Pathfinder instructions - The WoodRat

Pathfinder instructions - The WoodRat

Pathfinder instructions - The WoodRat

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

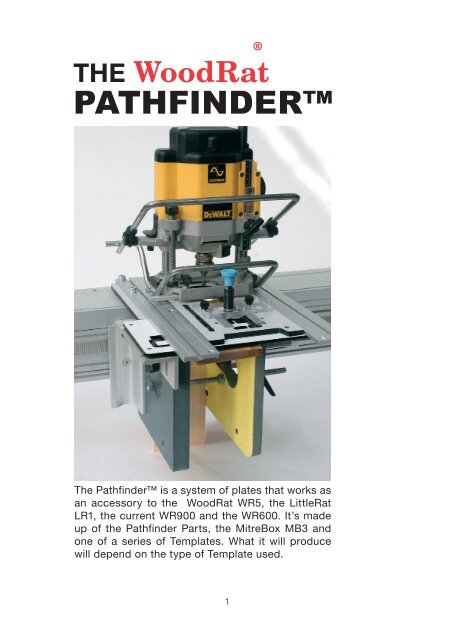

THE <strong>WoodRat</strong><br />

PATHFINDER<br />

<strong>The</strong> <strong>Pathfinder</strong> is a system of plates that works as<br />

an accessory to the <strong>WoodRat</strong> WR5, the LittleRat<br />

LR1, the current WR900 and the WR600. It’s made<br />

up of the <strong>Pathfinder</strong> Parts, the MitreBox MB3 and<br />

one of a series of Templates. What it will produce<br />

will depend on the type of Template used.<br />

1<br />

®

Contents<br />

Introduction<br />

Before you begin<br />

parts not included in the <strong>Pathfinder</strong><br />

<strong>The</strong> <strong>Pathfinder</strong><br />

MitreBox MB3<br />

<strong>Pathfinder</strong> Parts<br />

<strong>The</strong> Templates<br />

Tenons<br />

Set up for Tenons<br />

Making the tenon<br />

Making the mortise<br />

Dovetails<br />

Set-up for Dovetails<br />

Grooving<br />

Symmetrical Dovetails:<br />

Run of Pins<br />

the Tail sockets<br />

Test Pins<br />

Asymmetrical Dovetails<br />

Half Blind or Lapped Dovetails<br />

Set-up<br />

Making classic drawers<br />

Tail sockets<br />

Test pins<br />

Run of Pins<br />

<strong>The</strong> Blank Template<br />

2

Introduction to the <strong>Pathfinder</strong><br />

A few years ago certain companies began producing<br />

Mortise and Tenon jigs to simplify the process<br />

of making mortise and tenon joints and at the same<br />

time to solve the problem inherent in routing with<br />

a round bit, which is that it makes round ended<br />

mortises – the proverbial square peg in the round<br />

hole.<br />

This niggled at us too, but having the <strong>WoodRat</strong> as<br />

a starting point, the direction it took us surprised<br />

us by producing not only a foolproof way of cracking<br />

out tenons, but it also led on to a whole variety<br />

of joints – tenons, through dovetails and half-blind<br />

dovetails and all sorts of shapes and so on, each<br />

ve Moreover it was all based on familiar <strong>WoodRat</strong><br />

technology.<br />

<strong>The</strong> one thing that it did not produce was an easy<br />

way of making mortises. But then mortises are traditionally<br />

made in a very separate way from tenons,<br />

and our solution for them, the MR4 Mortise Rail, has<br />

also led us to a lot of other ways of making many<br />

interesting things.<br />

I hope you get great pleasure from the <strong>Pathfinder</strong> as<br />

well as finding it useful. It is still in the experimental<br />

stage and the invitation is there for you to join us<br />

in discovering innovative ways to use it. Keep in<br />

touch.<br />

3

<strong>The</strong> WR600, WR5 and the WR900<br />

make a suitable platform for the <strong>Pathfinder</strong>. Use your<br />

Alu GuideRails and Router Plate RP3 (with new hole<br />

configuration) and raising plate if necesary. Older<br />

GuideRails need an extra counterbored M4 hole, and<br />

you will need to drill and tap older Router Plates or buy<br />

a new RP3 Router Plate. <strong>The</strong> new Ali Fences are ideal for<br />

firming up the MitreBox.<br />

6541 Starknob<br />

Halfplate<br />

3141 Guiderail Left<br />

4262<br />

Aluminium<br />

Fence<br />

Attaches to the Left<br />

hand Cheek to secure<br />

the MitreBox.<br />

5616 M4 16<br />

M6 Locking key x 2<br />

Aluminum Bracket<br />

5684 4M Nut<br />

3. <strong>Pathfinder</strong><br />

Templates<br />

<strong>The</strong>re are a growing selection<br />

of Templates for a wide variety<br />

of tasks. <strong>The</strong>y can be made to<br />

order.<br />

6461 Routerplate<br />

6421 Lobed Washer<br />

Left-hand Cheek<br />

Drop Pin<br />

4<br />

3142 Guiderail Right<br />

M6 Locking screw x2<br />

PARTS LIST<br />

PARTS FOR THE PATHFINDER Pf1<br />

<strong>The</strong> <strong>Pathfinder</strong> uses the <strong>WoodRat</strong> MitreBox MB3 to hold the workpieces plus several<br />

new components (<strong>Pathfinder</strong> Parts) that enable it to track the pathways in the<br />

