75 years of Egokiefer: Tradition and Innovation

75 years of Egokiefer: Tradition and Innovation

75 years of Egokiefer: Tradition and Innovation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

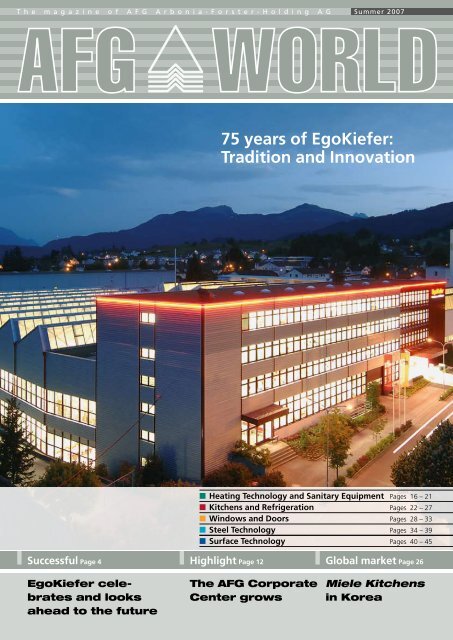

The magazine <strong>of</strong> AFG Arbonia-Forster-Holding AG Summer 2007<br />

Successful Page 4<br />

EgoKiefer celebrates<br />

<strong>and</strong> looks<br />

ahead to the future<br />

<strong>75</strong> <strong>years</strong> <strong>of</strong> EgoKiefer:<br />

<strong>Tradition</strong> <strong>and</strong> <strong>Innovation</strong><br />

n Heating Technology <strong>and</strong> Sanitary Equipment Pages 16 – 21<br />

n Kitchens <strong>and</strong> Refrigeration Pages 22 – 27<br />

n Windows <strong>and</strong> Doors Pages 28 – 33<br />

n Steel Technology Pages 34 – 39<br />

n Surface Technology Pages 40 – 45<br />

Highlight Page 12<br />

The AFG Corporate<br />

Center grows<br />

Global market Page 26<br />

Miele Kitchens<br />

in Korea

Contents<br />

n Prelude<br />

Editorial ............................................................................ 1<br />

n In a nutshell<br />

News ................................................................................ 2<br />

n Focus<br />

<strong>75</strong> <strong>years</strong> <strong>of</strong> EgoKiefer: fascinating encounters ................... 4<br />

n AFG Arbonia-Forster-Holding AG<br />

AFG half-yearly report 2007 .............................................. 10<br />

AFG goes back to school ................................................... 10<br />

Corporate Center: move-in set for November 2007 ........... 12<br />

New: AFG sponsors Swiss yachting .................................... 13<br />

Success at the «Eidgenössisches Turnfest» ......................... 13<br />

AFG electronic press kit – available at www.afg.ch .............. 14<br />

Building bridges with the AFG ARENA ............................... 15<br />

n Heating Technology <strong>and</strong> Sanitary Equipment<br />

Shiny worlds <strong>of</strong> experience at the ISH ................................ 17<br />

xlink: the perfect combination! ......................................... 18<br />

Russia: first we supplied the heating systems,<br />

now the showers .............................................................. 18<br />

Therm X2 panel radiators lower costs by up to 20% .......... 19<br />

Kermi: even more efficient with EDI ................................... 20<br />

Arbonia <strong>and</strong> Prolux: «Faites vos jeux!» .............................. 20<br />

Arbonia <strong>and</strong> Kermi unlock the Italian market ..................... 21<br />

2007 TGA congress at Kermi ............................................. 21<br />

n Kitchens <strong>and</strong> Refrigeration<br />

Forster kitchen at 3258 m ................................................. 23<br />

New: Forster kitchen centre Rupperswil ............................. 24<br />

Forster kitchens in Hohenems ............................................ 24<br />

Bruno Piatti AG: logistics as a position for strategic success 25<br />

Miele Kitchens in South Korea ........................................... 26<br />

Piatti: ISO 14001 for environment management ................ 26<br />

Giuseppe Giussani integrates Miele Kitchens in St.Moritz .. 27<br />

n Windows <strong>and</strong> Doors<br />

Welcome to the new EgoKiefer competence centre! ......... 29<br />

House <strong>of</strong> the future with EgoKiefer windows ..................... 30<br />

Climate Cent: EgoKiefer as a role model ............................. 30<br />

EgoKiefer window pr<strong>of</strong>iles: top eco-classification ............... 31<br />

PrefSUITE: knowledge at a click .......................................... 31<br />

RWD Schlatter <strong>and</strong> Empa: joint fire protection test ............. 32<br />

RWD Schlatter: successful burglary protection ................... 33<br />

RWD Schlatter passes on its experience ............................. 33<br />

Made in Switzerl<strong>and</strong> ......................................................... 33<br />

n Steel Technology<br />

Forster Steel Technology: shining premiere in Spain ........... 35<br />

Forster unico: new system – new shine .............................. 36<br />

Major project in Barcelona with Forster unico .................... 37<br />

Immomesse: Forster shines ................................................ 38<br />

Forster Pr<strong>of</strong>ile Systems: new sales network in Germany ..... 38<br />

Drawn pr<strong>of</strong>iles: from the idea to the product ..................... 39<br />

n Surface Technology<br />

STI | Hartchrom with state-<strong>of</strong>-the-art infrastructure ........... 41<br />

STI | Hartchrom: a powerhouse! ....................................... 42<br />

Environmentally sound business: the key to survival! ......... 44<br />

STI Worldwide Repair Service: unique! ............................. 45<br />

STI | Hartchrom: now also in construction ......................... 45<br />

Imprint<br />

AFG WORLD, the magazine <strong>of</strong> AFG Arbonia-Forster-<br />

Holding AG, appears three times a year in four<br />

languages in Switzerl<strong>and</strong>, Germany <strong>and</strong> the Czech<br />

Republic, as well as in other countries around the world.<br />

Circulation 23,500<br />

Editorial address<br />

AFG Arbonia-Forster-Holding AG<br />

Editorial AFG WORLD<br />

Dr. Stefan Holenstein<br />

P.O. Box 134<br />

CH-9320 Arbon, Thurgau<br />

T +41 71 447 41 41<br />

F +41 71 447 45 88<br />

afgworld@afg.ch<br />

Production<br />

Concept/Layout/Text Editorial:<br />

E,T&H Werbeagentur AG BSW,<br />

CH-9401 Rorschach, SG<br />

Printing: Druckerei Flawil AG, CH-9230 Flawil, SG<br />

Title image: EgoKiefer headquarters in Altstätten, SG

Focus Prelude<br />

Full <strong>of</strong> verve into<br />

the second half <strong>of</strong> 2007<br />

Dear Ladies <strong>and</strong> Gentlemen,<br />

Dear employees<br />

Up to now our forecasts have proved to be correct, <strong>and</strong> as expected<br />

the economy has developed very well. The fact that this<br />

positive development is holding up unabated is also reflected in<br />

the very good half-yearly results <strong>of</strong> AFG for 2007. For AFG Arbonia-Forster-Holding<br />

AG, whose fields <strong>of</strong> business – according<br />

to the particular orientation <strong>of</strong> the divisions – depend more or<br />

less directly on the economic situation within the building trade,<br />

this means order books which are full <strong>and</strong> capacity which is<br />

booked up to the hilt. These challenges, which must go h<strong>and</strong> in<br />

h<strong>and</strong> with consistently high quality <strong>and</strong> a top level <strong>of</strong> service for<br />

our customers, are something we face with relish. No surprise<br />

then that we are looking forward to the second period <strong>of</strong> 2007<br />

with that much more confidence.<br />

Focussing on internationalisation<br />

One <strong>of</strong> the targets we have set ourselves for the coming months<br />

is to actively press on with further internationalisation <strong>of</strong> AFG in<br />

Eastern Europe <strong>and</strong> in the Middle <strong>and</strong> Far East. Here, there is still<br />

a lot <strong>of</strong> catching-up to do in order to meet the pent-up dem<strong>and</strong><br />

for new homes <strong>and</strong> new commercial/industry buildings as well as<br />

for redevelopment <strong>and</strong> renovation work. We aim to increase our<br />

net share in foreign markets, i.e. outside our domestic markets in<br />

Germany <strong>and</strong> Switzerl<strong>and</strong>, from a current level <strong>of</strong> 22% to<br />

around 50% in the future. The response to our innovative br<strong>and</strong><br />

products is very positive, particularly in the new EU member<br />

states <strong>and</strong> the Middle <strong>and</strong> Far East. We have been able to secure<br />

a number <strong>of</strong> good orders there recently. Despite our hectic dayto-day<br />

business <strong>and</strong> various strategic challenges, I have taken the<br />

time to prepare a few thoughts about our special anniversary.<br />

Indeed, at AFG the current year is entirely shaped by the<br />

company’s anniversary: after all, AFG-Holding has turned 20,<br />

STI | Hart chrom 50, EgoKiefer <strong>75</strong> <strong>and</strong> Forster Kitchens <strong>and</strong> Steel<br />

