Brochure Eckold Clinching (PDF)

Brochure Eckold Clinching (PDF)

Brochure Eckold Clinching (PDF)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

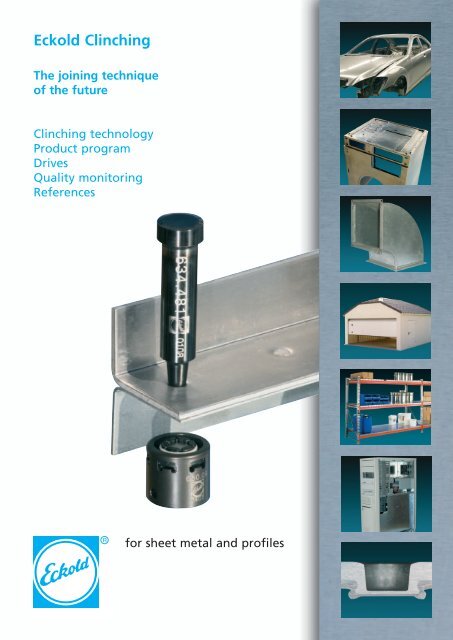

<strong>Eckold</strong> <strong>Clinching</strong><br />

The joining technique<br />

of the future<br />

<strong>Clinching</strong> technology<br />

Product program<br />

Drives<br />

Quality monitoring<br />

References<br />

for sheet metal and profiles

2<br />

<strong>Eckold</strong> <strong>Clinching</strong><br />

is where the future<br />

of joining technology begins.<br />

Starting with this catalogue the method known as “press joining“ will now be<br />

referred to as clinching.<br />

<strong>Eckold</strong> clinching is the innovative and proven technique for joining metal sheets and<br />

profiles. The permanent joints are created by cold forming alone, without the use of<br />

additional or ancillary parts. The most significant feature of this technique, which is<br />

established in the DIN 8593 standard, is that the joint is formed from the material of<br />

the metal parts to be clinched. Not only that, the parts to be clinched can be of the<br />

same or differing sheet thickness and be made from the same or different materials.<br />

The requirements of joints are so diverse that <strong>Eckold</strong> takes the individual requirements<br />

of the user into account. <strong>Eckold</strong> offers an unsurpassed diversity of joint types<br />

in order to allow the ideal clinch to be made for the respective application.<br />

<strong>Eckold</strong> clinching has proven its worth both in use in automatic production lines or<br />

with robots and with portable tooling. <strong>Clinching</strong> of oil-impregnated or painted<br />

panels or stainless steels and its ability to cope with fluctuations in sheet thickness<br />

are only a few of the advantages that have helped <strong>Eckold</strong> establish a prominent<br />

position in the market. In addition, <strong>Eckold</strong> offers a joining technique with which<br />

metal panels of aluminium alloys or non-malleable materials such as spring steels can<br />

be joined to malleable materials.<br />

Furthermore, <strong>Eckold</strong> clinching has special advantages with respect to the environment.<br />

No toxic welding vapours or emissions, no noise pollution and low energy<br />

consumption present the user with improved working conditions.<br />

In comparison with conventional joining techniques, the <strong>Eckold</strong> clinching offers a<br />

saving of up to 55% for investment costs and 25% for operating costs.<br />

Technologically, <strong>Eckold</strong> has remained true to its reputation as a trend-setter.<br />

Not only did <strong>Eckold</strong> introduce the clinching technique to industry 25 years ago,<br />

the company more recently set a new milestone with the economical clinching of<br />

stainless steels, thus continuing progress for joining technology of the future.

The basis of our success<br />

Portable<br />

Tools<br />

is our extensive<br />

product range...<br />

... starting with a widely varied tool<br />

programme through to a comprehensive<br />

range of standard machines and complete<br />

production systems:<br />

Modular<br />

C-frame range<br />

modular construction<br />

C-frame for mobile or<br />

stationary use<br />

CONECO 45/60<br />

easily portable, mobile,<br />

electric, electrohydraulic,<br />

hydraulic<br />

or pneumatic<br />

driven tools<br />

MZD 60/6<br />

mobile tool with<br />

adjustable fixed<br />

stop and large jaw<br />

capacity<br />

3

4<br />

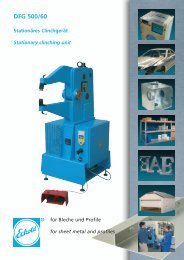

Stationary<br />

machines<br />

Automatic<br />

production<br />

systems<br />

Multipoint tooling<br />

Multipoint tooling<br />

for use in presses<br />

DFG 500/80 E<br />

universal machines,<br />

large throath,<br />

electrically driven<br />

Special installation

The Benefits<br />

Examples<br />

of <strong>Eckold</strong> <strong>Clinching</strong>.<br />

<strong>Eckold</strong> <strong>Clinching</strong> stands out from other joining techniques<br />

