Terminal Box Controller - Siemens

Terminal Box Controller - Siemens

Terminal Box Controller - Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong><br />

Figu gu gure gu e 1. . <strong>Terminal</strong> l <strong>Box</strong> x Con on ontr<br />

troller. tr<br />

The <strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> (Figure 1) is an integral<br />

part of the APOGEE� Automation System. The<br />

controller provides high performance Direct Digital<br />

Control (DDC) technology for room temperature<br />

control in Variable Air Volume (VAV) systems. The<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> and related components<br />

provide a totally electronic control system. The<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> can operate independently,<br />

stand-alone or networked to perform complex HVAC<br />

control, monitoring and energy management functions<br />

without relying on a higher level processor. The totally<br />

electronic approach to temperature control includes<br />

the following features.<br />

Features<br />

� PID control of HVAC systems to minimize offset<br />

and maintain tighter set point control,<br />

� Unique control algorithms for specific applications,<br />

� Reports airflow in CFM (l/s),<br />

� HVAC diagnostics through communication with a<br />

Portable Operator's <strong>Terminal</strong> at a room sensor or<br />

any field panel,<br />

Technical Specification Sheet<br />

Rev. 7, October, 1998<br />

� Set points and control parameters assigned and<br />

changed using the Portable Operator's <strong>Terminal</strong>,<br />

� Electrically Erasable Programmable Read Only<br />

Memory (EEPROM) used for storing set points<br />

and control parameters�no battery backup<br />

required,<br />

� Returns from power failure without operator<br />

intervention,<br />

� Meets low duct static pressure requirements,<br />

� Uses proven APOGEE Automation System DDC<br />

architecture,<br />

� No calibration required, thereby reducing<br />

maintenance costs, and<br />

� Separate minimum and maximum air volume<br />

setting for heating and cooling modes.<br />

Applications<br />

Operating independently, or as a part of the APOGEE<br />

Automation System, the <strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> can<br />

control a variety of Variable Air Volume (VAV) pressure<br />

independent terminal box applications, including:<br />

� VAV Cooling Only,<br />

� VAV Cooling or Heating,<br />

� VAV with Hot Water Reheat (proportional),<br />

� VAV with Electric Reheat (one-, two-, or threestage),<br />

� VAV Fan Powered Series or Parallel with Hot<br />

Water Reheat, and<br />

� VAV Fan Powered Series or Parallel with Electric<br />

Reheat (one-, two-, or three-stage).<br />

Document No. 149-171P25 Page 1 of 5

Description<br />

The <strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> consists of a differential<br />

pressure transducer and an electronic controller<br />

assembly. An Autozero Module is available for<br />

mounting on the controller for those applications<br />

where uninterrupted airflow is necessary. A Pneumatic<br />

Transducer provides for control of pneumatic damper<br />

and valve actuators.<br />

Control algorithms are preprogrammed. The controller<br />

is ready to operate after selecting the application and<br />

assigning the unit's controller address with the<br />

Portable Operator's <strong>Terminal</strong>. If desired, the operator<br />

may use the Portable Operator's <strong>Terminal</strong> to adjust<br />

the air volume set points in CFM (l/s), room<br />

temperature set points and other parameters. The<br />

controller is designed for operation and modification<br />

without vendor assistance.<br />

Differential Pressure Transducer<br />

The averaging air velocity sensor (provided by the VAV<br />

terminal unit manufacturer) sends an average air<br />

velocity measurement of the duct air velocity to the<br />

controller. The air velocity sensor connects to the<br />

differential pressure transducer (which is mounted in<br />

the <strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong>) and measures the<br />

average differential pressure. The <strong>Terminal</strong> <strong>Box</strong><br />