Techno logy is now 85 <strong>years</strong> old – albeit with the same levels<br />

<strong>of</strong> enthusiasm <strong>and</strong> commitment as ever.<br />

<strong>75</strong> <strong>years</strong> <strong>of</strong> EgoKiefer – <strong>and</strong> not a hint<br />

<strong>of</strong> things slowing down yet<br />

This year, one <strong>of</strong> our «flagships» – EgoKiefer AG – celebrates its<br />

<strong>75</strong> th anniversary. The <strong>of</strong>ficial celebrations took place on June<br />

8 <strong>and</strong> 9. In recent decades, EgoKiefer – a company which grew<br />

from humble beginnings as a small joiner’s workshop – has<br />

emerged as the leading manufacturer <strong>of</strong> windows <strong>and</strong> has distinguished<br />

itself with numerous international design, technology<br />

<strong>and</strong> environmental management awards. An excellent – <strong>and</strong> the<br />

most recent – example is the award-winning XL ® window technology.<br />

This window sets new st<strong>and</strong>ards in terms <strong>of</strong> energy <strong>and</strong><br />

the environment by helping measurably to save energy. However,<br />

anyone who looks back <strong>of</strong> the history <strong>of</strong> EgoKiefer will soon<br />

notice that the path from then to now has been anything but<br />

straightforward. Far from it – it is dotted with many highs <strong>and</strong><br />

lows as well as various changes in name <strong>and</strong> ownership. This is<br />

one <strong>of</strong> the reasons why I am still proud to this day that we managed<br />

the acquisition <strong>of</strong> EgoKiefer from the estate <strong>of</strong> Uniwood<br />

Holding AG (Erb group) in 2004, despite the intense national <strong>and</strong><br />

international competition, <strong>and</strong> to integrate it as a new fourth<br />

division into AFG. Since then, the br<strong>and</strong> has gone from strength<br />

to strength. Today, when people think <strong>of</strong> windows, they think <strong>of</strong><br />

EgoKiefer! So, here again, congratulations are due to EgoKiefer<br />

AG on reaching its <strong>75</strong> th birthday.<br />

1<br />

Independent <strong>and</strong> autonomous br<strong>and</strong>s –<br />

departing for new markets<br />

AFG cares a great deal about looking after its br<strong>and</strong>s, about<br />

strengthening the br<strong>and</strong>s <strong>and</strong> about developing them further.<br />

This also includes the independence <strong>and</strong> corporate flexibility <strong>of</strong><br />

each <strong>and</strong> every AFG company. Every AFG subsidiary must establish<br />

itself in existing markets <strong>and</strong> develop opportunities in new<br />

markets. What holds together AFG is our shared vision – a vision<br />

we work on every day, rigorously <strong>and</strong> without compromise. It is<br />

the unshakeable will not only to reach the top in all areas, but to<br />

stay at the top – both in terms <strong>of</strong> our ability to deliver innovative<br />

products <strong>and</strong> in terms <strong>of</strong> staying wide awake in our underst<strong>and</strong>ing<br />

<strong>of</strong> customer requirements. At EgoKiefer AG, this is documented<br />

impressively with an own name, an own corporate identity<br />

<strong>and</strong>, at the same time, a departure into new markets,<br />

something which perfectly reflects the philosophy <strong>of</strong> AFG. In the<br />

windows <strong>and</strong> doors sector, virtually 100% <strong>of</strong> our business comes<br />

from the Swiss market, <strong>and</strong> the size we have now reached here<br />

will make further sustained growth difficult. From this strong<br />

domestic launch pad we now feel strong enough to exp<strong>and</strong> into<br />

foreign markets with our windows <strong>and</strong> doors. We are currently<br />

examining suitable acquisitions in Europe. All this means that<br />

another exciting chapter in the history <strong>of</strong> EgoKiefer AG is about<br />

to unfold. We are also looking at potential acquisition projects in<br />

the field <strong>of</strong> surface technology, even though the Division Surface<br />

Technology already has by far the most international outlook<br />

<strong>of</strong> any division in AFG. In fact, it is completely at the opposite<br />

end <strong>of</strong> the scale, with around 100% <strong>of</strong> our production being<br />

destined for foreign markets.<br />

Ready for the future<br />

For us, corporate success should always be shared by shareholders,<br />

customers, partners, employees <strong>and</strong> the wider public. With<br />

the increase in capital stock which was completed on May 4, 2007,<br />

we have established a basis for further growth which will allow<br />

us to create further domestic <strong>and</strong> foreign jobs. The new AFG<br />

Corporate Center is already a proud l<strong>and</strong>mark which represents<br />

our continuously growing enterprise – an enterprise which is dynamically<br />

moving into the future, with no signs <strong>of</strong> slowing down.<br />

Yours sincerely<br />

AFG Arbonia-Forster-Holding AG<br />

Chairman <strong>of</strong> the Board <strong>of</strong> Directors <strong>and</strong> CEO<br />

Dr. Edgar Oehler

2<br />

The new exhibition centre in Stuttgart –<br />

currently the biggest construction site in Germany.<br />

Forster supplies systems<br />

for new exhibition<br />

centre in Stuttgart<br />

More than 50 fire protection elements from the Forster<br />

pr<strong>of</strong>ile system fuego light have been installed at the<br />

largest building site in Germany. The doors <strong>and</strong> fixed<br />

glazing guarantee high levels <strong>of</strong> safety <strong>and</strong> <strong>of</strong>fer certified<br />

protection against fire <strong>and</strong> smoke for – depending on requirements<br />

– between 30 <strong>and</strong> 90 minutes. The new exhibition<br />

centre in Stuttgart is set to virtually disappear in the l<strong>and</strong>scape<br />

once it is complete. The architects Wulf + Partners<br />

from Stuttgart have produced a design which blends the new<br />

buildings for the new exhibition centre in Stuttgart seamlessly<br />

into the environment. The 806-million Euro project is<br />

scheduled to open autumn 2007, 37 months after building<br />

work commenced. «<br />

Finishing 1 st at the United World Games 2007:<br />

the U17 girls’ team <strong>of</strong> SC Bronschh<strong>of</strong>en.<br />

news<br />

EgoKiefer: Nominated!<br />

The EgoKiefer XL ® plastic window system remains on<br />

the road to success. Its nomination for the 2008 design<br />

award <strong>of</strong> the Federal Republic <strong>of</strong> Germany is yet further<br />

pro<strong>of</strong> <strong>of</strong> its uniqueness <strong>and</strong> the outst<strong>and</strong>ing advantages<br />

it <strong>of</strong>fers customers. Opinion leaders regard this<br />

award as the «award <strong>of</strong> awards», as no other design prize<br />

places equally high dem<strong>and</strong>s on the nominees. The jury met<br />

to choose a winner on August 16 <strong>and</strong> 17, 2007. Up to five<br />

products <strong>and</strong> communication services can be awarded a gold<br />

award by the jury, <strong>and</strong> up to 20 products <strong>and</strong> communication<br />

services can receive the silver award for excellence in design<br />

quality. The nominees will be informed about the jury’s<br />

decisions in September 2007. The design prize will be<br />

awarded by the German Ministry <strong>of</strong><br />

Business <strong>and</strong> Technology as part <strong>of</strong> a<br />

public ceremonial act in Frankfurt in<br />

February 2008. «<br />

U17 girls’ team helps AFG onto<br />

international winners’ podium<br />

At the 2007 United World Games,<br />

the SC Bronschh<strong>of</strong>en U17 girls’ team<br />

was unstoppable, being crowned<br />

champions without losing a single<br />

match. At AFG, we would like to con-<br />

gratulate the girls on their tremendous<br />

success <strong>and</strong> say how pleased we are<br />

that the up-<strong>and</strong>-coming generation <strong>of</strong><br />

players h<strong>and</strong>led their initial foray onto<br />

the international stage so well. These<br />

girls have every right to be really proud<br />

<strong>of</strong> their excellent success. The United<br />

World Games are under the patronage<br />

<strong>of</strong> Unesco <strong>and</strong> are contested in eight<br />

different sporting events: football,<br />

basketball, volleyball, tennis, swimming,<br />

bowling, baseball <strong>and</strong> wrestling.<br />

This year around 3,000 youngsters aged<br />

between 13 <strong>and</strong> 17 took part from<br />

20 nations. «<br />

Success with AFG: one <strong>of</strong> the young<br />

sportswomen taking part in the<br />

United World Games 2007.

