Comfort 820 - Marantec

Comfort 820 - Marantec

Comfort 820 - Marantec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

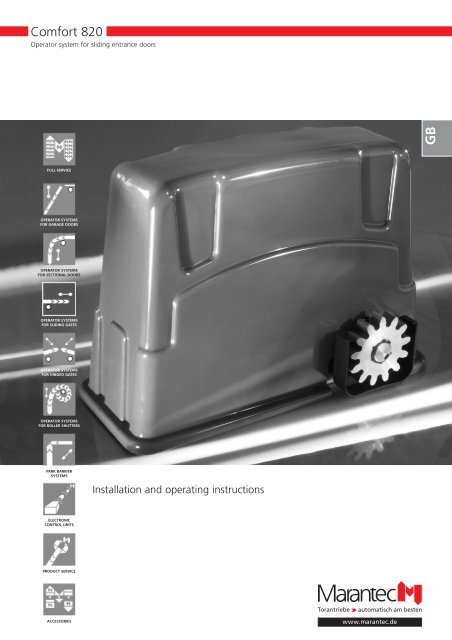

<strong>Comfort</strong> <strong>820</strong><br />

Operator system for sliding entrance doors<br />

FULL-SERVICE<br />

OPERATOR SYSTEMS<br />

FOR GARAGE DOORS<br />

OPERATOR SYSTEMS<br />

FOR SECTIONAL DOORS<br />

OPERATOR SYSTEMS<br />

FOR SLIDING GATES<br />

OPERATOR SYSTEMS<br />

FOR HINGED GATES<br />

OPERATOR SYSTEMS<br />

FOR ROLLER SHUTTERS<br />

PARK BARRIER<br />

SYSTEMS<br />

ELECTRONIC<br />

CONTROL UNITS<br />

PRODUCT SERVICE<br />

ACCESSORIES<br />

Installation and operating instructions<br />

GB

1. Meaning of symbols<br />

Symbols for control unit and operator Advice<br />

Photocell<br />

End position OPEN<br />

Automatic timer function<br />

End position CLOSED<br />

Control reference point<br />

Malfunction<br />

Impulse<br />

Operation, voltage<br />

Closing edge safety device<br />

Stop<br />

External control elements<br />

Electronic aerial<br />

Caution!<br />

Danger of personal injuries!<br />

The following safety advice must be<br />

observed at all times so as to avoid<br />

personal injuries!<br />

Attention!<br />

Danger of material damage!<br />

The following safety advice must be<br />

observed at all times so as to avoid<br />

material damages!<br />

Advice / Tip<br />

Control<br />

Reference<br />

2 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

i<br />

Type plate control unit<br />

Type:<br />

Art.-No.:<br />

Product-No.:<br />

Type plate operator<br />

Typ:<br />

Art.-No.:<br />

Product-No.:

2. Table of contents<br />

1. Meaning of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2<br />

2. Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3<br />

3. General safety advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4<br />

4. Summary of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

4.1 Supply package <strong>Comfort</strong> <strong>820</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

4.2 Mounting variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

5. Preparation for mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

5.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

5.2 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

5.3 Plan of door and foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

6. Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

6.1 Mounting the spur gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

6.2 Mounting the support brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

6.3 Cabling of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

6.4 Adjustment of the toothed rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17<br />

6.5 Mounting the toothed rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20<br />

6.6 Mounting the reference point magnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25<br />

6.7 Emergency release in case of power failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28<br />

6.8 Mounting the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29<br />

6.9 Connection of external control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

7. Hand transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32<br />

7.1 Operation and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32<br />

7.2 Coding of the hand transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33<br />

8. Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36<br />

8.1 Overview of the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36<br />

8.2 Overview on the display functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37<br />

9. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38<br />

9.1 General notes on programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38<br />

9.2 Programming of the basic level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40<br />

9.3 Extended operator functions (only for specialist personnel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46<br />

10. Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52<br />

10.1 Display of the messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52<br />

10.2 Overview of the error numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53<br />

10.3 Trouble-shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54<br />

11. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56<br />

11.1 Wiring plan <strong>Comfort</strong> <strong>820</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56<br />

11.2 Summary on spare parts <strong>Comfort</strong> <strong>820</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58<br />

11.3 Technical details <strong>Comfort</strong> <strong>820</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60<br />

11.4 Manufacturer's Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61<br />

11.5 EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)3

3. General safety advice<br />

Please read carefully!<br />

Target group<br />

Mounting, installation and initial operation of this operator may only be carried out by specialist personnel!<br />

Qualified and trained specialist personnel are persons<br />

• who have knowledge of the general and special safety regulations,<br />

• who have knowledge of the relevant electro-technical regulations,<br />

• with training in the use and maintenance of suitable safety equipment,<br />

• with sufficient training and supervision by electricians,<br />

• who are able to recognize the special hazards involved when working with electricity.<br />

Warranty<br />

For a warranty with respect to functioning and safety the advices in these instructions have to be observed.<br />

Disregarding these warnings may lead to personal injuries or material damages. The manufacturer will not be liable<br />

for damages that might occur when neglecting this advice.<br />

Batteries, fuses and bulbs are excluded from warranty.<br />

To avoid installation mistakes and damages to the door and operator please follow exactly the mounting advice in these<br />

installation instructions. The system may only be used after thorough information on the respective mounting and<br />

installation instructions.<br />

Please keep these installation and operating instructions for further use. They contain important advice for operation,<br />

checks and maintenance.<br />

This item is produced according to the directives and standards mentioned in the Manufacturer's Declaration and in the<br />

Declaration of Conformity. The product has left the factory in perfect condition with regard to safety.<br />

Power-driven windows, doors and gates for industrial use must be checked before initial operation and if necessary,<br />

but at least once a year by a specialist (with documentation in writing)!<br />

Correct use<br />

The operator is meant to be used exclusively to open and close sliding entrance doors.<br />

Beside the advice in these instructions please observe the general precautions and safety regulations!<br />

Our sales and supply terms and conditions are effective.<br />

4 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)

3. General safety advice<br />

Please read carefully!<br />

Advice for installation of the operator<br />

• Make sure that the door is in mechanical good condition.<br />

• Make sure, that the door is balanced.<br />

• Make sure that the door opens and closes correctly.<br />

• Remove all components that are not required (e.g. cords, chains, angles etc.).<br />

• Switch off all devices which will not be needed after the operator is installed.<br />

• Before cabling works the operator has to be disconnected by all means from power supply and a waiting time<br />

of 10 sec. has to be kept in order to be sure that the operator is without power.<br />

• Observe the local safety regulations.<br />

• Always lay mains and control cables separately. The control voltage is 24 V DC.<br />

• Only mount the operator when the door is closed.<br />

• Install all impulse and control devices (e.g. RC code keypad) within sight to the door and in a safe distance to<br />

movable parts of the door. A minimum mounting height of 1,5 m has to be kept.<br />

• Following installation, ensure that door parts do not protrude onto public footpaths or streets.<br />

