Miljørapport 06 - Sør-Norge Aluminium AS

Miljørapport 06 - Sør-Norge Aluminium AS

Miljørapport 06 - Sør-Norge Aluminium AS

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

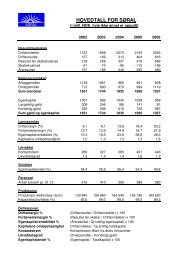

Utslepp av sulfat, fluorid ogsuspendert tørrstoff til vatn (kg/time)OmnshallaneUtslepp av støv til luft (g/kg Al)Omnshallane302520151050126011301140105685215,923658010,420,820,018,247213,210,92,10,86,21,26 0,93 1,43 1,82 2,19 1,911999 2000 2001 2002 2003 2004 2005 20<strong>06</strong>14001200100080<strong>06</strong>0040020004,03,02,01,00,01,29 1,19 1,30 1,250,920,53 0,47 0,50 0,491998 1999 2000 2001 2002 2003 2004 2005 20<strong>06</strong>Fluorid Suspendert tørrstoff SulfatStøvUtsleppsgrenseExternal environmentIn recent years there have been norecords of damage to the sprucefirs, the vegetation in the area or toany grazing animals.SØRAL delivers its waste materialsto various receiving stations. Thecompany’s own seaside landfillcovers an area of 50 000 sq.metres, 35 000 square metres ofwhich have been covered with soiland planted grass on. In the southwesternpart of this area you canfind a football field and courts forbeach volleyball, tennis and volleyball,which is open to the public.Within the plant area we had15,000 sq. metres as a depositoryfor cathode remnants and anodedust. This area will be permanentlyclosed and covered by soil andsubsequently planted in springtime2007. Between this area and thesea there is a large rock-filled partition.Only minor impact to themarine environment and the surroundingsassociated with thelandfill has been recorded. A planis already developed for coveringthe depository and monitoringenvironmental impacts. Last yearthe waste quantities depositedwere higher than previous yeardue to higher exchange of cathodescompared to the previousyear. At SØRAL all waste is sortedinto separate sections in order toachieve the highest possibledegree of recycling. We put a lot ofefforts into reducing the amount ofproduction waste by focusing onpackaging requirements from oursuppliers.SØRAL works actively to increaserecycling of production waste andto reduce the total waste quantity.The Company maintains healthdata sheets for oil, paint, solventsetc., in an electronic data base.Continuous efforts are being madeto replace health-damaging materialswith less dangerous alternatives.No acute pollution incidents havebeen recorded in 20<strong>06</strong>. The emissionof fluoride from the pot roomsas measured in g/kilo Al has had asmall decrease in the last year, asthe emission of sulphur dioxidehas had a small decrease in thesame period.The emission of dust from the potrooms is at a stable low level.The emission of fluorides from thecast house is at a low level.The emission of sulphur dioxidefrom the cast house is at a lowlevel due to use of natural gas.Dust emission has increased dueto higher quantity of processedconvert metal. The quantity of aluminiumdross per ton Al has beenreduced.Oil and gas consumption per kiloaluminium has increased as a consequenceof higher quantity ofremelted metal.The maximum permitted noiselevel close to neighboring borderis 50 dBA, and no breaches havebeen measured so far.The production of aluminium causesemissions of carbon dioxide,hydrogen fluoride, sulphur dioxideand dust. In addition to this, theprocess itself also emits gassessuch as carbon fluoride and nitrogenoxide.The anodes that are used atSØRAL are pre-calcinated, whichgenerates minimal tar (PAH) emissionfrom the process.The gasses emanating from theelectrolytic process are drycleansed and subsequently led toa washing unit utilising sea waterto reduce the content of sulphur16