FED 2019 - MIFAMAG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

088<br />

M.I.F.A. - <strong>FED</strong> <strong>2019</strong><br />

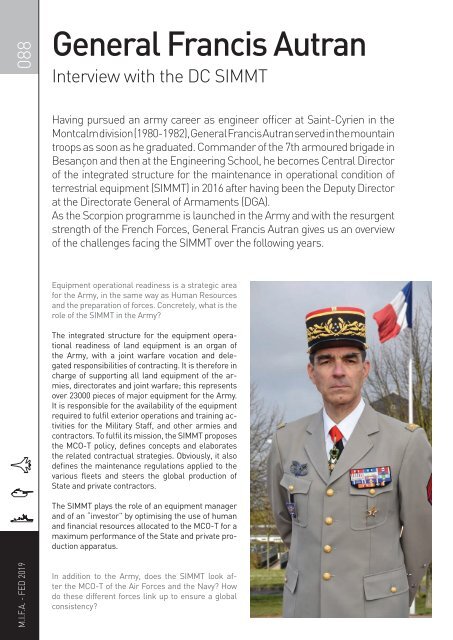

General Francis Autran<br />

Interview with the DC SIMMT<br />

Having pursued an army career as engineer officer at Saint-Cyrien in the<br />

Montcalm division (1980-1982), General Francis Autran served in the mountain<br />

troops as soon as he graduated. Commander of the 7th armoured brigade in<br />

Besançon and then at the Engineering School, he becomes Central Director<br />

of the integrated structure for the maintenance in operational condition of<br />

terrestrial equipment (SIMMT) in 2016 after having been the Deputy Director<br />