Advice for initial operation of the operator<br />

After initial operation, the door system operating personnel or their proxies must be familiarised with the use of the<br />

system<br />

• Make sure that no child will play with the door control unit.<br />

• Before movement of the door make sure that there are neither persons nor objects in the operating grange of the<br />

door.<br />

• Test all existing emergency command devices.<br />

• Never insert your hands into a running door or moving parts.<br />

Advice for maintenance of the operator<br />

To guarantee a function without faults, check and, if necessary, repair the following points. Always disconnect<br />

the operator from power supply before carrying out any works at the door system.<br />

• Check monthly whether the operator reverses as soon as the door meets an obstacle. For this put a 50 mm high /<br />

wide obstacle in the door travel path.<br />

• Check the settings of the "OPEN" and "CLOSE" power limit.<br />

• Check all movable parts of the door and operator system.<br />

• Check the door system for signs of wear or damages.<br />

• Check whether the door can be easily moved by hand.<br />

Advice for cleaning the operator<br />

For cleaning never use: direct jet of water, high pressure cleaner, acids or lye.<br />

• Clean the operator with a dry cloth if necessary.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)5

4. Summary of the product<br />

4.1 Supply package <strong>Comfort</strong> <strong>820</strong><br />

Standard supply package Spur gears incl. trap protection<br />

4.1 / 1<br />

C<br />

E F<br />

A Operator<br />

B Cover<br />

C Magnet holder kit<br />

D Hand transmitter<br />

E Learning plug<br />

F Visor clip<br />

G Key for emergency release<br />

H Plugs<br />

A B<br />

D G H<br />

Beside the standard supply package the following<br />

accessories are necessary for mounting:<br />

- Spur gear<br />

- Toothed rack<br />

- Support bracket<br />

The operator can be mounted with two different spur<br />

gears.<br />

6 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

4.1 / 2<br />

Modul 4<br />

Requires the combination with a rail M4.<br />

Modul 6<br />

Requires the combination with a rail M6.

4. Summary of the product<br />

Toothed racks<br />

The operator can be combined with seven different<br />

toothed racks.<br />

Special 431 (M4) + Special 433 (M6)<br />

Aluminium toothed rack profile<br />

with plastic toothed rack segment<br />

4.1 / 3<br />

I J<br />

I<br />

K<br />

K<br />

L<br />

Special 432 (M4) + Special 434 (M6)<br />

Steel toothed rack profile<br />

with plastic toothed rack segment<br />

4.1 / 4<br />

J<br />

L<br />

M<br />

M<br />

Special 441 (M4) + Special 443 (M6)<br />

Aluminium toothed rack profile with plastic<br />

toothed rack segments and cable duct<br />

4.1 / 5<br />

The supply package of the toothed rack contains:<br />

I Toothed rack profile<br />

J Plastic toothed rack segment<br />

K Fixing screws<br />

L End position damper<br />

M Clamping device<br />

N Plastic toothed rack with steel core<br />

The quantity of the supplied components depends on<br />

the door length.<br />

Special 471<br />

Plastic toothed rack with steel core<br />

Advice!<br />

The toothed rack Special 471 cannot<br />

be combined with the swivel support.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)7<br />

4.1 / 6<br />

I J<br />

K<br />

L<br />

M

4. Summary of the product<br />

Support brackets<br />

The operator can be mounted with two different<br />

supports.<br />

Floor console<br />

4.1 / 7<br />

Swivel support<br />

4.1 / 8<br />

Advice!<br />

The swivel support cannot be combined<br />

with the toothed rack Special 471.<br />

4.2 Mounting variations<br />

The operator can be mounted in two different<br />

variations.<br />

Mounting the operator with floor console<br />

Mounting the operator with swivel support<br />

8 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

4.2 / 1<br />

4.2 / 2<br />

270<br />

120<br />

328<br />

390

5. Preparation for mounting<br />

5.1 General notes<br />

The pictures in these instructions are not true-to-scale.<br />

The sizes are always indicated in millimetres (mm)!<br />

Depending on the opening direction the operator can<br />

be mounted on the right or on the left side of the<br />

door. These instructions show the mounting on the<br />

right side.<br />

For correct mounting you will need the following tools:<br />

5.1 / 1<br />

13<br />

ø 8 ø 10<br />

ø 7 6<br />

5 2<br />

ø 3,5 ø 4,5<br />

5.2 Checks<br />

Attention!<br />

Before you start to work, please always<br />

check the following points in order to<br />

guarantee correct mounting.<br />

Supply package<br />

• Check whether the supply package is complete.<br />

• Check whether all accessories required for your<br />

installation situation are at hand:<br />

- Spur gear<br />

- Toothed rack<br />

- Support bracket<br />

Foundation<br />

• Check the intended position of the operator:<br />

- The mounting of the operator must be carried out<br />

on the inside with the door closed.<br />

• - The operator must not be mounted in the<br />

clearance (q)!<br />

• Check whether there is a suitable foundation.<br />

• Check the laying of the supply line.<br />

Pay attention that the cable comes out on operator<br />

position (A). The minimum requirement for the earth<br />

cable is 3x1,5 mm 2 .<br />

Door<br />

• Check whether the sliding gate to be operated fulfils<br />

the following conditions:<br />

- The door has to be mounted horizontally, i.e. no<br />

slope in travel direction.<br />

• - In closed position the door should project the clear<br />

driveway by at least 250 mm on the installation<br />

side.<br />

- The door needs a mechanical end stop in both<br />

directions.<br />

• - The closing edges must be equipped with a flexible<br />

door sealing profile.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)9

5. Preparation for mounting<br />

5.3 Plan of door and foundation<br />

5.3 / 1<br />

p<br />

q<br />

r<br />

A Empty conduit for supply line / control cable<br />

B Control cable<br />

C Supply line<br />

p Door length<br />

q Clear driveway<br />

r Opening direction<br />

s Frost-proof depth<br />

x Thickness of the door + distance to the wall<br />

A<br />

10 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

≥ 250<br />

380<br />

s<br />

x<br />

B<br />

C<br />

X<br />

101<br />

60<br />

≥ 250 + x<br />

≥ 640<br />

X

6. Mounting<br />

6.1 Mounting the spur gear<br />

6.1 / 1<br />

• Mount the spur gear kit to the operator.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)11

