BOPI in intregime - agepi

BOPI in intregime - agepi

BOPI in intregime - agepi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

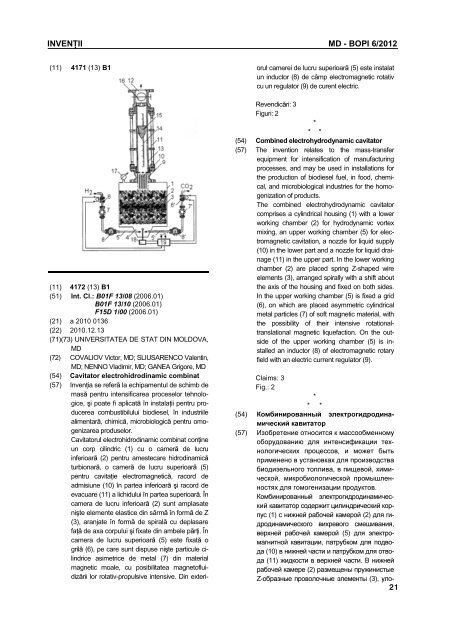

INVENŢII MD - <strong>BOPI</strong> 6/2012<br />

(11) 4171 (13) B1<br />

(11) 4172 (13) B1<br />

(51) Int. Cl.: B01F 13/08 (2006.01)<br />

B01F 13/10 (2006.01)<br />

F15D 1/00 (2006.01)<br />

(21) a 2010 0136<br />

(22) 2010.12.13<br />

(71)(73) UNIVERSITATEA DE STAT DIN MOLDOVA,<br />

MD<br />

(72) COVALIOV Victor, MD; SLIUSARENCO Valent<strong>in</strong>,<br />

MD; NENNO Vladimir, MD; GANEA Grigore, MD<br />

(54) Cavitator electrohidrod<strong>in</strong>amic comb<strong>in</strong>at<br />

(57) Invenţia se referă la echipamentul de schimb de<br />

masă pentru <strong>in</strong>tensificarea proceselor tehnologice,<br />

şi poate fi aplicată în <strong>in</strong>stalaţii pentru producerea<br />

combustibilului biodiesel, în <strong>in</strong>dustriile<br />

alimentară, chimică, microbiologică pentru omogenizarea<br />

produselor.<br />

Cavitatorul electrohidrod<strong>in</strong>amic comb<strong>in</strong>at conţ<strong>in</strong>e<br />

un corp cil<strong>in</strong>dric (1) cu o cameră de lucru<br />

<strong>in</strong>ferioară (2) pentru amestecare hidrod<strong>in</strong>amică<br />

turbionară, o cameră de lucru superioară (5)<br />

pentru cavitaţie electromagnetică, racord de<br />

admisiune (10) în partea <strong>in</strong>ferioară şi racord de<br />

evacuare (11) a lichidului în partea superioară. În<br />

camera de lucru <strong>in</strong>ferioară (2) sunt amplasate<br />

nişte elemente elastice d<strong>in</strong> sârmă în formă de Z<br />

(3), aranjate în formă de spirală cu deplasare<br />

faţă de axa corpului şi fixate d<strong>in</strong> ambele părţi. În<br />

camera de lucru superioară (5) este fixată o<br />

grilă (6), pe care sunt dispuse nişte particule cil<strong>in</strong>drice<br />

asimetrice de metal (7) d<strong>in</strong> material<br />

magnetic moale, cu posibilitatea magnetofluidizării<br />

lor rotativ-propulsive <strong>in</strong>tensive. D<strong>in</strong> exteriorul<br />

camerei de lucru superioară (5) este <strong>in</strong>stalat<br />

un <strong>in</strong>ductor (8) de câmp electromagnetic rotativ<br />

cu un regulator (9) de curent electric.<br />

Revendicări: 3<br />

Figuri: 2<br />

*<br />

* *<br />

(54) Comb<strong>in</strong>ed electrohydrodynamic cavitator<br />

(57) The <strong>in</strong>vention relates to the mass-transfer<br />

equipment for <strong>in</strong>tensification of manufactur<strong>in</strong>g<br />

processes, and may be used <strong>in</strong> <strong>in</strong>stallations for<br />

the production of biodiesel fuel, <strong>in</strong> food, chemical,<br />

and microbiological <strong>in</strong>dustries for the homogenization<br />

of products.<br />

The comb<strong>in</strong>ed electrohydrodynamic cavitator<br />

comprises a cyl<strong>in</strong>drical hous<strong>in</strong>g (1) with a lower<br />

work<strong>in</strong>g chamber (2) for hydrodynamic vortex<br />

mix<strong>in</strong>g, an upper work<strong>in</strong>g chamber (5) for electromagnetic<br />

cavitation, a nozzle for liquid supply<br />

(10) <strong>in</strong> the lower part and a nozzle for liquid dra<strong>in</strong>age<br />

(11) <strong>in</strong> the upper part. In the lower work<strong>in</strong>g<br />

chamber (2) are placed spr<strong>in</strong>g Z-shaped wire<br />

elements (3), arranged spirally with a shift about<br />

the axis of the hous<strong>in</strong>g and fixed on both sides.<br />

In the upper work<strong>in</strong>g chamber (5) is fixed a grid<br />

(6), on which are placed asymmetric cyl<strong>in</strong>drical<br />

metal particles (7) of soft magnetic material, with<br />

the possibility of their <strong>in</strong>tensive rotationaltranslational<br />

magnetic liquefaction. On the outside<br />

of the upper work<strong>in</strong>g chamber (5) is <strong>in</strong>stalled<br />

an <strong>in</strong>ductor (8) of electromagnetic rotary<br />

field with an electric current regulator (9).<br />

Claims: 3<br />

Fig.: 2<br />

*<br />

* *<br />

(54) Комбинированный электрогидродинамический<br />

кавитатор<br />

(57) Изобретение относится к массообменному<br />

оборудованию для интенсификации технологических<br />

процессов, и может быть<br />

применено в установках для производства<br />

биодизельного топлива, в пищевой, химической,<br />

микробиологической промышленностях<br />

для гомогенизации продуктов.<br />

Комбинированный электрогидродинамический<br />

кавитатор содержит цилиндрический корпус<br />

(1) с нижней рабочей камерой (2) для гидродинамического<br />

вихревого смешивания,<br />

верхней рабочей камерой (5) для электромагнитной<br />

кавитации, патрубком для подвода<br />

(10) в нижней части и патрубком для отвода<br />

(11) жидкости в верхней части. В нижней<br />

рабочей камере (2) размещены пружинистые<br />

Z-образные проволочные элементы (3), уло-<br />

21