Templates. Templates come in a variety of patterns depending on the joint or<br />

3316 Raising Plate<br />

Use your Raising<br />

Plates if needed for<br />

extra depth for<br />

tenons<br />

M8 50<br />

6mm Hex key<br />

component to be made.<br />

M8 nut<br />

M8 Self-tapping inserts<br />

Tenon Template<br />

Through DovetailsTemplate<br />

1. <strong>Pathfinder</strong> Parts:<br />

Half plate<br />

Drop-Pin Plate<br />

Drop pin<br />

Bracket<br />

M6 Locking screws x4<br />

M8 20 x2<br />

2. MiterBox MB3<br />

Left hand Cheek<br />

Right hand Cheek<br />

Drop-Pin Plate<br />

M4 16 x 4<br />

M4 nuts x 4<br />

Rod Clamp components<br />

5424 Locking Lever<br />

5421 Lobed Washer<br />

M10 nuts x 4<br />

M10 washers x 5<br />

300mm threaded Rod x 2<br />

Right-hand M8 self tapping inserts x 2<br />

M8 nut<br />

5512 Rubber washer x 2<br />

Rod Lock<br />

Half-blind Dovetail Template<br />

5424 Locking Lever<br />

Spreader Rod<br />

Although we will try to advertise any item changes in good time, in the interest of continuous improvement in the quality and value of our products,<br />

<strong>WoodRat</strong> reserve the right to change components in colour, function and material without prior warning.

5616 M4 16<br />

5684 4M Nut<br />

<strong>The</strong> aluminium fence has two tee-slots<br />

that will hold the left-hand cheek firm<br />

and square to the sliding bar.<br />

<strong>The</strong> guiderails have an extra<br />

pair of counterbored<br />

4mm holes to take an<br />

M410 to attach it to the<br />

half-plate<br />

<strong>The</strong> router plate has<br />

three pairs of M6 holes<br />

to take the Drop-pin<br />

plate<br />

5<br />

Before you begin<br />

Some parts are not part of the <strong>Pathfinder</strong>, as they are<br />

now a standard part of the <strong>WoodRat</strong> kit. <strong>The</strong>y can be bought<br />

separately from your <strong>WoodRat</strong> dealer if you need them.<br />

1. <strong>The</strong> Aluminium Fences<br />

We have recently introduced new Aluminium Fences to replace<br />

the earlier moulded nylon ones. Firm and square enough for<br />

ordinary purposes, they are well worth having for <strong>Pathfinder</strong><br />

work as they allow you firmly to attach the Left hand Cheek<br />

to the Sliding Bar to form the MitreBox MB3.<br />

<strong>The</strong> Fence has two tee slots in it so that the Left hand Cheek<br />

can be bolted to it with four M4 16 screws to hold it firm and<br />

exactly square. A third tee-slot behind the finger grip takes<br />

the Big Cursor. This is not generally of use with the templates<br />

which have their own way of registering where the cuts are<br />

to come.<br />

<strong>The</strong> ali fences come with wooden faces that allow you to add<br />

sandpaper to stop the wood slipping. Do not sandpaper the<br />

aluminium Fence direct.<br />

But now take off the Ali Fence. Take off the Plywood Face<br />

and store it, before you put the Left Cheek into the tee-slots<br />

of the Sliding Bar.<br />

<strong>The</strong> M4 16 screws go into cheek. <strong>The</strong> nuts go on loosely and<br />

the Cheek is slid into the tee-slot of the Sliding Bar <strong>The</strong> Fence<br />

is slid upwards onto the nuts before being screwed to the Bar,<br />

and the M4 screws tightened.<br />

2. Ali GuideRails:<br />

You will need your <strong>WoodRat</strong> or LittleRat GuideRails. Note<br />

that there is an extra M4 threaded hole in the HalfPlate. If your<br />

GuideRails do not have corresponding holes, you will need<br />

to drill them 4mm counterbored to 8mm to house the head<br />

of the M4 10 screw. <strong>The</strong>se extra screws stop the routerplate<br />

from twisting the rails out of true, and hold everything firm on<br />

the Half Plate.<br />

3. <strong>The</strong> New RP3 RouterPlate has 6 x 6mm tapped holes that<br />

take the locking keys for the Drop-pin plate. If you have an old<br />

routerplate and you are not confident at drilling and tapping,<br />

it might be best to buy a new RP3.<br />

Otherwise the RP3 is similar to the RP2 routerplate except<br />

that is has two extra tapped M8 holes for attaching fences<br />

of different types to the underside of the Plate. This allows<br />

you to use the Router for freehand work without taking the<br />

router off the Plate. You have the advantage of a larger base<br />

for the router, plus the ability to make a fence that suits the<br />

job in hand: 8mm deep for running against an 8mm straight<br />

edge laid across a sheet of material or, for example, deeper<br />

for moulding the edge of a table, for example.

