You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CONTENTS<br />

– Contents 3<br />

Chapter 1:<br />

Features 4<br />

– Pipe system <strong>aquatherm</strong> <strong>ISO</strong> 5<br />

Fields of application<br />

– Medium pipes 6-8<br />

Material<br />

Environment<br />

Use of metal deactivators<br />

System advantages<br />

fusiotherm ® <strong>ISO</strong>-faser composite<br />

pipe SDR 7.4<br />

climatherm <strong>ISO</strong>-faser<br />

composite pipe SDR 11<br />

climatherm OT <strong>ISO</strong>-faser<br />

composite pipe SDR 11<br />

Dimensions<br />

Permissible working pressure<br />

– Insulation 9<br />

Material<br />

Material parameters<br />

– Casing pipes 10<br />

Material<br />

Material parameters<br />

– <strong>aquatherm</strong> <strong>ISO</strong> data sheet 11<br />

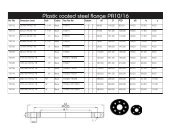

Dimensions<br />

Chapter 2:<br />

Processing 12<br />

– Part A: Assembly of welding tools 12-15<br />

Part A: Tools and accessories<br />

Part A: Heating-up phase / Handling<br />

Part A: Standards and data<br />

– Part B: Notes for preparation 16-18<br />

– Part C: Heating-element socket welding<br />

with the manual welding device<br />

– Part C: Heating-element socket welding with 20-21<br />

manual welding device and electric welding jig<br />

– Part C: Heating-element socket welding with 22-23<br />

the welding machine<br />

– Part C: Heating-element butt-welding with 24-25<br />

the butt-welding machine type: Light<br />

Chapter 3:<br />

Assembly 26<br />

– Product specification 26<br />

Storage and safety guidelines / Equipment list<br />

for processing<br />

– Shrink sleeve system 27<br />

– Backfilling trench / Flame intensity 28<br />

CONTENTS<br />

– Casing preparation / 29<br />

Insulation half-shell installation<br />

– Marking of shrink sleeve position 30<br />

– Preparation of the seal areas 31<br />

Assembly of melting adhesive strips<br />

– Assembly of casing shrink film 32<br />

– Positioning of the shrink sleeve 33<br />

– Shrinking sequence / 34<br />

Quality control - „finger test“ /<br />

Processing of the tension tape<br />

– Quality control by „finger tip test“ 35<br />

Final control<br />

Recommendations<br />

Elements / System review /<br />

Available articles<br />

– Applications 36<br />

Chapter 4:<br />

Notes 37-38<br />

3