English edition - Buchen UmweltService GmbH

English edition - Buchen UmweltService GmbH

English edition - Buchen UmweltService GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DOWN<br />

L FOR BUCHEN<br />

high head of the FCC system was separated<br />

by our cold welding specialists with the<br />

help of the automated <strong>Buchen</strong> cold welding<br />

process and lifted with a special 1,800 ton<br />

crane. The dome was then safely cleaned<br />

and improved in order to be able to be<br />

setup again precisely with the crane.<br />

Around 700 apparatuses like heat exchangers,<br />

columns, air coolers, containers, filters<br />

and reactors were cleaned in record time<br />

by up to 300 employees from the <strong>Buchen</strong><br />

Group between the middle of February<br />

and end of March. The focus here was<br />

always on the optimal and goal-oriented<br />

application of specialized technology and<br />

qualified personnel under compliance with<br />

the strictest safety measures for people and<br />

environment.<br />

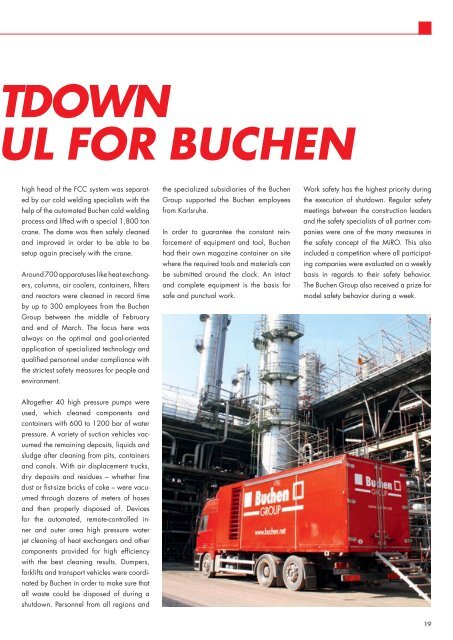

Altogether 40 high pressure pumps were<br />

used, which cleaned components and<br />

containers with 600 to 1200 bar of water<br />

pressure. A variety of suction vehicles vacuumed<br />

the remaining deposits, liquids and<br />

sludge after cleaning from pits, containers<br />

and canals. With air displacement trucks,<br />

dry deposits and residues – whether fine<br />

dust or fist-size bricks of coke – were vacuumed<br />

through dozens of meters of hoses<br />

and then properly disposed of. Devices<br />

for the automated, remote-controlled inner<br />

and outer area high pressure water<br />

jet cleaning of heat exchangers and other<br />

components provided for high efficiency<br />

with the best cleaning results. Dumpers,<br />

forklifts and transport vehicles were coordinated<br />

by <strong>Buchen</strong> in order to make sure that<br />

all waste could be disposed of during a<br />

shutdown. Personnel from all regions and<br />

the specialized subsidiaries of the <strong>Buchen</strong><br />

Group supported the <strong>Buchen</strong> employees<br />

from Karlsruhe.<br />

In order to guarantee the constant reinforcement<br />

of equipment and tool, <strong>Buchen</strong><br />

had their own magazine container on site<br />

where the required tools and materials can<br />

be submitted around the clock. An intact<br />

and complete equipment is the basis for<br />

safe and punctual work.<br />

Work safety has the highest priority during<br />

the execution of shutdown. Regular safety<br />

meetings between the construction leaders<br />

and the safety specialists of all partner companies<br />

were one of the many measures in<br />

the safety concept of the MiRO. This also<br />

included a competition where all participating<br />

companies were evaluated on a weekly<br />

basis in regards to their safety behavior.<br />

The <strong>Buchen</strong> Group also received a prize for<br />

model safety behavior during a week.<br />

19