Setting up the <strong>Pathfinder</strong><br />

<strong>The</strong> <strong>Pathfinder</strong> Pf1 comes in three parts. <strong>The</strong>y can be<br />

bought separately, or bundled together. If you have an<br />

MB3 MitreBox you will need only the <strong>Pathfinder</strong> Parts and<br />

a Template to begin wo.<br />

Most of the actions and techniques such as the tracking, holding<br />

wood in the CamLocks, using the raising plates, plunging<br />

and depthing the router, will be familiar to anyone who knows<br />

the <strong>WoodRat</strong>, but if you are new to it, you will find it helpful to<br />

read the Manual that comes with your basic machine, and put<br />

in some practice.<br />

<strong>The</strong> workings of the <strong>Pathfinder</strong> itself are mostly self-evident. Tenons<br />

are a breeze and Through Dovetails are not too difficult, but<br />

the Half-Blinds are so quick in operation that it is well worth the<br />

initial mental effort. It’s even worth following the <strong>instructions</strong>.<br />

1. <strong>The</strong> <strong>Pathfinder</strong> Parts<br />

<strong>The</strong> first part of the <strong>Pathfinder</strong> is what we call the ‘<strong>Pathfinder</strong><br />

Parts’.<br />

<strong>The</strong>se need to work with the MB3 MitreBox to complete the Pf1<br />

<strong>Pathfinder</strong>.<br />

1.1. <strong>The</strong> Halfplate<br />

<strong>The</strong> BasePlate of the <strong>WoodRat</strong> is replaced for <strong>Pathfinder</strong> work<br />

by the HalfPlate. <strong>The</strong> front edge of the Halfplate has a groove<br />

that takes the tongue cut into edge of all the Templates which<br />

interlock with it and can slide east/west with no north/south<br />

movement. Use the M8 25 screws that come as standard with<br />

the <strong>WoodRat</strong> kit.<br />

Raising Plates<br />

Loosen the HalfPlate and add Raising Plates under it as necessary<br />

to give more depth of cut. <strong>The</strong> Raising Plate (or plates) come<br />

as standard with the <strong>WoodRat</strong> kit, to allow a greater depth of<br />

cut when needed for tenons. It uses the M8 25 or M8 50 screws<br />

which come standard with the <strong>WoodRat</strong> kit. Plus the M4 10<br />

screws to hold the GuideRail to the Halfplate.<br />

1.2 Drop-pin Plate<br />

<strong>The</strong> new RP3 RouterPlate is largely the same as the older Plate<br />

but is modified to take the Drop Pin Plate. This fits into its tee slot<br />

and is held either side by M6 10 Locking Keys. Its position can<br />

be adjusted north/south in the RouterPlate, and it can be locked<br />

down. It determines the distance between the Pin as it wanders<br />

around the template and the Bit as it cuts the workpiece.<br />

It governs the distance between the Bit and Pin.<br />

<strong>The</strong> Drop Pin<br />

<strong>The</strong> Drop Pin has a sprung pin that can be raised and kept up,<br />

or dropped down to engage with the grooves, islands, wedges<br />

and pathways in the Template. So, as the Template and with it<br />

the Workpiece is tracked west/east, the Pin, and with it the Bit,<br />

can go north/south.<br />

So in effect, the pin finds its way around any useful kind of Pathway<br />

cut in the template allowing the bit to travel a similar kind of<br />

pathway in the workpiece; hence the name <strong>Pathfinder</strong>.<br />

6<br />

M6 Locking Key<br />

Drop Pin<br />

Make sure that you have the<br />

4mm counterbored hole here.<br />

M6 Locking Key<br />

Drop Pin Plate

M8 50<br />

6mm Hex key<br />

M8 nut<br />

M8 Self-tapping inserts<br />

<strong>The</strong> cheeks are made of HDF which<br />

is brittle, but can be drilled, worked<br />

and added to.<br />

<strong>The</strong> <strong>WoodRat</strong> manual gives a lot of<br />

hints on how to use the MitreBox<br />

for many other uses than simply<br />

working at 45° angles<br />

1.3. <strong>The</strong> Bracket<br />

This attaches to the Left Hand Cheek of the MitreBox MB3. <strong>The</strong> Cheek<br />

must be fitted with two M8 brass inserts which take the two M8 25’s.<br />

<strong>The</strong>y go through the two vertical slots, allowing the Bracket, and the<br />