as a result of the following benefits:<br />

• no thermal effects on the clinch area<br />

• no toxic gases or vapours arising<br />

• no preservative afterwork<br />

• no additional or ancillary parts<br />

• no pre-treatment of surface<br />

• technique compensates for fluctuations in sheet thickness<br />

• also suitable for joining coated sheets<br />

• electricity or compressed air are the only energy sources<br />

required<br />

• suitable for joining sheets of different materials<br />

and thicknesses<br />

• non-destructive quality assurance possible<br />

Casing for laboratory or domestic appliances<br />

Window opener – car door<br />

Engine bonnet – motor car<br />

Flow safety device – gas heating appliance<br />

5

6<br />

An unsurpassed range of variations<br />

Stempel Punch<br />

Blech,<br />

Panel,<br />

matrizen-<br />

die-side<br />

seitig<br />

Matrize Die<br />

Blech, Panel, punch-side stempelseitig<br />

CLINCHING<br />

R<br />

for individual problems.<br />

The principle of <strong>Eckold</strong> <strong>Clinching</strong>: diagram showing how a clinching element is created,<br />

taking R-DF as an example<br />

<strong>Clinching</strong> element<br />

Fügeelement<br />

The wide range of variations and the tool concept allows you to choose the right<br />

type of joint for your purposes.<br />

R-DF S-DF H-DF CONFIX clinch<br />

Cutting of sheet neither sheet both sheets one sheet one sheet with<br />

cut cut cut prepunched round hole<br />

Geometry of<br />

clinching element<br />

Benefits /<br />

particular applications<br />

round rectangular rectangular round<br />

- circular, closed element - high economy tools - high economy tools - circular element with<br />

= visually better - anti-twist element - anti-twist element flush finish on die side<br />

- high-strenght - also suitable for - high holding forces = visually better<br />

clinching element clinching more than - element ist closed - symmetry of shear tension<br />

- symmetry of shear two sheets on punch side holding forces<br />

tension holding forces - beneficial when - for clinching pairs of<br />

- particularly clinching sheets materials with<br />

beneficial when with different difficult to form material<br />

clinching sheets with forming behaviour on die side (spring steel)<br />

different forming behaviour (e.g. steel/aluminium) - clinching of sheets with<br />

(e.g. steel/aluminium or different<br />

steel/sandwich) thicknesses<br />

- high holding forces (e.g. 1.0 mm in 4.0 mm)<br />

Possible tool<br />

design<br />

Die-side element<br />

diameter<br />

Punch width S punch width<br />

Anvil diameter<br />

depending on pre-punched<br />

hole diameter<br />

[Tw = twin element] 6 mm 8 mm 10 mm 2 mm 3 mm 4 mm Tw 3 mm 4 mm Tw 5 mm 6 mm<br />

Possible individual sheet thicknesses [mm] 0.5 – 1.5 0.5 – 2.0 1.0 – 3.0 0.5 – 1.25 0.5 – 1.5 0.5 – 2.5 0.5 – 1.5 0.5 – 1.25 0.5 – 1.25 0.5 – 1.25 punch side: 0.7 – 3.0<br />

Possible overall sheet thickness [mm] 1.0 – 3.0 1.0 – 4.0 2.0 – 6.0 1.0 – 2.50 1.0 – 3.0 1.0 – 5.0 1.0 – 3.0 1.0 – 2.50 1.0 – 2.50 1.0 – 2.50 to be checked in each case<br />

Tool life<br />

quantities:<br />

The tool life quantities of the clinching tools can be in the order of 200.000 to 250.000<br />

clinching operations. Customers confirm from tests and typical actual cases<br />

that far greater tool life quantities have been achieved, dependant on the material,<br />

the thickness and the quality.