6. Mounting<br />

6.2 Mounting the support brackets<br />

6.2.1 Operator with floor console<br />

6.2.1 / 1<br />

M10 x 40<br />

• Screw the adjustment screws into the floor console.<br />

6.2.1 / 2<br />

M8 x 20<br />

Attention!<br />

To lay the cables correctly, the opening<br />

in the floor console (A) has to be<br />

aligned to the cable outlet of the<br />

operator!<br />

A<br />

• Screw the operator to the floor console.<br />

6.2.1 / 3<br />

• Remove the cover of the operator.<br />

• Take off the aerial.<br />

Attention!<br />

Lift the cover carefully because the aerial<br />

may be torn.<br />

• Punch the plastic seals (B) for the control cable and<br />

supply line with a sharp screw driver.<br />

12 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

B<br />

B

6. Mounting<br />

6.2.1 / 4<br />

q<br />

E<br />

H<br />

15<br />

≥ 80<br />

Attention!<br />

The console must be aligned to the<br />

door so that the spur gear will grap into<br />

the toothed rack in every door position.<br />

C<br />

300<br />

360<br />

390<br />

G<br />

D<br />

F<br />

C Wall<br />

D Door<br />

E Screw area for the toothed rack<br />

F Empty conduit for supply line / control cable<br />

G Floor console<br />

H Foundation<br />

q Clear driveway<br />

• Align the floor console with the operator parallel<br />

to the door.<br />

• Measure the distance from the screw area<br />

of the toothed rack (E) to the operator.<br />

Observe measurement X.<br />

Special 431 + Special 433: X = 104<br />

Special 432 + Special 434: X = 104<br />

Special 441 + Special 443 X = 104<br />

Special 471: X = 114<br />

• Drill the holes for the dowels according to the<br />

indicated drilling scheme.<br />

X<br />

6.2.1 / 5<br />

• Insert the dowels.<br />

• Guide the control cable (I) and the supply line (J)<br />

through the floor console and through the opening<br />

in the operator.<br />

• Fix the floor console.<br />

I J<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)13<br />

40<br />

50<br />

ø 8

6. Mounting<br />

6.2.2 Operator with swivel support<br />

6.2.2/ 1<br />

q<br />

E<br />

Attention!<br />

The support must be aligned to the<br />

door so that the spur gear will grap into<br />

the toothed rack in every door position<br />

H<br />

80<br />

C<br />

360<br />

≥ 380<br />

F<br />

G<br />

D<br />

C Wall<br />

D Door<br />

E Screw area for the toothed rack<br />

F Empty conduit for supply line / control cable<br />

G Swivel support<br />

H Foundation<br />

q Clear driveway<br />

• Align the swivel support flush with the door.<br />

• Measure the distance from the screw area<br />

of the toothed rack (E) to the operator.<br />

Observe measurement X.<br />

Special 431 + Special 433: X = 104<br />

Special 432 + Special 434: X = 104<br />

Special 441 + Special 443 X = 104<br />

Special 471: not possible<br />

• Drill the holes according to the indicated drilling<br />

scheme.<br />

17<br />

50<br />

90<br />

108<br />

X<br />

6.2.2 / 2<br />

10 x 70<br />

• Mount the swivel support.<br />

6.2.2 / 3<br />

Attention!<br />

To maintain the swivel function,<br />

the support angel must be movable<br />

after fixing.<br />

• Screw the support angle to the operator.<br />

14 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

M10

6. Mounting<br />

6.2.2 / 4<br />

Attention!<br />

Lift the cover carefully because the aerial<br />

may be torn.<br />

• Remove the cover of the operator.<br />

B<br />

• Punch the plastic seals (B) for the control cable and<br />

supply line with a sharp screw driver.<br />

6.2.2 / 5<br />

B 6.2.2 / 6<br />

• Guide the control cable (I) and the supply line (J)<br />

through the swivel support and through the opening<br />

in the operator<br />

• Put the operator into the swivel support.<br />

M10 x 20<br />

Advice!<br />

For a correct installation the operator<br />

must be shimmed so that it is aligned<br />

horizontally.<br />

• Shim the operator to a horizontal position.<br />

• Screw on the swivel support.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)15<br />

I<br />

J

6. Mounting<br />

6.3 Cabling of the operator<br />

• Connect the supply line meeting your mounting<br />

situation:<br />

Mounting the operator inside right-hand side<br />

(supplied version)<br />

6.3 / 1<br />

Mounting the operator inside left-hand side<br />

6.3 / 2<br />

Legend cabling plans:<br />

C Motor capacitor<br />

H40 Signal light<br />

M1 Motor with thermal overload protection<br />

X1 Power line (from building)<br />

bk black<br />

bl blue<br />

rd red<br />

wt white<br />

vi violet<br />

bn brown<br />

ye yellow<br />

• Connect the control unit with the control line<br />

according to cabling plan (point 6.10).<br />

• Connect the aerial (C).<br />

• Mount the cover (B) to the operator.<br />

• Insert the plugs (A).<br />

16 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

6.3 / 3<br />

A<br />

B<br />

C

6. Mounting<br />

6.4 Adjustment of the toothed rack<br />

6.4.1 Special 431 / Special 432 /<br />

Special 433 / Special 434 /<br />

Special 441 / Special 443<br />

6.4.1 / 1<br />

p<br />

The toothed rack profiles are supplied in two standard<br />

lengths: 2.000 mm and 4.000 mm.<br />

In the ideal case the door length (p) corresponds to the<br />

sum of the joined standard lengths. Then a change of<br />

the profiles is not necessary.<br />

In case the door length does not correspond to one of<br />

the standard lengths:<br />

• Join the toothed rack profiles.<br />

• Mark the door length (p).<br />

A projection can be cut with a metal saw<br />

(only if necessary).<br />

6.4.1 / 2<br />

To mount the first end position damper:<br />

• Drill two holes for the screws of the clamping device.<br />

6.4.1 / 3<br />

• Insert the end position dampers (A) and the clamping<br />

device (B) into the toothed rack profile.<br />

• Screw on the clamping device (B).<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)17<br />

ø7<br />

A<br />

15<br />

10<br />

B<br />

15

6. Mounting<br />

6.4.1 / 4<br />

• Join the toothed rack segments until the required<br />

measurement (q = door length - approx. 160 mm)<br />

is reached.<br />

In case the segments are longer than the necessary<br />

length:<br />

• Cut the projecting part.<br />

6.4.1 / 5<br />

q<br />

• Slide the toothed rack segments into the toothed<br />

rack segment profile.<br />

6.4.1 / 6<br />

• Insert the end position dampers (A) and the clamping<br />

device (B) into the toothed rack profile.<br />

6.4.1 / 7<br />

B A<br />

Attention!<br />

The toothed rack segments must have<br />

a slight tension in the completely<br />

mounted toothed rack.<br />

Otherwise malfunction and damages to<br />

the toothed rack could result.<br />

To mount the second end position damper:<br />

• Press the clamping device (B) into the profile until the<br />

toothed rack segments (C) are under slight tension.<br />

• Mark the two drill points of the clamping device on<br />

the profile.<br />

18 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

B<br />

C

6. Mounting<br />

6.4.1 / 8<br />

B<br />

• Pull the clamping device (B) and the end position<br />

damper (A) out of the toothed rack profile.<br />

• Drill the two holes you marked before to screw on<br />

the clamping device.<br />

6.4.1 / 9<br />

B<br />

A<br />

A<br />

• Insert the end position dampers (A) and the clamping<br />

device (B) again into the toothed rack profile.<br />

• Screw on the clamping device (B).<br />

6.4.2 Special 471<br />

6.4.2 / 1<br />

• Assemble as much toothed rack segments as<br />

required in length for your door situation.<br />

6.4.2 / 2<br />

Any projecting part can be cut with a metal saw<br />

(only if necessary).<br />

Reference:<br />

For mounting the magnet holder please<br />

look up chapter 6.6.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)19<br />

i<br />

Before mounting the toothed rack to the door the<br />

magnet holder has to be mounted to the toothed rack.<br />

• Mount the magnet holder to the toothed rack.

