Winter 2010 - Pennsylvania Railroad Technical and Historical Society

Winter 2010 - Pennsylvania Railroad Technical and Historical Society

Winter 2010 - Pennsylvania Railroad Technical and Historical Society

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

No. 72 <strong>Winter</strong> <strong>2010</strong><br />

Inside:<br />

• Two PRR Gondola Reviews<br />

• Model Roster for Operations on<br />

the on the Panh<strong>and</strong>le<br />

• Build “KASE” Tower in HO<br />

• Kitbash an NA Cabin Car<br />

• Easy Station <strong>and</strong> Tower Signs<br />

•

Published Quarterly by<br />

The PENNSYLVANIA RAILROAD<br />

TECHNICAL <strong>and</strong> HISTORICAL SOCIETY<br />

A non-profit organization<br />

OFFICERS<br />

President Alan B. Buchan<br />

Vice President John J. Consoli<br />

Corporate Secretary Robert D. Brubaker<br />

Asst. Corporate Secretary Ralph M. Weischedel<br />

Treasurer Edward Swain<br />

Marketing <strong>and</strong> Sales Director Fred Freitas<br />

Membership Coordinator Andrew J. Hart<br />

Publisher Frederic V. Shaefer<br />

General Counsel James G. Trope<br />

Public Relations Manager Stan Trzoniec<br />

Station & Archives Chairman Rich Ader<br />

Historian Christopher T. Baer<br />

BOARD OF DIRECTORS<br />

Term Expires <strong>2010</strong> Term Expires 2011<br />

Robert D. Brubaker Chuck Blardone<br />

James B. Winslow Ivan E. Frantz<br />

Term Expires 2012<br />

Alan B. Buchan<br />

John J. Consoli<br />

Edward Swain<br />

THE KEYSTONE MODELER STAFF<br />

EDITOR<br />

Jim Hunter<br />

Jhunter6360@comcast.net<br />

ASSOCIATE EDITOR<br />

Jack Consoli<br />

jjconsoli@comcast.net<br />

NEWSWIRE EDITOR<br />

Steve Hoxie<br />

stevehprr@cox.net<br />

EDITOR EMERITUS<br />

Al Buchan<br />

abbuchan1@comcast.net<br />

CHAIRMAN MODELING COMMITTEE<br />

Elden Gatwood<br />

Elden.J.Gatwood@sad01.usace.army.mil<br />

ART DIRECTOR<br />

Tim Garner<br />

t.a.garner@verizon.net<br />

Send comments <strong>and</strong> corrections to the Editor at:<br />

Jhunter6360@comcast.net<br />

MEMBERSHIP INFORMATION<br />

PRRT&HS, PO Box 54, Bryn Mawr, PA 19010-0054<br />

PRRT&HS MONTHLY E-NEW S<br />

Keystone-e-news-request@lists.keystonepubs.org?Subject=subscribe<br />

Number 72 CONTENTS <strong>Winter</strong> <strong>2010</strong><br />

FROM THE CAB<br />

Jim Hunter, Editor ......................................................................................................... 3<br />

TKM NEWSWIRE<br />

By Steve Hoxie ............................................................................................................... 4<br />

MODEL REVIEW – N-SCALE G26 MILL GONDOLA<br />

By Bob Losse Jr. ........................................................................................................... 6<br />

MODEL REVIEW – HO-SCALE G31B GONDOLA<br />

By Jack Consoli ........................................................................................................... 10<br />

BALANCED LOCOMOTIVE ROSTER FOR OPERATIONS ON<br />

THE PANHANDLE<br />

By Bill Neale ................................................................................................................ 17<br />

KITBASHING AN NA CABIN CAR IN N OR HO<br />

By Claus Schlund ......................................................................................................... MEMBERSHIP INFORMATION<br />

25<br />

MAKING MODEL PRR PRRT&HS, STATION P.O. AND Box 54, TOWER Bryn Mawr, SIGNS PA 19010-0054<br />

By Tim Garner ............................................................................................................. 31<br />

MODELING “KASE” TOWER IN HO<br />

By Chuck Cover ........................................................................................................... 34<br />

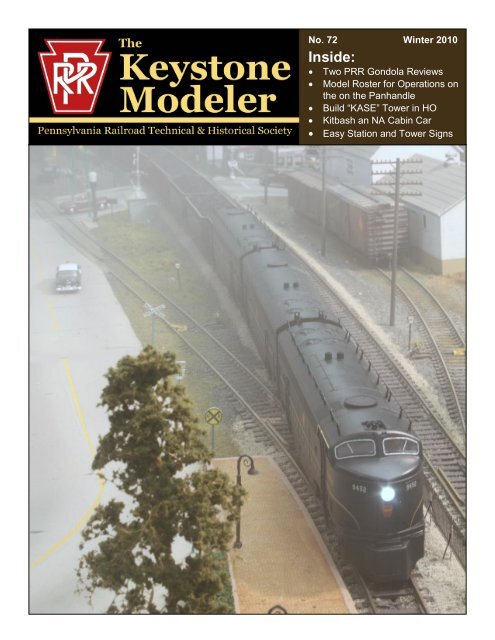

Front Cover<br />

C-Liner #9452 on a Coal Drag enters Johnsville<br />

Tim Garner repainted <strong>and</strong> detailed this set of Proto 1000 C-Liners for PRR service on his<br />

PRR Willsburgh Division layout. Tim likes to model cab units fresh from the factory including<br />

pilot coupler covers. He used Scalecoat Brunswick Green <strong>and</strong> a mix of Champ <strong>and</strong><br />

Microscale decals. One mistake, since corrected, is the protruding exhaust stacks. Tim installed<br />

a Soundtraxx DSD sound decoder <strong>and</strong> speaker in the lead unit along with a Miniatronics<br />

LED headlight. A special fog spray was used during the exposure to create the humid<br />

effect.<br />

The Keystone Modeler<br />

This publication of the PRRT&HS is for the purpose of disseminating PRR modeling information.<br />

The copyright is owned by the <strong>Pennsylvania</strong> <strong>Railroad</strong> <strong>Technical</strong> <strong>and</strong> <strong>Historical</strong><br />

<strong>Society</strong> – all rights reserved. It may be reproduced for personal use only. Not for sale other<br />

than by the PRRT&HS.<br />

Manuscripts <strong>and</strong> photographs submitted for publication are welcome. Materials submitted<br />

are considered to be gratis <strong>and</strong> no reimbursement will be made to the author(s) or the<br />

photographer(s) or his/her representative(s). The <strong>Society</strong> reserves the right to reject, for<br />

any reason, any material submitted for publication.<br />

Please contact the editor for information <strong>and</strong> guidelines for submission. If you submit<br />

photos, preferably at 800x600 pixels, not less than 640x480, preferably in TIFF format.<br />

Statements <strong>and</strong> opinions made are those of the authors <strong>and</strong> do not necessarily represent<br />

those of the <strong>Society</strong>.<br />

The Keystone Modeler<br />

CD-ROMs – Issues 49-60 <strong>and</strong> 1-60<br />

A CD-ROM of TKM issues 49-60 is now available for members residing outside of New Jersey<br />

($16.05 for New Jersey members); TKM 1-48 with over 1,500 pages of PRR information<br />

now also is available for $60 for members residing outside New Jersey ($64.20 for New Jersey<br />

Members).<br />

CD-ROMs are also available for issues 1-12, 13-24, 1-24, 25-36, 37-48, <strong>and</strong> 1-48 at a cost of<br />

$15.00 per 12-issues (one year). Each CD-ROM contains a very comprehensive index of all<br />

previous issues. Send a check or money order in US dollars payable to PRRT&HS to<br />

Al Buchan<br />

785 Cornwallis Drive<br />

Mt. Laurel, NJ 08054-3209<br />

To subscribe to The Keystone Modeler, click on the link below <strong>and</strong> send:<br />

mailto:the-keystone-modeler-request@lists.keystone-pubs.org?Subject-subscribe<br />

To unsubscribe, click on the link below <strong>and</strong> send:<br />

mailto:the-keystone-modeler-request@lists.keystone-pubs.org?Subject-unsubscribe<br />

