Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

pool then increases the storage capacity of<br />

the storage pool inside the reactor building,<br />

which holds approximately 600 spent fuel<br />

assemblies.<br />

The pool cooling system comprises four symmetrically<br />

arranged independent trains with<br />

two trains being connected to a cooling tower<br />

in each case. The heat from the spent fuel assemblies<br />

is eliminated into the outside air via<br />

an intermediate cooling circuit with natural<br />

circulation. This involves the intermediate<br />

coolant flowing through heat exchangers that<br />

are hung inside the storage pool. The heat is<br />

then dissipated to the outside air by natural<br />

circulation via water/air heat exchangers.<br />

With very high outside temperatures <strong>and</strong> a<br />

large spent fuel inventory in the storage pool,<br />

fans are available to boost the air circulation<br />

in the cooling towers. The first spent fuel assemblies<br />

were loaded into the new storage<br />

pool in mid-May 2008.<br />

Refuelling<br />

Once a year the power plant is shut down for<br />

refuelling. It takes some two to three weeks to<br />

discharge the spent fuel assemblies, reposition<br />

the assemblies remaining in the reactor<br />

core, load the fresh fuel assemblies <strong>and</strong> to<br />

carry out inspection <strong>and</strong> maintenance work.<br />

The fuel assemblies discharged from the reactor<br />

core are first placed in high-density<br />

racks in the spent-fuel reactor storage pool.<br />

There are more than 600 storage positions in<br />

this pool, which can take not only spent fuel<br />

assemblies but also instrumentation thimble<br />

tubes, control elements <strong>and</strong> tools. In the<br />

compact storage pool, the radiation <strong>and</strong> decay<br />

heat are allowed to subside before the<br />

fuel assemblies are conveyed in special<br />

transport casks to the spent fuel storage<br />

Plant design <strong>and</strong> special technical features<br />

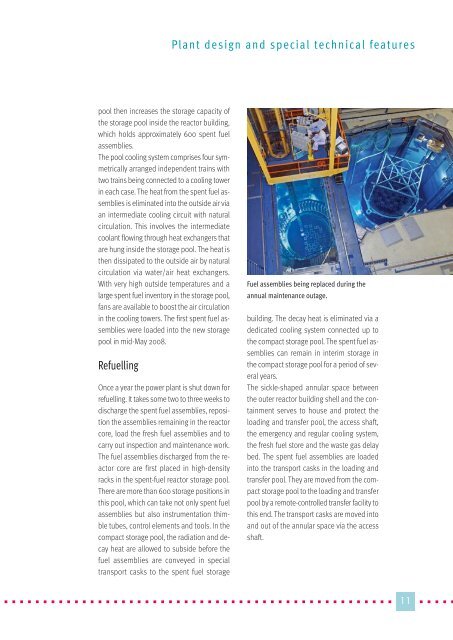

Fuel assemblies being replaced during the<br />

annual maintenance outage.<br />

building. The decay heat is eliminated via a<br />

dedicated cooling system connected up to<br />

the compact storage pool. The spent fuel assemblies<br />

can remain in interim storage in<br />

the compact storage pool for a period of several<br />

years.<br />

The sickle-shaped annular space between<br />

the outer reactor building shell <strong>and</strong> the containment<br />

serves to house <strong>and</strong> protect the<br />

loading <strong>and</strong> transfer pool, the access shaft,<br />

the emergency <strong>and</strong> regular cooling system,<br />

the fresh fuel store <strong>and</strong> the waste gas delay<br />

bed. The spent fuel assemblies are loaded<br />

into the transport casks in the loading <strong>and</strong><br />

transfer pool. They are moved from the compact<br />

storage pool to the loading <strong>and</strong> transfer<br />

pool by a remote-controlled transfer facility to<br />

this end. The transport casks are moved into<br />

<strong>and</strong> out of the annular space via the access<br />

shaft.<br />

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11 � � � � � � �