Brochure Eckold Clinching (PDF)

Brochure Eckold Clinching (PDF)

Brochure Eckold Clinching (PDF)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6<br />

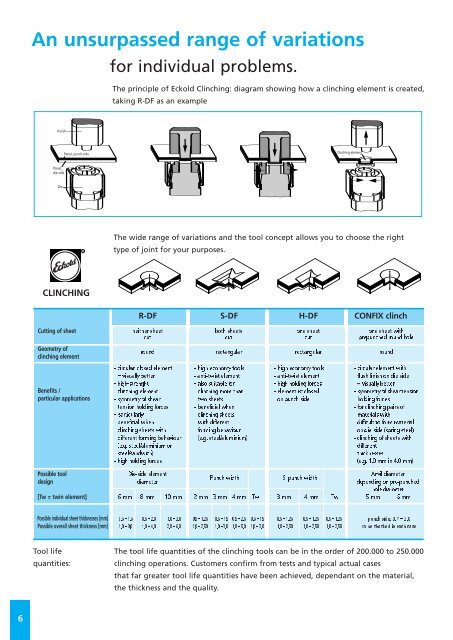

An unsurpassed range of variations<br />

Stempel Punch<br />

Blech,<br />

Panel,<br />

matrizen-<br />

die-side<br />

seitig<br />

Matrize Die<br />

Blech, Panel, punch-side stempelseitig<br />

CLINCHING<br />

R<br />

for individual problems.<br />

The principle of <strong>Eckold</strong> <strong>Clinching</strong>: diagram showing how a clinching element is created,<br />

taking R-DF as an example<br />

<strong>Clinching</strong> element<br />

Fügeelement<br />

The wide range of variations and the tool concept allows you to choose the right<br />

type of joint for your purposes.<br />

R-DF S-DF H-DF CONFIX clinch<br />

Cutting of sheet neither sheet both sheets one sheet one sheet with<br />

cut cut cut prepunched round hole<br />

Geometry of<br />

clinching element<br />

Benefits /<br />

particular applications<br />

round rectangular rectangular round<br />

- circular, closed element - high economy tools - high economy tools - circular element with<br />

= visually better - anti-twist element - anti-twist element flush finish on die side<br />

- high-strenght - also suitable for - high holding forces = visually better<br />

clinching element clinching more than - element ist closed - symmetry of shear tension<br />

- symmetry of shear two sheets on punch side holding forces<br />

tension holding forces - beneficial when - for clinching pairs of<br />

- particularly clinching sheets materials with<br />

beneficial when with different difficult to form material<br />

clinching sheets with forming behaviour on die side (spring steel)<br />

different forming behaviour (e.g. steel/aluminium) - clinching of sheets with<br />

(e.g. steel/aluminium or different<br />

steel/sandwich) thicknesses<br />

- high holding forces (e.g. 1.0 mm in 4.0 mm)<br />

Possible tool<br />

design<br />

Die-side element<br />

diameter<br />

Punch width S punch width<br />

Anvil diameter<br />

depending on pre-punched<br />

hole diameter<br />

[Tw = twin element] 6 mm 8 mm 10 mm 2 mm 3 mm 4 mm Tw 3 mm 4 mm Tw 5 mm 6 mm<br />

Possible individual sheet thicknesses [mm] 0.5 – 1.5 0.5 – 2.0 1.0 – 3.0 0.5 – 1.25 0.5 – 1.5 0.5 – 2.5 0.5 – 1.5 0.5 – 1.25 0.5 – 1.25 0.5 – 1.25 punch side: 0.7 – 3.0<br />

Possible overall sheet thickness [mm] 1.0 – 3.0 1.0 – 4.0 2.0 – 6.0 1.0 – 2.50 1.0 – 3.0 1.0 – 5.0 1.0 – 3.0 1.0 – 2.50 1.0 – 2.50 1.0 – 2.50 to be checked in each case<br />

Tool life<br />

quantities:<br />

The tool life quantities of the clinching tools can be in the order of 200.000 to 250.000<br />

clinching operations. Customers confirm from tests and typical actual cases<br />

that far greater tool life quantities have been achieved, dependant on the material,<br />

the thickness and the quality.