1 - Hjallerup Maskinforretning A/S

1 - Hjallerup Maskinforretning A/S

1 - Hjallerup Maskinforretning A/S

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DRIVING INSTRUCTIONS AND MAINTE-<br />

NANCE<br />

LEVEL INDICATOR<br />

The loader is equipped with a level indicator, which gives<br />

the angle of the implement relative to the ground, when,<br />

for example, handling pallets. See "Loader, Mounting".<br />

ENGLISH (119-501)<br />

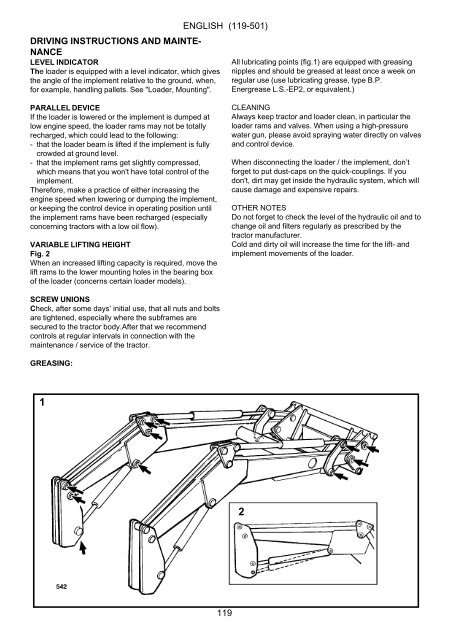

All lubricating points (fig.1) are equipped with greasing<br />

nipples and should be greased at least once a week on<br />

regular use (use lubricating grease, type B.P.<br />

Energrease L.S.-EP2, or equivalent.)<br />

PARALLEL DEVICE<br />

If the loader is lowered or the implement is dumped at<br />

low engine speed, the loader rams may not be totally<br />

recharged, which could lead to the following:<br />

- that the loader beam is lifted if the implement is fully<br />

crowded at ground level.<br />

- that the implement rams get slightly compressed,<br />

which means that you won't have total control of the<br />

implement.<br />

Therefore, make a practice of either increasing the<br />

engine speed when lowering or dumping the implement,<br />

or keeping the control device in operating position until<br />

the implement rams have been recharged (especially<br />

concerning tractors with a low oil flow).<br />

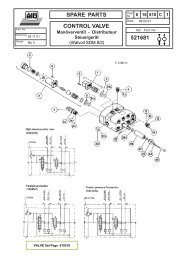

VARIABLE LIFTING HEIGHT<br />

Fig. 2<br />

When an increased lifting capacity is required, move the<br />

lift rams to the lower mounting holes in the bearing box<br />

of the loader (concerns certain loader models).<br />

CLEANING<br />

Always keep tractor and loader clean, in particular the<br />

loader rams and valves. When using a high-pressure<br />

water gun, please avoid spraying water directly on valves<br />

and control device.<br />

When disconnecting the loader / the implement, don’t<br />

forget to put dust-caps on the quick-couplings. If you<br />

don't, dirt may get inside the hydraulic system, which will<br />

cause damage and expensive repairs.<br />

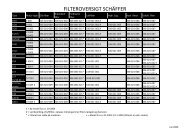

OTHER NOTES<br />

Do not forget to check the level of the hydraulic oil and to<br />

change oil and filters regularly as prescribed by the<br />

tractor manufacturer.<br />

Cold and dirty oil will increase the time for the lift- and<br />

implement movements of the loader.<br />

SCREW UNIONS<br />

Check, after some days’ initial use, that all nuts and bolts<br />

are tightened, especially where the subframes are<br />

secured to the tractor body.After that we recommend<br />

controls at regular intervals in connection with the<br />

maintenance / service of the tractor.<br />

GREASING:<br />

1<br />

2<br />

119