6. Mounting<br />

6.5 Mounting the toothed rack<br />

6.5.1 Preparation<br />

i<br />

6.5.1 / 1<br />

• Move the door to the CLOSED position.<br />

6.5.1 / 2<br />

Attention!<br />

To get a correct function of the system,<br />

observe the following points:<br />

- The console must be firmly screwed<br />

to the floor.<br />

- The operator must be firmly screwed<br />

to the console.<br />

- The operator must be unlocked.<br />

- It must be possible to move the door<br />

by hand.<br />

Reference:<br />

To unlock the operator please look up<br />

chapter 6.7.<br />

Attention:<br />

To guarantee a correct door travel<br />

the screws must be tightened and sunk<br />

flush.<br />

The five toothed rack versions (A) require different<br />

screw points to the door (B):<br />

Special 431 / 433 + Special 441 / 433<br />

Aluminium version<br />

6.5.1 / 3<br />

Special 432 + Special 434<br />

Steel version<br />

6.5.1 / 4<br />

6.5.1 / 5<br />

B A<br />

100 360 360 100<br />

20 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

B<br />

A<br />

100 360 360 100<br />

Special 471<br />

Plastic version<br />

B A<br />

240 100 240 100 240

6. Mounting<br />

6.5.2 Operator with floor console<br />

6.5.2 / 1<br />

A<br />

Attention!<br />

To guarantee a correct door travel:<br />

- the rail has to be screwed to the door<br />

in the matching height,<br />

- the support has to be aligned parallel<br />

to the door.<br />

The matching height of the rail depends on the<br />

toothed rack.<br />

Special 431: 170 mm (+/- 10 mm)<br />

Special 432: 170 mm (+/- 10 mm)<br />

Special 433: 170 mm (+/- 10 mm)<br />

Special 434: 170 mm (+/- 10 mm)<br />

Special 441: 180 mm (+/- 10 mm)<br />

Special 443: 180 mm (+/- 10 mm)<br />

Special 471: 150 mm (+/- 10 mm)<br />

With differences of more than 10 mm:<br />

• Mount a suitable device to the door.<br />

For fine adjustment (+/- 10 mm) the height of the<br />

operator can be changed with the screws (A).<br />

6.5.2 / 2<br />

• Put the toothed rack onto the spur gear so that it<br />

grabs.<br />

• Align the toothed rack horizontally.<br />

• Use a clamp to fix the rail on the other side.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)21

6. Mounting<br />

6.5.2 / 3<br />

6.5.2 / 4<br />

Attention:<br />

For a correct door travel it is important<br />

to keep a distance of 1 - 2 mm<br />

between the toothed rack and the spur<br />

gear.<br />

1-2<br />

• Fix the toothed rack at the first screw point<br />

according to the respective drill pattern.<br />

100<br />

6.5.2 / 5<br />

• Loosen the clamp.<br />

• Open the door by approx. 500 mm at a time.<br />

• Then fix the toothed rack to the currently open door<br />

section and screw it on according the respective drill<br />

pattern.<br />

6.5.2 / 6<br />

• Open the door completely.<br />

• Fix the toothed rack to the last section and screw<br />

it on according to the respective drill pattern.<br />

Test:<br />

The door has to be moved once to the<br />

OPEN position and once to the CLOSED<br />

position in order to check whether the<br />

rail engages with the spur gear on its<br />

total length.<br />

22 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)

6. Mounting<br />

6.5.3 Operator with swivel support<br />

6.5.3 / 1<br />

With differences of more than 10 mm:<br />

• Mount a suitable device to the door.<br />

6.5.3 / 2<br />

• Open the door half.<br />

Attention!<br />

To guarantee a correct door travel,<br />

the toothed rack has to be screwed<br />

to the door in the matching height.<br />

The matching height of the rail depends on the<br />

toothed rack.<br />

Special 431: 170 mm (+/- 10 mm)<br />

Special 432: 170 mm (+/- 10 mm)<br />

Special 433: 170 mm (+/- 10 mm)<br />

Special 434: 170 mm (+/- 10 mm)<br />

Special 441: 180 mm (+/- 10 mm)<br />

Special 443: 180 mm (+/- 10 mm)<br />

Special 471: not possible<br />

6.5.3 / 3<br />

• Mount the rail support for the swivel support in<br />

the uppermost position. Only tighten the screws<br />

by hand.<br />

6.5.3 / 4<br />

<br />

• Insert the toothed rack between the spur gear and<br />

the rail support for the swivel support.<br />

<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)23

6. Mounting<br />

6.5.3 / 5<br />

• Align the toothed rack horizontally.<br />

• Fix the toothed rack with clamps.<br />

6.5.3 / 6<br />

Attention:<br />

For a correct door travel it is important<br />

to keep a distance of 1 - 2 mm<br />

between the toothed rack and the spur<br />

gear.<br />

6.5.3 / 7<br />

• Push the rail support for the swivel support so far<br />

down that it lies firmly on the toothed rack.<br />

<br />

1-2<br />

• Screw the toothed rack to the complete door<br />

according to the drill pattern that matches to your<br />

toothed rack.<br />

• Screw the rail support for the swivel support firmly<br />

to the operator.<br />

6.5.3 / 8<br />

• Remove the lining.<br />

Attention!<br />

Take care that there are no objects<br />

under the operator because otherwise<br />

the swivel function will be disturbed.<br />

Test:<br />

The door has to be moved once to the<br />

OPEN position and once to the CLOSED<br />

position in order to check whether the<br />

rail engages with the spur gear on its<br />

total length.<br />

24 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)

6. Mounting<br />

6.6 Mounting the reference point<br />

magnet<br />

6.6.1 Preparation<br />

6.6.1 / 1<br />

Attention!<br />

In order to make an operation of the<br />

system without dangers possible, the<br />

door needs a mechanical end stop to<br />

both directions.<br />

The door operator is cut-out in the end positions<br />

"door open" and "door closed" without mechanical<br />

end switches but with electronic microprocessor<br />

control. An incremental transmitter that is integrated<br />

in the operator is activated by a magnet and registers<br />

the actual door position.<br />

800-1000<br />

• Determine the position for the reference point<br />

magnet.<br />

The magnet for the reference point sensor is<br />

two-colored.<br />

Always mount the magnet with the green side to the<br />

operator.<br />

6.6.2 Operator with floor console<br />

The mounting of the magnet depends on the toothed<br />

rack used.<br />

Special 431 + Special 433<br />

Version: aluminium without cable duct<br />

6.6.2 / 1<br />

B4,2 x 19<br />

B4,2 x 25<br />

Special 432 + Special 434<br />

Steel version<br />

6.6.2 / 2<br />

B4,2 x 19<br />

B4,2 x 25<br />

Special 441 + Special 443<br />

Version: aluminium with cable duct<br />

6.6.2 / 3<br />

B4,2 x 19<br />

B4,2 x 25<br />

• Mount the magnet to the magnet holder.<br />

• Mount the magnet holder to the toothed rack at the<br />

determined position.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)25

6. Mounting<br />

Special 471<br />

Plastic toothed rack with steel core<br />

6.6.2 / 4<br />

B4,2 x 25<br />

B4,2 x 9,5<br />

• Mount the magnet to the magnet holder.<br />

• Mount the magnet holder to the toothed rack<br />

at the determined position, so that the magnet lies<br />

on the toothed rack.<br />

6.6.2 / 5<br />

26 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

3 - 7<br />

• Check the position of the reference point magnet.<br />

6.6.2 / 6<br />

Attention!<br />

The distance between the magnet (A)<br />

and the reference point sensor (B) must<br />

be 15 - 25 mm!<br />

Please keep this measurement by all<br />

means in order to avoid malfunctions!<br />

A<br />

15 - 25<br />

B<br />

• Check the distance between magnet (A) and<br />

reference point sensor (B).