at the Directorate General of Armaments (DGA).<br />

As the Scorpion programme is launched in the Army and with the resurgent<br />

strength of the French Forces, General Francis Autran gives us an overview<br />

of the challenges facing the SIMMT over the following years.<br />

Equipment operational readiness is a strategic area<br />

for the Army, in the same way as Human Resources<br />

and the preparation of forces. Concretely, what is the<br />

role of the SIMMT in the Army?<br />

The integrated structure for the equipment operational<br />

readiness of land equipment is an organ of<br />

the Army, with a joint warfare vocation and delegated<br />

responsibilities of contracting. It is therefore in<br />

charge of supporting all land equipment of the armies,<br />

directorates and joint warfare; this represents<br />

over 23000 pieces of major equipment for the Army.<br />

It is responsible for the availability of the equipment<br />

required to fulfil exterior operations and training activities<br />

for the Military Staff, and other armies and<br />

contractors. To fulfil its mission, the SIMMT proposes<br />

the MCO-T policy, defines concepts and elaborates<br />

the related contractual strategies. Obviously, it also<br />

defines the maintenance regulations applied to the<br />

various fleets and steers the global production of<br />

State and private contractors.<br />

The SIMMT plays the role of an equipment manager<br />

and of an “investor” by optimising the use of human<br />

and financial resources allocated to the MCO-T for a<br />

maximum performance of the State and private production<br />

apparatus.<br />

In addition to the Army, does the SIMMT look after<br />

the MCO-T of the Air Forces and the Navy? How<br />

do these different forces link up to ensure a global<br />

consistency?<br />

The SIMMT guarantees the maintenance in operational<br />

condition of terrestrial equipment for the Army,<br />

Air Force and Navy and for the War Intendancy, the<br />

Military Fuel Service and the French Defence Health<br />

Service. We speak of logic of the environment. Every<br />

year, objectives are defined for the SIMMT by each<br />

department and the necessary financial resources<br />

are allocated. Moreover, the Navy, Air Force and Joint<br />

Warfare divisions staff are represented in the Directorate<br />

to facilitate the steering of protocols agreed<br />

between the SIMMT, delegated contractor and its<br />

own contractors.<br />

The Army ambitions to secure the maintenance in<br />

operational condition of land equipment (MCI-T) into<br />

modernity. What must we understand by modernity?<br />

Is it a change in mentality in the way of apprehending<br />

the MCO-T?<br />

The modernisation of the MCO-T has been underway<br />

since 2016 with a first phase that consisted in reorganising<br />

the sector from an organic perspective. It<br />

capitalises the transformation plans Maintenance<br />

2010 and MCO-T 2025 with the aim of improving the<br />

quality of support for our equipment relating to their<br />

service life by controlling the human and financial<br />

to be allocated. This modernisation process covers<br />

all the areas contributing to the performance of the<br />

MCO-T, i.e., the organisation, recruitment and training<br />

of staff, engineering and production processes,<br />

logistics, technical infrastructures and tools of the<br />

workshops. It exploits every opportunity offered by<br />

innovation and digital tools to gain in simplicity, reactivity,<br />

visibility and capacity of decision.<br />

This year, with the entry into force of the Military Programming<br />

law, this modernisation gathers pace to<br />

allow the MCO-T to exploit a productive model adapted<br />

to the recovery of the activity of the forces in 2024<br />

during a delicate phase of capacity transition with the<br />

arrival of the SCORPION equipment.<br />

Nothing will be done without the approval of the entire<br />

civilian and military staff. This is an undeniable<br />

factor for success. In fact, we must put ourselves in<br />

optimal conditions for success by adapting training,<br />

by adjusting the organisations and by ensuring that<br />

each one exercises their prerogatives at their level. In<br />

truth, I consider that mentalities are already turned<br />

towards modernity in our mature Army.<br />

What place is left for innovation in the MCO-T?<br />

Many MCO-T innovations emerge in the MCO-T<br />

workshops, and this has been the case for a long<br />

time. Today, we must link the modernisation of the<br />

MCO-T with innovation and digital transformation.<br />

Innovation must allow grasping every technological,<br />

methodical and managerial opportunity capable of<br />

optimising the maintenance and its logistics chain.<br />

It is not only a question of using the tools and processes<br />

that have proven their worth today to elaborate<br />

economic models, but we must also be capable<br />

of integrating flexibly mature technologies as they<br />

become accessible in all the MCO-T processes of<br />

maintenance and logistics.<br />

Digital transformation ambitions to improve productivity<br />

in our workshops through the digitalization of<br />

several actions, which is what I call “repairing more”.<br />

Using the various sensors placed on the main organs<br />

of the equipment, we must also progressively shift<br />

from preventive maintenance to projected maintenance;<br />

in other words, “repair better”, i.e., at the<br />

right need thus at the right cost, by limiting the delay<br />

of loss of use of the equipment for the various units<br />

as much as possible.<br />

The SIMMT progresses hand-in-hand with innovation,<br />

particularly thanks to the MCO LAB Terre. It<br />

imposes itself as a place for encounters between a<br />

wide range of key players, to create a tank of thinking<br />

and reflection to see the emergence of new projects<br />

responding to the needs of the forces.<br />

Can you tell us a little bit more about some of the<br />

innovative projects backed by the MCO-T?<br />

Intrinsically, our maintenance operators have a<br />

strong appetite for “the technical thing”, i.e., mastering<br />

the functioning of the equipment to increase<br />

its support. This state of mind percolates the entire<br />

MCO-T and spreads well beyond the pure technical<br />

sphere. I would like to mention three examples illustrating<br />

this culture for modernity and innovation.<br />

First of all, in the financial area, I would like to mention<br />

analytical accounting. It does not seem like<br />

much at first. But it extremely ground-breaking that<br />

the MCO should know its precise costs and to fully<br />

put the choices on offer in a perspective, particularly<br />

for finding the balance between the various industrial<br />

contractors.<br />

Then in the area of production, additive manufacturing<br />

is an emblematic and promising innovation. Experiments<br />

with this new technology are underway in<br />

France and in exterior operations. It allows making<br />

ex nihilo potentially complex spare parts. Tomorrow,<br />

this option could automatically be integrated into the<br />

design of the new equipment and their support.<br />

Finally, an information system feeds the MCO-T. Its<br />

modernisation by “both ends” is an innovation in<br />

itself. “Upwards”, by exploiting all the useful data<br />

stored inside the MCO-T’s Information System, with<br />

mathematic modelling tools relying on artificial intelligence<br />

to help in the decision-taking of support<br />

strategies and develop projected maintenance. The<br />

089<br />

M.I.F.A. - <strong>FED</strong> <strong>2019</strong>