Program Information Mobile Hydraulics, Mobile ... - Bosch Rexroth AG

Program Information Mobile Hydraulics, Mobile ... - Bosch Rexroth AG

Program Information Mobile Hydraulics, Mobile ... - Bosch Rexroth AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

102 BODAS <strong>Mobile</strong> Electronics<br />

7<br />

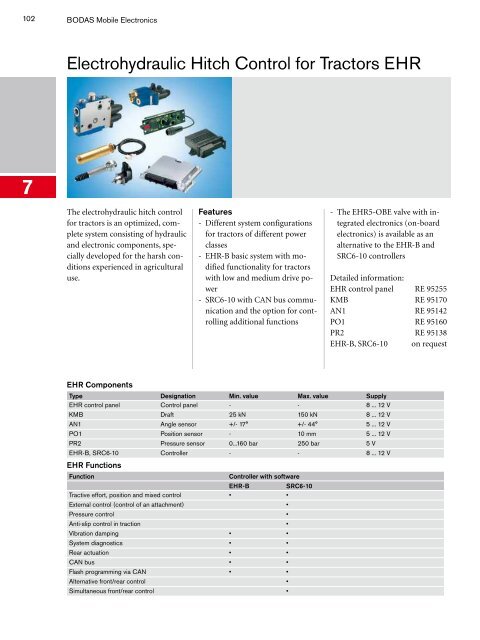

Electrohydraulic Hitch Control for Tractors EHR<br />

The electrohydraulic hitch control<br />

for tractors is an optimized, complete<br />

system consisting of hydraulic<br />

and electronic components, specially<br />

developed for the harsh conditions<br />

experienced in agricultural<br />

use.<br />

Features<br />

- Different system configurations<br />

for tractors of different power<br />

classes<br />

- EHR-B basic system with modified<br />

functionality for tractors<br />

with low and medium drive power<br />

- SRC6-10 with CAN bus communication<br />

and the option for controlling<br />

additional functions<br />

- The EHR5-OBE valve with integrated<br />

electronics (on-board<br />

electronics) is available as an<br />

alternative to the EHR-B and<br />

SRC6-10 controllers<br />

Detailed information:<br />

EHR control panel RE 95255<br />

KMB RE 95170<br />

AN1 RE 95142<br />

PO1 RE 95160<br />

PR2 RE 95138<br />

EHR-B, SRC6-10 on request<br />

EHR Components<br />

Type Designation Min. value Max. value Supply<br />

EHR control panel Control panel - - 8 ... 12 V<br />

KMB Draft 25 kN 150 kN 8 ... 12 V<br />

AN1 Angle sensor +/- 17° +/- 44° 5 ... 12 V<br />

PO1 Position sensor - 10 mm 5 ... 12 V<br />

PR2 Pressure sensor 0...160 bar 250 bar 5 V<br />

EHR-B, SRC6-10<br />

EHR Functions<br />

Controller - - 8 ... 12 V<br />

Function Controller with software<br />

EHR-B SRC6-10<br />

Tractive effort, position and mixed control • •<br />

External control (control of an attachment) •<br />

Pressure control •<br />

Anti-slip control in traction •<br />

Vibration damping • •<br />

System diagnostics • •<br />

Rear actuation • •<br />

CAN bus • •<br />

Flash programming via CAN • •<br />

Alternative front/rear control •<br />

Simultaneous front/rear control •