You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

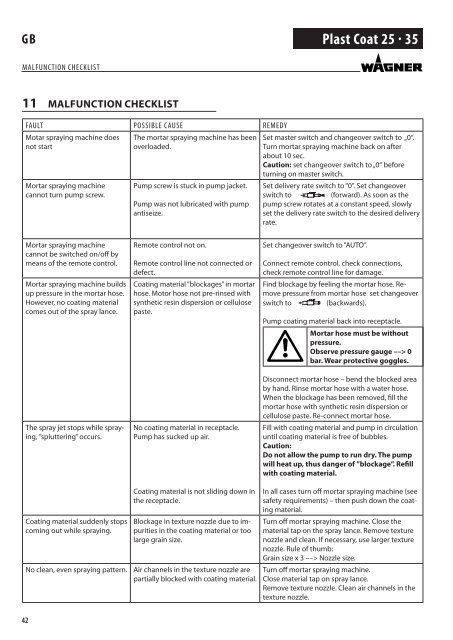

GB<strong>Plast</strong> <strong>Coat</strong> <strong>25</strong> · <strong>35</strong>Malfunction checklist11 Malfunction checklistFault Possible cause RemedyMotar spraying machine doesnot startMortar spraying machinecannot turn pump screw.The mortar spraying machine has beenoverloaded.Pump screw is stuck in pump jacket.Pump was not lubricated with pumpantiseize.Set master switch and changeover switch to „0“.Turn mortar spraying machine back on afterabout 10 sec.Caution: set changeover switch to „0“ beforeturning on master switch.Set delivery rate switch to “0”. Set changeoverswitch to(forward). As soon as thepump screw rotates at a constant speed, slowlyset the delivery rate switch to the desired deliveryrate.Mortar spraying machinecannot be switched on/off bymeans of the remote control.Mortar spraying machine buildsup pressure in the mortar hose.However, no coating materialcomes out of the spray lance.The spray jet stops while spraying,”spluttering” occurs.<strong>Coat</strong>ing material suddenly stopscoming out while spraying.No clean, even spraying pattern.Remote control not on.Remote control line not connected ordefect.<strong>Coat</strong>ing material “blockages” in mortarhose. Motor hose not pre-rinsed withsynthetic resin dispersion or cellulosepaste.No coating material in receptacle.Pump has sucked up air.<strong>Coat</strong>ing material is not sliding down inthe receptacle.Blockage in texture nozzle due to impuritiesin the coating material or toolarge grain size.Air channels in the texture nozzle arepartially blocked with coating material.Set changeover switch to “AUTO”.Connect remote control, check connections,check remote control line for damage.Find blockage by feeling the mortar hose. Removepressure from mortar hose set changeoverswitch to(backwards).Pump coating material back into receptacle.Mortar hose must be withoutpressure.Observe pressure gauge ––> 0bar. Wear protective goggles.Disconnect mortar hose – bend the blocked areaby hand. Rinse mortar hose with a water hose.When the blockage has been removed, fill themortar hose with synthetic resin dispersion orcellulose paste. Re-connect mortar hose.Fill with coating material and pump in circulationuntil coating material is free of bubbles.Caution:Do not allow the pump to run dry. The pumpwill heat up, thus danger of ”blockage”. Refillwith coating material.In all cases turn off mortar spraying machine (seesafety requirements) – then push down the coatingmaterial.Turn off mortar spraying machine. Close thematerial tap on the spray lance. Remove texturenozzle and clean. If necessary, use larger texturenozzle. Rule of thumb:Grain size x 3 ––> Nozzle size.Turn off mortar spraying machine.Close material tap on spray lance.Remove texture nozzle. Clean air channels in thetexture nozzle.42