The Keystone Modeler 2 No. 72, <strong>Winter</strong> <strong>2010</strong>

The challenge of paint matching<br />

Modelers never seem to finish their discussion of the “correct”<br />

color for the models they paint. For many, especially prototype modelers,<br />

color is a serious business. What did that car look like when it<br />

was fresh out of the paint shop? Did the paint fade? What color is under<br />

all that soot <strong>and</strong> grime? How did film quality, or lighting conditions,<br />

or computer technicalities affect what I see? Our <strong>Society</strong> even<br />

has a Paint Committee to advise model manufacturers.<br />

Recently, I have had the opportunity to observe first-h<strong>and</strong> how the<br />

same kinds of questions perplex those who have the responsibility to<br />

restore a piece of equipment for display in a museum. Sometimes it is<br />

possible to find traces of earlier exterior colors in the crevices of wooden<br />

equipment or other hard-to-reach places in steel equipment. These<br />

traces can be analyzed by companies which specialize in that kind of<br />

detective work. Traces of paint down through fifteen or sixteen layers<br />

may be discovered. Restorers may consult experts in the history of the<br />

railroad which owned the equipment being restored. Photographic evidence,<br />

if it exists, together with the known limitations of old photographs,<br />

often only in black <strong>and</strong> white, may be examined. Finally, there<br />

is the issue of what period in the history of that piece of equipment<br />

should be represented. If the piece has had several owners or has been<br />

extensively modified, it may not be appropriate to repaint it into its<br />

original color, so the restorer may choose to approximate a later color<br />

<strong>and</strong> lettering scheme.<br />

In this process, just as in modeling, there often is no absolutely<br />

correct choice. The restorer does the best he can, <strong>and</strong>, inevitably,<br />

someone will look at the result <strong>and</strong> declare it is not correct. If you find<br />

yourself being critical of a modeler’s or restorer’s color choice, be prepared<br />

to show how you arrived at your opinion of what is “correct.”<br />

In roughly five months we will be holding the Annual Meetings<br />

again in Camp Hill. Since that location is nearer the epicenter of Pennsy<br />

f<strong>and</strong>om, I hope there will be more models on display. Time to finish<br />

up that project <strong>and</strong> bring it to the Meetings.<br />

This past October was the final Prototype Modelers’ Seminar in<br />

Naperville, Illinois for Sunshine Models. The Seminar will continue,<br />

but Joe Delia of Proto Power <strong>and</strong> ALine models will be in charge. This<br />

event has always been exciting <strong>and</strong> informative, <strong>and</strong> I hope it continues<br />

to be so. For further information, the web site is: http://www.PPW-<br />

ALINE.com.<br />

In this issue of TKM, we have an article by Bill Neale about operations<br />

on his Pennsy layout. Bill’s beautiful railroad recently appeared<br />

in Great Model <strong>Railroad</strong>s <strong>2010</strong>. Jack Consoli has contributed a review<br />

of Tangent Models new G31B. Coincidentally, additional prototype<br />

information can be found in Ed Hawkins’ Railway Prototype Cyclopedia<br />

#19, which appeared just this past fall. Two essays of interest to N<br />

scale modelers also appear this month. Bob Losse, Jr. has written a review<br />

of the new G26 by Eastern Seaboard Models, while Claus<br />

Schlund has kitbashed an NA cabin. We also have Tim Garner’s howto<br />

article on station <strong>and</strong> tower signs, plus Chuck Cover’s article on<br />

scratchbuilding “KASE” Tower from styrene in HO-scale.<br />

Jim Hunter, Editor<br />

The <strong>Pennsylvania</strong> <strong>Railroad</strong> <strong>Technical</strong><br />

& <strong>Historical</strong> <strong>Society</strong><br />

The purpose of the <strong>Pennsylvania</strong> <strong>Railroad</strong> <strong>Technical</strong> & <strong>Historical</strong><br />

<strong>Society</strong> is to bring together persons interested in the history <strong>and</strong> modeling<br />

of the <strong>Pennsylvania</strong> <strong>Railroad</strong>, its subsidiaries <strong>and</strong> its acquired companies.<br />

Our goals are to promote the preservation <strong>and</strong> recording of all<br />

information regarding the organization, operation, facilities, <strong>and</strong> equipment<br />

of the PRR.<br />

The <strong>Society</strong>’s quarterly illustrated journal, The Keystone, has been<br />

published continuously since 1968. Each issue of 64 or more pages contains<br />

illustrated original authoritative articles about locomotives, cars,<br />

other equipment, facilities, <strong>and</strong> operating practices of the PRR. The <strong>Society</strong><br />

also publishes its own thoroughly researched books <strong>and</strong> other materials<br />

concerning PRR history. The Keystone Modeler is also a quarterly<br />

special 30-plus page online publication of the <strong>Society</strong>.<br />

The <strong>Society</strong> meets annually, usually during a weekend in early May,<br />

providing an opportunity for its members to get together <strong>and</strong> learn more<br />

about the PRR. Local chapters around the country also provide members<br />

<strong>and</strong> guests with regular meetings that feature PRR related programs.<br />

Information about our <strong>Society</strong> may be found on our website –<br />

www.prrths.com. To join the <strong>Society</strong>, send $35.00 to:<br />

PRRT&HS<br />

PO Box 54<br />

Bryn Mawr, PA 19010-0054<br />

All memberships are for a calendar year, back issues of The Keystone<br />

for the current year are sent upon joining. Overseas membership<br />

has added postage fees.<br />

PRRT&HS Interchange<br />

Selected <strong>Society</strong> Merch<strong>and</strong>ise of Interest to Modelers<br />

PRR Equipment Drawings on Microfilm<br />

Copies of PRR equipment drawings are available from the <strong>Society</strong>’s<br />

microfilm collection. To order drawings, you must know the drawing<br />

number <strong>and</strong> title. Ordering information <strong>and</strong> lists of arrangement<br />

drawings are available on the <strong>Society</strong>’s website. Go to<br />

www.prrths.com, select National <strong>Society</strong>, <strong>and</strong> then The Interchange. If<br />

you require a printed copy of this information, please send your address<br />

<strong>and</strong> a check for $2.00 made out to PRRT&HS to:<br />

Richard C. Price<br />

779 Irvin Hill Road<br />

McVeytown, PA 17051<br />

The Keystone CD 5<br />

The Keystone CD No. 5, The Glory Days,<br />

covering 1998 to 2002, is now for sale at the<br />

price of $75 for members. New Jersey residents<br />

add $5.25 sales tax. Order CDs from:<br />

Al Buchan<br />

785 Cornwallis Drive<br />

Mt. Laurel, NJ 08054-3209<br />

The Keystone DVD 1<br />

The Keystone DVD No. 1 covering 35<br />

years of The Keystone from 1968 to 2002 is<br />

available. The navigation of this product is<br />

being upgraded as are some of the administrative<br />

notes <strong>and</strong> text. The improved edition<br />

will be ready for ordering soon. Those few<br />

who have already purchased the DVD will<br />

be able to trade it in for a new one when it’s<br />

available. The price of this DVD is $375.<br />

This DVD requires a computer with a DVD<br />

drive. It is NOT a video disk that can be<br />

played on a DVD player for viewing on<br />

your TV.<br />

The Keystone Modeler 3 No. 72, <strong>Winter</strong> <strong>2010</strong>

PRR Product News<br />

Division Point<br />

http://www.divisionpoint.com<br />

PRR/NH/B&M/MEC East Wind Passenger Train – HO<br />

Division Point is taking reservations for brass models of all the<br />

cars in this train. Individual cars will also be available.<br />

Eastern Seaboard Models Corporation<br />

http://www.esmc.com<br />

PRR G26 Gondola – Special Limited Edition – N Scale<br />

Detail Parts – N Scale<br />

ESMC has made available their G26 gon expertly finished <strong>and</strong><br />

weathered by Tom Mann. They have also launched a line of N<br />

detail parts.<br />

InterMountain Railway Company<br />

http://www.imrcmodels.com/index.html<br />

PRR X29 Boxcar – HO Scale<br />

IMRC is scheduled to deliver Red Caboose X29 boxcars in circle<br />

keystone in March <strong>2010</strong>. Planned car numbers are 504219,<br />

504263, 504326, 504388, 504415, <strong>and</strong> 504477. They will all<br />

have a re-weigh date of 1-51. These car numbers model cars<br />

with flat plate ends built new in 1924-25.<br />

JnJ Trains<br />

http://jnjtrains.com<br />

Diesel resin body shells <strong>and</strong> detail parts – N Scale<br />

JnJ has developed resin shells designed to fit on available chassis<br />

from Atlas, Bachmann, Kato, or Life-Like. Available PRR<br />

shells include Erie-built A & B, RF16 A & B, H16-44, <strong>and</strong><br />

SD45.<br />

Middle Division<br />

http://www.middledivision.com<br />

Decals – HO Scale<br />

Middle Division has a very welcome new decal set, HHP-4 for<br />

PRR two bay hoppers in the Circle Keystone scheme. The<br />

PE NNSY LVAN IA is divided to fit between the ribs. Classes<br />

covered include GLA, GLD, GLG, <strong>and</strong> H31. The decals are<br />

printed <strong>and</strong> are awaiting packaging. A corresponding set in O<br />

scale is planned. Order direct from Northern Central Supply at<br />

http://www.northerncentralsupply.com/indexdc.html .<br />

Sunshine Models<br />

(Although Sunshine does not maintain a web presence, a current<br />

summary of products is available at an independentlymaintained<br />

site at www.sunshinekits.com.)<br />

PRR G24 Gondola - HO<br />

With Steve Hoxie<br />

Sunshine has available four versions of the G24 (USRA) gondola.<br />

This class was covered in TKM #7, February 04.<br />

• Kit#92.2 steel sides, Murphy ends, circle keystone decals<br />

(1937-60’s)<br />

• Kit #92.3 steel sides, Murphy ends, Long Isl<strong>and</strong> decals,<br />

(1937-40)<br />

• Kit #92.4 steel sides, Murphy ends, “A” frame for loading automobile<br />

frames, circle keystone decals, (1937-44)<br />

• Kit #92.5 steel sides, WW II replacement ends, circle keystone<br />

decals, (1943-60’s)<br />

Tangent Scale Models<br />

http://tangentscalemodels.com<br />

G31B Gondola – HO Scale<br />

Tangent is offering a ready-to-run, highly accurate model of the<br />

70 ton welded G31B class gondola built by ACF. The cars are<br />

lettered in the circle keystone scheme <strong>and</strong> are available in several<br />

numbers. This class was covered in TKM #17, December ’04.<br />

See product review in this issue of TKM.<br />

Tom Haag Decals<br />

haagtk@aol.com<br />

Shadow Keystone Boxcar Decals – HO Scale<br />

Tom has a new decal set for lettering PRR 50’ boxcars in the<br />

Shadow Keystone scheme with 7” numbers <strong>and</strong> reporting marks<br />