In Focus a nutshell<br />

3<br />

KMU Campus – «Learning from the best»<br />

KMU Campus: AFG shares knowledge with<br />

SMEs, date: September 21, 2007 in Arbon,<br />

Thurgau.<br />

Spedition Gächter AG <strong>and</strong><br />

Asta AG join forces<br />

In recent <strong>years</strong>, Asta AG <strong>and</strong> Spedition Gächter AG, which has been part<br />

<strong>of</strong> the AFG group since 2004, have formed a well-functioning team in the<br />

area <strong>of</strong> transport <strong>and</strong> logistics in the AFG group. The fusion <strong>of</strong> these two<br />

companies under the unified name Asta AG contributes to further optimisation<br />

<strong>of</strong> our processes. Importantly for our customers, we are going to be able to <strong>of</strong>fer<br />

even better area coverage in future. The fusion <strong>of</strong> Spedition Gächter AG with<br />

Asta AG was completed on June 26, 2007, with retrospective effect dating back<br />

to the start <strong>of</strong> 2007. Of course, our customers will continue to be looked after<br />

by the usual contact persons.<br />

Gia XP shower cabin with harmoniously<br />

integrated wall pr<strong>of</strong>iles in fashionable<br />

XXL design.<br />

KMU Campus, the leading provider <strong>of</strong> «Best Practice» seminars in Switzerl<strong>and</strong>,<br />

<strong>of</strong>fers directors <strong>and</strong> senior managers <strong>of</strong> SMEs a varied pr<strong>of</strong>essional<br />

training programme. In this programme, managers visit host companies where<br />

they receive direct practical coaching – <strong>and</strong> AFG has now joined this roster <strong>of</strong> host<br />

companies. The best companies in Switzerl<strong>and</strong> share their knowledge <strong>and</strong> expertise<br />

in a number <strong>of</strong> different business sectors with a limited number <strong>of</strong> participating<br />

managers. The initiative is under the patronage <strong>of</strong> the Swiss State Secretariat<br />

for Economic Affairs (Seco) <strong>and</strong> is supported by the «Stiftung Produktive Schweiz»<br />

foundation, UBS, Ernst & Young, IBM, Ringier, the «Organisator» <strong>and</strong> the «Wirtschaftsmagazin»<br />

business magazine. On September 21, 2007 the AFG in Arbon<br />

will be hosting a seminar on the subject <strong>of</strong> «Continuous innovation as a strategic<br />

success factor». The two business units Forster Pipes <strong>and</strong> Forster Pr<strong>of</strong>iles will<br />

demonstrate with specific product examples (keyword: Forster unico) how they<br />

utilise targeted innovation management to help shape the technology in the<br />

marketplace <strong>and</strong> keep one step ahead <strong>of</strong> the competition. Accordingly, this seminar<br />

is directed at directors <strong>and</strong> senior managers <strong>of</strong> manufacturing companies who<br />

would like to learn about the «lessons learned» in product <strong>and</strong> process development<br />

in the successful business units <strong>of</strong> the Division Steel Technology. «<br />

New shower cabins:<br />

Gia/Gia XP<br />

Elegant design, combined with all <strong>of</strong> the characteristics <strong>of</strong> contemporary<br />

comfort: the new Gia/Gia XP range <strong>of</strong> shower cabins from Kermi blends<br />

seamlessly into the sophisticated ambience <strong>of</strong> modern bathroom design.<br />

Whereas each Gia is made individually to measure, the Gia XP range <strong>of</strong>fers a corresponding<br />

<strong>of</strong>f-the-shelf solution for virtually all shower <strong>and</strong> shower tray applications<br />

thanks to its available wall pr<strong>of</strong>ile compensation <strong>of</strong> up to 30 mm <strong>and</strong> comprehensive<br />

selection <strong>of</strong> st<strong>and</strong>ard sizes. The upmarket style <strong>of</strong> the fittings <strong>and</strong> the<br />

h<strong>and</strong>les attached both on the inside <strong>and</strong> outside unify puristic straight lines with<br />

gentle curves. Smart detail: the transparent towel hook can be hung up anywhere<br />

on the glass. A transparent sealing strip in the shape <strong>of</strong> a ro<strong>of</strong> gutter <strong>and</strong><br />

a floor threshold are also included with the shower. «

4<br />

<strong>75</strong> <strong>years</strong> <strong>of</strong> EgoKiefer:<br />

fascinating encounters<br />

«Fascinating encounters» is the motto <strong>of</strong> the <strong>75</strong> th anniversary <strong>of</strong> EgoKiefer.<br />

The year 2007 is characterised by large anniversary celebrations <strong>and</strong><br />

award-winning innovations. For EgoKiefer, this anniversary is the perfect<br />

opportunity to reminisce <strong>and</strong> to look ahead.

Focus 5<br />

It came as no surprise that the company started 2007 with an<br />

impressive presence at Swissbau in Basel. EgoKiefer shone<br />

with the new XL ® generation <strong>of</strong> windows at the heart <strong>of</strong> their<br />

display. This new technology is symbolic for the EgoKiefer<br />

maxim <strong>of</strong> «advantage through ideas». Just like all other<br />

EgoKiefer window <strong>and</strong> door systems, the XL ® windows can<br />

also be equipped with a whole range <strong>of</strong> modular system<br />

components which can be used in combination. New system<br />

components from the fields <strong>of</strong> automation, photovoltaic<br />

systems, fire protection, ventilation, safety <strong>and</strong> shading also<br />

represent further highlights.<br />

EgoKiefer windows as a source <strong>of</strong> energy<br />

The XL ® range <strong>of</strong> plastic windows is another total success,<br />

winning the iF product design award 2007 in the category <strong>of</strong><br />

industrial buildings – even though this was its first entry in<br />

the competition. The excellent design <strong>of</strong> the new XL ® window<br />

convinced the international jury. Equally impressive are<br />

the findings <strong>of</strong> a recent eco-balance assessment carried out<br />

by Empa Dübendorf. According to these findings, EgoKiefer<br />

window systems actually yield a positive gain for the environment.<br />

The energy gained through the service life <strong>of</strong> the<br />

windows significantly outweighs the amount <strong>of</strong> energy required<br />

for production <strong>and</strong> disposal <strong>of</strong> the windows. As such,<br />

EgoKiefer window assemblies are actually sources <strong>of</strong> energy.<br />

The use <strong>of</strong> the new XL ® window technology is particularly<br />

friendly to the environment. These good results have been<br />

further optimised through the use <strong>of</strong> the exclusive EgoKiefer<br />

high-performance insulating glass EgoVerre ® .<br />

Special encounters in a miniature village <strong>of</strong> tents<br />

The two days <strong>of</strong> celebrations on June 8 <strong>and</strong> 9, 2007 in Altstätten,<br />

St.Gallen were without doubt one <strong>of</strong> the highpoints.<br />

Around 2,400 guests enjoyed several unforgettable hours in<br />

a unique ambience. EgoKiefer set up a miniature village <strong>of</strong><br />

tents in Allmend/Altstätten especially for the gala evening<br />

(attended by around 1,050 guests) <strong>and</strong> for the anniversary<br />

celebrations for employees <strong>and</strong> retired employees (attended<br />

by around 1,350 guests). Maybe it was the proverbial system<br />

competence <strong>of</strong> the company which helped bind together the<br />

extensive celebration programme into a perfect <strong>and</strong> highly<br />

successful overall event, but the 1,050 customers, suppliers,<br />

partners <strong>and</strong> guests from politics <strong>and</strong> industry certainly<br />

enjoyed Friday June 8, 2007, to the full. Many <strong>of</strong> them were<br />

«The new technology <strong>of</strong> the XL ® generation<br />

<strong>of</strong> windows is a symbol <strong>of</strong> the EgoKiefer motto<br />

advantage through ideas.»<br />

Around 2,400 guests enjoyed an unforgettable few hours at the anniversary celebrations in Altstätten, St.Gallen.

