Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

Technology and Operation - Kernkraftwerk Gösgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

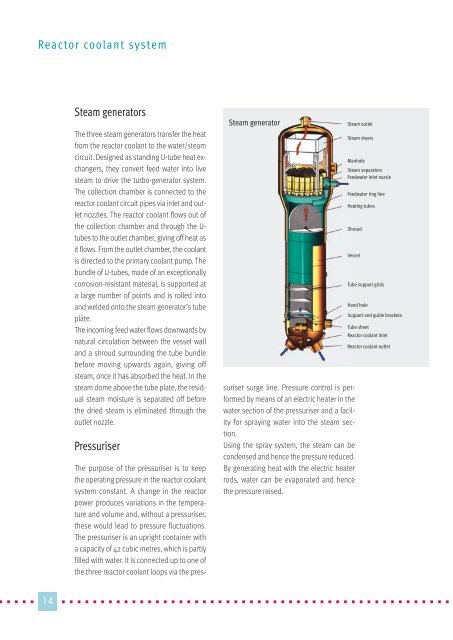

Reactor coolant system<br />

Steam generators<br />

The three steam generators transfer the heat<br />

from the reactor coolant to the water/steam<br />

circuit. Designed as st<strong>and</strong>ing U-tube heat exchangers,<br />

they convert feed water into live<br />

steam to drive the turbo-generator system.<br />

The collection chamber is connected to the<br />

reactor coolant circuit pipes via inlet <strong>and</strong> outlet<br />

nozzles. The reactor coolant flows out of<br />

the collection chamber <strong>and</strong> through the Utubes<br />

to the outlet chamber, giving off heat as<br />

it flows. From the outlet chamber, the coolant<br />

is directed to the primary coolant pump. The<br />

bundle of U-tubes, made of an exceptionally<br />

corrosion-resistant material, is supported at<br />

a large number of points <strong>and</strong> is rolled into<br />

<strong>and</strong> welded onto the steam generator’s tube<br />

plate.<br />

The incoming feed water flows downwards by<br />

natural circulation between the vessel wall<br />

<strong>and</strong> a shroud surrounding the tube bundle<br />

before moving upwards again, giving off<br />

steam, once it has absorbed the heat. In the<br />

steam dome above the tube plate, the residual<br />

steam moisture is separated off before<br />

the dried steam is eliminated through the<br />

outlet nozzle.<br />

Pressuriser<br />

The purpose of the pressuriser is to keep<br />

the operating pressure in the reactor coolant<br />

system constant. A change in the reactor<br />

power produces variations in the temperature<br />

<strong>and</strong> volume <strong>and</strong>, without a pressuriser,<br />

these would lead to pressure fluctuations.<br />

The pressuriser is an upright container with<br />

a capacity of 42 cubic metres, which is partly<br />

filled with water. It is connected up to one of<br />

the three reactor coolant loops via the pres-<br />

Steam generator<br />

suriser surge line. Pressure control is performed<br />

by means of an electric heater in the<br />

water section of the pressuriser <strong>and</strong> a facility<br />

for spraying water into the steam section.<br />

Using the spray system, the steam can be<br />

condensed <strong>and</strong> hence the pressure reduced.<br />

By generating heat with the electric heater<br />

rods, water can be evaporated <strong>and</strong> hence<br />

the pressure raised.<br />

Steam outlet<br />

Steam dryers<br />

Manhole<br />

Steam separators<br />

Feedwater inlet nozzle<br />

Feedwater ring line<br />

Heating tubes<br />

� � � � �14 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �<br />

Shroud<br />

Vessel<br />

Tube support grids<br />

H<strong>and</strong> hole<br />

Support <strong>and</strong> guide brackets<br />

Tube sheet<br />

Reactor coolant inlet<br />

Reactor coolant outlet