Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

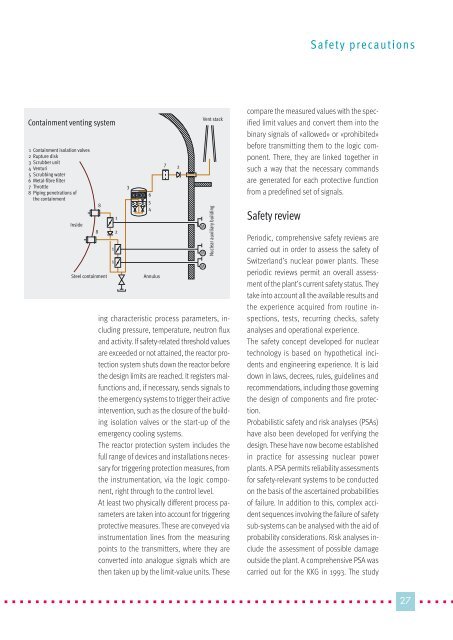

Containment venting system<br />

1 Containment isolation valves<br />

2 Rupture disk<br />

3 Scrubber unit<br />

4 Venturi<br />

5 Scrubbing water<br />

6 Metal-fibre filter<br />

7 Throttle<br />

8 Piping penetrations of<br />

the containment<br />

Inside<br />

8<br />

8<br />

Steel containment<br />

1<br />

1<br />

1<br />

2<br />

3<br />

6<br />

5<br />

4<br />

Annulus<br />

7<br />

ing characteristic process parameters, including<br />

pressure, temperature, neutron flux<br />

<strong>and</strong> activity. If safety-related threshold values<br />

are exceeded or not attained, the reactor protection<br />

system shuts down the reactor before<br />

the design limits are reached. It registers malfunctions<br />

<strong>and</strong>, if necessary, sends signals to<br />

the emergency systems to trigger their active<br />

intervention, such as the closure of the building<br />

isolation valves or the start-up of the<br />

emergency cooling systems.<br />

The reactor protection system includes the<br />

full range of devices <strong>and</strong> installations necessary<br />

for triggering protection measures, from<br />

the instrumentation, via the logic component,<br />

right through to the control level.<br />

At least two physically different process parameters<br />

are taken into account for triggering<br />

protective measures. These are conveyed via<br />

instrumentation lines from the measuring<br />

points to the transmitters, where they are<br />

converted into analogue signals which are<br />

then taken up by the limit-value units. These<br />

2<br />

Vent stack<br />

M<br />

M<br />

M<br />

Nuclear auxiliary building<br />

Safety precautions<br />

compare the measured values with the specified<br />

limit values <strong>and</strong> convert them into the<br />

binary signals of «allowed» or «prohibited»<br />

before transmitting them to the logic component.<br />

There, they are linked together in<br />

such a way that the necessary comm<strong>and</strong>s<br />

are generated for each protective function<br />

from a predefined set of signals.<br />

Safety review<br />

Periodic, comprehensive safety reviews are<br />

carried out in order to assess the safety of<br />

Switzerl<strong>and</strong>’s nuclear power plants. These<br />

periodic reviews permit an overall assessment<br />

of the plant’s current safety status. They<br />

take into account all the available results <strong>and</strong><br />

the experience acquired from routine inspections,<br />

tests, recurring checks, safety<br />

analyses <strong>and</strong> operational experience.<br />

The safety concept developed for nuclear<br />

technology is based on hypothetical incidents<br />

<strong>and</strong> engineering experience. It is laid<br />

down in laws, decrees, rules, guidelines <strong>and</strong><br />

recommendations, including those governing<br />

the design of components <strong>and</strong> fire protection.<br />

Probabilistic safety <strong>and</strong> risk analyses (PSAs)<br />

have also been developed for verifying the<br />

design. These have now become established<br />

in practice for assessing nuclear power<br />

plants. A PSA permits reliability assessments<br />

for safety-relevant systems to be conducted<br />

on the basis of the ascertained probabilities<br />

of failure. In addition to this, complex accident<br />

sequences involving the failure of safety<br />

sub-systems can be analysed with the aid of<br />

probability considerations. Risk analyses include<br />

the assessment of possible damage<br />

outside the plant. A comprehensive PSA was<br />

carried out for the KKG in 1993. The study<br />

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �27 � � � � � � �