6<br />

Impressions from the multifaceted celebration programme. The speeches given by Dr. Edgar Oehler (middle picture above),<br />

Thomas Gerosa (see page 9 for an interview) <strong>and</strong> the renowned architect Max Dudler (bottom left).<br />

also keen on an early visit to the headquarters <strong>of</strong> EgoKiefer in<br />

the afternoon, in order to experience firsth<strong>and</strong> the production<br />

<strong>of</strong> the high quality products.<br />

An evening full <strong>of</strong> highlights<br />

Expectations ran high – <strong>and</strong> nobody was disappointed. The<br />

guests stepped through oversized windows into the miniature<br />

village <strong>of</strong> tents set up by EgoKiefer – the perfect aperitif<br />

for an unforgettable evening. Speeches by Dr. Edgar Oehler,<br />

Chairman <strong>of</strong> the Board <strong>of</strong> Directors <strong>and</strong> CEO <strong>of</strong> AFG Arbonia-<br />

Forster-Holding AG, by Thomas Gerosa, Chairman <strong>of</strong> the<br />

Board <strong>of</strong> Directors <strong>and</strong> CEO <strong>of</strong> EgoKiefer AG, <strong>and</strong> by renowned<br />

architect Pr<strong>of</strong>. Max Dudler took their place in a<br />

successful programme alongside the show put on specially<br />

EgoKiefer at a glance<br />

EgoKiefer AG is the number 1 company in the Swiss windows<br />

<strong>and</strong> doors market; in Europe it is one <strong>of</strong> the leading<br />

companies in the industry. It employs around 950 people<br />

<strong>and</strong> achieved a net turnover in excess <strong>of</strong> CHF 230 million in<br />

2006. The company headquarters are located in Altstätten,<br />

St.Gallen, where the company was initially founded in 1932.<br />

Additional production facilities are also located in Villeneuve,<br />

Vaud. As an integrated supplier, EgoKiefer develops, produces,<br />

sells <strong>and</strong> installs window solutions made <strong>of</strong> plastic,<br />

plastic/aluminium, wood <strong>and</strong> wood/aluminium, as well as<br />

doors for indoor <strong>and</strong> outdoor applications. In 2006, a total<br />

«EgoKiefer is the<br />

leading company in<br />

the Swiss windows<br />

<strong>and</strong> doors market.»<br />

for the event by the Tanzfabrik dance troupe, all <strong>of</strong> which<br />

was held together excellently by presenter Lolita Morena.<br />

Mind you, the food <strong>and</strong> drink left nothing to be desired<br />

either.<br />

A number <strong>of</strong> guests were openly surprised how it had been<br />

possible to entertain so many people all at the same time<br />

with such exquisite freshly prepared food. Happy memories<br />

<strong>of</strong> this gala evening are sure to linger for a long time among<br />

the highly satisfied audience. The organisation team around<br />

Michael Dietsche, head <strong>of</strong> Marketing Services at EgoKiefer,<br />

has certainly received much praise since, keeping things perfectly<br />

in line with the motto according to which «fascinating<br />

encounters» can form the basis <strong>of</strong> relationships <strong>and</strong> even<br />

friendships for life. «<br />

<strong>of</strong> more than 600,000 m 2 <strong>of</strong> windows were produced, with<br />

the number <strong>of</strong> doors produced st<strong>and</strong>ing at over 22,000<br />

units. EgoKiefer is committed to progress <strong>and</strong> has a well-<br />

established corporate culture which is best summarised in<br />

the motto «advantage through ideas». Customers benefit<br />

from this advantage in many ways both in terms <strong>of</strong> the<br />

products on <strong>of</strong>fer <strong>and</strong> in the services provided by the company.<br />

Within the industry, EgoKiefer AG has continuously<br />

set new st<strong>and</strong>ards with countless innovations. EgoKiefer<br />

has an active presence in all regions <strong>of</strong> Switzerl<strong>and</strong>.

Focus 7<br />

History<br />

<strong>75</strong> <strong>years</strong> <strong>of</strong> EgoKiefer<br />

A history:<br />

1932 Zurich entrepreneur Ernst Göhner (Ego) purchases the joiner’s workshop<br />

J.B. Geisser in Altstätten, St.Gallen. TUFA AG, the doors <strong>and</strong> windows factory,<br />

is created.<br />

1957 Development <strong>and</strong> production <strong>of</strong> the first plastic window in Switzerl<strong>and</strong>.<br />

1958 Acquisition <strong>of</strong> Maurice Guyot S.A. in Villeneuve, Vaud, on Lake Geneva.<br />

1962 Merging <strong>of</strong> TUFA AG <strong>and</strong> E. Göhner AG to form EgoWerke AG.<br />

1967 Already twelve sales branches throughout the whole <strong>of</strong> Switzerl<strong>and</strong>.<br />

1971 EgoWerke AG becomes an independent subsidiary <strong>of</strong> Elektrowatt<br />

following the sale <strong>of</strong> the Göhner Group.<br />

1972 EgoWerke acquires window manufacturer Kiefer Windows AG.<br />

1976 Merger resulting in the creation <strong>of</strong> EgoKiefer AG.<br />

1980 Creation <strong>of</strong> a sales network for plastic windows.<br />

1987 Uniwood Holding AG <strong>of</strong> the Erb Group takes over EgoKiefer AG.<br />

1993 Expansion <strong>of</strong> the sales organisation in southern Germany <strong>and</strong> Vorarlberg (Austria).<br />

1994 Creation <strong>of</strong> the first national windows <strong>and</strong> doors service organisation.<br />

2000 New logistics centre in Altstätten is taken into service.<br />

2002 MINERGIE label awarded for all window systems.<br />

2003 Collapse <strong>of</strong> the Erb Group, composition proceedings conducted<br />

by Uniwood Holding AG.<br />

2004 AFG Arbonia-Forster-Holding AG takes over EgoKiefer from the estate.<br />

2005 Expansion <strong>of</strong> the production plants in Villeneuve <strong>and</strong> Altstätten East.<br />

2006 Expansion <strong>of</strong> the sales organisation in Switzerl<strong>and</strong>.<br />

2007 Expansion <strong>of</strong> the headquarters <strong>and</strong> extensive anniversary celebration activities.

8<br />

«Powerful symbolism:<br />

oversized window frames lead into<br />

EgoKiefer’s miniature tent village.»

Focus 9<br />

Interview with Thomas Gerosa,<br />

Chairman <strong>of</strong> the Board <strong>of</strong> Directors<br />

<strong>and</strong> CEO <strong>of</strong> EgoKiefer AG<br />

<strong>75</strong> <strong>years</strong> – quite a happy anniversary. So what exactly<br />

is the secret <strong>of</strong> the success <strong>of</strong> EgoKiefer?<br />

Thomas Gerosa: There are several reasons why now –<br />

<strong>75</strong> <strong>years</strong> after the company was founded – our prospects are<br />

better than ever. One <strong>of</strong> the key factors is the fact that we always<br />

put people first. We know where we are coming from,<br />

<strong>and</strong> we know for whom we keep refining <strong>and</strong> developing<br />

our products.<br />

So there is no chance <strong>of</strong> EgoKiefer<br />

resting on its laurels?<br />

Thomas Gerosa: Quite the opposite. The positive developments<br />

in 2006, with more turnover <strong>and</strong> greater market<br />

shares in a highly competitive environment, are set to continue.<br />

In order to do this we have invested a lot <strong>of</strong> money, for<br />

example in the expansion <strong>of</strong> our headquarters. But the opening<br />

<strong>of</strong> the new business site in the Zurich region <strong>and</strong> – not<br />

least – the ongoing capacity expansion for window production<br />

in Altstätten <strong>and</strong> Villeneuve all form important building<br />

blocks for our future success.<br />

Celebrating a partnership lived<br />

«Advantage through ideas» is the motto which is taken<br />

very seriously at EgoKiefer. What can the company’s<br />

customers expect?<br />

Thomas Gerosa: One really good <strong>and</strong> completely up-to-date<br />

example is our award-winning XL ® plastic window technology.<br />

This window surpasses all requirements in terms <strong>of</strong> energy<br />

<strong>and</strong> the environment, <strong>and</strong> as a result it measurably saves energy.<br />

You don’t need a crystal ball to see that these are the<br />

perfect requirements for sustained success <strong>of</strong> the system in<br />

the future.<br />

So you are approaching the next <strong>75</strong> <strong>years</strong><br />

with a lot <strong>of</strong> optimism?<br />

Thomas Gerosa: Definitely, because as a company in the<br />

dynamic <strong>and</strong> strong AFG Arbonia-Forster-Holding AG group,<br />

<strong>and</strong> therefore as part <strong>of</strong> the leading supplier to the building<br />

industry, we are part <strong>of</strong> a strong network. Our self-confidence<br />

has been given a further boost by the acquisition <strong>and</strong><br />

integration <strong>of</strong> RWD Schlatter AG. As an independent unit in<br />

our division, new perspectives are opening up for all <strong>of</strong> us,<br />

particularly in the areas <strong>of</strong> fire protection, safety doors <strong>and</strong><br />

sound protection doors. «

10<br />

Net turnover<br />

+22.8%<br />

AFG half-yearly report 2007<br />

EBIT<br />

+14.2%<br />

As the half-yearly report dated August 7, 2007 shows, AFG Arbonia-Forster-Holding AG has delivered<br />

a solid half-yearly result together with a continued high rate <strong>of</strong> growth. AFG pr<strong>of</strong>ited from a largely<br />

friendly economic situation within the building trade in most <strong>of</strong> their key sales markets. Net turnover<br />

increased year-on-year by 22.8% to CHF 679.66 million (previous year: CHF 553.57 million), or by 9.3%<br />

once acquisitions are taken into account.<br />

With a capital increase <strong>of</strong> CHF 108 million with preferential<br />

subscription rights, around 1,000 shareholders set the course<br />

for the future at the AGM on April 20, 2007.<br />

«AFG is sharing its<br />

knowledge with<br />

young people.»<br />

Continuing high rate <strong>of</strong> growth<br />

Despite the in some cases significantly higher material, wage<br />

<strong>and</strong> energy costs, the revenue growth largely managed to<br />

keep up with this development in turnover. The EBITDA increased<br />

by 16.6% to CHF 65.21 million (previous year:<br />

CHF 55,93 million) <strong>and</strong> reached 9.6% (previous year: 10.1%)<br />

