F 110 NT - RAPIDO Wärmetechnik GmbH

F 110 NT - RAPIDO Wärmetechnik GmbH

F 110 NT - RAPIDO Wärmetechnik GmbH

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

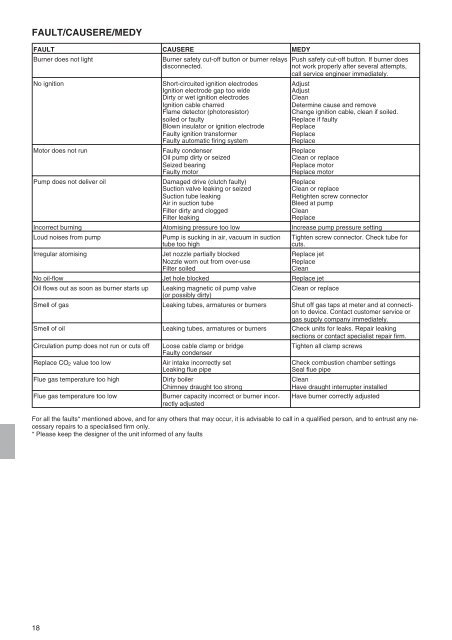

FAULT/CAUSERE/MEDY<br />

FAULT CAUSERE MEDY<br />

Burner does not light Burner safety cut-off button or burner relays<br />

disconnected.<br />

No ignition Short-circuited ignition electrodes<br />

Ignition electrode gap too wide<br />

Dirty or wet ignition electrodes<br />

Ignition cable charred<br />

Flame detector (photoresistor)<br />

soiled or faulty<br />

Blown insulator or ignition electrode<br />

Faulty ignition transformer<br />

Faulty automatic firing system<br />

Motor does not run Faulty condenser<br />

Oil pump dirty or seized<br />

Seized bearing<br />

Faulty motor<br />

Pump does not deliver oil Damaged drive (clutch faulty)<br />

Suction valve leaking or seized<br />

Suction tube leaking<br />

Air in suction tube<br />

Filter dirty and clogged<br />

Filter leaking<br />

18<br />

Push safety cut-off button. If burner does<br />

not work properly after several attempts,<br />

call service engineer immediately.<br />

Adjust<br />

Adjust<br />

Clean<br />

Determine cause and remove<br />

Change ignition cable, clean if soiled.<br />

Replace if faulty<br />

Replace<br />

Replace<br />

Replace<br />

Replace<br />

Clean or replace<br />

Replace motor<br />

Replace motor<br />

Replace<br />

Clean or replace<br />

Retighten screw connector<br />

Bleed at pump<br />

Clean<br />

Replace<br />

Incorrect burning Atomising pressure too low Increase pump pressure setting<br />

Loud noises from pump Pump is sucking in air, vacuum in suction<br />

tube too high<br />

Irregular atomising Jet nozzle partially blocked<br />

Nozzle worn out from over-use<br />

Filter soiled<br />

Tighten screw connector. Check tube for<br />

cuts.<br />

Replace jet<br />

Replace<br />

Clean<br />

No oil-flow Jet hole blocked Replace jet<br />

Oil flows out as soon as burner starts up Leaking magnetic oil pump valve<br />

(or possibly dirty)<br />

Clean or replace<br />

Smell of gas Leaking tubes, armatures or burners Shut off gas taps at meter and at connection<br />

to device. Contact customer service or<br />

gas supply company immediately.<br />

Smell of oil Leaking tubes, armatures or burners Check units for leaks. Repair leaking<br />

sections or contact specialist repair firm.<br />

Circulation pump does not run or cuts off Loose cable clamp or bridge<br />

Faulty condenser<br />

Tighten all clamp screws<br />

Replace CO2 value too low Air intake incorrectly set<br />

Check combustion chamber settings<br />

Leaking flue pipe<br />

Seal flue pipe<br />

Flue gas temperature too high Dirty boiler<br />

Clean<br />

Chimney draught too strong<br />

Have draught interrupter installed<br />

Flue gas temperature too low Burner capacity incorrect or burner incorrectly<br />

adjusted<br />

Have burner correctly adjusted<br />

For all the faults* mentioned above, and for any others that may occur, it is advisable to call in a qualified person, and to entrust any necessary<br />

repairs to a specialised firm only.<br />

* Please keep the designer of the unit informed of any faults