6. Mounting<br />

6.6.3 Operator with swivel support<br />

The mounting of the magnet depends on the toothed<br />

rack used.<br />

Special 431 + Special 433<br />

Version: aluminium without cable duct<br />

6.6.3 / 1<br />

B4,2 x 19<br />

B4,2 x 25<br />

Special 432 + Special 434<br />

Steel version<br />

6.6.3 / 2<br />

B4,2 x 19<br />

B4,2 x 25<br />

Special 441 + Special 443<br />

Version: aluminium with cable duct<br />

6.6.3 / 3<br />

B4,2 x 19<br />

B4,2 x 25<br />

• Mount the magnet to the magnet holder.<br />

• Mount the magnet holder to the support plate.<br />

• Mount the magnet holder to the toothed rack at the<br />

determined position.<br />

6.6.3 / 4<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)27<br />

0 ± 2<br />

• Check the position of the reference point magnet.<br />

6.6.3 / 5<br />

Attention!<br />

The distance between the magnet (A)<br />

and the reference point sensor (B) must<br />

be 15 - 25 mm!<br />

Please keep this measurement by all<br />

means in order to avoid malfunctions!<br />

A<br />

C<br />

15 - 25<br />

B<br />

• Check the distance between magnet (A) and<br />

reference point sensor (B).

6. Mounting<br />

6.7 Emergency release in case<br />

of power failure<br />

Unlocking<br />

6.7 / 1<br />

• Remove screw (A).<br />

6.7 / 2<br />

B<br />

A<br />

• Turn the emergency release lever (B) to the right side<br />

by means of the enclosed wrench.<br />

• Screw the emergency release lever with screw (A) to<br />

the new position.<br />

The gear is now separated mechanically and the door<br />

can be moved by hand. At the same time the control<br />

unit is cut out.<br />

Locking<br />

• Remove screw (A).<br />

A A<br />

• Turn the emergency release lever (B) to the left side<br />

by means of the enclosed wrench.<br />

• Screw the emergency release lever with screw (A) to<br />

the new position.<br />

The gear is now connected mechanically with the drive<br />

shaft and the door can be power-operated. At the<br />

same time the control unit is switched on.<br />

28 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

6.7 / 3<br />

6.7 / 4<br />

B<br />

A

6. Mounting<br />

6.8 Mounting the cover<br />

6.8.1 Programming cover<br />

6.8.1 / 1<br />

• Remove the programming cover (A).<br />

6.8.1 / 2<br />

A<br />

Advice:<br />

After programming of the operator the<br />

programming cover must be put back.<br />

B<br />

• Mount the programming cover (A).<br />

• Insert the plugs (B).<br />

A<br />

6.8.2 Protective cover<br />

Advice:<br />

To protect the operator against weather<br />

influences the operator must be<br />

covered with the protective cover after<br />

programming and mounting of the<br />

programming cover.<br />

Operator with floor console<br />

6.8.2 / 1<br />

• Put the protective cover (B) on the operator.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)29<br />

B

6. Mounting<br />

Operator with swivel support<br />

6.8.2 / 2<br />

C<br />

Advice:<br />

To mount the protective cover to<br />

an operator with swivel support, the<br />

cover has to be adapted accordingly.<br />

The cover can only protect the system<br />

if the required openings are as small as<br />

possible.<br />

B<br />

• Cut the areas that are marked in grey (C) as shown<br />

in the picture.<br />

• Put the protective cover (B) on the operator.<br />

30 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)

6. Mounting<br />

6.9 Connection of external control elements<br />

6.9 / 1<br />

i<br />

Attention!<br />

To avoid damages to the control unit:<br />

- only connect potential-free closing contacts to the terminals 1 and 2 (A).<br />

- don't insert the short-circuit plug (C) into socked (E)!<br />

G<br />

A<br />

A Connection of control elements on site without <strong>Marantec</strong> system cabling only to the connecting terminals:<br />

1 GND<br />

2 Impulse<br />

3 24 V DC max. 50 mA<br />

B Socket for "external closing edge safety device"<br />

When connecting any element the short-circuit plug (C) must be removed.<br />

C Short-circuit plug<br />

D Socket for "external control elements"<br />

When connecting any element the short-circuit plug (C) must be removed.<br />

E Socket for "electronic aerial" or "external photocell"<br />

F Connection cable electronic aerial<br />

G Fuse for control unit (4A)<br />

Reference:<br />

To install external control elements please look up the respective instructions.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)31<br />

+<br />

P<br />

B C D E F<br />

A<br />

1 2 3

7. Hand transmitter<br />

7.1 Operation and accessories<br />

Operation<br />

7.1 / 1<br />

Caution!<br />

Children are not allowed to operate<br />

the hand transmitters!<br />

Before operating the hand transmitter<br />

make sure that there are neither<br />

persons nor objects in the operating<br />

range of the door.<br />

A Operating button<br />

B Operating button<br />

C Battery - transmission control light<br />

D Socket for learning plug<br />

E Back of hand transmitter<br />

F Battery 3V CR 2032<br />

The operating buttons (A + B) can be programmed<br />

with different functions.<br />

Possible functions are for example:<br />

Operating button A:<br />

Impulse for door OPEN / door CLOSE<br />

Operating button B:<br />

External light<br />

i<br />

D<br />

B<br />

C<br />

A<br />

D<br />

Reference:<br />

The programming of the hand<br />

transmitters (RC remote controls)<br />

for the operator control unit used is<br />

described in chapter 9.2.7.<br />

Change batteries<br />

• Open the back of the hand transmitter (E) e.g.<br />

with a coin.<br />

• Change the battery (F) and observe right poling.<br />

32 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

7.1 / 2<br />

Accessory<br />

7.1 / 3<br />

1<br />

F<br />

E<br />

Visor clip to attach the hand transmitter to a visor<br />

in the car.

7. Hand transmitter<br />

7.2 Coding of the hand transmitters<br />

7.2.1 Learn coding<br />

This function is meant to transfer the coding of<br />

an existing hand transmitter (Master) to an additional<br />

hand transmitter.<br />

7.2.1 / 1<br />

Caution!<br />

Before operating the hand transmitter<br />

please make sure that there are neither<br />

persons nor objects in the operating<br />

range of the door.<br />

• Connect both transmitters with the enclosed learning<br />

plug.<br />

Advice!<br />

The plug connections on both sides<br />

of the hand transmitter can be used<br />

identically.<br />

7.2.1 / 2<br />

• Actuate the master transmitter and hold the button.<br />

The LED on the transmitter is on.<br />

7.2.1 / 3<br />

• Actuate the desired button on the new hand<br />

transmitter while still holding the button on the<br />

master transmitter.<br />

After 1 - 2 sec. the LED on the new transmitter glows<br />

permanently.<br />

The programming is finished.<br />

The new hand transmitter has now taken over the<br />

coding of the master transmitter.<br />

• Remove the learning plug.<br />

Advice!<br />

For multi-channel hand transmitters<br />

the coding process has to be carried<br />

out for every single button separately.<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)33