<strong>of</strong> the net turnover. By contrast, the amortisation <strong>of</strong> intangible<br />

assets at the acquired companies STI Surface Technologies<br />

International Holding AG <strong>and</strong> RWD Schlatter AG had a slowing<br />

effect on the EBIT development <strong>of</strong> the group. Despite this<br />

it increased by 14.2% to CHF 37.73 million (previous year:<br />

CHF 33.05 million). The EBIT margin measured against net<br />

turnover achieved 5.6% as a result (previous year: 6.0%).<br />

Due, among other things, to the increase in capital stock,<br />

own capital increased by more than a half in comparison<br />

to the cut-<strong>of</strong>f date <strong>of</strong> June 30, 2006 to CHF 500.1 million<br />

(+54.7%).<br />

Success despite inflationary pressure<br />

«In what continues to be a challenging environment, we<br />

have once again managed to attain high growth continuity<br />

<strong>and</strong> thus further exp<strong>and</strong>ed our position in all markets in<br />

which we are active», comments Dr. Edgar Oehler, Chairman<br />

<strong>of</strong> the Board <strong>of</strong> Directors <strong>and</strong> CEO <strong>of</strong> AFG Arbonia-Forster-<br />

AFG goes back to school<br />

In Switzerl<strong>and</strong>, the concept <strong>and</strong> content <strong>of</strong> the seminal textbook «Recht Staat<br />

Wirtschaft» (Law – The State – The Economy) is known to virtually everybody.<br />

September 2007 has been set as the date for publication <strong>of</strong> the 4 th edition – an edition<br />

in which AFG Arbonia-Forster-Holding AG plays an important role: the company<br />

will be acting as a partner in the area <strong>of</strong> political economics. The innovative concept<br />

<strong>of</strong> this general Swiss textbook tackles questions relating to strategies, leadership<br />

structures <strong>and</strong> market development <strong>and</strong> delivers the answers in a practical textbook<br />

format for vocational schools, technical schools, middle secondary schools (Diplommittelschule)<br />

<strong>and</strong> higher secondary schools (Gymnasium). In the process, students<br />

can utilise Internet platforms like www.afg.ch as well as the websites <strong>of</strong> the AFG<br />

subsidiaries for targeted research which allows them to draw current <strong>and</strong> practice-<br />

related links. The AFG content has been edited by Pr<strong>of</strong>. Dr. Herbert Wattenh<strong>of</strong>er.<br />

During his time as a postgraduate student at the University <strong>of</strong> St.Gallen (HSG),<br />

he taught in secondary schools, business schools <strong>and</strong> technical vocational schools.

AFG Arbonia-Forster-Holding AG 11<br />

Own capital<br />

+54.7% A<br />

Holding AG, on the pleasing half-yearly results. This was<br />

made possible despite the significantly increased cost <strong>of</strong> materials,<br />

in particular steel, energy <strong>and</strong> wage costs, which was<br />

noticeable for the first time in several <strong>years</strong> again in all markets<br />

<strong>and</strong> areas. In turn this is largely down to the weakness<br />

<strong>of</strong> the Swiss Franc <strong>and</strong> the record strength <strong>of</strong> the Euro. Material<br />

costs increased as a result by a two-digit figure in some<br />

cases, <strong>and</strong> as a rule these surcharges could not be passed on<br />

in full into the end prices.<br />

A confident outlook<br />

Thanks to the expectation <strong>of</strong> continued good market conditions,<br />

AFG expects to deliver the forecast consolidated<br />

overall turnover <strong>of</strong> CHF 1.4 billion <strong>and</strong> an operating pr<strong>of</strong>it<br />

<strong>of</strong> more than CHF 100 million in the current year – despite<br />

increasing pressure from competitors. By the end <strong>of</strong> 2007,<br />

the equity-to-assets ratio should be above 40%, which will<br />

mean that it has achieved a previously defined benchmark<br />

<strong>of</strong> the balance sheet. According to Dr. Edgar Oehler, no acquisitions<br />

are planned in the short term: «However, in the<br />

future we will continue to make the most <strong>of</strong> any opportunities<br />

to round <strong>of</strong>f our existing services portfolio. In addition,<br />

we are working intensively on intensifying activities outside<br />

our two domestic markets <strong>of</strong> Switzerl<strong>and</strong> <strong>and</strong> Germany, in<br />

order to achieve a ratio <strong>of</strong> 50:50 between the two domestic<br />

markets <strong>and</strong> all other markets in the medium term.» In<br />

order to secure the financial flexibility required for further<br />

acquisition-based <strong>and</strong> organic growth, AFG is also intending<br />

to take on a syndicated credit in the second semester. «<br />

New topics<br />

The following AFG subject areas have been incorporated in the 4 th edition:<br />

Topic 1: The value creation chain. The concept <strong>of</strong> value creation is demonstrated<br />

on the basis <strong>of</strong> a selected AFG business sector: research <strong>and</strong> development, purchasing,<br />

production, sales, customer service. Topic 2: International expansion.<br />

Here, the expansion <strong>of</strong> AFG is illustrated in terms <strong>of</strong> markets <strong>and</strong> production sites.<br />

Topic 3: AFG as a «corporate citizen» (Corporate Citizenship). AFG has always<br />

emphasised its social responsibility <strong>and</strong> observes this responsibility on a daily basis,<br />

through the provision <strong>of</strong> jobs <strong>and</strong> training positions, through environmentally<br />

friendly production processes, sustained products, sponsoring, active information<br />

policy <strong>and</strong> cooperation with authorities through to assistance with the securing<br />

<strong>and</strong>/or renovation <strong>of</strong> institutions or companies which are <strong>of</strong> public interest. The<br />

textbook is available to order free <strong>of</strong> charge from AFG via afgworld@afg.ch. «<br />

visionary:<br />

Dr. Edgar Oehler.<br />

More liquidity,<br />

more continuity<br />

AFG Arbonia-Forster-Holding AG has secured<br />

CHF 108 million for further growth <strong>and</strong> further innovation.<br />

Thanks to a capital increase <strong>of</strong> CHF 108 million<br />

with preferential subscription rights, further expansion <strong>of</strong><br />

AFG is assured. The decision was ratified at the AGM on<br />

April 20, 2007 – a memorable occasion given that the<br />

AGM was held under the banner <strong>of</strong> our 20 th anniversary<br />

celebrations. At the time, around 1,000 shareholders –<br />

a record in terms <strong>of</strong> participation – set the course for the<br />

future. 156,716 new transferable shares with a nominal<br />

value <strong>of</strong> CHF 4.20 <strong>and</strong> 337,500 registered shares (nominal<br />

value CHF 0.84) were tendered by exercising the corresponding<br />

subscription rights. This corresponds to 99.84%<br />

<strong>of</strong> all newly issued transferable shares <strong>and</strong> registered<br />

shares. The 791 registered shares which were not tendered<br />

were sold at market rate. The capital increase has<br />

not only been a success, but it is also an important prerequisite<br />

for continued successful implementation <strong>of</strong> our<br />

growth strategy, as it provides the financial flexibility<br />

which is necessary for future investments. AFG Arbonia-<br />

Forster-Holding AG will continue to rigorously follow its<br />

course <strong>of</strong> growth: increased international engagement,<br />

even more investment in research <strong>and</strong> development <strong>and</strong><br />

further acquisitions. In addition, the capital increase also<br />

helps to be able to release the funds borrowed in the<br />

short term for acquisitions. «<br />

Even more thorough: the 4 th edition<br />

<strong>of</strong> the textbook «Recht Staat Wirtschaft»<br />

(Law – The State – The Economy).

