F 110 NT - RAPIDO Wärmetechnik GmbH

F 110 NT - RAPIDO Wärmetechnik GmbH

F 110 NT - RAPIDO Wärmetechnik GmbH

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

7. Installation<br />

Installation must be carried out by a qualified technician,<br />

who takes responsibility both for installation and for putting<br />

the unit into operation, as laid down in regulations.<br />

7.1 Connection to water supply<br />

The heating advance and back-flow connections are in the<br />

end section in the upper and lower boiler hub axis extension.<br />

The water distribution pipe drain holes must be lined<br />

up horizontally. A heating back-flow connection must be<br />

pre-fitted to permit filling and draining of the boiler.<br />

The safety valve should be installed in the heating advance,<br />

in the immediate vicinity of the boiler (valid for enclosed<br />

units).<br />

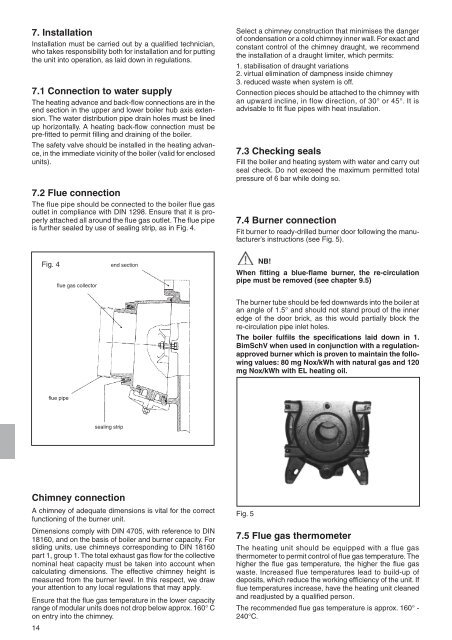

7.2 Flue connection<br />

The flue pipe should be connected to the boiler flue gas<br />

outlet in compliance with DIN 1298. Ensure that it is properly<br />

attached all around the flue gas outlet. The flue pipe<br />

is further sealed by use of sealing strip, as in Fig. 4.<br />

Fig. 4 end section<br />

flue gas collector<br />

flue pipe<br />

sealing strip<br />

Chimney connection<br />

A chimney of adequate dimensions is vital for the correct<br />

functioning of the burner unit.<br />

Dimensions comply with DIN 4705, with reference to DIN<br />

18160, and on the basis of boiler and burner capacity. For<br />

sliding units, use chimneys corresponding to DIN 18160<br />

part 1, group 1. The total exhaust gas flow for the collective<br />

nominal heat capacity must be taken into account when<br />

calculating dimensions. The effective chimney height is<br />

measured from the burner level. In this respect, we draw<br />

your attention to any local regulations that may apply.<br />

Ensure that the flue gas temperature in the lower capacity<br />

range of modular units does not drop below approx. 160° C<br />

on entry into the chimney.<br />

14<br />

Select a chimney construction that minimises the danger<br />

of condensation or a cold chimney inner wall. For exact and<br />

constant control of the chimney draught, we recommend<br />

the installation of a draught limiter, which permits:<br />

1. stabilisation of draught variations<br />

2. virtual elimination of dampness inside chimney<br />

3. reduced waste when system is off.<br />

Connection pieces should be attached to the chimney with<br />

an upward incline, in flow direction, of 30° or 45°. It is<br />

advisable to fit flue pipes with heat insulation.<br />

7.3 Checking seals<br />

Fill the boiler and heating system with water and carry out<br />

seal check. Do not exceed the maximum permitted total<br />

pressure of 6 bar while doing so.<br />

7.4 Burner connection<br />

Fit burner to ready-drilled burner door following the manufacturer’s<br />

instructions (see Fig. 5).<br />

NB!<br />

When fitting a blue-flame burner, the re-circulation<br />

pipe must be removed (see chapter 9.5)<br />

The burner tube should be fed downwards into the boiler at<br />

an angle of 1.5° and should not stand proud of the inner<br />

edge of the door brick, as this would partially block the<br />

re-circulation pipe inlet holes.<br />

The boiler fulfils the specifications laid down in 1.<br />

BimSchV when used in conjunction with a regulationapproved<br />

burner which is proven to maintain the following<br />

values: 80 mg Nox/kWh with natural gas and 120<br />

mg Nox/kWh with EL heating oil.<br />

Fig. 5<br />

7.5 Flue gas thermometer<br />

The heating unit should be equipped with a flue gas<br />

thermometer to permit control of flue gas temperature. The<br />

higher the flue gas temperature, the higher the flue gas<br />

waste. Increased flue temperatures lead to build-up of<br />

deposits, which reduce the working efficiency of the unit. If<br />

flue temperatures increase, have the heating unit cleaned<br />

and readjusted by a qualified person.<br />

The recommended flue gas temperature is approx. 160° -<br />

240°C.