Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Pads<br />

HARDINGE ® "AF" MASTER FEED FINGER PADS<br />

© <strong>Hardinge</strong> <strong>Inc</strong>., 2003 All specifications are subject to change without notice.<br />

"AF" Master Feed Finger Pads<br />

For master feed finger part numbers see chapters 1 and 2, listed by manufacturer<br />

or use the Cross Reference at the end of this chapter.<br />

Chapter 3<br />

Page 121<br />

The <strong>Hardinge</strong> style "AF" feed finger is versatile, adjusting quickly and easily to the tension you need. The style "AF" feed finger<br />

uses inexpensive pads which are readily available from stock. Each master feed finger includes a threaded locking cap which<br />

rotates to adjust in five- to seven-pound increments to increase or decrease tension. For thin-wall tubing and delicate stock,<br />

extremely light tension can be achieved.<br />

Because the style "AF" master feed finger can be adjusted to hold greater variations of bar stock sizes, you'll need to purchase<br />

fewer pads than with most other types of master feed fingers. Pads, which are sold separately and are required with each master,<br />

are held securely in place without screws. Guide bushings are sold separately and are recommended to minimize bar whip.<br />

The benefits of "AF" feed fingers include:<br />

Dependability. The feed bushings control bar whip to minimize feed "hang-ups" and allow a better finish on the part being<br />

machined.<br />

Versatility. A variety of inexpensive pads can be used to adjust to different bar stock diameters. A full 1 ⁄32" adjustment can be<br />

achieved from the rated size down. This eliminates the need for decimal/millimeter pads and pads in 1 ⁄64" increments.<br />

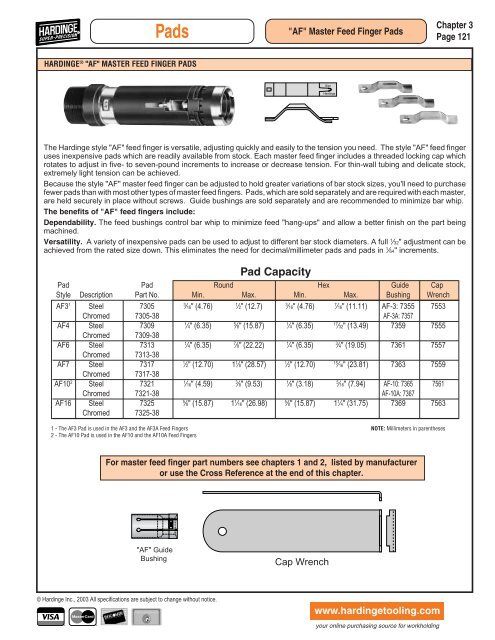

Pad Pad Round Hex Guide Cap<br />

Style Description Part No. Min. Max. Min. Max. Bushing Wrench<br />

AF31 Steel 7305 3<br />

⁄16" (4.76) 1 ⁄2" (12.7) 3<br />

⁄16" (4.76) 7<br />

⁄16" (11.11) AF-3: 7355 7553<br />

Chromed 7305-38 AF-3A: 7357<br />

AF4 Steel 7309 1 ⁄4" (6.35) 5 ⁄8" (15.87) 1 ⁄4" (6.35) 17<br />

⁄32" (13.49) 7359 7555<br />

Chromed 7309-38<br />

AF6 Steel 7313 1 ⁄4" (6.35) 7 ⁄8" (22.22) 1 ⁄4" (6.35) 3 ⁄4" (19.05) 7361 7557<br />

Chromed 7313-38<br />

AF7 Steel 7317 1 ⁄2" (12.70) 1 1 ⁄8" (28.57) 1 ⁄2" (12.70) 15<br />

⁄16" (23.81) 7363 7559<br />

Chromed 7317-38<br />

AF102 Pad Capacity<br />

Steel 7321 1<br />

⁄16" (4.59) 3 ⁄8" (9.53) 1 ⁄8" (3.18) 5<br />

⁄16" (7.94) AF-10: 7365 7561<br />

Chromed 7321-38 AF-10A: 7367<br />

AF16 Steel 7325 5 ⁄8" (15.87) 1 1 ⁄16" (26.98) 5 ⁄8" (15.87) 1 1 ⁄4" (31.75) 7369 7563<br />

Chromed 7325-38<br />

1 - The AF3 Pad is used in the AF3 and the AF3A Feed Fingers<br />

2 - The AF10 Pad is used in the AF10 and the AF10A Feed Fingers<br />

"AF" Guide<br />

Bushing<br />

Cap Wrench<br />

NOTE: Millimeters in parentheses