Template with it, to be raised up under the Guiderails when the Raising<br />

Plate is in use.<br />

<strong>The</strong> Bracket also has two open slots which take the M6 Locking Keys<br />

screwed into the Template. <strong>The</strong> keys, when loose, can slide in the<br />

slots and can be positioned and tightened up, so that the Template,<br />

sliding in the groove in the HalfPlate may be tracked east/west under<br />

the RouterPlate,<br />

This east/west adjustment of Template on the Bracket governs the<br />

way the joints are laid onto the workpiece.<br />

1.4. <strong>The</strong> Brass Inserts<br />

<strong>The</strong>re are two brass inserts that need to be wound into the two holes<br />

at the top of the left Cheek. they can be driven in with a large screwdriver,<br />

but it is simpler to use a long M8 socket head cap screw. If<br />

you just use the screw, put the insert on it, and wind it in with the hex<br />

key, you might find that the insert jams on the screw and unscrews<br />

when you wind the screw out again. A nut on the screw, then the insert,<br />

before winding it in will prevent this happening. Make sure that<br />

it winds in straight.<br />

Recently we have been placing the inserts for you.<br />

2. <strong>The</strong> MitreBox MB3<br />

This is the second part of the <strong>Pathfinder</strong><br />

<strong>The</strong>re are differences between the setups needed for the different<br />

Templates, but this is the basic system:<br />

2.1. <strong>The</strong> Left Cheek<br />

of the MB3 attaches to the Ali Fence. It is placed first with its ‘toes’ in<br />

the big tee-slot of the Sliding Bar. <strong>The</strong> four M4 16 screws are put into<br />

the four counter-bored holes in the Cheek with the M4 nuts placed<br />

loosely: the Fence is slid upward taking the nuts into the two tee-slots<br />

and the Fence is screwed to the Sliding Bar with the M8 countersunk<br />

screws in the usual way. Before the four M4 16’s are tightened fully,<br />

pull the Fence forward and push the Cheek gently but firmly against<br />

the Machine Face to take out any slack in the Bar.<br />

For most work with the <strong>Pathfinder</strong> you only need the Left Cheek. When<br />

you do need the Right Cheek, you’ll need the RodLock to hold it all<br />

firmly, as a Box.<br />

Set up the parts of the <strong>Pathfinder</strong> as the diagram. For the <strong>WoodRat</strong>,<br />

use the right-hand CamLock. <strong>The</strong> LR1 and WR600 have only one gate,<br />

but the process is exactly the same.<br />

Some people buy an extra fence so that it can be kept permanently<br />

with the left cheek.<br />

2.2. <strong>The</strong> Right Cheek<br />

<strong>The</strong> right-hand cheek is the thinner one. You’ll not<br />

need it for the tenons or for through dovetails: only<br />

later, for half-blind dovetails, and for mitred work<br />

generally.<br />

7

2.3. <strong>The</strong> Rod Lock<br />

<strong>The</strong> threaded rods and how they are used is covered in a later<br />

section on Half-blind Dovetails.<br />

3. <strong>The</strong> Templates<br />

<strong>The</strong> third essential part of the <strong>Pathfinder</strong> is the Template.<br />

<strong>The</strong>se plates have a shaped long edge that interlocks<br />

with the Half-plate. <strong>The</strong>y each have a way<br />

of being screwed to slots in the Bracket, using<br />

M6 Locking Keys from below.<br />

3.1. <strong>The</strong> Tenon Template<br />

works with straight bits: 8mm 10mm and Half<br />

inch. It will make Twin and Single and Double<br />

Twin tenons in a range of lengths. <strong>The</strong> tenons<br />

can be made round or square ended. It<br />

will also make dowels. This technique<br />

complements mortises made in the MR4<br />

Mortice Rail.<br />

3.2. Through Dovetail Plates<br />

Each plate makes classic through dovetails<br />

of fixed pitch but for a range of sizes<br />

of dovetail bit.<br />

3.3. <strong>The</strong> Half-Blind Dovetail Template<br />

is the fastest way to joint drawers. Each Template<br />

has two different pitches for the same size<br />

of <strong>WoodRat</strong> dovetail bit. This Template and the<br />

correct bit have to be used together.<br />

3.4. <strong>The</strong>re is also a Blank Template<br />

You can cut out any shape in 3mm sheet acrylic and make<br />

from it any wooden shape you wish. Any kind of shape that<br />

can be devised in the template can cut a similar shape in<br />

the wood.<br />

<strong>The</strong> pathway might make stars, animal shapes for a Noah’s<br />

Ark, or a line of multiple Santa Clauses. More practically,<br />

circles or squares will make inter-locking lids and boxes. You<br />

will need to experiment with different sized bits and different<br />

thicknesses of wall for the drop-pin to run against.<br />

6421 Lobed Washer<br />

8<br />

Rod Lock<br />

5424 Locking Lever<br />

Spreader Rod

Simple strips of sandpaper<br />

are quite adequate to hold<br />

the wood vertical, horizontal<br />

and at angles.<br />

9<br />

Working with the <strong>Pathfinder</strong><br />

Preparation<br />

However well the <strong>WoodRat</strong> parts are finished, your <strong>Pathfinder</strong><br />