12<br />

The magnificent new Corporate Center in Arbon, Thurgau is also a role model for modern <strong>and</strong> energy-saving building.<br />

Corporate Center:<br />

move-in set for November 2007<br />

The new flagship <strong>of</strong> AFG, the Corporate Center on the outskirts <strong>of</strong> Arbon, Thurgau,<br />

is taking shape. Thanks to an ambitious schedule, the proud new building will already<br />

be ready to move into by November 2007.<br />

The symbol <strong>of</strong> a successful future at AFG<br />

No other project embodies the ambitious expansion <strong>of</strong> AFG<br />

<strong>and</strong> its clear commitment to the region better than the new<br />

Corporate Center. The project, which began with the groundbreaking<br />

ceremony on July 11, 2006 <strong>and</strong> already enjoyed the<br />

topping-out ceremony on May 2, 2007, is now nearly complete.<br />

These new headquarters <strong>of</strong> the AFG Group will pull together<br />

all <strong>of</strong> the central group services which – at present – are<br />

spread across a number <strong>of</strong> different sites. However, the new<br />

Corporate Center is more than the headquarters <strong>of</strong> AFG. «It<br />

reflects the successful development <strong>of</strong> the Group in recent<br />

<strong>years</strong> <strong>and</strong> also represents a symbol for our belief in the continued<br />

success <strong>of</strong> AFG in the future», explains Dr. Edgar Oehler.<br />

Perfect conditions for concentration <strong>and</strong> hard work<br />

Pack, relocate to the new headquarters <strong>and</strong> unpack again –<br />

this will be the order <strong>of</strong> the day for the around 250 employees<br />

currently staffing AFG’s central services in the city centre <strong>of</strong><br />

Arbon, including the senior executive management, Finance<br />

<strong>and</strong> Accounting, Central Services, Sales Management, Marketing<br />

<strong>and</strong> IT. The old buildings in the Romanshornerstrasse <strong>and</strong><br />

Zelgstrasse will be demolished <strong>and</strong> to make way for new residential<br />

buildings. In the medium term, AFG is also planning to<br />

relocate all <strong>of</strong> its employees currently working at facilities on<br />

the periphery <strong>of</strong> Arbon to the Winzelnwies industrial area. The<br />

architecture <strong>of</strong> the Corporate Center was designed by local architects’<br />

<strong>of</strong>fice Gisel + Partners AG, who worked together with<br />

the general contractor Karl Steiner AG <strong>and</strong> other companies<br />

from the field <strong>of</strong> planning to deliver a modern <strong>and</strong> contemporary<br />

design.<br />

An «Arboneria» for the Corporate Center<br />

The «Arboneria» cafeteria/restaurant in the Corporate Center<br />

is definitely set to go ahead. The further construction will include<br />

the installation <strong>of</strong> many <strong>of</strong> AFG’s own innovative products.<br />

For instance, the large windows facing Amriswilerstrasse<br />

will be supplied by EgoKiefer AG, while Forster Pr<strong>of</strong>ile Systems<br />

will be kitting out the opposite building facade with its products.<br />

The contracts for the interior finishing work are to be<br />

awarded shortly. Important elements include, for instance, the<br />

two large conference rooms to be installed on the second<br />

floor. In addition to this, there is the «Board Room» which is<br />

to be embellished with a large round or oval table. The «L<strong>and</strong>haus»<br />

restaurant <strong>and</strong> the bordering agricultural buildings are<br />

to be taken down in August 2007. One <strong>of</strong> the aims <strong>of</strong><br />

Dr. Edgar Oehler is to hold the Christmas Apéro 2007 in the<br />

lobby <strong>of</strong> the new headquarters. If the present pace continues<br />

without problems then the AFG Corporate Center will be <strong>of</strong>ficially<br />

opened on March 1, 2008. «<br />

AFG Corporate Center – key figures<br />

Space Total 62,000 m 3<br />

Office space Total 4,600 m 2<br />

Ground floor space Total 2,<strong>75</strong>0 m 2<br />

Max. building height 19 m from the ground<br />

Sublevels 3, with 290 car parking spaces<br />

Above-ground floors 4, ground floor to 3 rd floor<br />

+ 1 attic floor

AFG Arbonia-Forster-Holding AG<br />

New: AFG sponsors Swiss yachting<br />

Sailing hard into the wind.<br />

Success at the «Eidge-<br />

nössisches Turnfest»<br />

While male <strong>and</strong> female gymnasts from the whole <strong>of</strong><br />

Switzerl<strong>and</strong> displayed their skills between June 14 <strong>and</strong><br />

24, 2007 in Frauenfeld, Thurgau, AFG took an active<br />

role in the large-scale event on behalf <strong>of</strong> Thurgau<br />

commerce <strong>and</strong> enterprise. AFG <strong>and</strong> ten other renowned<br />

companies from Thurgau supported the big occasion not<br />

only through financial sponsorship, but they also took part<br />

in a special event. Under the patronage <strong>of</strong> the Thurgau<br />

Chamber <strong>of</strong> Industry <strong>and</strong> Trade (IHK), a special tent was<br />

erected containing an unusual <strong>and</strong> original assault course<br />

<strong>and</strong> a comfortable guest area serving refreshments. AFG<br />

contributed an original goal wall which drew a lot <strong>of</strong><br />

attention to the company’s activities in relation to the AFG<br />

ARENA. Anyone who managed to complete the course was<br />

immediately awarded one <strong>of</strong> the sought-after prizes: a small<br />

bag <strong>of</strong> AFG gummi-bears. In addition, visitors entered their<br />

ticket stubs into a prize draw, with a number <strong>of</strong> teams winning<br />

attractive cash prizes for their team kitty.<br />

High level <strong>of</strong> commitment<br />

In recent <strong>years</strong>, AFG has been very closely involved in a<br />

number <strong>of</strong> sponsorship activities: cultural, social, youth development,<br />

education, sport ... Of course, more recently<br />

the AFG ARENA has been the subject <strong>of</strong> much discussion.<br />

AFG aims to combine support for youth sports <strong>and</strong> general<br />

sport in the community with support for sports at top pr<strong>of</strong>es-<br />

In terms <strong>of</strong> football sponsorship, AFG Arbonia-Forster-Holding AG has<br />

already made a name for itself with the AFG ARENA in St.Gallen. Now the<br />

company is also set to get right behind Swiss yachting. AFG will become the<br />

new main sponsor <strong>of</strong> the Swiss Sailing Association, investing a generous amount<br />

every year in return. Together with the Swiss Sailing Pool (SSP), the group responsible<br />

for sponsoring within the association, a several-year deal has been struck leading<br />

up to the 2012 Olympics. The aim is to provide the up <strong>and</strong> coming talents with<br />

the support they need to achieve their ambitious goal <strong>of</strong> winning one or even<br />

several Olympic medals at the 2012 games. The task <strong>of</strong> helping to achieve these<br />

goals has fallen to the Swiss Sailing Team AG which has been specially set up for<br />

the Olympics. This task sharing is a first for Swiss Sailing – <strong>and</strong> for Swiss sports in<br />

general. AFG <strong>and</strong> SSP are thus embarking on a new <strong>and</strong> highly promising joint<br />

venture. «<br />

The AFG goal wall challenged many<br />

footballers both young <strong>and</strong> old.<br />

13<br />

A clear commitment to sport in the community<br />

The commitment shown by AFG <strong>and</strong> the other ten representatives<br />

<strong>of</strong> IHK Thurgau conveyed a clear message: together<br />

with the wider population <strong>and</strong> the sportsmen <strong>and</strong> sportswomen<br />

themselves, the business community in Thurgau has<br />

got right behind the Eidgenössisches Turnfest, the premium<br />

event for sports in the community. «<br />

sional level. In addition, AFG is also getting behind selected<br />

cultural activities <strong>and</strong> also plays a key role in maintaining the<br />

Swiss Lake Constance Fleet (SBS) <strong>and</strong> continuing the Pizol<br />

mountain railways. The company <strong>of</strong>fers committed support<br />

for sponsorship projects, whereby the funds are used even<br />

more carefully than in the past.

