Instruction Manual - Service - Black & Decker

Instruction Manual - Service - Black & Decker

Instruction Manual - Service - Black & Decker

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

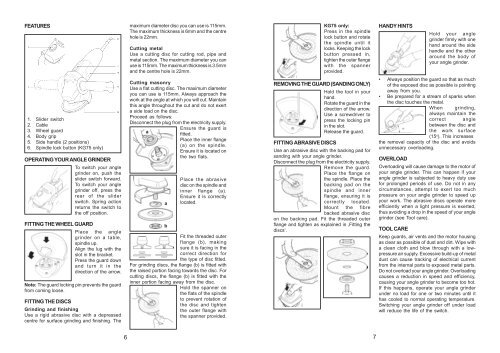

FEATURESmaximum diameter disc you can use is 115mm.The maximum thickness is 6mm and the centrehole is 22mm.Cutting metalUse a cutting disc for cutting rod, pipe andmetal section. The maximum diameter you canuse is 115mm. The maximum thickness is 3.5mmand the centre hole is 22mm.KG75 only:Press in the spindlelock button and rotatethe spindle until itlocks. Keeping the lockbutton pressed in,tighten the outer flangewith the spannerprovided.HANDY HINTSHold your anglegrinder firmly with onehand around the sidehandle and the otheraround the body ofyour angle grinder.1. Slider switch2. Cable3. Wheel guard4. Body grip5. Side handle (2 positions)6. Spindle lock button (KG75 only)OPERATING YOUR ANGLE GRINDERTo switch your anglegrinder on, push theslider switch forward.To switch your anglegrinder off, press therear of the sliderswitch. Spring actionreturns the switch tothe off position.FITTING THE WHEEL GUARDPlace the anglegrinder on a table,spindle up.Align the lug with theslot in the bracket.Press the guard downand turn it in thedirection of the arrow.Note: The guard locking pin prevents the guardfrom coming loose.FITTING THE DISCSGrinding and finishingUse a rigid abrasive disc with a depressedcentre for surface grinding and finishing. TheCutting masonryUse a flat cutting disc. The maximum diameteryou can use is 115mm. Always approach thework at the angle at which you will cut. Maintainthis angle throughout the cut and do not exerta side load on the disc.Proceed as follows:Disconnect the plug from the electricity supply.Ensure the guard isafitted.Place the inner flange(a) on the spindle.Ensure it is located onthe two flats.abPlace the abrasivedisc on the spindle andinner flange (a).Ensure it is correctlylocated.Fit the threaded outerflange (b), makingsure it is facing in thecorrect direction forthe type of disc fitted.For grinding discs, the flange (b) is fitted withthe raised portion facing towards the disc. Forcutting discs, the flange (b) is fitted with theinner portion facing away from the disc.Hold the spanner onthe flats of the spindleto prevent rotation ofthe disc and tightenthe outer flange withthe spanner provided.REMOVING THE GUARD (SANDING ONLY)Hold the tool in yourhand.Rotate the guard in thedirection of the arrow.Use a screwdriver topress the locking pinin the slot.Release the guard.FITTING ABRASIVE DISCSUse an abrasive disc with the backing pad forsanding with your angle grinder.Disconnect the plug from the electricity supply.Remove the guard.Place the flange onthe spindle. Place thebacking pad on thespindle and innerflange, ensuring it iscorrectly located.Mount the fibrebacked abrasive discon the backing pad. Fit the threaded outerflange and tighten as explained in ‚Fitting thediscs‘.• Always position the guard so that as muchof the exposed disc as possible is pointingaway from you.• Be prepared for a stream of sparks whenthe disc touches the metal.When grinding,always maintain thecorrect anglebetween the disc andthe work surface(15 o ). This increasesthe removal capacity of the disc and avoidsunnecessary overloading.OVERLOADOverloading will cause damage to the motor ofyour angle grinder. This can happen if yourangle grinder is subjected to heavy duty usefor prolonged periods of use. Do not in anycircumstances, attempt to exert too muchpressure on your angle grinder to speed upyour work. The abrasive discs operate moreefficiently when a light pressure is exerted,thus avoiding a drop in the speed of your anglegrinder (see Tool care).TOOL CAREKeep guards, air vents and the motor housingas clear as possible of dust and dirt. Wipe witha clean cloth and blow through with a lowpressureair supply. Excessive build-up of metaldust can cause tracking of electrical currentfrom the internal parts to exposed metal parts.Do not overload your angle grinder. Overloadingcauses a reduction in speed and efficiency,causing your angle grinder to become too hot.If this happens, operate your angle grinderunder no load for one or two minutes until ithas cooled to normal operating temperature.Switching your angle grinder off under loadwill reduce the life of the switch.67