(SK2a <strong>and</strong> SK2b). X45, X47, X50, X52, <strong>and</strong> X56 classes can be<br />

lettered.<br />

Traincat Model Sales<br />

http://www.traincat2.com/<br />

PRR G22B Gondola – N Scale<br />

PRR GRA Gondola – N Scale<br />

Traincat is taking reservations for class G22B <strong>and</strong> GRA gondolas<br />

in brass.<br />

Weaver Models<br />

http://www.weavermodels.com/page76.html<br />

PRR Passenger Sharks BP20 A & B – O Scale<br />

Weaver is taking reservations for ¼” scale brass Passenger<br />

Sharks offered as an A <strong>and</strong> B unit combination or as a single A<br />

unit. 2 <strong>and</strong> 3 rail, Brunswick Green <strong>and</strong> Tuscan Red, with <strong>and</strong><br />

without sound will be available.<br />

The Keystone Modeler 4 No. 72, <strong>Winter</strong> <strong>2010</strong><br />

.

Upcoming Events<br />

January 30-31 – West Springfield, Massachusetts<br />

Amherst Railway <strong>Society</strong> <strong>Railroad</strong> Hobby Show<br />

http://www.railroadhobbyshow.com<br />

March 13 – Peabody, Massachusetts<br />

Spring TRAINing – Hub Division, NMRA<br />

http://hubdiv.org/springshow/index.htm<br />

March 26-28 – Malvern, <strong>Pennsylvania</strong><br />

<strong>Railroad</strong> Protoype Modelers of Valley Forge<br />

Contact Paul Backenstose at prrpaul@aol.com<br />

April 29 – May 2 Camp Hill, <strong>Pennsylvania</strong><br />

PRRT&HS Annual Meeting<br />

http://www.prrths.com/conventions/PRR_Annual.html<br />

Host New Engl<strong>and</strong> Chapter has model room forms available online<br />

so you can fill out more detailed model descriptions in advance.<br />

By doing so, you’ll have more time for fun at the Annual<br />

Meeting <strong>and</strong> you’ll give the TKM staff more to work from in describing<br />

your efforts.<br />

Follow the link above or go to: http://prrths-ne.org/.<br />

June 4-5 – Collinsville, Connecticut<br />

New Engl<strong>and</strong>/Northeast Prototype Modelers Meet<br />

http://www.neprototypemeet.com/Welcome.html<br />

Additional Information<br />

RP Cyc Publishing Co.<br />

http://www.rpcycpub.com<br />

Railway Prototype Cyclopedia Vol. 19<br />

Vol. 19 includes a 53 page article with photos documenting the<br />

G31 class of gondolas. This is an outst<strong>and</strong>ing soft cover reference<br />

for the modeler.<br />

Model <strong>Railroad</strong> Hobbyist Magazine<br />

The Jan/Feb <strong>2010</strong> issue is available for downloading at<br />

http://model-railroad-hobbyist.com<br />

The B&O Modeler<br />

The Baltimore <strong>and</strong> Ohio <strong>Railroad</strong> <strong>Historical</strong> <strong>Society</strong> has the latest<br />

editions available at http://borhs.org/ModelerMag/index.html<br />

The Seaboard-Coastline Modeler<br />

Our friends at the ACL & SAL <strong>Historical</strong> <strong>Society</strong> have the latest<br />

edition of this magazine available at http://www.aclsal.org/ .<br />

Paul Ziesmer, a long-time <strong>Society</strong> member <strong>and</strong> founder of the New Engl<strong>and</strong> Chapter, has a passion for building antique HO kits.<br />

The two PRR P70GR coaches were kits produced by Megow in 1939 or 1940. Paul saw cars like these in Wanamaker’s Store in<br />

Philadelphia in 1943. They are shot on Tim Garner’s PRR Willsburgh Division layout. Tim Garner photo.<br />

The Keystone Modeler 5 No. 72, <strong>Winter</strong> <strong>2010</strong>

Model Review – Eastern Seaboard<br />

Models N-Scale PRR G26 Mill Gondola<br />

By Bob Losse Jr., photos by Jack Consoli unless noted<br />

(Above) Eastern Seaboard Models PRR class G26 65 ft. 6 in. mill gondola. (Below) Eastern Seaboard Models’ two G26 offerings.<br />

Recently, Al Buchan passed on two of Eastern Seaboard<br />

Models Corp’s new N Scale G26 class gondolas. When he did,<br />

he asked me if I could help. He needed a product review <strong>and</strong> I<br />

said yes. This is the first time I’ve ever done this <strong>and</strong> it leaves me<br />

with one thing to say to all you rivet counting sharks out there, I<br />

give good indigestion.<br />

A brief history about the G26 <strong>and</strong> its successors. In October<br />

1930 Altoona built the first 200 cars. From January 1931 through<br />

May 1931 the PRR built 1500 G26 gondolas. Construction was<br />

divided up amongst Altoona, Enola <strong>and</strong> Pitcairn <strong>and</strong> they were<br />

numbered PRR 439010-440709. The Lehigh Valley had 50 cars<br />

built in 1931 by the PRR numbered LV 34000-34049. In 1941<br />

the PRR made some subtle improvements to the design <strong>and</strong> built<br />

the G26A. 700 cars were built by Altoona <strong>and</strong> Pitcairn in the last<br />

quarter of 1941. The Norfolk & Western liked this design <strong>and</strong><br />

had the Virginia Bridge Co. build N&W 70500-70524 G-3 in<br />

1941. In 1949 the N&W received N&W 70525-70549 G-3A<br />

again from Virginia Bridge Co. All of these cars as built were<br />

rated at 70 tons capacity.<br />

So much for the cars as originally built. The LV cars operated<br />

in almost total obscurity <strong>and</strong> were gone from the roster by<br />

1965. As far as I know, no photos of these cars exist. At some<br />

point, the N&W started to upgrade their cars to 77 tons capacity.<br />

I don’t know if any other changes were made to these cars. By<br />

1989 these cars had disappeared from the roster.<br />

The PRR was a little different. In the mid 1960's two distinct<br />

versions, the G26C <strong>and</strong> G26S, would emerge from the shops. The<br />

G26C was basically an upgrading of the two earlier classes <strong>and</strong><br />

used in revenue service. The G26S was a radically different car<br />

<strong>and</strong> was used in company service. This configuration was used to<br />

carry prefabricated switches.<br />

This past Labor Day, I found two in Roanoke, VA working<br />

for NS. Cars for these programs were pulled at r<strong>and</strong>om <strong>and</strong> not<br />

every car was rebuilt. Many found their way to the Holidaysburg<br />

Reclaim Plant, while others were sold to various steel mills, pipe<br />

plants <strong>and</strong> even Pullman St<strong>and</strong>ard.<br />

By April 1, 1976, D-Day for Conrail, 16 G26 <strong>and</strong> 12 G26A<br />

were on the roster still painted PRR. Yes, these cars had serious<br />

longevity.<br />

Not only did they have longevity, they also got around. I<br />

have records showing these cars operated on the B&M, B&O,<br />

CN, CNW, EL, IC, L&N, MKT, SP, SR <strong>and</strong> UP. Unfortunately,<br />

the records weren’t indicating the types of loads. Only that the<br />

cars had been destroyed in wrecks. Some railroads liked proving<br />

this to me so much, that they did it twice.<br />

PRR company photo of G26 #439048, 10-27-30, neg. #E8963, displaying the as-delivered Circle Keystone lettering arrangement.<br />

PRRT&HS collection.<br />

The Keystone Modeler 6 No. 72, <strong>Winter</strong> <strong>2010</strong>

PRR photo of G26 #439048, 10-27-30, neg. #E8964, showing brake end details <strong>and</strong> drop end door arrangement. The cars were<br />

narrower than shorter gondolas to deal with clearance issue due to the long wheelbase. This car is equipped with 2E-F4 trucks.<br />

