Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

gency <strong>and</strong> residual heat removal systems,<br />

from the 6-kilovolt <strong>and</strong> 380-volt emergency<br />

distribution systems. A 2940-kilowatt diesel<br />

generator unit is assigned to each train. This<br />

starts up automatically if the main bus voltage<br />

in the associated train falls below 80 %<br />

for 2 seconds. Once the diesel start-up time<br />

of a maximum of 15 seconds has elapsed, the<br />

reactor protection system then sequentially<br />

reconnects the key safety-related consumer<br />

groups. Each of the four diesel generator sets<br />

can independently cover the electricity requirements<br />

of the associated safety system<br />

line for several hours.<br />

Instrumentation <strong>and</strong> control systems, such as<br />

the reactor protection system, which need<br />

to operate without interruption during the<br />

diesel start-up phase too, are supplied in duplicate<br />

via diode-decoupled, battery-based<br />

48-volt or 220-volt direct-current bus bars.<br />

For particularly important components, which<br />

must be able to implement rapid isolation<br />

<strong>and</strong> shutdown measures at any time, there<br />

are four non-interrupted, secure 380-volt networks<br />

fed by battery-based rotary converters.<br />

For the extremely unlikely case of more than<br />

two safety system lines failing at once, there<br />

are an additional two special emergency systems<br />

ready to come into operation. Their<br />

diesel generators start up automatically <strong>and</strong><br />

are self-supporting with electricity <strong>and</strong><br />

coolant for 10 hours.<br />

Great importance is attached to the electrical<br />

<strong>and</strong> spatial separation of the four trains. It<br />

must be ensured that no interaction occurs in<br />

the event of electrical malfunctions or a fire.<br />

The cable routing for the different lines is<br />

also kept strictly separate, with the trains insulated<br />

against each other from the emergency<br />

diesel generator units, via the<br />

switchgear, right through to the electrical<br />

Station service power supply<br />

consumers. The redundancy concept with 6<br />

trains, 4 of which are emergency power networks<br />

<strong>and</strong> 2 emergency st<strong>and</strong>by networks<br />

with a total of 6 diesel generators, has been<br />

consistently implemented in the building<br />

structure, with the switchgear building split<br />

into four parts. This strict spatial separation<br />

is clearly evident when looking at the emergency<br />

diesel generator buildings <strong>and</strong> the special<br />

emergency building. These are separate<br />

from the switchgear building <strong>and</strong> more than<br />

60 metres away from each other. This then<br />

also makes allowance for the consequences<br />

of a hypothetical aircraft crash.<br />

The service power network described above,<br />

which has 35 transformers, supplies the energy<br />

for approximately 1400 motors <strong>and</strong> 950<br />

electric valves.<br />

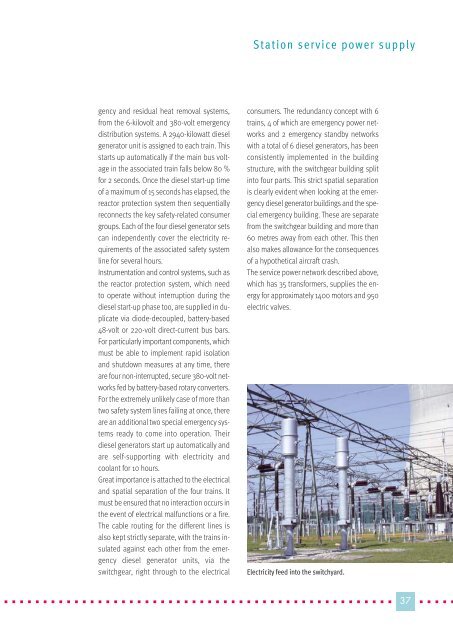

Electricity feed into the switchyard.<br />

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �37 � � � � � � �