Betriebsanleitung Operating Instructions Instructions de ... - Andritz

Betriebsanleitung Operating Instructions Instructions de ... - Andritz

Betriebsanleitung Operating Instructions Instructions de ... - Andritz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Series HP 45<br />

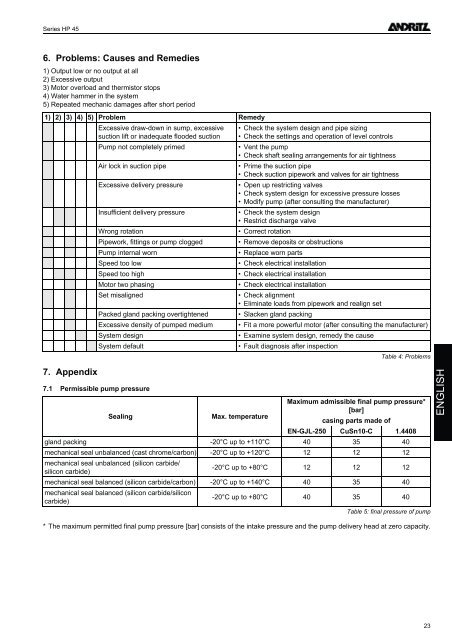

6. Problems: Causes and Remedies<br />

1) Output low or no output at all<br />

2) Excessive output<br />

3) Motor overload and thermistor stops<br />

4) Water hammer in the system<br />

5) Repeated mechanic damages after short period<br />

1) 2) 3) 4) 5) Problem Remedy<br />

Excessive draw-down in sump, excessive<br />

suction lift or ina<strong>de</strong>quate floo<strong>de</strong>d suction<br />

Pump not completely primed<br />

Air lock in suction pipe<br />

Excessive <strong>de</strong>livery pressure<br />

Insufficient <strong>de</strong>livery pressure<br />

Wrong rotation<br />

Pipework, fittings or pump clogged<br />

Pump internal worn<br />

Speed too low<br />

Speed too high<br />

Motor two phasing<br />

Set misaligned<br />

Packed gland packing overtightened<br />

Excessive <strong>de</strong>nsity of pumped medium<br />

System <strong>de</strong>sign<br />

System <strong>de</strong>fault<br />

• Check the system <strong>de</strong>sign and pipe sizing<br />

• Check the settings and operation of level controls<br />

• Vent the pump<br />

• Check shaft sealing arrangements for air tightness<br />

• Prime the suction pipe<br />

• Check suction pipework and valves for air tightness<br />

• Open up restricting valves<br />

• Check system <strong>de</strong>sign for excessive pressure losses<br />

• Modify pump (after consulting the manufacturer)<br />

• Check the system <strong>de</strong>sign<br />

• Restrict discharge valve<br />

• Correct rotation<br />

• Remove <strong>de</strong>posits or obstructions<br />

• Replace worn parts<br />

• Check electrical installation<br />

• Check electrical installation<br />

• Check electrical installation<br />

• Check alignment<br />

• Eliminate loads from pipework and realign set<br />

• Slacken gland packing<br />

• Fit a more powerful motor (after consulting the manufacturer)<br />

• Examine system <strong>de</strong>sign, remedy the cause<br />

• Fault diagnosis after inspection<br />

Table 4: Problems<br />

7. Appendix<br />

7.1 Permissible pump pressure<br />

Sealing<br />

Max. temperature<br />

Maximum admissible final pump pressure*<br />

[bar]<br />

casing parts ma<strong>de</strong> of<br />

EN-GJL-250 CuSn10-C 1.4408<br />

gland packing -20°C up to +110°C 40 35 40<br />

mechanical seal unbalanced (cast chrome/carbon) -20°C up to +120°C 12 12 12<br />

mechanical seal unbalanced (silicon carbi<strong>de</strong>/<br />

silicon carbi<strong>de</strong>)<br />

-20°C up to +80°C 12 12 12<br />

mechanical seal balanced (silicon carbi<strong>de</strong>/carbon) -20°C up to +140°C 40 35 40<br />

mechanical seal balanced (silicon carbi<strong>de</strong>/silicon<br />

carbi<strong>de</strong>)<br />

-20°C up to +80°C 40 35 40<br />

Table 5: final pressure of pump<br />

ENGLISH<br />

* The maximum permitted final pump pressure [bar] consists of the intake pressure and the pump <strong>de</strong>livery head at zero capacity.<br />

23