7. Hand transmitter<br />

7.2.2 Change coding<br />

This function is meant to change the coding of<br />

the remote control in case a hand transmitter has<br />

gone lost.<br />

7.2.2 / 1<br />

• Insert the learning plug into the hand transmitter.<br />

• Short-circuit one of the two outer pins of the<br />

learning plug with the centre lead (e.g. by means<br />

of a screwdriver).<br />

• Actuate the desired button on the hand transmitter.<br />

The integrated random programming determines a<br />

new coding.<br />

The LED is flashing quickly.<br />

As soon as the LED on the hand transmitter glows<br />

permanently, you can release the button on the<br />

transmitter and remove the learning plug.<br />

Advice!<br />

After a new coding of the hand<br />

transmitter the operator for the sliding<br />

gate has to be re-programmed as well<br />

to the new coding as the old coding<br />

has gone lost irrevocably.<br />

For multi-channel hand transmitters the<br />

coding process has to be carried out for<br />

every single button separately.<br />

34 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)35

8. Control unit<br />

8.1 Overview of the control unit<br />

8.1 / 1<br />

G<br />

F<br />

H A<br />

8<br />

1<br />

2<br />

7 3<br />

6<br />

5 4<br />

1 2 3<br />

E<br />

LED display<br />

A LED for external photocell (only programming)<br />

B LED "OPEN door"<br />

C LED automatic timer function<br />

D LED "CLOSE door"<br />

E LED reference point<br />

F LED malfunction<br />

G LED impulse<br />

H LED voltage<br />

B C I K<br />

Operating elements<br />

I Button + (e.g. to travel the door to the OPEN position or to increase values)<br />

J Button - (e.g. to travel the door to the CLOSE position or to reduce values)<br />

K Button P (e.g. to save values)<br />

D<br />

36 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

P<br />

J

8. Control unit<br />

8.2 Overview on the display functions<br />

Explanation of the LED's<br />

LED off<br />

LED on<br />

LED flashing slowly<br />

LED flashing quickly<br />

After switching on the power the control unit carries<br />

out a self-test:<br />

All LED's glow up for approx. 3 sec.<br />

LED displays in operating mode<br />

Door in end position OPEN<br />

Door in intermediate position OPEN<br />

Signal light is on<br />

Signal light is flashing<br />

Door in end position CLOSED<br />

Door in intermediate position CLOSED<br />

Door passes the reference point<br />

Permanent actuation of a control element<br />

Malfunction<br />

RC remote control is actuated<br />

Operating voltage<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)37

9. Programming<br />

9.1 General notes on programming<br />

The programming is carried out with the buttons +, -,<br />

and P.<br />

If none of the buttons is actuated within 120 sec. in<br />

programming mode, the control unit changes back to<br />

the operating mode.<br />

An error message is displayed accordingly.<br />

9.1.1 Programming levels<br />

The programming of the operator is divided in two<br />

areas:<br />

1. Programming of the basic level:<br />

The basic functions of the operator are programmed<br />

in this level. This programming process is carried out<br />

consecutively and it is compulsory.<br />

To come to the programming of the basic level,<br />

button P must be pressed longer than 2 sec. but less<br />

than 10 sec..<br />

LED 2 is flashing.<br />

2. Programming of the extended<br />

operator functions:<br />

The programming of the extended operator functions<br />

may only be carried out by specialist personnel.<br />

As soon as the button P is pressed longer than 10 sec.,<br />

the control unit changes to the programming of the<br />

extended operator functions.<br />

LED 2 is then flashing quickly.<br />

Advice:<br />

In the extended operator functions<br />

important factory settings can be<br />

changed.<br />

38 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)

9. Programming<br />

9.1.2 Reference point<br />

The following is displayed:<br />

In operating mode<br />

The LED shortly lights up when the reference<br />

point is passed<br />

In programming mode<br />

Advice:<br />

The control unit can only be<br />

programmed when the reference point<br />

has been passed electrically.<br />

Therefore the door has to be travelled<br />

1x to the end position OPEN and 1x to<br />

the end position CLOSED before first<br />

programming.<br />

The operator is between the reference point<br />

and the end position OPEN.<br />

The operator is between the reference point<br />

and the end position CLOSED.<br />

9.1.3 Setting the door positions<br />

The programming of the "end position OPEN" and<br />

"end position CLOSED" can be carried out in two ways:<br />

1. Coarse adjustment by permanently holding<br />

a button<br />

The setting is carried out when button + or - is pressed<br />

permanently.<br />

The door travels correspondingly to the OPEN or<br />

CLOSED position.<br />

2. Fine adjustment by a short button impulse<br />

The setting is carried out by a short button impulse<br />

on button + or -. The door does not move during this<br />

procedure.<br />

Every time the button is pressed the end position is<br />

shifted by 4 mm to the respective direction.<br />

To test the end position, the door has to be traveled<br />

over the reference point to the OPEN position or to the<br />

CLOSED position.<br />

During the button impulse the LED 7<br />

is flashing quickly.<br />

Advice:<br />

The control unit travels without<br />

press-and-release.<br />

Legend:<br />

LED off<br />

LED on<br />

LED flashing slowly<br />

LED flashing quickly<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)39

9. Programming<br />

9.2 Programming of the basic level<br />

9.2.1 Programming of the "end position OPEN"<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

The control unit is in<br />

operating mode.<br />

To change to the<br />

programming mode<br />

press button P:<br />

> 2 Sec. < 10 Sec.<br />

Do not hold button P<br />

longer than 10 sec.!<br />

The control unit is in<br />

menu 1 of the basic<br />

programming.<br />

Set the end position<br />

DOOR OPEN.<br />

The reference point<br />

must be passed 1x.<br />

Fine adjustment is carried<br />

out with impulse on<br />

button + or -.<br />

Press button P 1x:<br />

save the end position.<br />

Automatic change to<br />

the programming of the<br />

"end position CLOSED".<br />

9.2.2 Programming of the<br />

"intermediate position OPEN"<br />

40 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

The control unit is in<br />

menu 2 of the basic<br />

programming.<br />

Set the intermediate<br />

position DOOR OPEN.<br />

Fine adjustment is<br />

carried out with impulse<br />

on button + or -.<br />

Press button P 1x:<br />

Save the intermediate<br />

position.<br />

Automatic change to<br />

the programming of the<br />

"intermediate position<br />

CLOSED".

