Program Time Controller: 6.9 lb<br />

1463/1463-220 Program Time Controller: 15.3 lb<br />

External Dimensions: 1462/1462-220 Program Time Controller: 12.000" X 7.250" X 3.875"<br />

1463/1463-220 Program Time Controller: 19.000" X 13.000" X 3.500"<br />

ELECTRICAL<br />

Power Requirements:<br />

Line Voltage: 1462/1463 Program Time Controller: 120 VAC 50/60 HZ 0.25 A<br />

1462-220/1463-220 Program Time Controller: 220 VAC 50/60 HZ 0.13 A<br />

Battery: Lithium Primary Battery<br />

(included)<br />

Input Power: 25 VA<br />

Memory Retention: 10 years<br />

ENVIRONMENTAL<br />

Normal Ambient Temperature for Operation: 25 C° (77 F°)<br />

OPERATION<br />

Clock Circuits:<br />

Number Available: 1 clock drive circuit<br />

Type: Form C<br />

Contact Ratings: Dry Contacts rated @<br />

3 A inductive<br />

(10 A resistive),<br />

28 VDC/120 VAC<br />

Surge protected and<br />

Fused @ 4 A<br />

Signal Circuits:<br />

Number Available: Standard: 2 signal circuits<br />

Maximum (with 1464/1464R): 6 signal circuits<br />

Type: Form A<br />

Contact Ratings: Dry Contacts rated @<br />

8 A inductive<br />

(30 A resistive),<br />

28 VDC/120 VAC<br />

Surge protected and unfused<br />

Number of Possible Schedules: 10 schedules<br />

Programmable Alternate Dates: 32 dates<br />

Programmable Events: per week: 2100 <strong>events</strong><br />

per day: 300 <strong>events</strong><br />

Time Base Accuracy:<br />

Line Frequency: line synchronous<br />

Oscillator: 200 ppm<br />

UL LISTED, File No. E-46264<br />

Page 9

1462/63 INSTRUCTION MANUAL<br />

WARNING:Installation to be done only by qualified<br />

personnel who read these installation<br />

instructions and understand them. Installation<br />

is to be done in accordance with the National<br />

Electrical Code and local electrical codes.<br />

I.) Parts Checklist<br />

INSTALLATION<br />

Parts Checklist for 1462 Program Time Controller<br />

Clock Assembly (complete surface mount Program Time Controller)<br />

Installation Kit<br />

(to include)<br />

Owner's Manual<br />

Screw, #6-32 x 1/2 Phillips Bnd Hd Machine Screw (qty 4)<br />

Flow<strong>chart</strong><br />

Envelope, Plastic<br />

Parts Checklist for 1463 Program Time Controller<br />

Panel Assembly (complete rack mount Program Time Controller)<br />

Installation Kit<br />

(to include)<br />

Owner's Manual<br />

Screw, #10-32 x 3/8 Truss Head Machine Screw (qty 4)<br />

Flow<strong>chart</strong><br />

Envelope, Plastic<br />

Screw, #6-32 x 1/2 Phillips Bnd Hd Machine Screw<br />

Screw, #10-32 x 3/8 Truss Head Machine<br />

Screw<br />

Page 10

II.) Surface Mount Unit (1462, 1462-220):<br />

A.) Panel Mounting:<br />

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

1.) Prior to installing the 1462, ensure that all necessary parts are included in the carton. Check all<br />

items in the carton against the Parts Checklist.<br />

2.) Prepare the backplate for mounting.<br />

a.) Remove the four #6 X 3/8” sheet metal screws holding the front cover onto the backplate. Refer<br />

to diagram on page 15. Save these four sheet metal screws.<br />

b.) Carefully remove the front cover.<br />

c.) Locate the circuit board assemblies of the 1462. The main board is mounted to the backplate.<br />

The CPU/display board is mounted to the front cover. They are connected by a cable.<br />

d.) Disconnect the cable between the main board and the CPU/display board.<br />

e.) Remove the main board from the backplate. Save the six #6-32 X 1/4” machine screws that held<br />

the main board to the backplate.<br />

3.) Mount the backplate.<br />

a.) Locate the backplate on the wall at a height of approximately 4-1/2 feet from the floor. ENSURE<br />

THAT THE KNOCKOUTS ON THE BACK OF THE BACKPLATE ARE TO THE BOTTOM WHEN<br />

FACING THE BACKPLATE.<br />

b.) Four 3/16" holes are provided for securing the backplate to the wall. Use the #6- 32 X 1/2”<br />

screws provided in the installation kit when securing the backplate to a 2 gang box. Use the<br />

screws provided with the 4" square box when securing the backplate to a 4" square box.<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

4.) Pull all field wiring a minimum of 2 feet into the backplate through the knockouts. Knockouts are<br />

provided in the top, bottom, and back of the backplate.<br />

5.) Remove all metal shavings, dust, etc. from the backplate.<br />

6.) Remount the main board on the backplate using the six #6-32 X 1/4” machine screws saved from<br />

step II.A.2.e.<br />

NOTE: If an optional 1464, 1466, or 1468A module is to be added for the initial setup, installation should<br />

be done at this <strong>time</strong>. Refer to the Installation Instructions included with the module or<br />

Appendix E.<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

7.) Prepare field wiring for connection to the 1462.<br />

a.) Ensure that all field wiring is free of shorts and grounds.<br />

b.) Dress the wires for connection to the terminal blocks of the main board.<br />

i.) Ensure that no wire will be pinched or obstruct closure of the unit.<br />

ii.) Route field wiring away from sharp projections, corners, and internal components.<br />

NOTE: DO NOT CONNECT ANY WIRING AT THIS TIME.<br />

8.) Reconnect the cable disconnected in step II.A.2.d. The cable connects to main board J4 and<br />