PRRT&HS collection.<br />

Enough about the prototype, let’s talk about the model. In<br />

checking the dimensions, I used the General Arrangement drawing<br />

that appears in the 1937 Car Builders Cyclopedia <strong>and</strong> Clearance<br />

Diagram E-93171. When I checked the Circle Keystone lettering,<br />

I used various builders <strong>and</strong> in service photos.<br />

The Shadow Keystone paint scheme was easier. I used the<br />

<strong>Pennsylvania</strong> <strong>Railroad</strong> Compendium. For color comparisons, I<br />

used Vol. 2 <strong>and</strong> Vol. 3 of the PRR Color Guides. For anyone<br />

who wants to compare the G26 to the G26A, the General Arrangement<br />

drawing is available from PRRT&HS. PRR diagrams<br />

for the G26 <strong>and</strong> G26A, respectively, are located at:<br />

http://prr.railfan.net/diagrams/PRRdiagrams.html?diag=g26.<br />

gif&sel=gon&sz=sm&fr=<br />

http://prr.railfan.net/diagrams/PRRdiagrams.html?diag=g26a<br />

.gif&sel=gon&sz=sm&fr=<br />

The G26C <strong>and</strong> G26S don’t fit my plans, so I haven’t tried to<br />

locate them.<br />

The only dimension that was way off was the length over<br />

couplers. This has been an ongoing debate within the scale for<br />

many years. No I’m not going there. All of the other dimensions<br />

were within inches. The rivet detail is excellent <strong>and</strong> the various<br />

patterns match the prototype. They also took the time <strong>and</strong> effort<br />

to cast interior details. This is a nice touch, but the way it needed<br />

to be done can cause problems. To get a clear picture of the quality<br />

of this casting, check out the area around the brake wheel. As<br />

built these cars were equipped with early Dreadnaught drop ends,<br />

the ones on this model match <strong>and</strong> work.<br />

Fine details of the parts, inside <strong>and</strong> out, are visible here. This car is equipped with National-type PRR class 2E-F7 trucks, one of<br />

several correct options for these cars.<br />

The Keystone Modeler 7 No. 72, <strong>Winter</strong> <strong>2010</strong>

H<strong>and</strong> brake detail <strong>and</strong> end door shown in dropped position.<br />

I took the time to talk to Bryan Bussey of Eastern Seaboard,<br />

about the two freight car colors used. He told me that both freight<br />

car colors were provided by PRRT&HS. I think he got an FCC<br />

drift card <strong>and</strong> used it on both CK <strong>and</strong> SK models. The CK color<br />

is not orange enough. When it comes to the colors, only real consistency<br />

from manufacturer to manufacturer has been the inconsistency.<br />

Hopefully, the paint committee has come to a consensus<br />

<strong>and</strong> begun to put the right info out to the manufacturers. My observations<br />

about the CK color are that it is a little off. The SK<br />

color on the model is brown, while all of photos I looked at show<br />

a red.<br />

I’ll start with the lettering for the Circle Keystone, CK, car.<br />

It matched up perfectly with the photos I had. The quality <strong>and</strong><br />

detail are amazing. You can read the “ACS” build date as well as<br />

all the other fine print. The Shadow Keystone, SK, car is a different<br />

story. The word “PENNSYLVANIA” <strong>and</strong> the road number<br />

need to be shifted one panel to the left. The keystone <strong>and</strong> all<br />

of the dimensional data are correctly placed. Aside from this<br />

misplacement, all of the other lettering is excellent. At first<br />

glance, you don’t notice this mistake. Bryan told me it would be<br />

corrected for subsequent runs.<br />

This car comes equipped from the factory with body mount<br />

couplers. Typically you’ll only see this in new locomotives or<br />

cabin cars. This caused me some concern, which was very quickly<br />

dispelled.<br />

As anyone in N Scale knows, we have several different types<br />

of couplers on the market now. I used an Intermountain FP7A<br />

<strong>and</strong> an Atlas C-420 as my two test locomotives. The FP7A<br />

comes equipped with Micro-Trains couplers while the C-420 has<br />

Accumate couplers.<br />

I also used an Atlas offset side twin hopper, an Athearn offset<br />

side triple hopper <strong>and</strong> a Micro-Trains boxcar. The Atlas car<br />

has the Accumates, the Athearn car has the new McHenry couplers<br />

<strong>and</strong> we know what the Micro-Trains car has. I was looking<br />

for a variety of things <strong>and</strong> all of my questions were answered.<br />

They all coupled easily <strong>and</strong> smoothly. Coupler height matched<br />

perfectly. There was basically, no difference between the body<br />

mount <strong>and</strong> truck mounted couplers.<br />

Next would be the road tests. Being an apartment dweller, I<br />

don’t have space for the model railroad that I want. What I do<br />

have is a test track. A few years back, Des Plaines Hobbies released<br />

a Pullman <strong>and</strong> it got its turn on my test track. Only by<br />

tweaking the trucks, would these cars tolerate my test track.<br />

Needless to say, any locomotive, freight car, passenger car or cabin<br />

car will get put through its paces on my test track. Using the<br />

five cars <strong>and</strong> two locomotives mentioned above, I put one gon on<br />

the end of the train <strong>and</strong> the other in the middle. I both pushed <strong>and</strong><br />

pulled the cut of cars around the curves <strong>and</strong> through the crossover<br />

switches. These two cars had no problems.<br />

The body mounted couplers <strong>and</strong> the low profile wheels were<br />

used for a reason. Bryan wanted to get the height from rail dimension<br />

correct <strong>and</strong> this was accomplished. I did have one problem<br />

with the road tests. My track is the older 100-million-lbswon’t-wear-out-until-your-gr<strong>and</strong>-kids-have-gr<strong>and</strong>-kids<br />

trackage.<br />

In one direction only, it sounded like the flanges were hitting the<br />

ties. It was coming from the A-end of both cars. When I brought<br />

this to Bryan’s attention, he said it wasn’t the flanges. It was<br />

flash on the axles hitting the coupler box. My X-Acto knife<br />

seems to have fixed this problem.<br />

ESM G26 in as-built Circle Keystone lettering (above) <strong>and</strong> in the later repaint Shadow Keystone lettering (below).<br />

The Keystone Modeler 8 No. 72, <strong>Winter</strong> <strong>2010</strong>

One thing I discovered while investigating this problem, is<br />

how fragile these cars are. The two sides are glued to the metal<br />

frame. Needless to say, these cars need to be h<strong>and</strong>led with kid<br />

gloves. Anyone thinking about doing kit bashing with this car<br />

has been warned. This problem with the trucks should be fully<br />

investigated, so it doesn’t come back to haunt anyone.<br />

My overall impressions are positive. This is a highly detailed<br />

car that h<strong>and</strong>led itself well in tests. The only problems I found<br />

were either fixable or ones we’ve had before. It is a different car<br />

in the way it is assembled, but those differences are a positive. I<br />

took the time to do a little additional research on the welded G33<br />

<strong>and</strong> G37 classes. They share many common dimensions with the<br />

G26. The G33 was built with drop ends while the G37 was built<br />

with fixed ends.<br />

References<br />

The Keystone Modeler, No. 9, April 2004, page 32, G26- classes<br />

historical background <strong>and</strong> photographs.<br />

(Top) Underside view of G26 shows construction of plastic sides<br />

attached to a cast metal floor.<br />

(Above) Correct proportions <strong>and</strong> long length (causing the depth-offield<br />

focus problems) of the ESM G26 is evident in this view.<br />

(Left) Detail showing where flash has been removed from the near<br />

axle. The flash was interferring with the with the coupler pocket pin<br />

only on the A-end of the car.<br />

The Keystone Modeler 9 No. 72, <strong>Winter</strong> <strong>2010</strong>

Model Review – Tangent Scale Models<br />

G31B Gondola<br />

By Jack Consoli, photos by the author unless noted<br />

Class G31B HO injection-molded plastic model.<br />

Let’s just cut to the chase: this is the nicest off-the-shelf,<br />

ready-to-run, state-of-the-art PRR gondola model out there, period.<br />

And unless you are overly concerned about a few details of<br />

the underframe which can’t be seen in any normal model pose,<br />

you won’t end up with a better gon starting with any brass import<br />

or plastic or resin kit, even after you assemble, paint <strong>and</strong> letter it.<br />

Even better news is that (the vast majority of) we modelers need<br />

this car, badly. So let me explain why <strong>and</strong> then get to the details<br />

of the model.<br />

The Prototypes<br />

Following World War II, the PRR’s freight car fleet was in<br />

serious need of repair <strong>and</strong> replacement following the abuse of<br />

supporting the war effort, particularly on many classes of aging<br />

cars. The PRR thus undertook a massive building program of<br />

new freight cars, including gondolas. The first gon type they targeted<br />

was the 52’6” inside length general service mill gondola.<br />

As per their historical mode of operation, they developed a new<br />

design, their first state-of-the-art all-welded gon class in this<br />

case, <strong>and</strong> proceeded to build the 2900 G31 (no-subclass) cars<br />

from 1948 to 1950. These cars featured thirteen welded side<br />

stakes in a W-N-N-N-W-N-W-N-W-N-N-N-W (W=wide,<br />

N=Narrow section stake) pattern. Although the side sheets had a<br />

fishbelly contour, the stakes all ended at the same height across<br />

PRR photo of G31B B-end, showing Universal lever-style h<strong>and</strong> brake <strong>and</strong> A.S.F. trucks.<br />

the length of the car, not extending fully down over the fishbelly<br />

area. The cars had steel floors <strong>and</strong> drop-type 2-rib Improved<br />