<strong>Controller</strong> converts this value to actual airflow in CFM<br />

(l/s).<br />

Specifications<br />

Temperature Range 48�F to 112�F (9�C to 45�C)<br />

Measurement Range 0 to 4000 fpm (0 to 20 m/s)<br />

Measurement Resolution �4 fpm (�0.02 m/s)<br />

Measurement Accuracy*<br />

300 to 4000 fpm<br />

(1.5 to 20 m/s)<br />

200 to 300 fpm<br />

(1 to 1.5 m/s)<br />

�5% of actual reading<br />

+12% to -15% of actual<br />

reading<br />

Repeatability �8 fpm (0.04 m/s)<br />

*All l specifica ca cations ca s assume e an n un unadjusted un d flow w coe oe oeff oeff<br />

fficien ff en ent<br />

t of f 1.<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong><br />

This controller provides all wiring terminations: input/<br />

output, system and local communication and power.<br />

The cable from the room sensor connects to a RJ-11<br />

jack on the controller. All other connections are<br />

removable terminal blocks. The controller assembly is<br />

mounted on a plastic track that is mounted directly on<br />

the terminal box. An optional enclosure protects the<br />

controller assembly.<br />

The controller interfaces with the following external<br />

devices:<br />

� Averaging air velocity sensor provided by VAV<br />

terminal unit manufacturers,<br />

� Floating control valve and damper actuators,<br />

� Temperature sensors (room, duct, immersion, and<br />

outside air),<br />

� Portable Operator's <strong>Terminal</strong>,<br />

� APOGEE Automation System,<br />

� Digital input devices (dry contacts from motion<br />

sensors, alarm contacts), and<br />

� Digital output devices (fan, stages of electric heat).<br />

Specifications<br />

Power Requirements<br />

Operating Range<br />

Power Consumption<br />

Inputs<br />

Analog<br />

18 to 28 Vac 50 or 60 Hz<br />

3.5 VA (Nominal) to 5.0 VA<br />

(Peak) @ 24 Vac<br />

(plus loads)<br />

<strong>Siemens</strong> Building Technologies, Inc Page 2 of 5<br />

Digital<br />

1 room temperature sensor<br />

1 velocity sensor<br />

1 set point (optional)<br />

1 auxiliary temperature sensor<br />

2 dry contacts<br />

Outputs 6 DO 24 Vac optically isolated<br />

solid state switches @ 0.5 amp<br />

Controlled Temperature �1.5�F (0.9�C)<br />

Accuracy, Heating or<br />

Cooling<br />

Dimensions 4-1/8" W x 7-3/4" L x 1-1/2" H<br />

(105 mm x 197 mm x 38 mm)<br />

Weight approx. 3 lbs. (1.35 kg)<br />

Communications<br />

Remote<br />

Local<br />

Ambient Conditions<br />

Storage Temperature<br />

Operating<br />

Temperature<br />

Humidity Range<br />

Agency Listings<br />

UL Listing<br />

CSA Certified<br />

FCC Compliance<br />

LAN Trunk<br />

Portable Operator's <strong>Terminal</strong><br />

-20�F to 167�F (-29�C 75�C)<br />

32�F to 122�F (0�C to 50�C)<br />

10% to 95% (non-condensing)<br />

UL 916, PAZX,<br />

UL 864, UDTZ

Optional Accessories<br />

Autozero o Module<br />

The optional Autozero Module (Figure 2) is required<br />

when continuous operation at occupied flow is<br />

required for an area. The Autozero Module is<br />

connected to the air velocity inlet ports of the <strong>Terminal</strong><br />

<strong>Box</strong> <strong>Controller</strong> and provides periodic recalibration of<br />

the air velocity transducer without changing air volume<br />

being delivered to a room. This recalibration ensures<br />

long-term precise airflow delivery.<br />

Specifications<br />

Power Consumption 1.5 VA @ 24 Vac max.<br />

Dimensions 2-1/2" W x 2-1/2" H x 1"D<br />

(64 mm x 64 mm x 32)<br />

Weight 0.5 lb. (0.2 kg)<br />

Figu gu gure gu e 2. . Autozero o Module.<br />

Pneumatic Transducer<br />

The PTS Pneumatic Transducer (Figure 3) contains the<br />

transducers that provide the signal conversion from<br />

electronic to pneumatic. The module is piped to the<br />

pneumatic actuator and wired to the <strong>Terminal</strong> <strong>Box</strong><br />

<strong>Controller</strong>. This transducer provides for accurate<br />

control of pneumatic actuators for precise temperature<br />

and air volume control.<br />

Specifications<br />

Maximum Input Pressure 30 psi (207 kPa)<br />

Air Consumption 0 SCIM<br />

Power Consumption 4 VA @ 24 Vac max.<br />

Dimensions 3-1/2" L x 2-1/4" W x 1-1/2" H<br />

(87 mm x 57 mm x 38 mm)<br />

Weight 9 oz (0.3 kg)<br />

Figu gu gure gu e e 3. . PTS S Pneu neu neumatic neu c Transducer.<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> Communication<br />