CPU/display board J1.<br />

Page 11

B.) Applying Power:<br />

1462/63 INSTRUCTION MANUAL<br />

1.) Remove the protective cover on TB3 of the main board. Save the protective cover for<br />

step II.B.3.<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

2.) Connect the AC power wires to the 1462. The wiring diagrams on page 14 show the proper connections<br />

to TB3 of the main board. Refer to the appropriate wiring diagram for your application.<br />

CAUTION: RISK OF ELECTRIC SHOCK! Chassis ground (“GND” terminal) MUST be<br />

connected to conduit/Earth ground to provide proper protection from electric shock.<br />

NOTE: Chassis ground (“GND” terminal) MUST be connected to conduit/Earth ground to provide proper<br />

protection of Program Time Controller circuitry.<br />

NOTE: Do not connect field devices at this <strong>time</strong>.<br />

3.) Replace the protective cover over TB3 of the main board.<br />

4.) Apply power to the 1462 by switching its circuit breaker on at the circuit breaker<br />

panel.<br />

a.) The 1462 should show the <strong>time</strong> and date (there may be as much as a 30 second delay after<br />

power up for the display to show <strong>time</strong> and date).<br />

b.) The LED on the main board (and on the 1464, if installed) blinks at a rate of about once per<br />

second.<br />

C.) Adjusting the Display:<br />

1.) Adjust the contrast of the display, if necessary.<br />

a.) Contrast affects the display’s readability. The following diagram will help you decide if the<br />

contrast of your display needs to be adjusted. IF CONTRAST OF THE DISPLAY IS ACCEPT-<br />

ABLE, SKIP THE REMAINDER OF STEP 1.<br />

GOOD<br />

CONTRAST<br />

TOO<br />

DARK<br />

INSTALLATION<br />

Good contrast- text is easy to read<br />

Contrast is too dark- text is difficult to read<br />

through the darkened background<br />

Contrast is too light- text is not dark enough to<br />

read<br />

b.) If the contrast needs to be adjusted, locate jumper W1 on the CPU/display board (see diagram<br />

on page 15). W1 sets the contrast for the display. If W1 is removed, the contrast becomes<br />

lighter. If W1 is installed, the contrast becomes darker.<br />

c.) Remove power to the 1462 by switching its circuit breaker off at the circuit breaker panel.<br />

d.) Adjust the contrast of the display.<br />

i.) If contrast is too dark, cut jumper W1 of the CPU/display board.<br />

ii.) If contrast is too light and jumper W1 of the CPU/display board is already cut, reinstall<br />

jumper W1.<br />

Page 12

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

e.) Restore power to the 1462 by switching its circuit breaker on at the circuit breaker panel.<br />

i.) The 1462 should show the <strong>time</strong> and date.<br />

ii.) The LED on the main board (and on the 1464, if installed) blinks at a rate of about once per<br />

second.<br />

2.) Enable the display’s backlight <strong>time</strong>-out, if necessary.<br />

a.) Determine if the application requires the display’s backlight to turn off after 2 minutes. If not,<br />

SKIP THE REMAINDER OF STEP 2.<br />

The display is equipped with a backlight. The backlight makes the display easier to read, but<br />

causes the 1462 to draw slightly more current than if the backlight were not present. In most<br />

cases, the extra current consumption is not objectionable.<br />

b.) If the extra current consumption of having the backlight on continuously is objectionable, locate<br />

jumper W2 on the CPU/display board (see diagram on page 15). W2 is provided as a means to<br />

enable a <strong>time</strong>-out feature for the backlight. As long as W2 is installed, the display’s backlight<br />

will be on continuously. If W2 isremoved, the display’s backlight will be turned off most of the<br />

<strong>time</strong>. If someone operates the 1462, the display’s backlight will automatically turn on. When the<br />

user is finished operating the 1462, the display’s backlight automatically turns off about 2<br />

minutes later.<br />

c.) Remove power to the 1462 by switching its circuit breaker off at the circuit breaker panel.<br />

d.) Disable/enable the <strong>time</strong>-out feature of the display’s backlight as required.<br />

i.) To enable the <strong>time</strong>-out feature, cut jumper W2 of the CPU/display board.<br />

ii.) If you want the backlight to be on continuously and jumper W2 of the CPU/display board is<br />

already cut, re-install jumper W2.<br />

e.) Restore power to the 1462 by switching its circuit breaker on at the circuit breaker panel.<br />

i.) The 1462 should show the <strong>time</strong> and date.<br />

ii.) The LED on the main board (and on the 1464, if installed) blinks at a rate of about once per<br />

second.<br />

3.) Some applications demand a larger display than that of the 1462. For those applications, mount a<br />

secondary clock near the Program Time Controller.<br />

D.) Connecting Field Devices:<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

1.) Remove power to the 1462 by switching its circuit breaker off at the circuit breaker panel.<br />

2.) Connect appropriate field wiring to the clock circuit of the 1462. See Appendix B for clock circuit<br />

wiring diagrams.<br />

3.) Connect appropriate field wiring to the signal circuits of the 1462. See Appendix C for signal circuit<br />

wiring diagrams.<br />

4.) Restore power to the 1462 by switching its circuit breaker on at the circuit breaker panel.<br />

a.) The 1462 should show the <strong>time</strong> and date.<br />

b.) The LED on the main board (and on the 1464, if installed) blinks at a rate of about once per<br />

second.<br />

E.) Finishing the Installation:<br />

1.) Reattach the front cover of the 1462 to the backplate. Use the four #6 X 3/8” sheet metal screws<br />

removed in step II.A.2.a.<br />

2.) Fill out the “Installer Information” section on page 1 of this manual.<br />

Page 13

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

Wiring AC Power to the 1462 Program Time Controller<br />

AC Input Terminals<br />

Location of AC Input Terminals on 1462 Main Board<br />

Page 14<br />

Line<br />

Neutral<br />

Conduit / Earth Ground<br />

Wiring a 1462 to 120VAC Power<br />

Line<br />

Neutral<br />

Conduit / Earth Ground<br />

Wiring a 1462-220 to 220VAC Power (Two Wire)<br />

Line1<br />

Neutral<br />

Line2<br />

Conduit / Earth Ground<br />

Wiring a 1462-220 to 220VAC Power (Three Wire)<br />

(Not connected)