Dreadnaught style end doors. The G31 had a 3’6” inside height<br />

<strong>and</strong> 1745 cu.ft. capacity.<br />

The <strong>Railroad</strong> then did something very un-Pennsy-like <strong>and</strong><br />

farmed out the construction of all the subclasses to several of the<br />

major commercial car builders. In the end, there were only three<br />

types of cars: drop-end/steel floor, drop-end/wood floor <strong>and</strong><br />

fixed-end/wood floor. However, since the three commercial<br />

builders opted to construct the last two types per their own respective<br />

preferences, a total of six class designations were required<br />

to keep similarly built cars segregated. Pullman St<strong>and</strong>ard<br />

built the 4800 welded, drop-end/wood floor G31A in three lots<br />

from 1950 through 1952 with their proprietary PS end. This<br />

stamped end door had two large, essentially straight horizontal<br />

corrugations. American Car & Foundry built one lot of 2000 very<br />

similar welded, drop-end/wood floor G31B in March through July<br />

1951, using instead the 2-rib Improved Dreadnaught style end<br />

doors that were used on the G31. They also constructed the 1200<br />

G31D in 1951 <strong>and</strong> 1952, essentially just a fixed-end version of<br />

the same car. These welded cars had 3-rib Dreadnaught ends.<br />

General American, like AC&F, also built both drop end <strong>and</strong><br />

fixed-end, wood floor cars, with corrugated ends. Their 750<br />

G31C of 1951 had 2-rib Improved Dreadnaught end doors <strong>and</strong><br />

The Keystone Modeler 10 No. 72, <strong>Winter</strong> <strong>2010</strong>

their 500 G31E of 1952 had 3-rib Dreadnaught ends. The big difference<br />

between the General American cars <strong>and</strong> all the others<br />

was that they chose to stick with riveted-style construction.<br />

These would be the last riveted gons acquired by the PRR. (The<br />

only other post-war riveted gons, the 2000 46’0” inside length<br />

G34 cars, were actually built earlier, starting in late 1950.)<br />

In addition to the G31-classes, a very similar car, the G35,<br />

factors into this discussion. This class was essentially a slightly<br />

upgraded version of the G31B. The primary differences were that<br />

the newer design incorporated uninterrupted floor stringers <strong>and</strong> a<br />

taller inside height due to a beefed-up top chord configuration.<br />

On the G31’s the crossbearers had straight tops <strong>and</strong> fit up against<br />

the bottom of the floor, requiring the perpendicular stringer<br />

members to be cut <strong>and</strong> fitted in between all the cross members.<br />

On the G35 the crossbearers were dipped on top allowing continuous<br />

floor stringers to pass over top of them along the length of<br />

the car. The G31’s all had a “Z” member for a top chord along<br />

the car sides. For increased strength, the top chord on the G35<br />

was a welded assembly of two horizontal channel members to<br />

form a stronger box beam. Although the inside height of these<br />

cars was 3” taller than the G31B, they had the same side construction<br />

with just a larger top chord. This difference accounts<br />

for the larger cubical capacity of 1745 cu.ft. versus the 1646<br />

cu.ft. of all the wood floor G31-subclasses. The G35 were built<br />

with three different types of flooring.<br />

PRR G31 & G35* – CLASS GONDOLAS (as built)<br />

Class Number Series Quantity Builder Body Ends Floor<br />

G31 363400-366299 2900 PRR Welded<br />

G31A<br />

Drop – 2-rib<br />

Imp.Dreadnaught<br />

Outside<br />

Length<br />

Inside<br />

Height<br />

The Keystone Modeler 11 No. 72, <strong>Winter</strong> <strong>2010</strong><br />

Cubic<br />

Feet<br />

Hold-down<br />

clip location<br />

Steel 54' 8" 3' 6" 1745 Side panels<br />

373950-374949 1000 PS Welded Drop – 2-rib - PS Wood 54' 8" 3' 3" 1646 Side panels<br />

612000-614999 3000 PS Welded Drop – 2-rib - PS Wood 54' 8" 3' 3" 1646 Side panels<br />

374950-375749 800 PS Welded Drop – 2-rib - PS Wood 54' 8" 3' 3" 1646<br />

G31B 371950-373949 2000 ACF Welded<br />

G31C 371200-371949 750 GA Riveted<br />

G31D 375750-376949 1200 ACF Welded<br />

G31E 376950-377449 500 GA Riveted<br />

G35<br />

377450-378449 1000 PRR Welded<br />

378450-379149 700 PRR Welded<br />

379150-379349 200 PRR Welded<br />

Drop – 2-rib<br />

Imp.Dreadnaught<br />

Drop – 2-rib<br />

Imp.Dreadnaught<br />

Fixed – 3-rib Dreadnaught<br />

Fixed – 3-rib Dreadnaught<br />

Drop – 2-rib<br />

Imp.Dreadnaught<br />

Drop – 2-rib<br />

Imp.Dreadnaught<br />

Drop – 2-rib<br />

Imp.Dreadnaught<br />

All classes above: IL = 52' 6", IW = 9' 6", EXH = 10' 7", Capacity = 70 tons<br />

PS = Pullman St<strong>and</strong>ard Car Manufacturing Co.<br />

ACF = American Car & Foundry<br />

GA = General American Transportation Corp.<br />

Wood 54' 8" 3' 3" 1646<br />

Wood 54' 8" 3' 3" 1646<br />

Wood 54' 8" 3' 3" 1646<br />

Wood 54' 0" 3' 3" 1646<br />

Wood 54' 8" 3' 6" 1745<br />

Nailable steel 54' 8" 3' 6" 1745<br />

Composite 54' 8" 3' 6" 1745<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Outer side of top<br />

chord<br />

Note: All the G31 classes had the same height sides: the G31 had larger capacity due to the steel floor – the wood floor consumed approximately 100<br />

cubic feet of volume. The capacity in the ORER is listed as 1646 for all the wood floor cars, but the G31A <strong>and</strong> G31B were stenciled as being 1647 cubic<br />

feet.<br />

* Note: The wood floor G35 essentially the same as G31 design except for having main crossbearers dipped to allow for continuous passage of the<br />

floor stringers between the bolsters <strong>and</strong> the side height extended by the top chord to yield the same capacity as the steel floor G31.<br />

REBUILDS Date Details<br />

G31F Rebuilt from class G31 1960<br />

G31H Rebuilt from class G31 1966 StanRay corrugated side panels<br />

G31K Rebuilt from class G31A 1967<br />

G31L Rebuilt from class G31B 1967<br />

G31M Rebuilt from class G31C 1967<br />

G31N Rebuilt from class G31D 1968<br />

G31P Rebuilt from class G31E PC era<br />

G35A Rebuilt from class G35 PC era<br />

Breakdown <strong>and</strong> details of the G31- <strong>and</strong> G35-class gondolas.

There were a total of 12,150 G31-class cars constructed;<br />

14,050 if the G31 – plus the similar G35 – are included. With the<br />

loss of many older cars during the decade preceding their construction,<br />

The G31/G35 classes comprised a very significant part<br />

of the PRR’s gondola fleet. To illustrate the magnitude of the<br />

place in the PRR roster these cars filled, look at the totals from<br />

the Official Railway Equipment Register roster dated October<br />

31, 1952 (issue cover date January 1953). Keep in mind there<br />

were almost 1000 G35 not yet built as of this date.<br />

ALL FREIGHT CARS<br />

Number of Percent of<br />

Freight Car Type Cars Total<br />

Open Hopper 75,077 38.57<br />

Box Car 68,145 35.01<br />

Gondola 44,594 22.91<br />

Flat Car 3,189 1.64<br />

Covered Hopper 2,297 1.18<br />

Stock Car 1,327 0.68<br />

Total 194,629 100.00<br />

Here is the breakdown by gondola class (with subclass included<br />

within the base class for simplicity).<br />

PRR Gondola Number of Percent of<br />

Class<br />

Cars Total<br />

GR 3,689 8.27<br />

GS 882 1.98<br />

G21 1 0.00<br />

G22 6,127 13.74<br />

G24 545 1.22<br />

G25 2,461 5.52<br />

G26 2,348 5.27<br />

G27 4,495 10.08<br />

G28 1,895 4.25<br />

G29 2,981 6.68<br />

G30 997 2.24<br />

G31 12,149 27.24<br />

G32 2,100 4.71<br />

G33 950 2.13<br />

G34 2,000 4.48<br />

G35 974 2.18<br />

Total 44,594 100.00<br />

Here is the breakdown by sub-class for G31/G35.<br />

PRR Gondola Number of Percent of<br />

Class<br />

Cars Total<br />

G31 2,900 6.50<br />

G31A 4,799 10.76<br />

G31B 2,000 4.48<br />

G31C 750 1.68<br />

G31D 1,200 2.69<br />

G31E 500 1.12<br />

G35 974 2.18<br />

Total 13,123 29.41<br />

So the bottom line here is that in the early 1950’s gons made<br />

up close to one quarter of the total PPR fleet of nearly 200,000<br />

cars <strong>and</strong> of those, almost one in three was a G31/G35. PRR <strong>and</strong><br />

