Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

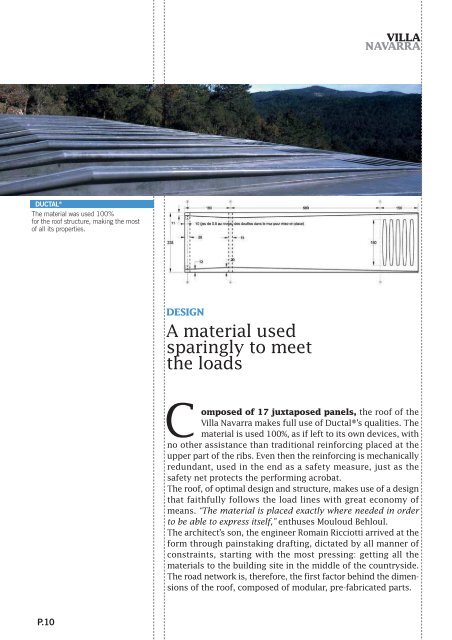

DUCTAL ®<br />

The material was used 100%<br />

for the roof structure, making the most<br />

of all its properties.<br />

P.10<br />

DESIGN<br />

A material used<br />

sparingly to meet<br />

the loads<br />

VILLA<br />

NAVARRA<br />

Composed of 17 juxtaposed panels, the roof of the<br />

<strong>Villa</strong> <strong>Navarra</strong> makes full use of Ductal®’s qualities. The<br />

material is used 100%, as if left to its own devices, with<br />

no other assistance than traditional reinforcing placed at the<br />

upper part of the ribs. Even then the reinforcing is mechanically<br />

redundant, used in the end as a safety measure, just as the<br />

safety net protects the performing acrobat.<br />

The roof, of optimal design and structure, makes use of a design<br />

that faithfully follows the load lines with great economy of<br />

means. “The material is placed exactly where needed in order<br />

to be able to express itself,” enthuses Mouloud Behloul.<br />

The architect’s son, the engineer Romain Ricciotti arrived at the<br />

form through painstaking drafting, dictated by all manner of<br />

constraints, starting with the most pressing: getting all the<br />

materials to the building site in the middle of the countryside.<br />

The road network is, therefore, the first factor behind the dimensions<br />

of the roof, composed of modular, pre-fabricated parts.<br />

The final module is a panel measuring 9.25 m x 2.35 m, whose<br />

design is suitable for the spreading of the load in the planned<br />

structure, which is made up of a plate of a constant thickness<br />

edged by two lateral progressive inertia ribs, higher at the<br />

supports and becoming gradually thinner, meeting the thickness<br />

of the plate at the far ends. The ends have a clever open<br />

design to save weight and to allow the light to enter this part<br />

opened up as a porch. “The design produces an optimal<br />

mechanic, which is not without similarities to steel forms, comprising<br />

a web, wings or a purlin,” comments Romain Ricciotti, “and<br />

this form is not the result of any particular design feature.”<br />

A specialist in mathematical modelling, the young civil works<br />

engineer almost goes on the defensive about having held the<br />

pencil. “Structures behave as conceived and calculated,” points<br />

out Mouloud Behloul, who accepts the pre-defining of the shape,<br />

namely a plate edged by lateral ribs, “in as much as a structure<br />

never imposes itself and is always a matter of choice,” so says<br />

the engineer!<br />

The decisive factors behind the size of the roof panel are, therefore,<br />

its own weight, the allowable overload due to weather,<br />

wind resistance and heat expansion, which it is likely to suffer<br />

in a region subject to high amplitudes linked to sunshine and<br />

high winds. These amplitudes are all the greater, as the surface<br />

of the un-insulated roof is left bare, benefiting from the finished<br />

look and the waterproof qualities of the Ductal® panels.<br />

PRE-CASTED MODULES<br />

The extremity of the modules<br />

is open to add weight and make use the<br />

light in this part with an open top.<br />

“The aim to<br />

reduce the impact<br />

of the villa<br />

on the site led<br />

to the use of an<br />

ultra-thin roof<br />

made of Ductal®<br />

which comes<br />

to a thickness of<br />

3 cm at its tip.”<br />

P.11