parts, plates and sliding bar, will need to be thoroughly<br />

waxed and polished before work can begin. <strong>The</strong><br />

whole mechanism must run like silk.<br />

When the Template is added it needs to be locked in so<br />

that there is the minimum of movement when the pin is<br />

dropped, for instance, in the centre hole in the tenon<br />

template. You will need to check that the router plate<br />

runs smoothly fore and back and that there is no sideways<br />

slap between plate and guiderails.<br />

It might be necessary to take everything apart to ensure<br />

that all sliding parts are as slick as can be.<br />

Holding the work<br />

Locking a rail in the Camlock is the same as for general Wood-<br />

Rat work, you need to pull with your fingers and push with<br />

your thumb as you clamp in the work, to take out any slack in<br />

the sliding bar, and make sure it’s firmly seated. Bring up the<br />

Camlock, and lock in a scrap rail, making sure that the Bar<br />

tracks nicely west/east....<br />

and that the Router runs smoothly north/south: if necessary,<br />

wax all rubbing surfaces. Take out any lateral movement between<br />

GuideRails and RouterPlate.<br />

Sandpaper your faces:<br />

to give some friction to the inner faces of the Cheeks, we recommend<br />

that you sandpaper the faces. Use impact adhesive,<br />

pasted on both surfaces and allowed to dry before bonding<br />

the two surfaces together: this makes for very durable non-slip<br />

surfaces to hold the work. Alternatively use a rubber cement<br />

(Copydex) that does not last for ever, but which can be peeled<br />

off and replaced more easily.<br />

Use around a 120 grit and trim round the Cheeks with a sharp<br />

knife.<br />

Dust Extraction<br />

Ensure that you have good strong dust extraction, particularly<br />

for the harmful fine dust.<br />

Note: LR1 LittleRat users can use the new RP3 RouterPlate for<br />

all normal LittleRat work except variably spaced half-blind dovetails.<br />

Either revert to your LittleRat router plate or invest in a HalfBlind<br />

Dovetail Template and use the <strong>Pathfinder</strong>.<br />

<strong>The</strong> Bracket<br />

<strong>The</strong> Alu bracket is set by screwing two M8 20 screws into<br />

the brass inserts. Do not tighten the screws you have set the<br />

Template, and raised it up under the guiderails. <strong>The</strong> slots allow<br />

you to raise the Template when Raising Plates are in use.<br />

Check your router for run out. Make a test cut with a straight<br />

bit in some hardwood scrap to check that a socket made<br />

with a 10mm bit is indeed cutting 10 mm wide. If it is cutting<br />

large, check that there is no slack between the guiderails and<br />

routerplate.<br />

If there is still serious run-out and you are using a quick release<br />

chuck, re-insert your original collet and try again. If there is still<br />

run-out, you have a problem with the router. if not, you have a<br />

problem with the quick release chuck. In which case undo the<br />

chuck and turn it a quarter turn and retighten, and test again. This<br />

may improve the seating. If you cannot improve it, let us know.

A collection of tenons made during the experimental<br />

stages of developing the <strong>Pathfinder</strong>.<br />

<strong>The</strong> collection comprises tenons double tenons and dowels and stars made<br />

with a star shape placed in the blank template<br />

10

Using the Tenon Template<br />

Aluminium<br />

guiderails allow the<br />

router to cut the<br />

work on the axis<br />

north/south<br />

<strong>The</strong> half-plate<br />

holds the<br />

Template as it<br />

slides East/West<br />

Bracket is raised so as<br />

to lift the Template up<br />

under the half-plate<br />

<strong>Pathfinder</strong> Tenons – either single or double – are very straightforward. <strong>The</strong> Template<br />

forms not only round ended tenons of various useful sizes, but also dowels at the extreme<br />

left, and a long tenon that can be used for square ended tenons with haunches at<br />

the extreme right of the plate.<br />

Introducing the Tenon Template.<br />

Polish all sliding surfaces so that everything slides easily when<br />

it should, or locks down firmly when it needs to be firm.<br />

Use the left-hand Cheek only. Place one 25mm/1” or two<br />

12mm 1 /2” Raising Plates under the HalfPlate to give you up<br />

to 50mm/2” depth of cut.<br />

<strong>The</strong> Tenon Template has four lines of Islands – in two pairs of<br />

two, each pair starts with circles and ends with long islands.<br />

<strong>The</strong> top line of each pair is for single tenons; twins are made<br />

using both lines.<br />

<strong>The</strong> tenon Template is designed to make tenons that fit mortises<br />

cut by an 8mm, 10mm or a half inch (12.7mm) bit.<br />

11<br />

Left Cheek of the MB3<br />

mitreBox only is used<br />

for makingTenons<br />

<strong>The</strong> Drop-pin in the<br />

Drop-pin plate follows<br />

around the ‘islands’ in<br />

the Template, as the<br />

Bit cuts the<br />

workpiece under<br />

the plate<br />

<strong>The</strong> Tenon template allows the<br />

work to move east/west depending<br />

on the drop-pin controling the<br />

position of the router. With this<br />

Template it makes round ended<br />

tenons – double and twin, and also<br />

dowels.<br />

Look at the rail end, and check it against the islands to decide<br />

whether you need twin or single, or single or double tenons.<br />

Or double twins.<br />

Decide which bit you are going to use for your mortises, and<br />

therefore the tenon size. <strong>The</strong> Template will make your tenons<br />

