Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

03<br />

04<br />

08<br />

10<br />

13<br />

17<br />

P.02<br />

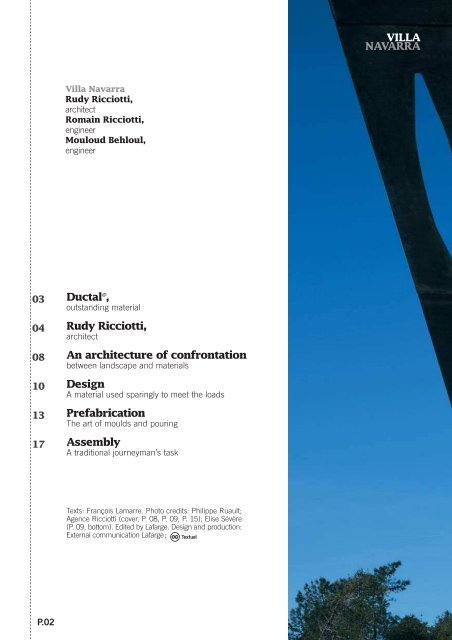

<strong>Villa</strong> <strong>Navarra</strong><br />

Rudy Ricciotti,<br />

architect<br />

Romain Ricciotti,<br />

engineer<br />

Mouloud Behloul,<br />

engineer<br />

Ductal ® ,<br />

outstanding material<br />

Rudy Ricciotti,<br />

architect<br />

An architecture of confrontation<br />

between landscape and materials<br />

Design<br />

A material used sparingly to meet the loads<br />

Prefabrication<br />

The art of moulds and pouring<br />

Assembly<br />

A traditional journeyman’s task<br />

Texts: François Lamarre. Photo credits: Philippe Ruault;<br />

Agence Ricciotti (cover, P. 08, P. 09, P. 15); Elise Sévère<br />

(P. 09, bottom). Edited by <strong>Lafarge</strong>. Design and production:<br />

External communication <strong>Lafarge</strong>;<br />

VILLA<br />

NAVARRA<br />

DUCTAL ® ,<br />

OUTSTANDING MATERIAL FOR<br />

AN ARCHITECTURE OF EXCEPTION<br />

Developed by <strong>Lafarge</strong>, Ductal ® ultra high performance fibre reinforced<br />

concrete has innovative properties which pave the way for architectural<br />

designs hitherto unheard of.<br />

Its special composition gives it exceptional compressive strength,<br />

six to eight times greater than normal concrete.<br />

For structural applications, the use of special metal fibres provides<br />

Ductal ® with ductile properties, hence the name: with flexural strength ten<br />

times that of standard concrete, it can undergo substantial working stress<br />

without shearing.<br />

Ductal ® is easy to use, and provides an infinite number of new<br />

possibilities. Its fluidity and the absence of conventional aggregates<br />

in its composition enable it to adapt to the slightest detail in the formwork<br />

and allow for the creation of extremely fine and thin forms that cannot<br />

be obtained with a traditional concrete structure. The resulting surfaces<br />

reproduce, with exceptional precision, the texture of the moulds.<br />

The surface appearance can thus adopt a range of aspects, and when<br />

polished, it can even imitate stone or marble, providing a remarkable<br />

aesthetic finish.<br />

Ductal ® is resistant to corrosion, abrasion, pollution, bad weather or<br />

shocks, making for a life span 2 to 3 times longer than that of<br />

conventional concrete.<br />

Ductal ® is an integral part of a sustainable development approach.<br />

Its mechanical performance, combined with its durability, its aesthetic<br />

qualities and its high compactness help reduce the environmental impact<br />

of construction, throughout the building's life cycle. Ductal ® requires<br />

half as much material and energy and results in CO2 emissions of up<br />

to half those induced by conventional concrete. It features the thermal<br />

mass capacity of concrete which, when optimized, helps reduce energy<br />

expenses when the building is in service.<br />

All these features make Ductal ® a high performance and sustainable<br />

construction material capable of the most impressive of architectural feats.<br />

P.03