Chapter 3 - Rolling of metals

Chapter 3 - Rolling of metals

Chapter 3 - Rolling of metals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

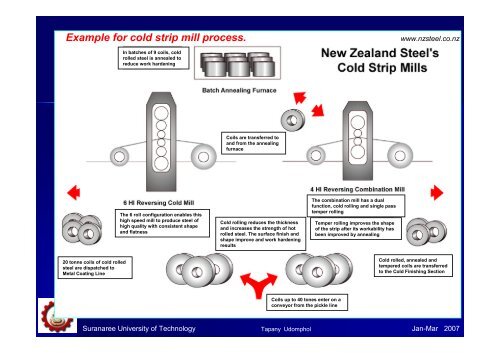

Example for cold strip mill process. www.nzsteel.co.nz<br />

20 tonne coils <strong>of</strong> cold rolled<br />

steel are dispatched to<br />

Metal Coating Line<br />

In batches <strong>of</strong> 9 coils, cold<br />

rolled steel is annealed to<br />

reduce work hardening<br />

The 6 roll configuration enables this<br />

high speed mill to produce steel <strong>of</strong><br />

high quality with consistent shape<br />

and flatness Cold rolling mill<br />

Coils are transferred to<br />

and from the annealing<br />

furnace<br />

Cold rolling reduces the thickness<br />

and increases the strength <strong>of</strong> hot<br />

rolled steel. The surface finish and<br />

shape improve and work hardening<br />

results<br />

Coils up to 40 tones enter on a<br />

conveyor from the pickle line<br />

The combination mill has a dual<br />

function, cold rolling and single pass<br />

temper rolling<br />

Temper rolling improves the shape<br />

<strong>of</strong> the strip after its workability has<br />

been improved by annealing<br />

Cold rolled, annealed and<br />

tempered coils are transferred<br />

to the Cold Finishing Section<br />

Suranaree University <strong>of</strong> Technology Tapany Udomphol<br />

Jan-Mar 2007