English edition - Buchen UmweltService GmbH

English edition - Buchen UmweltService GmbH

English edition - Buchen UmweltService GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

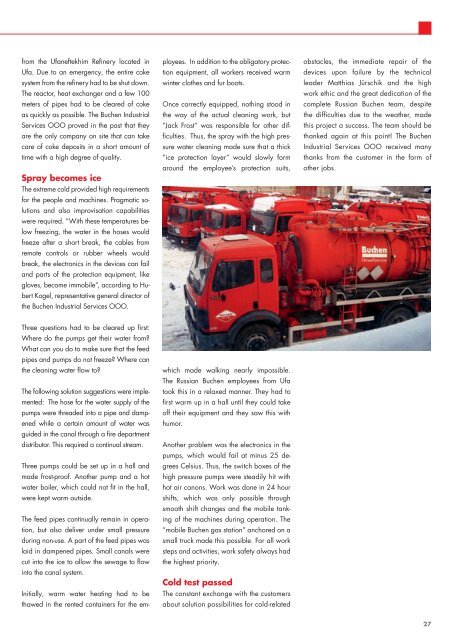

from the Ufaneftekhim Refinery located in<br />

Ufa. Due to an emergency, the entire coke<br />

system from the refinery had to be shut down.<br />

The reactor, heat exchanger and a few 100<br />

meters of pipes had to be cleared of coke<br />

as quickly as possible. The <strong>Buchen</strong> Industrial<br />

Services OOO proved in the past that they<br />

are the only company on site that can take<br />

care of coke deposits in a short amount of<br />

time with a high degree of quality.<br />

Spray becomes ice<br />

The extreme cold provided high requirements<br />

for the people and machines. Pragmatic solutions<br />

and also improvisation capabilities<br />

were required. “With these temperatures below<br />

freezing, the water in the hoses would<br />

freeze after a short break, the cables from<br />

remote controls or rubber wheels would<br />

break, the electronics in the devices can fail<br />

and parts of the protection equipment, like<br />

gloves, become immobile”, according to Hubert<br />

Kogel, representative general director of<br />

the <strong>Buchen</strong> Industrial Services OOO.<br />

Three questions had to be cleared up first:<br />

Where do the pumps get their water from?<br />

What can you do to make sure that the feed<br />

pipes and pumps do not freeze? Where can<br />

the cleaning water flow to?<br />

The following solution suggestions were implemented:<br />

The hose for the water supply of the<br />

pumps were threaded into a pipe and dampened<br />

while a certain amount of water was<br />

guided in the canal through a fire department<br />

distributor. This required a continual stream.<br />

Three pumps could be set up in a hall and<br />

made frost-proof. Another pump and a hot<br />

water boiler, which could not fit in the hall,<br />

were kept warm outside.<br />

The feed pipes continually remain in operation,<br />

but also deliver under small pressure<br />

during non-use. A part of the feed pipes was<br />

laid in dampened pipes. Small canals were<br />

cut into the ice to allow the sewage to flow<br />

into the canal system.<br />

Initially, warm water heating had to be<br />

thawed in the rented containers for the em-<br />

ployees. In addition to the obligatory protection<br />

equipment, all workers received warm<br />

winter clothes and fur boots.<br />

Once correctly equipped, nothing stood in<br />

the way of the actual cleaning work, but<br />

“Jack Frost” was responsible for other difficulties.<br />

Thus, the spray with the high pressure<br />

water cleaning made sure that a thick<br />

“ice protection layer” would slowly form<br />

around the employee’s protection suits,<br />

which made walking nearly impossible.<br />

The Russian <strong>Buchen</strong> employees from Ufa<br />

took this in a relaxed manner. They had to<br />

first warm up in a hall until they could take<br />

off their equipment and they saw this with<br />

humor.<br />

Another problem was the electronics in the<br />

pumps, which would fail at minus 25 degrees<br />

Celsius. Thus, the switch boxes of the<br />

high pressure pumps were steadily hit with<br />

hot air canons. Work was done in 24 hour<br />

shifts, which was only possible through<br />

smooth shift changes and the mobile tanking<br />

of the machines during operation. The<br />

“mobile <strong>Buchen</strong> gas station” anchored on a<br />

small truck made this possible. For all work<br />

steps and activities, work safety always had<br />

the highest priority.<br />

Cold test passed<br />

The constant exchange with the customers<br />

about solution possibilities for cold-related<br />

obstacles, the immediate repair of the<br />

devices upon failure by the technical<br />

leader Matthias Jürschik and the high<br />

work ethic and the great dedication of the<br />

complete Russian <strong>Buchen</strong> team, despite<br />

the difficulties due to the weather, made<br />

this project a success. The team should be<br />

thanked again at this point! The <strong>Buchen</strong><br />

Industrial Services OOO received many<br />

thanks from the customer in the form of<br />

other jobs.<br />

27