non-PRR modelers alike need these cars.<br />

Additional background can be found in the previous TKM<br />

articles on the G31:<br />

• G31, G31A/B/D, G35 Gondolas – Vol. 16, page 23: background,<br />

diagram, numbers <strong>and</strong> quantities, photos.<br />

• G31, G31A/B/D, G35 Gondolas – Vol. 17, page 24: supplemental<br />

photos.<br />

• G31C/E Gondolas – Vol. 17, page 8: background, diagram,<br />

numbers <strong>and</strong> quantities, photos.<br />

The Model<br />

There is frankly very little to say about this model because it<br />

is so well done. The construction of the car is fairly typical, the<br />

execution is exemplary. The sides, ends <strong>and</strong> underframe members<br />

are a one-piece injection molded part. Small details including<br />

the tack boards, defect card holder, poling pockets, end sill<br />

gussets, drop door latches <strong>and</strong> weld seams (including those on<br />

the inside of the car) are molded into the body where appropriate.<br />

Especially well executed are the shallow oval slots along the face<br />

of the corner posts that aided in the welding process of the prototype<br />

as well as the small holes along the length of the top chords.<br />

Note also that the non-symmetric end sills on the car are properly<br />

recreated; this is not a mistake. Whereas the A-end sill has a<br />

shallow taper, the B-end sill has a much deeper taper to extend<br />

the draft gear outward <strong>and</strong> provide space from a coupled car for<br />

the h<strong>and</strong> brake <strong>and</strong> platform protruding from the end of the car.<br />

(Above left) A ¾-view of G31B model. (Above right) G31B A-end showing the shallow sill, drop end door, side bracket grab, etc.<br />

Note that the drop steps are not mangled here. The inside leg was vertical, but the outer leg was angled due to its being attached<br />

out on the angled part of the corner post.<br />

The Keystone Modeler 12 No. 72, <strong>Winter</strong> <strong>2010</strong>

(Right top) Inside view illustrating the floor<br />

detail, corrugated ends, weld seams <strong>and</strong> top<br />

chord holes. The recesses on the top of the<br />

corner posts <strong>and</strong> the door top stiffener rivets<br />

are prototypically correct as well.<br />

(Middle) Underside view of G31B showing<br />

brake gear <strong>and</strong> partial-depth center sill <strong>and</strong><br />

crossbearer members with steel weights buried<br />

beneath.<br />

(Bottom) Fine detailing of the hold down<br />

clips, retainer valve, <strong>and</strong> side ladder.<br />

The Keystone Modeler 13 No. 72, <strong>Winter</strong> <strong>2010</strong>

The rest of the fine details are separately attached<br />

parts that appear very close to proper scale<br />

size <strong>and</strong> cross-section. All the grab irons, ladder<br />

rungs <strong>and</strong> cut levers are wire parts. The half-bracket<br />

grabs on the left end of the sides <strong>and</strong> the half-ladders<br />

on the right ends are beautifully done. The retainer<br />

valve <strong>and</strong> piping, perforated brake platform (US<br />

Gypsum type), drop steps <strong>and</strong> air hoses are all nicely<br />

done as well. Tangent is to be thanked for their effort<br />

expended on the h<strong>and</strong> brake gear. Prototypically correct<br />

<strong>and</strong> scale-size lever-style h<strong>and</strong>brakes so common<br />

on drop-end gondolas have historically been a problem<br />

for modelers. Tangent tooled both Universal <strong>and</strong><br />

Equipco styles, each in two parts: the gear housing<br />

with attached chain <strong>and</strong> a separate lever. Even better,<br />

Tangent is selling them separately, two of each type<br />

on a single sprue per set. All their decorated G31B<br />

come with the Universal style. The prototypes are reported<br />

to have been equipped with a mixture of 500<br />

Universal, 1250 Equipco <strong>and</strong> 250 Klasing sets of<br />

brake gear. The underframe air brake gear, piping,<br />

rods <strong>and</strong> levers appear to be molded <strong>and</strong> applied in<br />

two sections. The delicate, open hold down clips attached<br />

along the outside face of the top chord have<br />

been cleanly molded onto a separate strip, <strong>and</strong> then<br />

applied along the top of the sides.<br />

The 2000 G31B were equipped with PRR class<br />

2E-F22B <strong>and</strong> 2E-F22C trucks. The first 1500 cars<br />

had 70 ton A.S.F. A-3 Ride-Control trucks <strong>and</strong> the<br />

last 500 had National C-1 trucks. Since no appropriate<br />

A.S.F. trucks existed for these models, Tangent<br />

tooled the 70 ton A-3 Ride-Control truck to fill this<br />

void. They are very nicely detailed <strong>and</strong> include casting<br />

markings <strong>and</strong> brake shoes along with the correct<br />

configuration of four visible springs.<br />

Fortunately, Tangent offers these trucks for sale separately<br />

also. (The 70 ton National C-1 trucks are available from Atlas if<br />

you care to model a car with them applied. If you replace the<br />

Tangent trucks, you can always use these A.S.F. trucks elsewhere<br />

as they were used under a number of gon classes.) The<br />

models are equipped with Kadee “scale” Whisker ® shank couplers.<br />

I have only three minor criticisms of this model. The first is<br />

that the prototypes only had one defect card holder. It was on the<br />

side of the car such that when faced, the B-end of the car would<br />

be to the viewer’s left, as seen in the prototype photo above. The<br />

model has two; one on each side of the car. This can be easily<br />

(Top) Drop end door <strong>and</strong> latch hardware, Universal lever h<strong>and</strong>brake gear,<br />

cut levers <strong>and</strong> corner ladders are visible here. (Above) Tangent 70-ton<br />

A.S.F. A-3 Ride-Control trucks. (Bottom) Decorated G31B in its as-built lettering<br />

scheme with gray wood floor.<br />

remedied with one flick of your h<strong>and</strong>y #17 X-Acto knife blade.<br />

The second item is that although the 26 hold down clips are included<br />

along each top chord, the prototype also had one mounted<br />

at an angle on each of the 2 nd <strong>and</strong> 3 rd side stakes in from each end<br />

for a total of 30 per side. Underst<strong>and</strong>ably, these would have been<br />

pretty much impossible to mold onto the model side stakes. It<br />

would require minimal effort to add these as separate bent plastic<br />

or metal rod pieces by the modeler. The last item is that the drop<br />

end doors of the assembled models are glued in (quite well), as<br />

shipped from the factory. This is only an issue if you wish to<br />

configure your car with the doors in their dropped positions.<br />

The Keystone Modeler 14 No. 72, <strong>Winter</strong> <strong>2010</strong>

I had heard that gluing in the doors was a compromise to keep<br />

the car cost down by eliminating all the extra work to decorate<br />

<strong>and</strong> h<strong>and</strong>le parts which have numbers on them that need to match<br />

the car to which they are applied. I started to try to free one with<br />

the sharp tip of a #11 blade <strong>and</strong> I think it is possible, if care is<br />

exercised. Any minor damage to the parts could be disguised as<br />

“weathering” anyway as prototype end doors were abused relentlessly.<br />

I have not yet purchased the kit version of the car (for<br />

conversions) to know for certain, but I am hopeful that the doors<br />

are not assembled to those bodies.<br />

Undoubtedly, some modelers may complain that some of the<br />

upper underframe member details are missing due to their<br />

“space” being occupied by the car weights. I personally would<br />

much prefer to have the car properly weighted right out of the<br />

box at the expense of some details I will never see anyway once I<br />

place the car on the rails, than have to fiddle around trying to<br />

squeeze little bits of weight here <strong>and</strong> there later. Agreed, that on<br />

some freight cars this approach could be a visual problem, but<br />

that is not the case on a gondola with low hanging sides like this.<br />

If it really bothers you, you can easily pop out the floor piece by<br />

pushing up on its underside at the ends of the car <strong>and</strong> then peel it<br />

out once you get the first end lifted, remove the weights, glue in<br />

a bunch of little styrene pieces <strong>and</strong> replace the floor, <strong>and</strong> then<br />

add the weight back via some other means: knock yourself out.<br />

Finishing<br />

The decorated cars are painted a color that is well within the<br />

bounds of what we believe PRR Freight Car color of the early<br />

1950’s to be. The simulated wood floors are painted a neutral<br />

gray. Since on the prototypes the floors of these cars were known<br />

to be unpainted even when new, the gray is intended to give the<br />

modeler a convenient starting point for getting a weathered bare<br />

wood look on the model. The air hoses are even painted black on<br />

their simulated rubber section. The truck sideframes are unpainted<br />

black plastic.<br />

All the lettering is properly applied in white. Note that with<br />

the dispersal of construction of the G31- <strong>and</strong> G35 classes<br />

amongst several builders, a few non-st<strong>and</strong>ard lettering practices<br />

appeared on the cars when built. Although the historically correct<br />

abbreviation on the PRR for the application of one-wear wrought<br />

steel wheels was “1W WRT ST WLS” (dashes <strong>and</strong> periods not<br />

withst<strong>and</strong>ing), ACF stenciled both the G31B <strong>and</strong> G31D “1W<br />

