English edition - Buchen UmweltService GmbH

English edition - Buchen UmweltService GmbH

English edition - Buchen UmweltService GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INNOVATION<br />

Two technical innovations from the <strong>Buchen</strong> Group, the environment-friendly cleaning technology “Low Emission<br />

Cleaning” and the Spiderjet, a technology for the automatic removal of paint, were subject to practice tests within<br />

the scope of the pilot projects in tight cooperation with the internationally active chemical company Dow in Stade,<br />

found as plausible and have been in use since then. The <strong>Buchen</strong> Group received a “Technology Center Award” from<br />

Dow for both technical developments.<br />

Environment-friendly cleaning of heat exchangers<br />

LOW EMISSION CLEANING<br />

For the interior cleaning of heat exchangers with high<br />

pressure devices, considerably noise emissions are<br />

caused through exiting chemical product remains and<br />

through emissions. In tight cooperation with Dow, the<br />

<strong>Buchen</strong> Group has developed the innovative cleaning<br />

technology “Low Emission Cleaning”, where, in addition<br />

to the standard equipment for heat exchanger<br />

cleaning with high pressurized water, a special absorber<br />

has been used as well.<br />

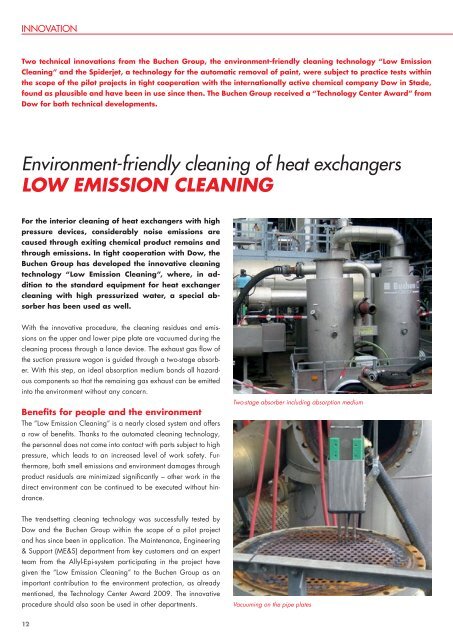

With the innovative procedure, the cleaning residues and emissions<br />

on the upper and lower pipe plate are vacuumed during the<br />

cleaning process through a lance device. The exhaust gas flow of<br />

the suction pressure wagon is guided through a two-stage absorber.<br />

With this step, an ideal absorption medium bonds all hazardous<br />

components so that the remaining gas exhaust can be emitted<br />

into the environment without any concern.<br />

Benefits for people and the environment<br />

The “Low Emission Cleaning” is a nearly closed system and offers<br />

a row of benefits. Thanks to the automated cleaning technology,<br />

the personnel does not come into contact with parts subject to high<br />

pressure, which leads to an increased level of work safety. Furthermore,<br />

both smell emissions and environment damages through<br />

product residuals are minimized significantly – other work in the<br />

direct environment can be continued to be executed without hindrance.<br />

The trendsetting cleaning technology was successfully tested by<br />

Dow and the <strong>Buchen</strong> Group within the scope of a pilot project<br />

and has since been in application. The Maintenance, Engineering<br />

& Support (ME&S) department from key customers and an expert<br />

team from the Allyl-Epi-system participating in the project have<br />

given the “Low Emission Cleaning” to the <strong>Buchen</strong> Group as an<br />

important contribution to the environment protection, as already<br />

mentioned, the Technology Center Award 2009. The innovative<br />

procedure should also soon be used in other departments.<br />

12<br />

Two-stage absorber including absorption medium<br />

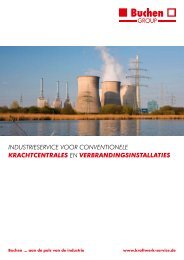

Vacuuming on the pipe plates