Up to 32 <strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong>s or other <strong>Terminal</strong><br />

Equipment <strong>Controller</strong>s can be connected to each of<br />

the three field panel LAN trunks. Communication with<br />

the <strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> can be initiated from any<br />

system field panel on the system network. The<br />

system network does not require additional hardware<br />

to connect <strong>Terminal</strong> Equipment <strong>Controller</strong>s. When<br />

<strong>Terminal</strong> Equipment <strong>Controller</strong>s are wired to a field<br />

panel, features such as energy management<br />

programs, alarm reporting, centralized control,<br />

modification of the system database, system-wide<br />

troubleshooting, and the global commanding of<br />

devices are available to them.<br />

Portable Operator's <strong>Terminal</strong><br />

The DOS-based laptop computer serving as the<br />

Portable Operator's <strong>Terminal</strong> can communicate with<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong>s or any field panel. The<br />

terminal connects to the controller, the room<br />

temperature sensor associated with the <strong>Terminal</strong> <strong>Box</strong><br />

<strong>Controller</strong> or field panel. The terminal can be used to<br />

remotely adjust air volume settings or temperature set<br />

points, to troubleshoot and start-up the system. When<br />

connected to the RS-232 port of a field panel, the<br />

terminal provides system-wide communication. The<br />

terminal uses full English language for all functions,<br />

eliminating the need to remember coded commands.<br />

<strong>Siemens</strong> Building Technologies, Inc. Page 3 of 5

NT0254R1<br />

Third<br />

Party<br />

Devices<br />

¥ Variable<br />

Frequency<br />

Drive<br />

Up to 4 Building<br />

Level Networks<br />

FLN FLN 1 FLN 2 FLN 3 BLN BLN Status Battery<br />

Transmit Receive Receive Receive Receive Transmit<br />

Low<br />

Up to<br />

3 Floor Level<br />

Networks<br />

FLOOR<br />

LEVEL<br />

NETWORK<br />

CONTROLLER<br />

INSIGHT<br />

GRAPHIC<br />

OPERATOR<br />

WORKSTATION<br />

Base or Advanced<br />

PORTABLE<br />

OPERATOR<br />

TERMINAL<br />

FUME HOOD<br />

CONTROLLER<br />

OPERATOR<br />

DISPLAY<br />

PANEL<br />

Figu gu gure gu e 3. . Port rt rtable rt e Operator’s s <strong>Terminal</strong> l Sample e Display.<br />

MANAGEMENT LEVEL NETWORK TCP/IP ETHERNET: Nominal 25 Insight Stations Speed: 10 M bps<br />

MODULAR<br />

EQUIPMENT<br />

CONTROLLER<br />

FUME HOOD<br />

MONITOR<br />

REPORT<br />

PRINTER<br />

BUILDING LEVEL NETWORK Peer To Peer Network: Up to 100 Nodes Per Network-Speed: 9600-115K bp<br />

MODULAR<br />

BUILDING<br />

CONTROLLERS<br />

LAB ROOM<br />

CONTROLLER<br />

<strong>Siemens</strong> Building Technologies, Inc. Page 4 of 5<br />

LED 4<br />

LED 5<br />

LED 6<br />

LED 7<br />

LED 8<br />

LED 9<br />

LED 2 LED 3<br />

TX<br />

RX TX<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16<br />

TERMINAL<br />

EQUIPMENT<br />

CONTROLLER<br />

INSIGHT<br />

With Dial Up<br />

Option to MLN<br />

and/or BLN<br />

Heat Pump<br />

Unit Vent<br />

Unit Conditioner<br />

<strong>Terminal</strong> <strong>Box</strong><br />

Constant Volume<br />

Dual Duct-1 AVS<br />

Dual Duct-2 AVS<br />

Room Pressurization<br />

Up to<br />

3 Floor Level<br />

Networks<br />

FLOOR LEVEL NETWORK Standalone DDC Control Network: Up to 32 Devices Per Network<br />

