bunsenmagazin - Deutsche Bunsengesellschaft für Physikalische ...

bunsenmagazin - Deutsche Bunsengesellschaft für Physikalische ...

bunsenmagazin - Deutsche Bunsengesellschaft für Physikalische ...

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

UNTERRICHT<br />

It is interesting to see, that the current effi ciency increases with<br />

increasing current density. Furthermore, as to be expected, the<br />

effi ciencies are independent from the substrate because after<br />

a short deposition time they are completely covered with<br />

nickel.<br />

b) electroless deposition<br />

Electroless metal deposition means the reduction of metal<br />

ions by a reducing agent that is present in the solution.<br />

Metal ion + Red ---> Metal + Ox<br />

This technique is especially advantageous when a layer of uniform<br />

thickness is desired on a material of complicated shape<br />

or when many similar objects are to be treated,<br />

The most prominent examples for such reactions are the copper<br />

deposition with formaldehyde in alkaline solution and the reduction<br />

of nickel with sodium hyphosphate. In the latter case not only<br />

nickel ions are reduced, also some hypophosphate is reduced to<br />

phosphorus. The product is a mixture of glassy nickel-phosphorus<br />

and hexagonal nickel, supersaturated with phosphorus. We<br />

will return to this reaction in the next paragraph. In order to stabilize<br />

copper ions in alkaline medium a complex former, in this<br />

case ethylendiamonotetraacetate, EDTA, must be present.<br />

In order to obtain a metal deposit only on a certain surface,<br />

it is necessary that the reaction occurs with negligible rate in<br />

the homogeneous phase and on the remaining other surfaces.<br />

This is achieved if the reduction reaction is heterogeneously<br />

catalyzed by the metal‘s surface. Hence, electroless deposition<br />

must be an autocatalytic process. If one wants to metallize an<br />

isolating surface like a polymer surface very small particles of<br />

a metallic catalyst like palladium must be deposited fi rst. The<br />

electroless deposition can easily be monitored with an EQCM.<br />

If, for instance, during the deposition a copper surface is the<br />

working electrode in an electrochemical cell, polarization leads<br />

to an external current. This current is the algebraic sum of the<br />

cathodic copper deposition current and the anodic formaldehyde<br />

oxidation current. The EQCM permits to monitor the cathodic<br />

current as a function of the potential because it is the<br />

only reaction that leads to a mass change of the electrode. The<br />

anodic current then is the difference between the total current<br />

and the cathodic current. Schumacher et al 22 detected by use<br />

of the EQCM that an intermediate of the formaldehyde oxidation<br />

catalyzes the copper reduction from the Cu-EDTA-complexes. It<br />

can be demonstrated by cathodic polarization that the copper<br />

reduction current is zero when no formaldehyde is present and<br />

increases with increasing formaldehyde concentration in spite<br />

of the fact that the necessary electrons are supplied by the<br />

outer circuit 23 , see Fig. 13. Also when by anodic<br />

168<br />

Ag 2.4 3.0 0.17<br />

Ni 2.4 3.1 0.18<br />

Au 2.4 3.0 0.17<br />

Ag 4.5 7.6 0.43<br />

Ni 4.5 7.8 0.44<br />

Au 4.5 8.4 0.47<br />

BUNSEN-MAGAZIN · 9. JAHRGANG · 5/2007<br />

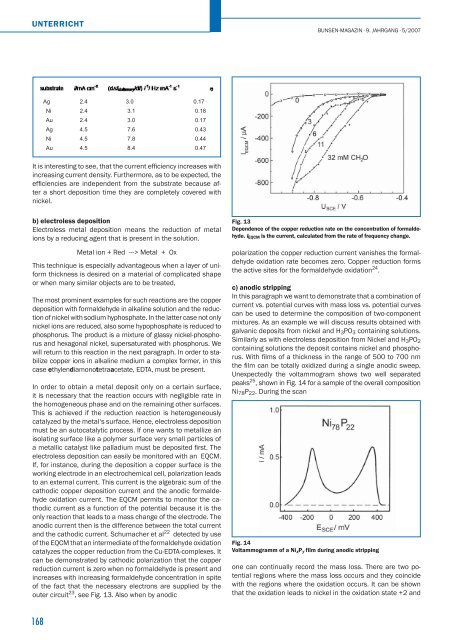

Fig. 13<br />

Dependence of the copper reduction rate on the concentration of formaldehyde.<br />

IEQCM is the current, calculated from the rate of frequency change.<br />

polarization the copper reduction current vanishes the formaldehyde<br />

oxidation rate becomes zero. Copper reduction forms<br />

the active sites for the formaldehyde oxidation 24 .<br />

c) anodic stripping<br />

In this paragraph we want to demonstrate that a combination of<br />

current vs. potential curves with mass loss vs. potential curves<br />

can be used to determine the composition of two-component<br />

mixtures. As an example we will discuss results obtained with<br />

galvanic deposits from nickel and H3PO3 containing solutions.<br />

Similarly as with electroless deposition from Nickel and H3PO2<br />

containing solutions the deposit contains nickel and phosphorus.<br />

With fi lms of a thickness in the range of 500 to 700 nm<br />

the fi lm can be totally oxidized during a single anodic sweep.<br />

Unexpectedly the voltammogram shows two well separated<br />

peaks 25 , shown in Fig. 14 for a sample of the overall composition<br />

Ni78P22. During the scan<br />

Fig. 14<br />

Voltammogramm of a NixPy film during anodic stripping<br />

one can continually record the mass loss. There are two potential<br />

regions where the mass loss occurs and they coincide<br />

with the regions where the oxidation occurs. It can be shown<br />

that the oxidation leads to nickel in the oxidation state +2 and