14<br />

Powerful pictures: The AFG electronic press kit<br />

leaves a lasting impression. With immediate<br />

effect, the full-length show reel is available to<br />

download from www.afg.ch.<br />

AFG electronic press kit –<br />

available at www.afg.ch<br />

Thanks to efforts made in the last two <strong>years</strong> to step up communication<br />

efforts, AFG Arbonia-Forster-Holding AG has now been able to close<br />

another gap: with immediate effect, anyone who is interested in seeing<br />

the show reel in its full length (approximately 15 minutes) can now do<br />

so by downloading it from www.afg.ch.<br />

At the same time it is also possible to view only the portions relating to individual<br />

segments <strong>of</strong> the division. So how did this film project come to be? As part <strong>of</strong> the<br />

production <strong>of</strong> the business magazine «Europa-Journal», which was produced in<br />

cooperation with the Thurgau Chamber <strong>of</strong> Industry <strong>and</strong> Trade (IHK) <strong>and</strong> private TV<br />

producer C.A.M.P.-TV in Munich, AFG decided in the late autumn <strong>of</strong> 2005 – just<br />

like a number <strong>of</strong> other companies from the Thurgau region – to sign up to this<br />

project <strong>and</strong> produce the company’s own electronic press kit. After an initial phase,<br />

which was characterised by intensive planning work <strong>and</strong> preparations, the next<br />

step was to work with the divisions to produce a watertight script. Filming started<br />

across Europe at all <strong>of</strong> AFG’s sites from autumn 2006 onwards. Following the<br />

acquisitions <strong>of</strong> STI | Hartchrom <strong>and</strong> RWD Schlatter, some <strong>of</strong> the work did need to<br />

be interrupted <strong>and</strong> restarted.<br />

Excellent cooperation<br />

The resulting film is a representative snapshot <strong>of</strong> the entire company which showcases<br />

all <strong>of</strong> the products, locations <strong>and</strong> markets <strong>of</strong> each division. With time, the<br />

cooperation between AFG <strong>and</strong> the TV production company blossomed in to a<br />

closely-knit <strong>and</strong> highly effective cooperation. The partnership resulted in a number<br />

<strong>of</strong> highly potent images, interesting reports <strong>and</strong> informative recordings in different<br />

areas <strong>of</strong> the business, which all made their way into the AFG electronic press kit.<br />

The recordings will also be used for a TV programme which is set to follow.<br />

Hermann Zellner, responsible project manager at C.A.M.P.-TV, expressed his gratitude<br />

for the trust displayed in his company by Dr. Edgar Oehler during the production<br />

<strong>of</strong> this film: «Even during his business trip to Plattling just before Christmas<br />

2006, when his diary was fit to burst with appointments <strong>and</strong> a tight schedule,<br />

Dr. Oehler was still available to the film crew during the Christmas celebrations for<br />

interviews for the TV film <strong>and</strong> the show reel. For this, all <strong>of</strong> us at C.A.M.P.-TV are<br />

particularly grateful to him. Thanks to the pr<strong>of</strong>essionalism <strong>of</strong> Dr. Oehler, the recordings<br />

in Plattling went <strong>of</strong>f without a hitch!» «

AFG Arbonia-Forster-Holding AG 15<br />

Building bridges<br />

with the AFG ARENA<br />

The AFG ARENA is being built to the west <strong>of</strong> the city <strong>of</strong> St.Gallen, a unique<br />

sports, shopping <strong>and</strong> leisure complex with many unusual features. The ball<br />

should start to roll as early as summer 2008. AFG Arbonia-Forster-Holding AG is<br />

not only proud to be the named backer <strong>of</strong> this superlative building project, but will<br />

also play an important role inside – for example with the gr<strong>and</strong> AFG lounge <strong>and</strong><br />

AFG st<strong>and</strong>s. «<br />

Inviting: this is where the 25 m wide staircase<br />

leading to the main entrance is being built.<br />

Safe: the AFG ARENA will have four <strong>of</strong> these pedestrian bridges, with lengths <strong>of</strong> up to 76 m. Two <strong>of</strong> them already span the A1 motorway.<br />

Impressive: the 10-level main st<strong>and</strong> reaches a proud 38.5 m into the sky<br />

(height measured from the floor section up).<br />

Unique: trucks drive straight into the heart <strong>of</strong><br />

the AFG ARENA. An approximately 300 m long<br />

tunnel which is lined with docking terminals<br />

leads through underneath the main st<strong>and</strong>.

16<br />

Heating Technology<br />

<strong>and</strong> Sanitary<br />

Equipment<br />

The Kermi Sanitary Equipment trade exhibition st<strong>and</strong>: the changing play <strong>of</strong> colours from red to blue symbolises the worlds <strong>of</strong> experience «water» <strong>and</strong> «warmth».

H e a t i n g Te c h n o l o g y a n d<br />

Sanitary Equipment<br />

Kermi Heating Technology: the elegant architecture <strong>of</strong> this st<strong>and</strong> alone was enough to turn heads.<br />

Shiny worlds <strong>of</strong> experience<br />

at the ISH<br />

At the ISH in Frankfurt in March 2007, the world-leading trade fair for bathroom technology, building<br />

services engineering, energy technology, air conditioning <strong>and</strong> renewable energies, the Division Heating<br />

Technology <strong>and</strong> Sanitary Equipment caused a real stir with their striking st<strong>and</strong> design.<br />

The three trade exhibition st<strong>and</strong>s <strong>of</strong> Arbonia, Kermi Heating<br />

Technology <strong>and</strong> Kermi Sanitary Equipment give an impressive<br />

account <strong>of</strong> the design division’s philosophy «Design & <strong>Innovation</strong>»<br />

– both in terms <strong>of</strong> the st<strong>and</strong>ard architecture <strong>and</strong> in<br />

terms <strong>of</strong> product competence. Visitors were captivated by the<br />

breezy, light <strong>and</strong> seemingly floating architecture. Staged with<br />

special lighting technology <strong>and</strong> semitransparent outer covers,<br />

the between 5 <strong>and</strong> 7.5 m high domes made an excellent impact.<br />

Depending on the chosen light settings, the visitors<br />

were guided into three different worlds <strong>of</strong> experience, each<br />

<strong>of</strong> which imparted its own clear <strong>and</strong> individual br<strong>and</strong> experience.<br />

Within the bright orange realm <strong>of</strong> the Arbonia trade<br />

fair st<strong>and</strong>, the visitors’ interest focussed on the new underfloor<br />

convector heaters being unveiled for the German market<br />

<strong>and</strong> the impressive variety <strong>of</strong> special radiators on show.<br />

Therm X2 – one <strong>of</strong> the highlights<br />

The Kermi exhibition st<strong>and</strong>s used the colours blue <strong>and</strong> red to<br />

symbolise not just the worlds <strong>of</strong> experience «water» <strong>and</strong><br />

«warmth», but also managed to use the intermittently<br />

changing lighting to impressively highlight the connection<br />

between the two st<strong>and</strong>s. Visitors to the st<strong>and</strong> were clearly<br />

impressed with the energy-saving panel radiator Therm X2,<br />

without doubt one <strong>of</strong> the highlights <strong>of</strong> the display. The xlink<br />

range <strong>of</strong> connection fittings, a smart system solution for connecting<br />

up the combination <strong>of</strong> heated towel rail <strong>and</strong> under-<br />

floor heating system, also enjoyed a very warm response. In<br />

the bathroom area, the trendsetting designs <strong>of</strong> the two new<br />

heated towel rails Credo-Duo <strong>and</strong> Icaro <strong>and</strong> the two new<br />

shower cabin ranges Gia <strong>and</strong> Gia XP also found widespread<br />

recognition. Impressions <strong>and</strong> clips <strong>of</strong> the three «experience<br />

worlds» can be downloaded on the Internet from<br />

www.arbonia.de or www.kermi.de. «<br />

ISH Frankfurt<br />

World-leading trade fair for bathroom technology, building<br />

services engineering, energy technology, air conditioning <strong>and</strong><br />

renewable energies<br />

Location Frankfurt exhibition grounds (Germany)<br />

Target group Trade visitors<br />

Duration March 6 to 10, 2007<br />

Frequency Every 2 <strong>years</strong><br />

Visitors 215,378 (2005: 192,187)<br />

<strong>of</strong> which 53,844 came from abroad<br />

Exhibitors 2,392 (2005: 2,345) from 58 countries<br />

Exhibition floor space 254,000 m 2<br />

Next ISH March 10 to 14, 2009<br />

17

18<br />

Warmth<br />

xlink: the perfect combination!<br />

More <strong>and</strong> more customers are opting for a combination <strong>of</strong> heated towel<br />

rail <strong>and</strong> underfloor heating system. Kermi GmbH has now developed<br />

xlink – a range <strong>of</strong> connection fittings for underfloor heating systems.<br />

Despite being completely invisible after installation, xlink delivers a constant floor<br />

temperature in the bathroom. As underfloor heating systems <strong>and</strong> radiators are<br />

operated at different temperatures, separate heating circuits were needed in<br />

the past. However, with the new xlink system, Kermi has now come up with the<br />

perfect solution – connection fittings for underfloor heating systems. xlink can<br />

be concealed behind the radiator cover <strong>of</strong> the Credo-V <strong>and</strong> the new Credo-Duo<br />

systems, from where it delivers constant floor temperature control in the bathroom<br />