either 8mm, 10mm or half inch, so your mortises will be either<br />

8, 10 or half inch.<br />

As the Template is designed to make the tenon fit the mortise,<br />

you can make the tenons first. This has advantages over<br />

making the mortises first, as we shall see.<br />

Decide how long you need your tenon by matching the rail<br />

end with an Island. At it’s simplest a single tenon will go in<br />

the centre of the rail, but you can place it where needed. A

twin tenon will have the socket between the tenons<br />

placed central. To get the length of tenon, place your<br />

work-piece against the islands to check which to use,<br />

but note that the actual size of the tenon is 2mm or<br />

so inside the island. Put a pencil mark on the Island<br />

you are using so you can find it when it’s under the<br />

plate.<br />

With the upper pair of lines, use an 8mm<br />

straight bit to make a 10mm tenon,<br />

or a 10mm bit, to make an 8mm tenon.<br />

With the lower pair of lines, use a 10mm<br />

bit to cut a 1/2” (12.7mm) tenon,<br />

or a 1/2” (12.7mm) bit to cut a 10mm tenon.<br />

Select a bit to make the tenon you want and place<br />

it in the collet.<br />

Screw the Template to the Bracket loosely, and track<br />

it under the Router Plate, threading the Template over<br />

the supporting groove in the HalfPlate and under the<br />

GuideRails. Lift the Template and Bracket gently up<br />

under the GuideRails and tighten the M8 20 screws<br />

on the Bracket. It should track west/east freely, so<br />

make sure that it does.<br />

<strong>The</strong> Drop-pin Plate<br />

<strong>The</strong> Drop Pin screws into the Drop Pin Plate.<br />

Place the DropPin Plate in the RouterPlate: screw in<br />

a 6mm Locking Key loosely either side. See how the<br />

plate will slide north/south when loose, and lock down<br />

when the screws are tightened. By placing the screws<br />

in one of the three pairs of holes, the pin can cover a<br />

distance fore and back across the Template.<br />

Lift the Pin, making sure that it moves freely over the<br />

template. Note that the cutter is free to cut at random<br />

into any work-piece placed in the CamLock when the<br />

Pin is raised.<br />

So raise the Bit. Get into the habit of raising the bit after each<br />

run of cuts.<br />

Drop the Pin and see how its travel is limited by the Islands of<br />

the Template. Track the Crank Handle as you move the router<br />

forward and back and see practice running around the Islands<br />

in the Template.<br />

Marking the rail end<br />

Mark up the end of the rail with two centre lines, the east/<br />

west (x-axis) and the north/south (y-axis) line... and cam it<br />

in place.<br />

Note that there‘s no need to find the exact centre, as you can<br />

make two lines, one from each face, rather than fuss about<br />

finding the centre. Set your cutting gauge to roughly a half<br />

and make two lines one from each face. One blade of the Bit<br />

will later line up with one, and the other blade with the other<br />

cut line, and the Bit will be exactly centered. If you have sharp<br />

eyes or alternatively good 3 diopter specs, this method will be<br />

extremely accurate.<br />

Note that the centre of the tenon might not need to be central<br />

to the rail. It will depend on your design.<br />

Locating the Template<br />

Place the two M6 Locking Keys, in the correct holes for the<br />

required Island. Note that the locking key holes are found two<br />

places away to the left of the island you are using (the one you<br />

marked up earlier).<br />

Slide the Template so that the Locking Keys engage in the open<br />

Bracket slots. Tighten them temporarily, and track the Bracket<br />

and Template under the GuideRails and Router Plate.<br />

Your marked-up Island will appear under the DropPin as the<br />

crossed lines on the Rail end appear under the bit, but not<br />

yet lined up. Now locate the Drop Pin in the hole in the Tenon<br />

Island (the exact center of the Island).<br />

12<br />

north/south<br />

east/west line<br />

Cross hairs find the<br />

centre of the rail end<br />

<strong>The</strong> Bit finds the<br />

middle of the rail,<br />

while the Pin finds<br />

the centre of the<br />

Island<br />

Two lines give the<br />

centre line when<br />

using a bit with<br />

two blades<br />

When the Pin is<br />

in the centre of<br />

the Island you<br />

can line up both<br />

axes on the cross<br />

hairs.

<strong>The</strong> half-plate<br />

which is screwed<br />

to the Channel<br />

engages with the<br />

Template, which<br />

moves with the<br />

workpiece.<br />

<strong>The</strong> Pin goes into the hole in the<br />

Island, the Template’s Locking<br />

Keys are slackened. <strong>The</strong> Bit lines<br />

up on the centre line of the rail<br />

end, and the Keys tightened.<br />

13<br />

Slacken the Template’s M6 Locking Keys, and track the rail,<br />

to centre the blades of the bit (set north/south) to align with<br />

the y-axis lines. Tighten the screws. This positions the tenon<br />

east/west on the rail end.<br />

2. Locating the DropPin Plate<br />

Loosen the DropPin Plate on the RouterPlate and move the<br />

Bit so that the blades line up with the horizontal lines on the<br />

rail end, then tighten the thumbscrews. You’re now aligned<br />

north/south (on the x-axis).<br />

<strong>The</strong> pin is still in the hole, so raise the pin.<br />

This frees the router bit, so un-plunge the router at the same<br />

time.<br />

Make it a habit: raise the router and the pin every time you<br />

finish a joint. <strong>The</strong>n you can’t harm anything.<br />

<strong>The</strong> Z-axis<br />

<strong>The</strong> Channel<br />

GuideRails<br />

<strong>The</strong> Template slides east/west in the groove in the Half-Plate. <strong>The</strong> Drop Pin in its plate controls the action<br />