DIGITAL<br />

ENERGY<br />

MONITOR<br />

(ELECTRICAL)<br />

DI1 11<br />

12 DI5<br />

13<br />

14 DI5<br />

15<br />

16 DI5<br />

1 2<br />

DI2 3 4<br />

DI3 5 6<br />

DI4 7 C 57<br />

DO25 NO 58<br />

9<br />

DI5<br />

NC 59<br />

10<br />

C 60<br />

DO26 NO 61<br />

NC 62<br />

C 63<br />

DO27 NO 64<br />

NC 65<br />

8<br />

C 66<br />

DO28 NO 67<br />

NC 68<br />

C 69<br />

DO29 NO 70<br />

NC 71<br />

AO13<br />

25 +<br />

C 72<br />

17 + 26 -<br />

AO9 DO30 NO 73<br />

18 -<br />

AO14<br />

27 +<br />

NC 74<br />

19 + 28 -<br />

AO10 C 75<br />

20 -<br />

AO15<br />

29 +<br />

DO31 NO 76<br />

AO11<br />

21 + 30 -<br />

NC 77<br />

22 - 31 +<br />

AO12<br />

23 +<br />

AO16 C 78<br />

32 -<br />

DO32 NO 79<br />

24 -<br />

NC 80<br />

49 53<br />

50 54<br />

51 55<br />

+ 24 V<br />

52 56<br />

SHIELD<br />

41 +<br />

AI21<br />

33 +<br />

42 -<br />

AI17 34 -<br />

43 +<br />

AI22<br />

35 +<br />

44 -<br />

AI18 36 -<br />

45 +<br />

AI23<br />

37 +<br />

46 -<br />

AI19 38 -<br />

47 +<br />

AI24<br />

39 +<br />

48 -<br />

BLN EXP<br />

AI20 40 -<br />

STATUS TX TX<br />

BLN EXP<br />

MODEM BATT RX RX<br />

STANDALONE<br />

CONTROL UNIT<br />

72 F<br />

DIGITAL<br />

ROOM<br />

SENSOR<br />

REMOTE<br />

BUILDING<br />

CONTROLLER<br />

To<br />

INSIGHT<br />

TO INTEGRATION SYSTEMS<br />

INCLUDING:<br />

Lighting<br />

Fire and Life Safety<br />

Access and Security<br />

Power Monitoring<br />

Programmable Logic Control<br />

Bac Net<br />

LON Talk<br />

HVAC Devices<br />

Other Building Automation<br />

Systems<br />

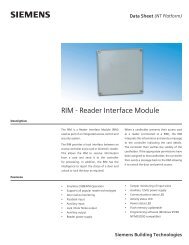

Figu gu gure gu e e 4. . . APOGEE E E Automation on on Sys ys ystem ys m Architecture e e fr from fr m m Siemen en ens ens<br />

s Buil il ilding il ng ng Techn hn hnolog hn og ogies, og , , Inc, , , Landis s s Division.

Product Ordering Information<br />

Description on Product t Part rt Numbers<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> 540-100<br />

<strong>Terminal</strong> <strong>Box</strong> <strong>Controller</strong> with Autozero Module 540-200<br />

Pneumatic Transducer PTS4<br />

Document Ordering Information<br />

Specification on Shee hee heet/App hee pp pplica pp ca cation ca on Bull ll lletin ll<br />

Documen en ent en t Part rt Number<br />

Room Temperature Sensors – Series 1000 149-312P25<br />

Duct Sensor 149-134P25<br />

Electronic Damper Actuator<br />

Powers Electronic Valve Actuators:<br />

155-114 (SQR 81.1) or 155-123 (EA 349)<br />

VE 339 2-Way Valve<br />

155-120<br />

VE 339 3-Way Valve<br />

155-121<br />

VE VMP<br />

155-116<br />

Electronic Retrofit Actuator<br />

155-122<br />

Information in this document is based on specifications believed correct at the time of publication. The right is reserved to make changes as design<br />

improvements are introduced. APOGEE is a trademark of <strong>Siemens</strong> Building Technologies, Inc. © 1998 <strong>Siemens</strong> Building Technologies, Inc.<br />

Siemen en ens<br />

s Buil il ilding il ng ng Techn hn hnolog hn og ogies, og , , Inc.<br />

Landis Division<br />

1000 Deerfield Parkway<br />

Buffalo Grove, IL 60089-4513<br />

Printed in the U.S.A. (origin)<br />

Page 5 of 5