WRT STL WLS” while General American stenciled the G31C<br />

<strong>and</strong> G31E “1W WRT ST WHLS”. ACF also used an angled line<br />

in the fraction in the spring travel data, whereas st<strong>and</strong>ard practice<br />

dictated a horizontal line. Further, ACF also formatted the “THIS<br />

CAR PROVIDED WITH HOLDDOWN CLIPS…” note in the<br />

center of car side to be both right- <strong>and</strong> left-justified, whereas on<br />

most all other classes, the note was only left-justified. Although<br />

PRR practice seemed to vary somewhat, the G31B were delivered<br />

with the “B” suffix in the class notation as a full height 4”<br />

capital letter. In later repaints, some cars received the smaller 3”<br />

capital “B”. Note also that in the period these various classes<br />

were being built, the PRR was in the process of moving some<br />

stenciling to the ends of the cars <strong>and</strong> then further rearranging<br />

their positions on the ends. Tangent got all these subtleties correct<br />

on their G31B.<br />

Other Versions?<br />

The G31B is a great addition to the stable of available models<br />

out there, but what does the introduction of this model mean<br />

to us modelers to help complete the whole picture of the PRR<br />

gondola fleet? How do we get to a G31, G31A, G31C, G31D,<br />

G31E, G35 <strong>and</strong> all the later rebuilt subclasses? As mentioned<br />

above, a significant part of the PRR gondola fleet was made up<br />

of this collection of cars.<br />

We certainly hope at a minimum, Tangent considers releasing<br />

this car in the later Shadow Keystone <strong>and</strong> Plain Keystone<br />

paint schemes as this is a fairly simple extension of their product<br />

line <strong>and</strong> is particularly appropriate as these cars lasted through<br />

<strong>and</strong> past the end of the PRR era.<br />

How similar are all the other classes mechanically? Ignoring<br />

little details like brake gear <strong>and</strong> trucks that can be very easily<br />

changed/corrected by the modelers (even on a decorated model),<br />

there are only a few features of the car to be discussed. The G31<br />

<strong>and</strong> first two groups of G31A had the hold-down clips attached to<br />

the side panels of the car (in addition to the two at each end on<br />

the side stakes). The last group of G31A, 374950 – 375749, all<br />

the subsequent subclasses built new, <strong>and</strong> the G35 had the clips<br />

along the edge of the top chord as on the Tangent model. Retooling<br />

the body for the side-mounted clips would appear to be a significant<br />

undertaking/expense, <strong>and</strong> I frankly don’t know how it<br />

could be done to yield open clips, short of applying them as separate<br />

parts.<br />

(Left) G31B B-end showing well detailed brake gear <strong>and</strong> end lettering. (Right) Enlargement of the fine small lettering <strong>and</strong> the<br />

open hold-down clips.<br />

The Keystone Modeler 15 No. 72, <strong>Winter</strong> <strong>2010</strong>

On the other h<strong>and</strong>, the modeler could easily cut off the G31B<br />

top chord clips or remove the entire piece they are molded onto<br />

<strong>and</strong> replace it with a styrene strip. Although adding the clips by<br />

h<strong>and</strong> is a little tedious, doing it with a plastic-bodied car is the<br />

best case scenario. (See the G31C/E construction article in TKM<br />

Vol.17.)<br />

The G31C <strong>and</strong> G31E were riveted construction cars. I would<br />

not expect Tangent to do these cars as they are almost completely<br />

different from the tooling perspective <strong>and</strong> were the smallest<br />

groups of cars of the lot – not likely a good business decision for<br />

Tangent. Even from the modeler’s perspective, a better starting<br />

point to build either subclass would probably not be the G31B.<br />

Since the drop end doors are tooled as separate parts on the<br />

model, Tangent could very easily tool a new Pullman St<strong>and</strong>ard<br />

three-corrugation style door. With this new door <strong>and</strong> some minor<br />

changes to the painting details they could then produce cars<br />

matching the last group of G31A with the hold-down clips along<br />

the top chord. If a modeler then purchased the unpainted kit version<br />

of this car with the P.S. door, making the change to the holddown<br />

clip location would be all that is required to get the first<br />

two groups of G31A. This largest subclass of the lot would then<br />

be covered. There are no P.S. ends currently on the market so if<br />

Tangent does not tool one, the modeler would have to scratchbuild<br />

these parts to make the G31A. (Note that after a few<br />

years, the end doors on all these classes seemed to get mixed up<br />

due to repairs, so some G31A did eventually end up with G31B<br />

doors.)<br />

Similarly, the straight G31 could be made from the existing<br />

G31B body <strong>and</strong> end doors by making the change to the holddown<br />

clips. The only other part needed is a steel floor. Since this<br />

is also a separate part, it could be tooled by Tangent or built by<br />

the modeler to get a G31.<br />

The G31D has fixed ends, but is otherwise very similar to the<br />

G31B since ACF constructed both classes. It would appear that<br />

Tangent could accurately address this subclass by tooling just the<br />

new fixed end <strong>and</strong> changing the painting accordingly. The particularly<br />

advantage to building this car is that it opens the previously<br />

untouched market for the “skid <strong>and</strong> cover” cars which the<br />

PRR specially converted to haul steel coils <strong>and</strong> plates. The G31E<br />

<strong>and</strong> G31D were similarly equipped <strong>and</strong> were the PRR’s first large<br />

scale venture into this special equipment. If this subclass is not<br />

tooled, it still would not be a particularly difficult kitbash.<br />

Side view of G31B.<br />

The G35 differed from the G31B primarily in its top chord<br />

construction <strong>and</strong> some underframe details (that would be obscured<br />

by the weights in this G31B model). The cars were also<br />

built with three variations of flooring. Tooling the top chord<br />

changes might be messy, but it makes for a very simple kitbash<br />

from the existing car. I have already started that conversion, so<br />

buy some undecorated cars <strong>and</strong> get ready for the details in the<br />

next issue of TKM.<br />

Penn Central <strong>and</strong> Conrail modelers need G31-‘s as well, but<br />

most/many of the classes were modified in the late 1960’s to become<br />

new subclasses (see the table above) <strong>and</strong> some physical<br />

changes would be required beyond just paint <strong>and</strong> lettering. I am<br />

not fully familiar with all the changes, but I expect it to be a fairly<br />

tangled web. It may be quite unrealistic for Tangent to spend<br />

the money necessary to make the tooling changes required, so<br />

this is likely to be a project left to us modelers. We have a G31L<br />

conversion article already in pipeline for the next issue as well.<br />

Summary<br />

So to summarize: this G31B is an excellent model <strong>and</strong> goes a<br />

long way towards allowing a significant group of related cars to<br />

be modeled, compared to what was previously available (nothing).<br />

If Tangent will do the later paint schemes, tool the G31D<br />

fixed end <strong>and</strong>/or possibly the PS end door, we modelers would be<br />

in great shape. If they tool the skids <strong>and</strong> covers… wow.<br />

Bottom line here though is that we consumers need to show<br />

our support of their efforts by buying the products. Additionally,<br />

please contact Tangent <strong>and</strong> let them know what you’d like to see<br />

as this “marketing” information can be valuable to them in<br />

choosing where to direct any potential future energy regarding<br />

this project.<br />

References<br />

• The Keystone, December 1980, page 35, article <strong>and</strong> photographs.<br />

• Rails Northeast, November 1976, Circle Keystone painting &<br />

lettering diagram.<br />

• Railway Prototype Cyclopedia: RP CYC 19, Ed Hawkins, page<br />

113, G31- article, photos <strong>and</strong> data, (also similar cars on other<br />

roads).<br />

• Tangent Models website, http://tangentscalemodels.com, prototype<br />

information <strong>and</strong> photos.<br />

The Keystone Modeler 16 No. 72, <strong>Winter</strong> <strong>2010</strong>

Balanced Locomotive Roster<br />

for Operations on the Panh<strong>and</strong>le<br />

By Bill Neale<br />

An eastbound symbol freight moves through Steubenville, Ohio behind by M1A #6734.<br />