north/south of the router. In effect you run round the template Islands with the Drop Pin which describes<br />

the shape of the island on the tail end.<br />

Router Plate with Drop-Pin Plate with<br />

Pin engaging in the Template. Lift the<br />

Pin and the router is free<br />

<strong>The</strong> Tenon Template<br />

Make sure you have enough depth of cut. Slide in a raising<br />

plate as necessary.<br />

Your rail will be marked out with the size between the stiles<br />

and cut with adequate length of tenon at either end. So when<br />

you place the rail beneath the plate you will be able to drop<br />

the bit to the inside line of the door or frame. No zeroing the<br />

bit this time.

If you work from an exact centre line, both your tenons will be<br />

of equal length. <strong>The</strong>y may be too long but you can cut them<br />

down later. If too short, you will need longer rails.<br />

Cutting the Tenon<br />

Drop the bit and with the pin up and the bit down, you’re set<br />

to go. You can now cut anywhere, so be careful.<br />

Cut clockwise all around the rail to clean the shoulder of the<br />

tenon. This without the pin hitting the Island. It is just to skim<br />

the outside of the rail to make a clean shoulder all round.<br />

Now drop the Pin and continue to cut the tenon clockwise. <strong>The</strong><br />

Pin wheel will now hit and run around the Island and describe<br />

the outline of the tenon on the rail end at the same time. Go<br />

gently and take your time.<br />

With a little practice, you’ll find the best track to take, and<br />

will develop your own techniques for maximum speed and a<br />

perfect finish.<br />

Go for finish first and speed later.<br />

Nothing much can go wrong. If you find that the cutter is<br />

cutting into the tenon, check that your locking pins are reasonably<br />

tight: the plate or the template can come loose, but<br />

shouldn’t.<br />

Be sure you are aware when the Bit is up and harmless, and<br />

when down and meaning business, and when the Pin is up<br />

and the bit not controlled by the template and when down and<br />

only cutting where you need it.<br />

Repeat for the tenon on the other end by cart-wheeling the<br />

rail (the face side kept always against the machine face)... and<br />

then the next, and so on.<br />

Twin Tenons<br />

Twins are made by running around the two twin islands together<br />

on the one rail. <strong>The</strong> centering method is a little bit<br />

different:<br />

Slacken the DropPin Plate Locking Screws. <strong>The</strong> y-axis alignment<br />

is done with the pin in the center hole as before.<br />

But the centreline of the joint north/south is given by placing<br />

the pin central between the Islands, and aligning the blades<br />

of the bit on the y-axis lines.<br />

14<br />

Now the Pin Plate’s Locking Keys<br />

are slackened. <strong>The</strong> Pin stays in<br />

the hole, but the Bit is brought<br />

forward to line up with the horizontal<br />

line.<br />

<strong>The</strong> bit cuts round the tenon as<br />

the Pin rolls around the island.

<strong>The</strong> halfplate is<br />

shown partly<br />

translucent<br />

3. With the template loose, the pin is<br />

moved up to the centre hole of the<br />

island, and the template moved so<br />

that the pin will fall in to it.<br />

Tighten the locking keys<br />

Layout for twin tenons using the bottom pair of lines of islands,<br />

and the sequence for centering the tenons on the rail.<br />

15<br />

Double Twins<br />

You can make double twin tenons if you don’t mind one pair<br />

of twins being a little longer than the other. This can be useful<br />

for placing a lock in the center rail.<br />

Dowels<br />

1. the rail is marked up<br />

with “cross-hairs” and<br />

tracked under the plate,<br />

and the bit is centred<br />

on them.<br />

2. the drop pin is loosened,<br />

and taken to<br />

between the islands and<br />

the keys tightened.<br />

4. Now drop pin and cutter, and cut<br />

the twin tenons in the same way as<br />

single tenons.<br />

Dowels are very short round ended tenons, so they are made<br />

in the same way as tenons, either single or twin. Note that they<br />

have the advantage that one end of the dowel is integral and<br />

need not be glued. <strong>The</strong> tenon is in the rail and stile is drilled<br />

to fit it, making a stronger joint.<br />

Note that the dowel can be made in anything... squares or<br />

hexagonal pieces or twigs with bark on.<br />

Note also that the bit does not have to be straight. You can put<br />

nice finials on things with a cove or fancy cutter of any kind.<br />

Gluing up<br />

Tip. If you make too good a job of fitting the mortises to the<br />

tenons, you could find that when you glue up and cramp the<br />

pieces together, air, trapped in the joint, compresses and<br />

shoots the joint apart again like an air gun when the clamping<br />

pressure is released.<br />

After making the tenon and before taking it out of the Camclamp,<br />

raise the Drop pin and just touch the tenon with the bit,<br />

to make an airway. This is quicker than doing it with a chisel.