Effect of load<br />

direction on the<br />

holding force of<br />

different joints<br />

Holding forces<br />

of R-DF<br />

elements<br />

Holding forces<br />

of S-DF<br />

elements<br />

Holding forces<br />

of H-DF<br />

elements<br />

Holding forces<br />

of CONFIX<br />

clinches<br />

Holding force [N]<br />

4000<br />

3000<br />

2000<br />

1000<br />

St12 / St14 / sheet thickness a 0 = 1.0 mm<br />

cross tension<br />

shear tension, longitudinal<br />

shear tension, transverse<br />

R-DF H-DF R-DF CONFIX<br />

Sheet material Sheet thickness Sheet thickness Tensile strength Holding force<br />

punch side die side Rm Shear Cross<br />

tension tension<br />

[mm] [mm] [N/mm 2 ] [N] [N]<br />

R-DF 8 element<br />

St 12/St 14 1.00 1.00 325 3000 1700<br />

AIMg3 W19 1.00 1.00 228 2620 1200<br />

R-DF 6 element<br />

St 12/St 14 1.50 1.50 300-350 1950 1860<br />

AIMg3 F 24 0.70 0.70 250 920 540<br />

Sheet material Sheet thickness Sheet thickness Tensile strength Holding force<br />

punch side die side Rm Shear tension Shear tension Cross tension<br />

transverse longitudinal<br />

[mm] [mm] [N/mm 2 ] [N] [N] [N]<br />

St 1203 1.00 1.00 303 2100 1900 –<br />

AIMg3 F22 1.00 1.00 256 1240 960 –<br />

Sheet material Sheet thickness Sheet thickness Tensile strength Holding force<br />

punch side die side Rm Shear tension Shear tension Cross tension<br />

transverse longitudinal<br />

[mm] [mm] [N/mm2 ] [N] [N] [N]<br />

St 12 / St 14 1.00 1.00 300-380 3150 2300 1300<br />

Sheet material Sheet material Sheet thickness Sheet thickness Tensile strength Holding force<br />

punch side die side punch side die side punch side Shear tension Cross tension<br />

[mm] [mm] [N/mm 2 ] [N] [N]<br />

St 1203 St 1203 1.00 1.00 335 3000 1300<br />

St 1203 Federstahl 1.50 0.50 – 4450 4400<br />

7

8<br />

Many Benefits<br />

Economic<br />

viability<br />

and costs<br />

Why <strong>Eckold</strong><br />

clinching?<br />

<strong>Clinching</strong> costs<br />

at low cost.<br />

Cost comparisons of customers and independent bodies have shown that <strong>Eckold</strong><br />

clinching is significantly more cost-effective than other joining techniques.<br />

Depending on the joining task, the overall costs for the manufacture of a clinched<br />

component are approximately 55% of the costs for spot welding, for example.<br />

This takes account of both investment costs and operating costs.<br />

100<br />

75<br />

50<br />

25<br />

0<br />

[%]<br />

16.8<br />

41.3<br />

14.7<br />

26.1<br />

Sheet steel<br />

uncoated<br />

31.1<br />

43.5<br />

14.7<br />

22.4<br />

Sheet steel<br />

zinc thickness 10 µm<br />

Comparison based on 1 industrial robot for setting a joining element<br />

• Various stainless steels can be joined economically<br />

<strong>Clinching</strong><br />

Spot welding<br />

55.8<br />

44.2<br />

22.4<br />

14.7<br />

Investment costs in [%]<br />

Operating costs in [%]<br />

Investment costs in [%]<br />

Operating costs in [%]<br />

29.5<br />

55.8<br />

22.9<br />

25.5<br />

Sheet steel Sheet aluminium<br />

zinc thickness 20 µm<br />

• Optional versions (R-DF, S-DF, H-DF and CONFIX) for the ideal joint to solve<br />

individual problems<br />

• Sheets of aluminium alloys or non-formable materials such as spring steels<br />

can be joined with a formable material by means of the CONFIX variation<br />

• Joining elements with the greatest holding forces<br />

• Compensates for fluctuations in sheet thickness<br />

• Joining of oil-impregnated sheets possible

Ecology<br />

and Health<br />

Quality<br />

control<br />

If you have ever experienced the smell of the toxic gases that<br />

arise during welding or the noise of punch riveting or had<br />

to physically carry the additional weight of protective clothing<br />

or additional materials, you will appreciate the benefits of<br />

<strong>Eckold</strong> clinching. This takes account of the user’s health in<br />

many respects. Besides the significantly lower physical stresses,<br />

<strong>Eckold</strong> clinching is distinguished by low energy consumption<br />

and no industrial effluents whatsoever are generated.<br />

All in all, the <strong>Eckold</strong> technique is a clean and user friendly<br />

process.<br />

A manual method and a computer-aided online monitoring<br />

system can be used for quality control of <strong>Eckold</strong> clinching.<br />