LOCATION OF W2 JUMPER<br />

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

Screw, #6 x 3/8 Rec. Truss Hd. Type<br />

"A"<br />

EXPLODED VIEW OF THE 1462 CHASSIS<br />

LOCATION OF HARDWARE RESET PINS<br />

Page 15<br />

Back Plate<br />

Note Knockout Orientation<br />

LOCATION OF W1 JUMPER<br />

LOCATION OF JUMPERS ON CPU/DISPLAY BOARD OF THE 1462<br />

Cover<br />

Assembly

III.) Rack Mount Unit (1463, 1463-220):<br />

A.) Preparing the Equipment Rack:<br />

1462/63 INSTRUCTION MANUAL<br />

1.) Pull all field wiring into the 19" rack or console. Be sure to allow adequate wire length for connection<br />

to the external field terminals on the back of the 1463.<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

2.) Prepare field wiring for connection to the 1463.<br />

a.) Ensure that all field wiring is free of shorts and grounds.<br />

b.) Dress the wires for connection to the external field terminals on the back of the 1463.<br />

i.) Ensure that no wire will be pinched or obstruct installation of the 1463 into the equipment<br />

rack.<br />

ii.) Route field wiring away from sharp projections, corners, and internal components.<br />

NOTE: DO NOT CONNECT ANY WIRING AT THIS TIME.<br />

B.) Giving the Unit a Bench Test<br />

INSTALLATION<br />

1.) Prior to installing the 1463, ensure that all necessary parts are included in the carton. Check all<br />

items in the carton against the Parts Checklist.<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that ALL sources of electrical power are disconnected<br />

from the 1463 so that no accidental contact with energized parts can be made.<br />

CAUTION: STATIC SENSITIVE DEVICES! Be sure to wear a static grounding wrist strap or similar<br />

protective device when working inside of the 1463 chassis.<br />

NOTE: If an optional 1464R, 1466, or 1468A module is to be added for the initial setup, installation<br />

should be done at this <strong>time</strong>. Refer to the Installation Instructions included with the module or<br />

Appendix E.<br />

2.) Prepare the 1463 for a bench test.<br />

a.) Place the 1463 on a table or other work surface.<br />

b.) Remove the four #6 X 3/8" sheet metal screws holding the top cover onto the chassis. Refer to<br />

diagram on page 21. Save these four sheet metal screws.<br />

c.) Carefully remove the top cover.<br />

d.) Locate the circuit board assemblies of the 1463. The main board is mounted to the bottom of the<br />

chassis. The CPU and display boards are mounted to the front of the chassis.<br />

e.) Ensure that all cables inside the chassis are properly connected.<br />

i.) The six position cable is connected between J4 of the main board and J1 of the CPU board.<br />

ii.) The twenty-four position cable is connected between J2 of the CPU board and J1 of the<br />

display board.<br />

f.) Connect wiring between the terminals of the main board and external field terminals to satisfy<br />

your application. Refer to Appendices B and C for typical wiring diagrams for clock and signal<br />

circuits.<br />

Page 16

3.) Perform a bench test on the 1463:<br />

1462/63 INSTRUCTION MANUAL<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that ALL sources of electrical power are<br />

disconnected from the 1463 PRIOR TO performing adjustments and optional module<br />

installations so that no accidental contact with energized parts can be made.<br />

a.) Connect a temporary AC power source to the to the 1463. The temporary AC power source<br />

should be equipped with a switch capable of disconnecting AC power from the 1463. The wiring<br />

diagrams on page 20 show the proper connections to external AC power terminal block of the<br />

1463. Refer to the appropriate wiring diagram for your application.<br />

CAUTION: RISK OF ELECTRIC SHOCK! Chassis ground (“GND” terminal) MUST be connected to<br />

conduit/Earth ground to provide proper protection from electric shock.<br />

NOTE: Chassis ground (“GND” terminal) MUST be connected to conduit/Earth ground to provide proper<br />

protection of Program Time Controller circuitry.<br />

NOTE: Do not connect field devices at this <strong>time</strong>.<br />

b.) Apply power to the 1463 by switching on the temporary AC power source.<br />

i.) The 1463 should show the <strong>time</strong> and date (there may be as much as a 30 second delay after<br />

power up for the display to show <strong>time</strong> and date).<br />

ii.) The LED on the main board (and on the 1464R, if installed) blinks at a rate of about once per<br />

second.<br />

C.) Adjusting the Display<br />

1.) Adjust the contrast of the display, if necessary.<br />

a.) Contrast affects the display’s readability. The following diagram will help you decide if the<br />

contrast of your display needs to be adjusted. IF CONTRAST OF THE DISPLAY IS ACCEPT-<br />

ABLE, SKIP THE REMAINDER OF STEP 1.<br />

GOOD<br />

CONTRAST<br />

TOO<br />

DARK<br />

INSTALLATION<br />

Good contrast- text is easy to read<br />

Contrast is too dark- text is difficult to read<br />

through the darkened background<br />

Contrast is too light- text is not dark enough to<br />

read<br />

b.) If the contrast needs to be adjusted, locate jumper W1 on the CPU board (see diagram on page<br />