9. Programming<br />

9.2.3 Programming of the<br />

"intermediate position CLOSED"<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

The control unit is in<br />

menu 3 of the basic<br />

programming.<br />

Set the intermediate<br />

position DOOR CLOSED.<br />

Fine adjustment is<br />

carried out with impulse<br />

on button + or -.<br />

Press button P 1x:<br />

Save the intermediate<br />

position.<br />

Automatic change to<br />

the programming of the<br />

"end position<br />

CLOSED".<br />

9.2.4 Programming of the "end position CLOSED"<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)41<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Legend:<br />

LED off<br />

LED on<br />

The control unit is in<br />

menu 4 of the basic<br />

programming.<br />

Set end position DOOR<br />

CLOSED.<br />

The reference point<br />

must be passed 1x.<br />

Fine adjustment is carried<br />

out with impulse on<br />

button + or -.<br />

Press button P 1x:<br />

save the end position.<br />

Automatic change to<br />

the programming of<br />

"power limit OPEN".<br />

LED flashing slowly<br />

LED flashing quickly

9. Programming<br />

9.2.5 Programming of the "power limit OPEN" 9.2.6 Programming of the "power limit CLOSE"<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

The control unit is in<br />

menu 5 of the basic<br />

programming.<br />

Press button + 1x:<br />

The current setting is<br />

displayed.<br />

Set the power limit as<br />

sensitive as possible.<br />

Press button + or -:<br />

Setting in steps from 1<br />

(sensitive) to 16.<br />

Press button P 1x:<br />

save the set value.<br />

Automatic change to<br />

the programming of the<br />

"power limit CLOSE".<br />

42 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

The control unit is in<br />

menu 6 of the basic<br />

programming.<br />

Press button + 1x:<br />

The current setting is<br />

displayed.<br />

Set the power limit as<br />

sensitive as possible.<br />

Press button + or -:<br />

Setting in steps from<br />

1 (sensitive) to 16.<br />

Press button P 1x:<br />

save the set value.<br />

Automatic change to<br />

the programming of the<br />

"RC remote control".

9. Programming<br />

9.2.7 Programming of the "RC remote control"<br />

Function allocation of the storage places<br />

You can read in up to 5 differently coded functions:<br />

1. Function Impulse<br />

2. Function half OPEN<br />

3. Function half CLOSED<br />

4. Function OPEN<br />

5. Function CLOSE<br />

Select the programming of RC remote control<br />

1.<br />

2.<br />

3.<br />

The control unit is in<br />

menu 7 of the basic<br />

programming.<br />

Press button + 1x:<br />

The first storage place is<br />

selected.<br />

Press button P 1x:<br />

The next storage place<br />

is selected.<br />

Program the RC remote control<br />

(example storage place 1)<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)43<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

The first storage place is<br />

selected.<br />

Press button + 1x:<br />

The selected storage<br />

place is ready to be<br />

programmed.<br />

Press the respective<br />

button on the hand<br />

transmitter.<br />

Press button P 1x:<br />

The coding of the hand<br />

transmitter is saved.<br />

Change to the next<br />

storage place.<br />

Advice:<br />

Wrongly programmed coding can be<br />

overwritten with a new coding.<br />

If necessary they can be deleted!<br />

Legend:<br />

LED off<br />

LED on<br />

LED flashing slowly<br />

LED flashing quickly

9. Programming<br />

Delete RC remote control - if necessary<br />

(example storage place 1)<br />

1.<br />

2.<br />

3.<br />

4.<br />

The first storage place is<br />

selected.<br />

Press button - 1x:<br />

The selected storage<br />

place is ready to be<br />

deleted.<br />

Press button P 1x:<br />

The coding of the selected<br />

storage place is<br />

deleted.<br />

Change to the next storage<br />

place.<br />

Finish the programming of the RC remote control<br />

44 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Press button P until the<br />

third storage place is<br />

selected.<br />

Press button P 1x:<br />

The programming of RC<br />

remote control is terminated.<br />

The control unit changes<br />

to the programming<br />

"reset factory settings".<br />

Press button P 1x:<br />

The programming of the<br />

basic level is terminated.<br />

The control unit is in<br />

operating mode.

9. Programming<br />

9.2.8 Programming of "reset factory settings"<br />

With the reset function all menus can be reset to the<br />

values already set from factory.<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

The control unit is in<br />

operating mode.<br />

To change to the<br />

programming mode:<br />

press button P:<br />

> 2 Sec. < 10 Sec.<br />

Do not hold button P<br />

longer than 10 sec.!<br />

Press button P 7x to<br />

get to the menu<br />

"reset factory settings".<br />

Press button + or - 1x:<br />

Selection "no reset" -<br />

all set values remain<br />

unchanged.<br />

Press button - or + 1x:<br />

Selection "reset" -<br />

factory settings are<br />

restored.<br />

Press button P 1x:<br />

Save and terminate<br />

programming.<br />

New start when RESET<br />

has been selected:<br />

All LED's glow up for<br />

2 sec.<br />

The control unit is in<br />

operating mode.<br />

Legend:<br />

LED off<br />

LED on<br />

LED flashing slowly<br />

LED flashing quickly<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)45

9. Programming<br />

9.3 Extended operator functions (only for specialist personnel)<br />

9.3.1 Overview of the extended operator functions<br />

Level Functions Explanation Factory settings<br />

3rd programming<br />

level<br />

Automatic timer<br />

function<br />

4th programming<br />

level<br />

Parameter<br />

6th programming<br />

level<br />

Reversion<br />

modes<br />

8th programming<br />

level<br />

Operating<br />

modes<br />

Open door time The time the door is open before it closes automatically.<br />

Warning time<br />

Warning before start<br />

Early closing after having<br />

passed the photocell<br />

Signal lights<br />

Excess travel stop<br />

The time the signal light is flashing before the door<br />

closes automatically.<br />

The time the signal light flashes before the door starts<br />

to move.<br />

The door closes either after the set open time or earlier<br />

after having passed the photocell.<br />

The signal light function can be set to flashing or to<br />

permanent light.<br />

The time period after which the operator cuts out<br />

without having reached an end position.<br />

Automatic timer<br />

function deactivated<br />

Automatic timer<br />

function deactivated<br />

0 seconds<br />

46 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

No<br />

Permanent light<br />

55 seconds<br />

Offset learned power limit The learned power limit can be set in steps from 1 - 16. Step 10<br />

Sensitivity power limit<br />

Power limit OPEN<br />

Power limit CLOSE<br />

Activation of photocell / photocell<br />

CLOSE<br />

Closing edge safety device<br />

OPEN<br />

Closing edge safety device<br />

CLOSE<br />

The sensitivity of the power limit can be set in steps<br />

from 1 - 16.<br />

Setting whether the operator stops, short or long<br />

reversion.<br />

Setting whether the operator stops, short or long<br />

reversion.<br />

Setting whether the operator stops, short or long<br />

reversion.<br />

Setting whether the operator stops, short or long<br />

reversion.<br />

Setting whether the operator stops, short or long<br />

reversion.<br />

press-and-release OPEN After start the operator runs to the selected position. On<br />

press-and-release CLOSE After start the operator runs to the selected position. On<br />