Many modelers like to put their models to work, doing in<br />

model form what their prototypes did. More than just circulating<br />

a train, prototype operation implies a purposeful use of the<br />

equipment that replicates the actions <strong>and</strong> events that might have<br />

taken place on the real PRR. Prototype operations provide a<br />

meaningful reason for each train, which enhances the experience<br />

of the operator. It affects the way we think about the trains we<br />

run <strong>and</strong> can increase our enjoyment of the fine equipment we<br />

create by putting the rolling stock into context. Of course not<br />

everyone enjoys operations <strong>and</strong> frankly not all operating sessions<br />

are enjoyable. However, I think many modelers of the<br />

PRR intend to have operating sessions even if that point is some<br />

distance in the future. They might find my experiences interesting.<br />

I model the PRR Panh<strong>and</strong>le in 1939, so only steam engines<br />

need apply for the front end of trains. Maybe it’s obvious, but<br />

which engines do what tasks? What are the limitations I have<br />

found putting together a roster to operate my railroad? Which<br />

br<strong>and</strong>s of models seem to work best for what service? At least<br />

once or twice during every operating session I hold, I am asked<br />

about the br<strong>and</strong> of locomotives, <strong>and</strong> what modifications I have<br />

done to get then to run nicely. Perhaps my experiences can help<br />

others, so I put together this synopsis of my approach to an engine<br />

roster, <strong>and</strong> related it to how I operate my section of the<br />

PRR. This is not a recitation of PRR practice; instead, it is focused<br />

on how to model operations on the PRR using today’s<br />

models.<br />

In the process of developing an operating scheme, some of<br />

the prototype operations of various trains were modified to fit<br />

the model. Over time, the make-up <strong>and</strong> importance of certain<br />

trains change. Maybe train PH-10 starts out as a hot-shot freight<br />

in the early 20 th century, degrades to a mixed freight in the<br />

1930’s, but becomes more important as traffic patterns shift<br />

again in the 1950’s. For model operations, I may choose to use<br />

PH-10 as a mixed freight, which may not be accurate for this<br />

train <strong>and</strong> time period, so please be cautious about taking the information<br />

in the modeling context <strong>and</strong> assuming it applies to the<br />

prototype PRR. In some cases I manufactured train numbers<br />

because I simply could not find the right information at the time.<br />

The Keystone Modeler 17 No. 72, <strong>Winter</strong> <strong>2010</strong>

(Top) The Steubenville Shifter behind a B6sb spots cars at<br />

the freight house. (Left) L1S #1122 drifts downgrade on<br />

PH-125. (Bottom left) An I1SA shoves hard against an N5B<br />

cabin car <strong>and</strong> a train of loaded H21A hoppers.<br />

Like most model railroads, my representation of the<br />

Panh<strong>and</strong>le is selectively compressed. I represent about 15-20<br />

miles of real track in three scale miles. My tracks are shorter<br />

<strong>and</strong> my grades are steeper than the prototype, but those compromises<br />

are very common on most model railroads. I have<br />

one main yard (Weirton Junction), one complex industrial<br />

area (Steubenville), <strong>and</strong> a multi-track mainline with a long<br />

2% grade that requires helpers. The operating pattern is<br />

based on many through trains interacting with the local facilities.<br />

I have substantial staging at both ends of the modeled<br />

section to support a large number of trains that roll across my<br />

section of the PRR.<br />

Let’s start with the through trains. The hottest trains on<br />

the railroad are powered by M-class engines. In 1939, the<br />

big 4-8-2 M1 <strong>and</strong> M1A Mountains were the most modern<br />

power available. These manifests are 20 to 25 cars long, <strong>and</strong><br />

consist of reefers, boxcars, <strong>and</strong> tank cars. My desire is to require<br />

a pusher if the train is more than about 22 cars. Manifests<br />

PH-10, VL-2, <strong>and</strong> JC-5 have BLI M1A power. CIN-1<br />

has a Westside M1A. The Westside has more pulling power<br />

than I like, so I keep it on the Westbound – down bound<br />

trains. That disguises the extra tractive effort this engine has.<br />

I also run a 30 car eastbound stock extra that is M1A powered.<br />

I intend to put a Sunset M1 (short tank) in service<br />

soon, as an alternative engine for any of these trains. However,<br />

the Broadway engines are the best for this service as<br />

they are reliable <strong>and</strong> pull just enough to occasionally need a<br />

pusher.<br />

The Keystone Modeler 18 No. 72, <strong>Winter</strong> <strong>2010</strong>

Trains PH-4 <strong>and</strong> PH-7, PH-11, <strong>and</strong> CIN-2 are symbol<br />

freights that are mixed in consist <strong>and</strong> do some work<br />

on the railroad. Often these trains will pick up or set off<br />

cars at Weirton, <strong>and</strong> a few trains also stop at Steubenville<br />

yard. I use I1’s, L1’s <strong>and</strong> sometimes N1’s, on<br />

these trains. The Precision Craft Models I1SA Decapod<br />

is one of the best plastic models done to date. However,<br />

in stock form, it did not pull sufficiently to meet the 20-<br />

22 criteria on the hill. I did some modifications to improve<br />

the pulling power <strong>and</strong> now they pull just fine. The<br />

N1’s are Westside models, <strong>and</strong> are some of the finest<br />

running five-axle brass engines ever made in my opinion.<br />

The N1’s required some TLC to straighten the<br />

valve gear <strong>and</strong> rods so they would run correctly.<br />

The PFM L1S is another nice running engine, but I<br />

found that a new NWSL gear box <strong>and</strong> can motor made it<br />

even better. The older Japanese built engines tend to<br />

have a sturdier frame <strong>and</strong> better running gear than later<br />

imports. I had to add weight to most of my brass engines<br />

to get them to pull better. However, I don’t want<br />

the L-class engine pulling more than the N-class, so balance<br />

<strong>and</strong> moderation are needed when setting up the engines.<br />

Casting an H6SB boiler out of depleted uranium<br />

so that it will drag 150 cars up the hill defeats the purpose<br />

of needing certain engines to do certain jobs.<br />

All along this part of the panh<strong>and</strong>le, small mines<br />

dotted the region in the 1930’s. I use PFM L1S locomotives<br />

to h<strong>and</strong>le the mine shifters along the mainline,<br />

one each way. These are trains PH-124 <strong>and</strong> PH-125<br />

(these are manufactured numbers but are within the<br />

scheme of train numbering that was used in the region).<br />

(Top right) H9S <strong>and</strong> B6SB yard shifters wait by the<br />

Weirton Yard Office. (Right) An I1SA backs down to<br />

an empty coal train in Weirton. (Bottom) The Weirton<br />

Shifter moves an N6B cabin car as a road freight<br />

rolls by.<br />

The Keystone Modeler 19 No. 72, <strong>Winter</strong> <strong>2010</strong>

(Above) The Steubenville Shifter, a B6SB 0-6-0, services Central Sewer Pipe <strong>and</strong> Supply Co. over some complex industrial trackage.<br />

(Below) A hard-working I1SA “Hippo” charges into Steubenville with a loaded coal train.<br />

The L1S locomotives operate exceptionally<br />

smoothly, so they make excellent<br />

engines to switch with, <strong>and</strong> they<br />

have enough muscle to h<strong>and</strong>le 20-25 coal<br />

loads on the hill. Maybe an I1 would be<br />

a better choice if there were more mines,<br />

or an H10S if the line were more level,<br />

however, the Mikado seems to have the<br />

right balance of power for this service.<br />

Coal service out of the Burgetts<br />

Branch is I1-powered. Because I want<br />

the Burgetts Branch Coaler to operate<br />

without the need of a helper, I used a<br />

PFM I1 on this train. The PFM has a<br />

Precision Scale gearbox <strong>and</strong> a can motor,<br />

so the operation is smooth <strong>and</strong> reliable.<br />

Extra weight was added to this engine to<br />

ensure it was sufficiently strong enough<br />

to h<strong>and</strong>le the eastbound (up bound) leg<br />

of its turn. On the prototype, coal from<br />

Burgettstown moved eastward. On my<br />

model, the coal moves down to Weirton,<br />

<strong>and</strong> empties go back up the hill to the<br />

Burgettstown mines.<br />

The Keystone Modeler 20 No. 72, <strong>Winter</strong> <strong>2010</strong>

(Top) K4s #439 on Train #412 paused in Steubenville next to a female admirer.<br />

(Bottom) K4s #1122 with a mate on Train #10 rolls through Bertha.<br />

Every day, a train load of steel products departs<br />

Weirton Yard for the east. Generally this consists of<br />

10-15 cars of plate steel, <strong>and</strong> 20-25 cars of rolled steel.<br />

The plate steel is heading for the Navy Yards on the<br />

East Coast. For this train, one or two PFM I1s are<br />

usually on the front end pulling <strong>and</strong> an I1 pusher is on<br />

the back end. Usually the pusher is a PFM Decapod,<br />

but lately I have been using a PCM Decapod very successfully.<br />

It gives enough push to get the train over<br />

the hill, without overpowering the back end of the<br />

train. Sometimes an N1S subs for one of the lead I1SA<br />

locomotives. In its modern configuration, this was the<br />