21). W1 sets the contrast for the display. If W1 is removed, the contrast becomes lighter. If W1<br />

is installed, the contrast becomes darker.<br />

c.) Remove power to the 1463 by switching its temporary AC power source off.<br />

d.) Adjust the contrast of the display.<br />

i.) If contrast is too dark, cut jumper W1 of the CPU board.<br />

ii.) If contrast is too light and jumper W1 of the CPU board is already cut, re-install jumper W1.<br />

e.) Restore power to the 1463 by switching its temporary AC power source on.<br />

i.) The 1463 should show the <strong>time</strong> and date.<br />

ii.) The LED on the main board (and on the 1464R, if installed) blinks at a rate of about once per<br />

second.<br />

Page 17

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

2.) Enable the display’s backlight <strong>time</strong>-out, if necessary.<br />

a.) Determine if the application requires the display’s backlight to turn off after 2 minutes. If not,<br />

SKIP THE REMAINDER OF STEP 2.<br />

The display is equipped with a backlight. The backlight makes the display easier to read, but<br />

causes the 1463 to draw slightly more current than if the backlight were not present. In most<br />

cases, the extra current consumption is not objectionable.<br />

b.) If the extra current consumption of having the backlight on continuously is objectionable, locate<br />

jumper W2 on the CPU board (see diagram on page 21). W2 is provided as a means to enable<br />

a <strong>time</strong>-out feature for the backlight. As long as W2 is installed, the display’s backlight will be on<br />

continuously. If W2 is removed, the display’s backlight will be turned off most of the <strong>time</strong>. If<br />

someone operates the 1463, the display’s backlight will automatically turn on. When the user is<br />

finished operating the 1463, the display’s backlight automatically turns off about 2 minutes later.<br />

c.) Remove power to the 1463 by switching its temporary AC power source off.<br />

d.) Disable/enable the <strong>time</strong>-out feature of the display’s backlight as required.<br />

i.) To enable the <strong>time</strong>-out feature, cut jumper W2 of the CPU board.<br />

ii.) If you want the backlight to be on continuously and jumper W2 of the CPU board is already<br />

cut, re-install jumper W2.<br />

e.) Restore power to the 1463 by switching its temporary AC power source on.<br />

i.) The 1463 should show the <strong>time</strong> and date.<br />

ii.) The LED on the main board (and on the 1464R, if installed) blinks at a rate of about once per<br />

second.<br />

3.) Some applications demand a larger display than that of the 1463. For those applications, mount a<br />

secondary clock near the equipment rack the 1463 will be installed into.<br />

D.) Installing the Unit into the Equipment Rack:<br />

1.) Prepare the 1463 for installation into the equipment rack<br />

a.) Remove the temporary AC power source used to bench test the 1463.<br />

i.) Remove power to the 1463 by switching its temporary AC power source off.<br />

ii.) Remove the connections between the 1463 and the temporary AC power source.<br />

b.) Return the top cover of the 1463 onto the chassis. Use the four #6 X 3/8" sheet metal screws<br />

removed in step III.B.2.b. to secure the top cover to the chassis.<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

2.) Mount the 1463 into the equipment rack. Four slotted holes are provided on the front of the chassis.<br />

Use the #10-32 X 3/8" machine screws provided in the installation kit when securing the 1463 to the<br />

equipment rack.<br />

3.) Connect the AC power wires to the 1463. The wiring diagrams on page 20 show the proper connections<br />

to external AC power terminal block of the 1463. Refer to the appropriate wiring diagram for<br />

your application.<br />

CAUTION: RISK OF ELECTRIC SHOCK! Chassis ground (“GND” terminal) MUST be connected to<br />

conduit/Earth ground to provide proper protection from electric shock.<br />

NOTE: Chassis ground (“GND” terminal) MUST be connected to conduit/Earth ground to provide proper<br />

protection of Program Time Controller circuitry.<br />

NOTE: Do not connect field devices at this <strong>time</strong>.<br />

Page 18

1462/63 INSTRUCTION MANUAL<br />

4.) Apply power to the 1463 by switching its circuit breaker on at the circuit breaker panel. The 1463<br />

should show the <strong>time</strong> and date.<br />

E.) Connecting Field Devices:<br />

CAUTION: ELECTRIC SHOCK HAZARD! Ensure that NO electrical power is present on any wire<br />

before installation.<br />

1.) Remove power to the 1463 by switching its circuit breaker off at the circuit breaker panel.<br />

2.) Connect appropriate field wiring to the clock circuit of the 1463. See Appendix B for clock circuit<br />

wiring diagrams.<br />

3.) Connect appropriate field wiring to the signal circuits of the 1463. See Appendix C for signal circuit<br />

wiring diagrams.<br />

4.) Restore power to the 1463 by switching its circuit breaker on at the circuit breaker panel. The 1463<br />

should show the <strong>time</strong> and date.<br />

F.) Finishing the Installation:<br />

INSTALLATION<br />

1.) Fill out the “Installer Information” section on page 1 of this manual.<br />

Page 19

AC<br />

N<br />

GND<br />

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

Wiring AC Power to the 1463 Program Time Controller<br />

Location of AC Input Terminals on 1463 Chassis<br />

Line<br />

Neutral<br />

Conduit / Earth Ground<br />

Wiring a 1463 to 120VAC Power<br />

Line<br />

Neutral<br />

Conduit / Earth Ground<br />

Wiring a 1463-220 to 220VAC Power (Two Wire)<br />

Line1<br />

Neutral<br />

Line2<br />

Conduit / Earth Ground<br />

Wiring a 1463-220 to 220VAC Power (Three Wire)<br />

Page 20<br />

AC Input Terminals<br />

AC Input Terminals<br />

(Not connected)