– completely independently <strong>of</strong> the room temperature, <strong>and</strong> with no power<br />

supply <strong>and</strong> no complicated installation required.<br />

Also suitable for renovation projects without complicated additional work<br />

Interventions into the boiler control system are also a thing <strong>of</strong> the past: xlink is<br />

simply attached to the existing set <strong>of</strong> valve fittings on the heated towel rail. xlink<br />

is suitable for all Kermi xnet underfloor heating systems. It also lends itself very<br />

well to renovation projects in combination with the new xnet C15 thin layer<br />

system. Thanks to the fact that this system is extremely flat <strong>and</strong> also very quick<br />

to install on a wide variety <strong>of</strong> floor coverings, warm feet can soon be an everyday<br />

luxury – without the need for heavy-duty demolition work! «<br />

Russia: first we supplied the heating<br />

systems, now the showers<br />

Kermi has already played an active role in the Russian market since 1996, with sales <strong>of</strong> heating<br />

technology products that have already shown quite some success. The company originally<br />

launched itself in Russia with panel radiators, but this was soon followed by convector heaters,<br />

designer radiators <strong>and</strong>, finally, the xnet surface temperature control systems.<br />

After the fall <strong>of</strong> the Iron Curtain, heating systems featuring<br />

modern, contemporary <strong>and</strong> reliable engineering <strong>and</strong> technology<br />

were given the highest priority. Looking at the impressive<br />

size <strong>of</strong> Russia on a map <strong>of</strong> the world, it is clear that, in addi-<br />

Trade exhibition st<strong>and</strong> at the Mosbuild trade fair in Moscow:<br />

this is where the Kermi shower cubicle systems were launched at<br />

the start <strong>of</strong> April 2007, together with the designer bathroom<br />

radiators <strong>and</strong> towel heaters.<br />

The perfect combination for your bathroom –<br />

Kermi Credo-V with integrated xlink connection<br />

fittings for xnet underfloor heating systems.<br />

tion to Moscow <strong>and</strong> St.Petersburg, the country has a large<br />

number <strong>of</strong> other cities, large towns <strong>and</strong> regions which are<br />

still a long way from having the significantly improved heating<br />

technology that is now found more regularly in the two<br />

major cities. Now the Russian market is ready for another<br />

product from the Division Heating Technology <strong>and</strong> Sanitary<br />

Equipment: shower cubicle systems. Although this was always<br />

part <strong>of</strong> the display on show in the showmobile, the focus at<br />

the time was clearly on selling the heating technology products.<br />

The launch <strong>of</strong> shower accessories was kicked <strong>of</strong>f at the<br />

start <strong>of</strong> April 2007 at the Mosbuild trade fair in Moscow.<br />

Here, Kermi presented a range <strong>of</strong> shower cubicle systems<br />

together with a partner, the company Eco Dusch – <strong>and</strong> naturally<br />

the st<strong>and</strong> also featured a selection <strong>of</strong> designer bathroom<br />

radiators <strong>and</strong> towel heaters. The display generated a lot <strong>of</strong><br />

interest among the exhibition visitors. Kermi is now working<br />

hard to ensure that the shower cubicle systems follow in the<br />

successful steps <strong>of</strong> the heating technology products. «

H e a t i n g Te c h n o l o g y a n d<br />

Sanitary Equipment<br />

Therm X2 panel radiators<br />

lower costs by up to 20%<br />

With the Therm X2, Kermi GmbH has managed to significantly improve the efficiency <strong>of</strong> their<br />

valve-design panel radiators – with an energy saving effect <strong>of</strong> up to 11%, heating time reduced<br />

by 25%, costs reduced by up to 20% <strong>and</strong> lower CO 2 emissions.<br />

At the same time, the Therm X2 impresses with dynamic performance<br />

<strong>and</strong> optimal thermal comfort. In accordance with<br />

the current st<strong>and</strong>ards, only a small proportion <strong>of</strong> the rated<br />

heating load is required during controlled operation, which<br />

accounts for up to 90 to 95% <strong>of</strong> a heating period. As a result,<br />

the flow (mass flow) is significantly reduced <strong>and</strong> the average<br />

surface temperature drops significantly. As only the upper<br />

part <strong>of</strong> the radiator is heated, this <strong>of</strong>ten gives the incorrect<br />

impression that the radiator is defective or inoperative.<br />

Connection: serial instead <strong>of</strong> parallel<br />

Kermi valve-design panel radiators solve this problem with<br />

the X2 technology. The innovative <strong>and</strong> patented way in<br />

which they work takes both energy saving aspects <strong>and</strong> thermal<br />

comfort considerations into account. Whereas on conventional<br />

multi-layer radiators, a parallel flow is directed<br />

through all <strong>of</strong> the plates, the Therm X2 features a serial flow<br />

layout. In controlled operation the front plate is heated preferentially,<br />

<strong>and</strong> its output is perfectly sufficient for this operating<br />

mode. As a result, a higher average surface temperature<br />

is generated in comparison to the conventional technology,<br />

with up to 100% more comfortable radiated heat.<br />

Heating time reduced by up to 25%<br />

The rear plates remain cooler, <strong>and</strong> during controlled operation<br />

they act as a heat shield to the wall thanks to their low<br />

emission <strong>of</strong> radiated heat, thus increasing the efficiency <strong>of</strong><br />

the radiator. They are only heated up when greater heating<br />

output is required, at which point they deliver a high convective<br />

heating output <strong>and</strong> contribute to efficient heating <strong>of</strong> the<br />

room. At the same time the X2 technology delivers a more<br />

dynamic performance <strong>and</strong> reduces heating times by up to<br />

25%. This results in a significant reduction <strong>of</strong> overall energy<br />

requirements. As a result, an energy saving effect <strong>of</strong> up to<br />

In controlled operation, the Therm X2 initially heats up the entire front<br />

plate <strong>of</strong> the serial-flow panel radiator; while the cold heating plate at<br />

the back acts as a shield between the warm front plate <strong>of</strong> the radiator<br />

<strong>and</strong> the external wall.<br />

11% can be achieved – an order <strong>of</strong> magnitude previously<br />

thought to be unattainable.<br />

Saving money – <strong>and</strong> the environment<br />

In conjunction with the valve inserts which are pre-adjusted<br />

in the factory it is possible to make further savings <strong>of</strong> up to<br />

20% <strong>of</strong> the energy costs for the heating circuit pump. The<br />

potential annual savings that can be made with the Therm<br />

X2 in comparison to conventional panel radiators can be<br />

calculated quickly <strong>and</strong> easily with the aid <strong>of</strong> the X2 energy<br />

savings calculation tool at www.thermx2.de. As well as the<br />

savings in terms <strong>of</strong> heating costs, another coincidental benefit<br />

is the lowering <strong>of</strong> CO 2 emissions from the heating system. «<br />

Kermi valve panel radiators blend harmoniously with any surroundings<br />

<strong>and</strong> contribute to a great feeling <strong>of</strong> warmth <strong>and</strong> comfort with their<br />

innovative X2 technology – whilst at the same time delivering energy<br />

savings <strong>of</strong> up to 11%.<br />

19

20<br />

EDI (Electronic Data Interchange) saves time,<br />

paper <strong>and</strong> money.<br />

At Kermi GmbH, Paul Puhl (left) <strong>and</strong><br />

Alfred Hackl are responsible for EDI.<br />

Kermi:<br />

even more efficient with EDI<br />

With EDI, this type <strong>of</strong> transaction is changed radically. The term EDI is used<br />

to describe an electronic, paperless system for exchanging business data<br />

(EDI = Electronic Data Interchange). A file with the ordering data arrives from<br />

the customer’s computer system. The ordering data are then automatically trans-<br />

ferred to the SAP system, which then instantly uses them to generate a customer<br />

order. The process is exactly the same for data which are sent to the customer. This<br />

means that no paper – <strong>and</strong> no postage – are needed any more for order confirma-<br />

tions <strong>and</strong> invoices. The EDI files for order confirmations <strong>and</strong> invoices are created<br />

automatically <strong>and</strong> sent electronically to the customer. «<br />

Arbonia <strong>and</strong> Prolux: «Faites vos jeux!»<br />

With radiators from the two companies Arbonia AG <strong>and</strong> Prolux AG Radiators, the customer is always<br />

a winner. The decision as to who could count themselves among the lucky winners at the roulette<br />

table was decided at the trade fair st<strong>and</strong> <strong>of</strong> Arbonia <strong>and</strong> Prolux at the Swissbau 07 exhibition.<br />

Comfort, warmth, living quality <strong>and</strong> wellbeing – all thanks to<br />

innovative technology from Arbonia <strong>and</strong> Prolux. However,<br />

visitors to the Swissbau trade exhibition were not only attracted<br />

by the excellent products <strong>and</strong> systems on display, as<br />

the excitement <strong>of</strong> the roulette wheel attracted many fascinated<br />

visitors to the st<strong>and</strong>. Every day, a winner was chosen from<br />

all the participants – with an experience day in eastern Switzerl<strong>and</strong>,<br />

the homel<strong>and</strong> <strong>of</strong> AFG Arbonia-Forster-Holding AG, up<br />

for grabs every day. On June 8, 2007 it was finally time! The<br />