Impulse commands<br />

Direction commands<br />

(Pushbutton OPEN or CLOSE)<br />

Activation of the impulse button when the operator<br />

runs.<br />

Activation of the direction button when the operator<br />

runs.<br />

Step 6<br />

short reversion<br />

short reversion<br />

not existing<br />

not existing<br />

not existing<br />

Yes<br />

No

9. Programming<br />

9.3.2 Programming sequences of the extended<br />

operator functions<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

The control unit is in<br />

operating mode.<br />

Press button P:<br />

> 10 Sec.<br />

Countdown from 8 to<br />

1, then all LED's are on.<br />

Release button P:<br />

The control unit is in the<br />

first level of the extended<br />

operator functions.<br />

Press button P 1x:<br />

Change to the next<br />

level of the extended<br />

functions.<br />

Press button + 1x:<br />

Change to the first<br />

menu of the selected<br />

level.<br />

Press button + 1x:<br />

Display of the current<br />

setting.<br />

Press button + or -:<br />

Change the current<br />

value.<br />

Press button P 1x:<br />

Save the value, display<br />

of the selected level.<br />

If P is pressed without<br />

changing the value,<br />

the setting remains<br />

unchanged!<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)47<br />

10.<br />

11.<br />

12.<br />

13.<br />

14.<br />

15.<br />

Legend:<br />

LED off<br />

LED on<br />

Press button P 1x:<br />

Change to the next<br />

menu in the selected<br />

level.<br />

After the last<br />

programming menu of<br />

the selected level the<br />

control unit displays the<br />

selected level.<br />

Press button P 1x:<br />

The control unit<br />

changes to the next<br />

level.<br />

After the last<br />

programming level the<br />

programming of the<br />

extended operator<br />

functions is terminated.<br />

Press button P 1x:<br />

The programming is<br />

terminated.<br />

The control unit is in<br />

operating mode.<br />

LED flashing slowly<br />

LED flashing quickly

9. Programming<br />

9.3.3 Programming level 3 - automatic timer function<br />

<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Menu 1: Open door time<br />

255<br />

Seconds<br />

180<br />

Seconds<br />

150<br />

Seconds<br />

120<br />

Seconds<br />

100<br />

Seconds<br />

80<br />

Seconds<br />

50<br />

Seconds<br />

40<br />

Seconds<br />

35<br />

Seconds<br />

30<br />

Seconds<br />

20<br />

Seconds<br />

25<br />

Seconds<br />

15<br />

Seconds<br />

10<br />

Seconds<br />

5<br />

Seconds<br />

Automatic<br />

timer<br />

function<br />

deactivated<br />

Menu 2: Warning time<br />

70<br />

Seconds<br />

65<br />

Seconds<br />

60<br />

Seconds<br />

55<br />

Seconds<br />

50<br />

Seconds<br />

45<br />

Seconds<br />

40<br />

Seconds<br />

35<br />

Seconds<br />

30<br />

Seconds<br />

25<br />

Seconds<br />

20<br />

Seconds<br />

15<br />

Seconds<br />

10<br />

Seconds<br />

5<br />

Seconds<br />

2<br />

Seconds<br />

Automatic<br />

timer<br />

function<br />

deactivated<br />

Menu 3: Warning before start<br />

7<br />

Seconds<br />

6<br />

Seconds<br />

5<br />

Seconds<br />

4<br />

Seconds<br />

3<br />

Seconds<br />

2<br />

Seconds<br />

1<br />

Seconds<br />

0<br />

Seconds<br />

9. Programming<br />

9.3.4 Programming level 4 - parameter<br />

<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Menu 1: Excess travel stop<br />

220<br />

Seconds<br />

220<br />

Seconds<br />

210<br />

Seconds<br />

200<br />

Seconds<br />

190<br />

Seconds<br />

180<br />

Seconds<br />

160<br />

Seconds<br />

140<br />

Seconds<br />

120<br />

Seconds<br />

100<br />

Seconds<br />

80<br />

Seconds<br />

65<br />

Seconds<br />

55<br />

Seconds<br />

50<br />

Seconds<br />

40<br />

Seconds<br />

30<br />

Seconds<br />

Menu 2: Offset learned power limit<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

9. Programming<br />

9.3.5 Programming level 6 - reversion modes<br />

<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Menu 1: Power limit for OPEN direction<br />

not<br />

existing<br />

long<br />

reversion<br />

short<br />

reversion<br />

Stop<br />

Menu 2: Power limit for CLOSE direction<br />

not<br />

existing<br />

long<br />

reversion<br />

short<br />

reversion<br />

Stop<br />

Menu 4: Activation of photocell / photocell for CLOSE direction<br />

not<br />

existing<br />

long<br />

reversion<br />

short<br />

reversion<br />

Stop<br />

9. Programming<br />

9.3.6 Programming level 8 - operating modes<br />

<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Menu 1: press-and-release for OPEN direction<br />

ON<br />

OFF<br />

Menu 2: press-and-release for CLOSE direction<br />

ON<br />

OFF<br />

Menu 3: Impulse - command device active when operator runs<br />

10. Messages<br />

10.1 Display of the messages<br />

Messages at permanent actuation<br />

When actuating operating and safety elements<br />

permanently the current status of the system is<br />

displayed.<br />

1.<br />

2.<br />

Status displays<br />

The control light<br />

MALFUNCTION (6)<br />

glows.<br />

Press button P 1x:<br />

Display of the status<br />

(see below).<br />

IMPULSE button actuated<br />

OPEN button actuated<br />

Closing edge safety device OPEN actuated<br />

CLOSE button actuated<br />

Closing edge safety device CLOSE actuated<br />

Photocell actuated<br />

Static current circuit interrupted<br />

Messages at malfunctions<br />

Malfunctions in the system are displayed by a<br />

corresponding error number.<br />

52 Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)<br />

1.<br />

2.<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

The control light<br />

MALFUNCTION (6) is<br />

flashing.<br />

Press button P 1x:<br />

Display of the error<br />

number (see 10.2).<br />

Message memory<br />

The message memory displays the last 5 messages of<br />

the control unit.<br />

Press button P:<br />

The LED's from<br />

1 - 8 are glowing.<br />

The control unit shows<br />

the current messages.<br />

Press button -:<br />

Old messages are<br />

displayed.<br />

Press button +:<br />

The current message is<br />

displayed.<br />

Press button P:<br />

The display of the<br />

message memory is<br />

finished.<br />

The control unit is in<br />

operating mode.

10. Messages<br />

10.2 Overview of the error numbers<br />

Number Message Display<br />

6 Photocell actuated<br />

7 Programming cancelled<br />

8 Reference point<br />

9 R.P.M sensor defective<br />

10 Power limit<br />

11 Excess travel stop<br />

12<br />

13<br />

15<br />

Testing<br />

closing edge safety device<br />

OPEN not o.k.<br />

Testing<br />

closing edge safety device<br />

CLOSE not o.k.<br />

Testing<br />

photocell not o.k.<br />

Number Message Display<br />

27 Sensitivity power limit<br />

Installation and operating instructions <strong>Comfort</strong> <strong>820</strong> GB (#70663)53<br />

28<br />

36<br />

Offset learned<br />

Power limit<br />

Static current circuit<br />

interrupted<br />

Legend:<br />

LED off<br />

LED on<br />

LED flashing slowly<br />

LED flashing quickly

10. Messages<br />

10.3 Trouble-shooting<br />

Error Cause Remedy<br />

LED 8 is not glowing. - No voltage. - Check voltage.<br />

- Check mains socket.<br />

- Fuse in the control unit defective. - Check control fuse in the operator (point 6.9).<br />

- Thermal overload protection in power<br />

transformer is active.<br />

- Have transformer cool down.<br />

- Operator is unlocked. - Lock emergency release.<br />

- Control unit defective. - Check control unit (point 6.2):<br />

Separate the operator from power supply / remove cover<br />

of housing / screw off control unit / pull the control unit a<br />

bit out / take off the connecting plug / take out the control<br />

unit.<br />

No reaction on impulse. - Connecting terminals for "Impulse"<br />

button bridged, e.g. by short circuit in<br />

cable or wrong connection.<br />