Cover<br />

1462/63 INSTRUCTION MANUAL<br />

Screw, #6-20 x 3/8<br />

Rec. Pan Hd.<br />

Type "AB"<br />

LOCATION OF W2 JUMPER<br />

INSTALLATION<br />

EXPLODED VIEW OF THE 1463 CHASSIS<br />

LOCATION OF HARDWARE RESET PINS<br />

LOCATION OF W1 JUMPER<br />

LOCATION OF JUMPERS ON CPU BOARD OF THE 1463<br />

Page 21<br />

1463<br />

Program Time<br />

Controller

1462/63 INSTRUCTION MANUAL<br />

IMPORTANT INSTALLATION AND WARRANTY INFORMATION<br />

WARRANTY INFORMATION: <strong>Faraday</strong>, LLC (the Manufacturer) provides a limited warranty to the Original Purchaser<br />

of this product. The Original Purchaser is the party to whom the Manufacturer issued its Sales Order, generally the<br />

Manufacturer's distributor. In order to preserve this warranty, it is important that the product be serviced only by<br />

persons who have been properly trained and authorized by the Manufacturer.<br />

Other parties involved in the installation of this product may have also provided a warranty which may be different<br />

than that of the manufacturer. The Manufacturer will only be responsible to the Original Purchaser and only for<br />

the Manufacturer's own warranty. For further information regarding the Manufacturer's warranty, contact the<br />

Original Purchaser.<br />

OWNER'S MANUAL: The owner's manual does not purport to cover all the details or variations in the equipment<br />

described, nor does it provide for every possible contingency to be met in connection with installation, operation<br />

and maintenance. All specifications subject to change without notice. Should further information be desired or<br />

should particular problems arise which are not covered sufficiently, the matter should be referred to the Installer<br />

or Original Purchaser listed below.<br />

INSTALLER INFORMATION<br />

COMPANY:_________________________________INSTALLER:___________________________PHONE:______________<br />

ADDRESS:__________________________________CITY:__________________STATE:___________ZIP:____________<br />

DATE INSTALLED:____________________________INSTALLER'S SIGNATURE:____________________<br />

ORIGINAL PURCHASER INFORMATION<br />

COMPANY:_________________________________________________________PHONE:____________________<br />

ADDRESS:__________________________________CITY:__________________STATE:___________ZIP:____________<br />

PURCHASER'S PURCHASE ORDER NO.:____________________________________________________<br />

DATE PURCHASED:______________________________________________________________________<br />

FARADAY SALES ORDER ACKNOWLEDGMENT NO.:__________________________________________<br />

ORIGINAL PURCHASER'S SIGNATURE:_____________________________________________________<br />

NOTE: A copy of the above completed information may be required by the manufacturer for authorization of<br />

Warranty services.<br />

Page 1

1462/63 INSTRUCTION MANUAL<br />

FCC FCC FCC COMPLIANCE<br />

COMPLIANCE<br />

WARNING: WARNING: This equipment generates, uses, and can radiate radio frequency energy and if<br />

not installed and used in accordance with this instruction manual, may cause interference to<br />

radio communications. It complies with the limits for a Class A computing device pursuant to<br />

Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection<br />

against such interference when operated in a commercial environment. Operation of this<br />

equipment in a residential area is likely to cause interference in which case the user at his own<br />

expense will be required to take whatever measures may be required to correct the interference.<br />

ATTENTION<br />

OBSERVE PRECAUTIONS<br />

FOR HANDLING<br />

ELECTROSTATIC<br />

SENSITIVE<br />

DEVICES<br />

STATIC STATIC WARNING<br />

WARNING<br />

CAUTION: CAUTION: CAUTION: This equipment contains electronic devices that are sensitive to static electric<br />

charges. To guarantee protection for the circuitry of this unit, it is required that electrostatic<br />

handling precautions be observed when installing or repairing this equipment. Any technician<br />

or other personnel working on this unit must wear a static grounding wrist strap or similar device<br />

to provide protection of sensitive components.<br />

ELECTRIC ELECTRIC ELECTRIC SHOCK SHOCK HAZARD<br />

HAZARD<br />

WARNING:<br />

WARNING: Hazardous voltage in electrical equipment can cause severe personal injury or<br />

death. Inspection, installation, and preventive maintenance should only be performed on<br />

equipment to which power has been turned off, disconnected and electrically isolated so no<br />

accidental contact can be made with energized parts.<br />

Page 2

1462/63 INSTRUCTION MANUAL<br />

Table of Contents<br />

IMPORTANT INSTALLATION AND WARRANTY INFORMATION .................................................................. 1<br />

FCC COMPLIANCE .................................................................................................................... 2<br />

STATIC WARNING...................................................................................................................... 2<br />

ELECTRIC SHOCK HAZARD .......................................................................................................... 2<br />

TABLE OF CONTENTS ................................................................................................................ 3<br />

DESCRIPTION............................................................................................................................ 7<br />

GENERAL DESCRIPTION OF UNIT .............................................................................................. 7<br />

PROGRAM FEATURES ........................................................................................................... 7<br />

SYSTEM OPTIONS ................................................................................................................ 8<br />

SPECIFICATIONS ........................................................................................................................ 9<br />

INSTALLATION ......................................................................................................................... 10<br />

PARTS CHECKLIST ............................................................................................................. 10<br />

SURFACE MOUNT UNIT (1462, 1462-220) .......................................................................... 11<br />

PANEL MOUNTING ........................................................................................................ 11<br />

APPLYING POWER ........................................................................................................ 12<br />

ADJUSTING THE DISPLAY................................................................................................ 12<br />

CONNECTING FIELD DEVICES .......................................................................................... 13<br />

FINISHING THE INSTALLATION........................................................................................... 13<br />