The quality of the clinch element can be examined manually<br />

by means of the bottom thickness or width. 100% control is<br />

provided by the computer-aided online monitoring system.<br />

This can be used to achieve unbroken quality control in automatic<br />

plants for mass production. Production becomes more<br />

efficient and cost effective because down time and rejection<br />

rates are reduced through early detection of load errors.<br />

<strong>Clinching</strong> force<br />

Envelope curve top<br />

Envelope curve bottom<br />

Tool travel<br />

9

10<br />

Power sources<br />

for every application.<br />

Hydraulic, air over oil, electric and electrohydraulic drive units<br />

from the <strong>Eckold</strong> company are available to drive <strong>Eckold</strong> clinching<br />

machines. Below are three standard units which, depending<br />

on the application, can be supplemented with special<br />

units that are also available in stationary versions.<br />

Drives HAT 525<br />

portable<br />

hydraulic unit<br />

HA 510<br />

mobile<br />

hydraulic unit<br />

Antriebsarten<br />

elektrisch<br />

hydraulisch<br />

pneumohydraulisch

<strong>Eckold</strong><br />

is available for you worldwide.<br />

Increasing in importance alongside the standard products are<br />

special tools, project organisation and design of special tools,<br />

machines and installations.<br />

Thanks to our years of experience, including the solving of<br />

particularly complex customer requirements, we are well<br />

equipped to move into this area. In close collaboration with you,<br />

our customer, we plan, design and produce for any location<br />

you wish.<br />

Our involvement does not stop at that either - the subsequent<br />

training of operating staff, the maintenance of machines and the<br />

worldwide service are a natural step for us.<br />

To cope with this demand - all over the world - we have<br />

established a widely distributed network of representatives.<br />

<strong>Eckold</strong> production plants are of course certified to ISO 9001:2000<br />

as well as VDA 6.4:2005.<br />

Further information is available on<br />

our CD-ROM and in our <strong>Clinching</strong><br />

manual, which we would be pleased to<br />

send you.<br />

Weitere Informationen finden Sie<br />

auf unserer CD-ROM und in unserem<br />

Leitfaden Clinchtechnik, welche wir<br />

Ihnen gerne zusenden.<br />

11

The <strong>Eckold</strong> Group<br />

• <strong>Eckold</strong> GmbH & Co. KG<br />

D-37444 St. Andreasberg<br />

Germany<br />

Tel.: ++ 49 (55 82) 8 02-0<br />

Fax: ++ 49 (55 82) 8 02-3 00<br />

Net: www.eckold.com<br />

eMail: info@eckold.de<br />

• <strong>Eckold</strong>-Biegetechnik GmbH & Co. KG<br />

D-37444 St. Andreasberg<br />

Germany<br />

Tel.: ++ 49 (55 82) 8 02-1 11<br />

Fax: ++ 49 (55 82) 8 02-2 50<br />

eMail: biegetechnik@eckold.de<br />

• <strong>Eckold</strong> AG<br />

Rheinstraße<br />

CH-7203 Trimmis<br />

Switzerland<br />

Tel.: ++ 41 (81) 3 54 12 70<br />

Fax: ++ 41 (81) 3 54 12 01<br />

Net: www.eckold.com<br />

eMail: info@eckold.ch<br />

• <strong>Eckold</strong> Limited<br />

15 Lifford Way<br />

Binley Industrial Estate<br />

GB-Coventry CV3 2RN<br />

Great Britain<br />

Tel.: ++ 44 (24) 76 45 55 80<br />

Fax: ++ 44 (24) 76 45 69 31<br />

eMail: sales@eckold.co.uk<br />

• <strong>Eckold</strong> France<br />

16, Rue de la Noue Guimante<br />

Z.I. de la Courtillière<br />

F-77400 St. Thibault-des-Vignes<br />

France<br />

Tel.: ++ 33 (1) 64 30 92 47<br />

Fax: ++ 33 (1) 64 30 81 92<br />

Net: www.eckold.fr<br />

eMail: info@eckold.fr<br />

• <strong>Eckold</strong> & Vavrouch spol. s.r.o.<br />

Jilemnickeho 8<br />

CZ-61400 Brno<br />

Czech Republic<br />

Tel.: ++ 420 (5) 45 24 18 36<br />

Fax: ++ 420 (5) 45 24 18 36<br />

Net: www.eckold.cz<br />

eMail: eckold@volny.cz<br />

• <strong>Eckold</strong> Japan Co. Ltd.<br />

2-14-2 Maihara-higashi<br />

274-0824 Funabashi-shi, Chiba pref.<br />

Japan<br />

Tel.: ++ 81 (47) 4 70 24 00<br />

Fax: ++ 81 (47) 4 70 24 02<br />

Net: www.eckold.co.jp<br />

eMail: info@eckold.co.jp<br />

Printed in Germany 002/09.08/4/500/D/Kohlmann<br />

Technische Änderungen vorbehalten/Technical modifications kept under reserve.