Brochure Eckold Clinching (PDF)

Brochure Eckold Clinching (PDF)

Brochure Eckold Clinching (PDF)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

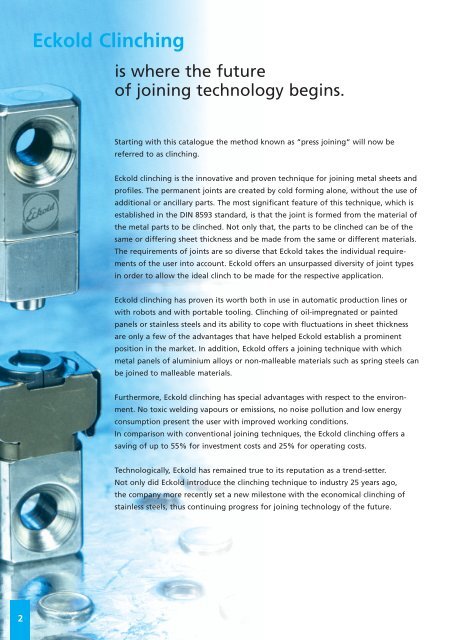

<strong>Eckold</strong> <strong>Clinching</strong><br />

is where the future<br />

of joining technology begins.<br />

Starting with this catalogue the method known as “press joining“ will now be<br />

referred to as clinching.<br />

<strong>Eckold</strong> clinching is the innovative and proven technique for joining metal sheets and<br />

profiles. The permanent joints are created by cold forming alone, without the use of<br />

additional or ancillary parts. The most significant feature of this technique, which is<br />

established in the DIN 8593 standard, is that the joint is formed from the material of<br />

the metal parts to be clinched. Not only that, the parts to be clinched can be of the<br />

same or differing sheet thickness and be made from the same or different materials.<br />

The requirements of joints are so diverse that <strong>Eckold</strong> takes the individual requirements<br />

of the user into account. <strong>Eckold</strong> offers an unsurpassed diversity of joint types<br />

in order to allow the ideal clinch to be made for the respective application.<br />

<strong>Eckold</strong> clinching has proven its worth both in use in automatic production lines or<br />

with robots and with portable tooling. <strong>Clinching</strong> of oil-impregnated or painted<br />

panels or stainless steels and its ability to cope with fluctuations in sheet thickness<br />

are only a few of the advantages that have helped <strong>Eckold</strong> establish a prominent<br />

position in the market. In addition, <strong>Eckold</strong> offers a joining technique with which<br />

metal panels of aluminium alloys or non-malleable materials such as spring steels can<br />

be joined to malleable materials.<br />

Furthermore, <strong>Eckold</strong> clinching has special advantages with respect to the environment.<br />

No toxic welding vapours or emissions, no noise pollution and low energy<br />

consumption present the user with improved working conditions.<br />

In comparison with conventional joining techniques, the <strong>Eckold</strong> clinching offers a<br />

saving of up to 55% for investment costs and 25% for operating costs.<br />

Technologically, <strong>Eckold</strong> has remained true to its reputation as a trend-setter.<br />

Not only did <strong>Eckold</strong> introduce the clinching technique to industry 25 years ago,<br />

the company more recently set a new milestone with the economical clinching of<br />

stainless steels, thus continuing progress for joining technology of the future.