LOCATION OF AC INPUT TERMINALS ON 1462 MAIN BOARD ................................................ 14<br />

WIRING A 1462 TO AC POWER ..................................................................................... 14<br />

EXPLODED VIEW OF 1462 CHASSIS ................................................................................ 15<br />

LOCATION OF JUMPERS ON CPU/DISPLAY BOARD OF THE 1462 .......................................... 15<br />

RACK MOUNT UNIT (1463, 1463-220) ................................................................................ 16<br />

PREPARING UNIT FOR EQUIPMENT RACK .......................................................................... 16<br />

GIVING UNIT A BENCH TEST .......................................................................................... 16<br />

ADJUSTING THE DISPLAY................................................................................................ 17<br />

INSTALLING THE UNIT INTO THE EQUIPMENT RACK .............................................................. 18<br />

CONNECTING FIELD DEVICES .......................................................................................... 19<br />

FINISHING THE INSTALLATION........................................................................................... 19<br />

LOCATION OF AC INPUT TERMINALS ON 1463 CHASSIS ...................................................... 20<br />

WIRING A 1463 TO AC POWER ..................................................................................... 20<br />

EXPLODED VIEW OF 1463 CHASSIS ................................................................................ 21<br />

LOCATION OF JUMPERS ON CPU BOARD OF THE 1463 ...................................................... 21<br />

OPERATION ............................................................................................................................ 22<br />

SYSTEM CONTROLS ........................................................................................................... 22<br />

HARDWARE RESET ....................................................................................................... 22<br />

KEYPAD ...................................................................................................................... 22<br />

DISPLAY ..................................................................................................................... 23<br />

USING THE SYSTEM CONTROLS TO OPERATE AND PROGRAM THE PROGRAM TIME CONTROLLER .23<br />

OPERATING THE PROGRAM TIME CONTROLLER ........................................................................ 25<br />

ACCESS CODE SECURITY .............................................................................................. 25<br />

DISPLAY CIRCUITS ........................................................................................................ 27<br />

FUNCTION KEYS ........................................................................................................... 27<br />

THE VIRTUAL ON/OFF/AUTO SWITCH .................................................................... 28<br />

MANUAL ON ..................................................................................................... 28<br />

MANUAL OFF .................................................................................................... 28<br />

AUTOMATIC ...................................................................................................... 29<br />

Page 3

1462/63 INSTRUCTION MANUAL<br />

Table of Contents<br />

ALL CALL .............................................................................................................. 29<br />

STEADY ALL CALL ............................................................................................. 29<br />

MTB ALL CALL ................................................................................................ 29<br />

PROGRAMMING THE PROGRAM TIME CONTROLLER .............................................................. 30<br />

LEVEL 1 PROGRAMMING ........................................................................................... 30<br />

SET SCHEDULE ................................................................................................. 30<br />

SET MAIN SCHEDULE.................................................................................... 30<br />

SET ALTERNATE SCHEDULE ........................................................................... 30<br />

LEVEL 2 PROGRAMMING ........................................................................................... 31<br />

PROGRAM EVENTS............................................................................................. 31<br />

WHAT IS AN EVENT AND WHY PROGRAM IT? .................................................... 31<br />

THE PROGRAM EVENTS / EDIT EVENTS MENU................................................... 32<br />

ADDING EVENTS .......................................................................................... 32<br />

SCANNING AND EDITING EVENTS ..................................................................... 33<br />

ALTERNATE DATES ............................................................................................ 36<br />

ADDING ALTERNATE DATES ............................................................................ 36<br />

SCANNING AND EDITING ALTERNATE DATES ...................................................... 37<br />

SET TIME......................................................................................................... 38<br />

SET DATE ........................................................................................................ 38<br />

MANUAL ADVANCE ............................................................................................. 39<br />

CLOCK ENABLE ................................................................................................. 39<br />

LEVEL 3 PROGRAMMING ........................................................................................... 40<br />

SET DEFAULTS.................................................................................................. 41<br />

SET TIME BASE ........................................................................................... 41<br />

TIME FORMAT.............................................................................................. 41<br />

SET LINE FREQ ........................................................................................... 42<br />

SET DAYLIGHT SAVINGS ................................................................................ 42<br />

ALL CALL FEATURE ...................................................................................... 42<br />

SERIAL PORT .............................................................................................. 42<br />

MASTER TO MASTER SYNC ............................................................................ 43<br />

PROGRAM CLOCKS ....................................................................................... 44<br />

FUNCTION KEYS........................................................................................... 44<br />

CLEAR MEMORY .......................................................................................... 45<br />

ACCESS CODE ................................................................................................... 45<br />

DIAGNOSTICS .................................................................................................... 46<br />

SPECIAL FUNCTIONS........................................................................................... 47<br />

TROUBLE SHOOTING GUIDE ...................................................................................................... 48<br />

TROUBLE SHOOTING GUIDELINES .......................................................................................... 48<br />

SECONDARY CLOCKS DON'T KEEP TIME ........................................................................... 48<br />

PROGRAM TIME CONTROLLER DOESN'T KEEP TIME ............................................................ 49<br />

BELL(S)/UTILITY DEVICE(S) WON'T OPERATE PROPERLY ........................................................... 49<br />

BELL(S)/UTILITY DEVICE(S) WON'T TURN OFF ........................................................................ 50<br />

Page 4

1462/63 INSTRUCTION MANUAL<br />

Table of Contents<br />

APPENDIX A: QUICK REFERENCE PROGRAMMING MENUS ........................................................... A-1<br />

PROGRAMMING MENU TABLE OF CONTENTS .......................................................................... A-1<br />

APPENDIX B: INSTALLATION OF SECONDARY CLOCKS ................................................................. B-1<br />

CLOCK CODE DESCRIPTIONS .............................................................................................. B-1<br />

CLOCK CODE TABLE ......................................................................................................... B-4<br />

FIG. 1 TYPICAL WIRING FOR SYNCHRONOUS CLOCK MOVEMENTS (SINGLE VOLTAGE) .......................... B-5<br />

FIG. 2 TYPICAL WIRING FOR SYNCHRONOUS CLOCK MOVEMENTS (DUAL VOLTAGE) ............................ B-6<br />

FIG. 3 TYPICAL WIRING FOR 2 WIRE POLARITY REVERSAL CLOCKS W/1415 CLOCK POWER SUPPLY<br />

AND 1416 CLOCK BOOSTER .............................................................................. B-7<br />

FIG. 4 TYPICAL WIRING FOR 2 WIRE POLARITY REVERSAL CLOCKS ......................................... B-8<br />

FIG. 5 TYPICAL WIRING FOR 2362 AND 2364 DIGITAL SECONDARY CLOCKS............................. B-9<br />

FIG. 6 TYPICAL WIRING FOR AR2 & AR2A CLOCKS .......................................................... B-10<br />

FIG. 7 TYPICAL WIRING FOR AR3 CLOCKS........................................................................ B-11<br />

FIG. 8 TYPICAL WIRING FOR 2 WIRE POLARITY REVERSAL IMPULSE CLOCKS (CLOCK CODE 21)......B-12<br />

FIG. 9 TYPICAL WIRING FOR 3 WIRE IMPULSE CLOCKS ........................................................ B-13<br />

FIG. 10 TYPICAL WIRING FOR 2 WIRE, MINUTE IMPULSE CLOCKS<br />

WITH NO HOURLY OR 12 HOUR CORRECTION ...................................................... B-14<br />

APPENDIX C: TYPICAL SIGNAL CIRCUIT WIRING ....................................................................... C-1<br />

FIG. A TYPICAL AUXILIARY CIRCUIT WIRING FOR SIGNAL DEVICES ........................................... C-1<br />

FIG. B TYPICAL AUXILIARY CIRCUIT WIRING FOR UTILITY CONTROL DEVICES ............................. C-2<br />

APPENDIX D: GLOSSARY OF TERMS ...................................................................................... D-1<br />

APPENDIX E: OPTION MODULE INSTALLATION INSTRUCTION SHEETS<br />

1464 FOUR BELL/AUXILIARY CIRCUIT ADDER OPTION INSTALLATION INSTRUCTIONS ........ P/N 445734<br />

1464R FOUR BELL/AUXILIARY CIRCUIT ADDER OPTION INSTALLATION INSTRUCTIONS ..... P/N 445735<br />

1466 MASTER-TO-MASTER SYNCHRONIZATION OPTION INSTALLATION INSTRUCTIONS ...... P/N 445739<br />

1468A RS-232 PORT OPTION INSTALLATION INSTRUCTIONS ..................................... P/N 445796<br />

APPENDIX F: PROGRAMMING SHEETS<br />

PROGRAM TIME CONTROLLER DEFAULT SETTINGS CHART<br />

PROGRAM TIME CONTROLLER - EVENTS CHART<br />

APPENDIX G: CODE CARD ................................................................................................... G-1<br />

Page 5

1462/63 INSTRUCTION MANUAL<br />

Page 6

I.) General Description of Unit:<br />

1462/63 INSTRUCTION MANUAL<br />

DESCRIPTION<br />

The 1462/1463 Program Time Controller is a microprocessor based <strong>time</strong> management unit. It<br />

provides synchronized control of most analog and digital secondary clock systems via its clock<br />

circuit.<br />

The 1462/1463 contains two <strong>program</strong>mable signal circuits. Each signal circuit provides automatic<br />

and manual control of signaling or utility devices. To increase the number of signal circuits to six,<br />

simply add the Four Bell/Auxiliary Circuit Adder Option.<br />

A sixteen key, multiple-function keypad allows the user to <strong>program</strong> the 1462/1463. It is also how<br />

the user performs manual clock advance, manual operation of the signal circuits, and all call. The<br />

abbreviated names for the keys provide a helpful reference for <strong>program</strong>ming the 1462/1463.<br />

A 16 character by 2 line LCD allows the user to monitor the 1462/1463’s status and response to<br />

<strong>program</strong>ming. Included is a backlight that either remains on continuously, or turns off after a short<br />

<strong>time</strong>, depending on the user’s requirements.<br />

Password security protects the system from unauthorized operation. Three levels of password<br />

security allow selective access to the 1462/1463’s features. The ability to enable or disable<br />

password security to some basic features, such as all call, provides even more flexibility.<br />

The 1462/1463’s <strong>time</strong> keeping synchronizes to either AC line frequency or a quartz controlled <strong>time</strong><br />

base. The <strong>time</strong> of day and date, as well as unit <strong>program</strong>ming, are stored in a non-volatile memory<br />

(NVRAM). The NVRAM saves this information in the event of a power failure.<br />

II.) Program Features:<br />

A.) NON-VOLATILE MEMORY (NVRAM) - The NVRAM stores all <strong>time</strong>, date, and <strong>program</strong>ming<br />

information. The NVRAM has an internal lithium battery. This pr<strong>events</strong> <strong>time</strong> keeping and data<br />

from being lost during AC power failures for up to ten years. The internal lithium battery<br />

requires no battery charging.<br />

B.) DAYLIGHT SAVINGS TIME - The 1462/1463 automatically changes the <strong>time</strong> of day for itself<br />

and the secondary clocks during a change to or from Daylight Savings Time. This feature can<br />

be “disabled” during <strong>program</strong>ming if not required.<br />

C.) LEAP YEAR - Event and calendar changes for leap year are done automatically.<br />

D.) ALTERNATE SCHEDULE - Any one of the available 10 schedules can be implemented on a<br />

per day basis for holidays, exam days, pep rallies, etc. The 1462/1463 will automatically return<br />

to the main schedule the next day.<br />

E.) ALTERNATE DATES - Up to 32 dates can be <strong>program</strong>med into the 1462/1463 in advance to<br />

automatically run alternate schedules for holidays, exam days, pep rallies, etc.The 1462/1463<br />

will automatically return to the main schedule the next day.<br />

Page 7

1462/63 INSTRUCTION MANUAL<br />

II.) Program Features (Cont'd)<br />

F.) EVENTS - The 1462 allows up to 300 <strong>events</strong> per day to be entered into memory. This is<br />

equivalent to 2100 possible <strong>events</strong> per week. Programmed <strong>events</strong> can be “start”, “stop”, or<br />

“duration” <strong>events</strong>. “Duration” <strong>events</strong> are normally used to operate signals. “Start” and “stop”<br />

<strong>events</strong> are usually used to turn utility devices on and off. Each “start” or “stop” event is<br />

considered a separate event.<br />

G.) DATE AND EVENT SCANNING - The alternate dates and <strong>events</strong> <strong>program</strong>med into the<br />

1462/1463 can be viewed and altered. The user can choose to scan all <strong>program</strong>med <strong>events</strong>,<br />

or just those connected with a certain schedule or signal circuit.<br />

III.) System Options:<br />

DESCRIPTION<br />

The standard 1462/1463 Program Time Controller can be enhanced by the following options:<br />

1464/1464R Four Bell/Auxiliary Circuit Adder Option expands the number of available signal<br />

circuits from two to six. With this option, all six signal circuits are independently <strong>program</strong>mable.<br />

1466 Master-to-Master Synchronization Option allows the 1462/1463 to synchronize or be<br />

synchronized by another device (usually another master clock).<br />

1468A RS-232 Port Option provides the 1462/1463 with an RS-232 serial port. The user can<br />

enable or disable this serial port, and select its baud rate. When enabled, once a minute it will<br />

transmit <strong>time</strong> and date to another RS-232 compatible device.<br />

Page 8

GENERAL<br />

1462/63 INSTRUCTION MANUAL<br />

SPECIFICATIONS<br />

Weight: 1462/1462-220 Program Time Controller: 6.9 lb<br />

1463/1463-220 Program Time Controller: 15.3 lb<br />

External Dimensions: 1462/1462-220 Program Time Controller: 12.000" X 7.250" X 3.875"<br />

1463/1463-220 Program Time Controller: 19.000" X 13.000" X 3.500"<br />

ELECTRICAL<br />

Power Requirements:<br />

Line Voltage: 1462/1463 Program Time Controller: 120 VAC 50/60 HZ 0.25 A<br />

1462-220/1463-220 Program Time Controller: 220 VAC 50/60 HZ 0.13 A<br />

Battery: Lithium Primary Battery<br />

(included)<br />

Input Power: 25 VA<br />

Memory Retention: 10 years<br />

ENVIRONMENTAL<br />

Normal Ambient Temperature for Operation: 25 C° (77 F°)<br />

OPERATION<br />

Clock Circuits:<br />

Number Available: 1 clock drive circuit<br />

Type: Form C<br />

Contact Ratings: Dry Contacts rated @<br />

3 A inductive<br />

(10 A resistive),<br />

28 VDC/120 VAC<br />

Surge protected and<br />

Fused @ 4 A<br />

Signal Circuits:<br />

Number Available: Standard: 2 signal circuits<br />

Maximum (with 1464/1464R): 6 signal circuits<br />

Type: Form A<br />

Contact Ratings: Dry Contacts rated @<br />

8 A inductive<br />

(30 A resistive),<br />

28 VDC/120 VAC<br />

Surge protected and unfused<br />

Number of Possible Schedules: 10 schedules<br />

Programmable Alternate Dates: 32 dates<br />

Programmable Events: per week: 2100 <strong>events</strong><br />

per day: 300 <strong>events</strong><br />

Time Base Accuracy:<br />

Line Frequency: line synchronous<br />

Oscillator: 200 ppm<br />

UL LISTED, File No. E-46264<br />

Page 9

1462/63 INSTRUCTION MANUAL<br />

WARNING:Installation to be done only by qualified<br />

personnel who read these installation<br />

instructions and understand them. Installation<br />

is to be done in accordance with the National<br />

Electrical Code and local electrical codes.<br />

I.) Parts Checklist<br />

INSTALLATION<br />

Parts Checklist for 1462 Program Time Controller<br />

Clock Assembly (complete surface mount Program Time Controller)<br />

Installation Kit<br />

(to include)<br />

Owner's Manual<br />

Screw, #6-32 x 1/2 Phillips Bnd Hd Machine Screw (qty 4)<br />

Flow<strong>chart</strong><br />

Envelope, Plastic<br />

Parts Checklist for 1463 Program Time Controller<br />

Panel Assembly (complete rack mount Program Time Controller)<br />

Installation Kit<br />

(to include)<br />

Owner's Manual<br />

Screw, #10-32 x 3/8 Truss Head Machine Screw (qty 4)<br />

Flow<strong>chart</strong><br />

Envelope, Plastic<br />

Screw, #6-32 x 1/2 Phillips Bnd Hd Machine Screw<br />

Screw, #10-32 x 3/8 Truss Head Machine<br />

Screw<br />

Page 10

II.) Surface Mount Unit (1462, 1462-220):<br />

A.) Panel Mounting:<br />

1462/63 INSTRUCTION MANUAL<br />

INSTALLATION<br />

1.) Prior to installing the 1462, ensure that all necessary parts are included in the carton. Check all<br />