Haunched Tenons for Cupboard Doors<br />

When making cupboard doors you can simply use the largest<br />

tenon island, and run the cuts off both edges of the rail without<br />

rounding either. Mark out the centre lines of your rail as described<br />

earlier. Make the two cuts, trimming the shoulders, going clockwise<br />

with the Pin down. <strong>The</strong>n raise the Bit by a gauged amount to make<br />

the haunch. This means unlocking and raising the router itself<br />

and lowering the Bit onto the gauging piece and locking it<br />

again. Do not reset the depthing foot, just lift the router.<br />

Raise the Pin and cut across to make the haunch on one end.<br />

Cartwheel the Rail and tenon the other end. Make sure you haunch<br />

the correct end of the tenon.<br />

Marking out for making a box<br />

This is a time-honoured method for keeping the parts of a<br />

project in their proper places and being able to tell which part<br />

is which when they are disassembled on the bench.<br />

Place the pieces together in the position that they will occupy<br />

in the project: the two drawer sides facing away from you, for<br />

example, and the ends across them, as you might find them in<br />

a chest of drawers.<br />

Put them together and draw an arrow across the top edges.<br />

<strong>The</strong> arrows point away from you.<br />

You will then be able to see at a glance which is the top edge<br />

and which the left side and which the right, and which is the<br />

inside and which the outside of the box.<br />

Later you will then be able to see which Side goes with which<br />

End to make a corner. Understanding this, you will never need<br />

to get lost again.<br />

If you have two or more drawers, you can draw a second or<br />

third line under the arrow, or on the right hand edge of the arrow<br />

head. It’s simple but effective.<br />

Making a box with continuous grain<br />

Take a thick plank and re-saw it.<br />

<strong>The</strong> trick is to turn the plank inside out so that the continuous<br />

inside marking is on the outside. Mark up the parts as shown,<br />

taking note of which is Side (the long pieces)) and which is<br />

End (the shorter pieces). When rightly orientated, the arrows<br />

will point away as shown earlier.<br />

Mark up the boards with mitres the arrows give you the inside<br />

and the upside of each piece the four pieces orientated as<br />

they are in the project with the broken arrows still pointing<br />

away from you: the two sides, collected together and marked<br />

with arrows pointing away from you.<br />

16<br />

Bit up<br />

Pin up<br />

safe<br />

position<br />

Bit down<br />

Pin down<br />

safe cutting<br />

as pin follows<br />

template<br />

Bit up<br />

Pin down:<br />

dry run as<br />

the pin<br />

follows the<br />

template<br />

Bit down<br />

Pin up<br />

Watch out!<br />

Pin not in<br />

control<br />

<strong>The</strong> two sides,<br />

collected together<br />

and marked with<br />

arrows pointing<br />

the four pieces<br />

orientated as they<br />

are in the project<br />

with the broken<br />

arrows still pointing<br />

away from you<br />

the arrows give<br />

you the inside and<br />

the upside of each<br />

piece

Dovetailing using the TD Templates<br />

For all those who have been perplexed by the workings of the <strong>WoodRat</strong>’s normal dovetailing<br />

method, this is an idiot-proof Dovetail Jig that never-the-less uses the <strong>WoodRat</strong> range<br />

of fine 1in7 bits and produces perfect results. It’s dovetailing for the rest of us.<br />

Set up for Dovetails<br />

You need only the left-hand Cheek, the Bracket, one Cam-<br />

Lock, and one of the Through Dovetail Templates for through<br />

dovetails.<br />

As always, through dovetails are made with the angled (dovetail)<br />

bit going straight through the work, with the straight bit<br />

cutting at angles to make the pins.<br />

In other words, the angled bit goes straight and the straight<br />

bit goes angled.<br />

So between the square Islands are for the tail sockets, with<br />

the Pin running straight in the alleys between the Islands....<br />

whereas the Pins are made with the wheel running down the<br />

sides of the angled wedges with the straight bit in charge.<br />

17<br />

Start with the dovetail sockets:<br />

To test the Template, you could make a simple box. You will<br />

need a pair of boards for the box sides and a pair for the ends.<br />

Make all the boards the same width, but the shorter pair will<br />

be the ends and the longer pair will be the sides.<br />

Mark them up with triangle marks as shown (on page 14) so<br />

that you don’t get lost and end up with a Z instead of a ring<br />

of dovetails.<br />

<strong>The</strong> bit<br />

Choose a dovetail bit for the sides that is your next size larger<br />

than the thic ness of the end or pin pieces.<br />

Note that you can match the bit size closely to the wood<br />

thickness, if you have a good selection of <strong>WoodRat</strong> dovetail<br />

bits.

You can also plane your wood down if it is too thick for the bit<br />

that you want to use.<br />

Tails first<br />

You cut all the tails first because you can adjust the pin size to<br />

fit later if you need to. <strong>The</strong>re’s not much you can do to a row of<br />

tail sockets.<br />

Select a Dovetail Template. Screw in the two M6 thumbscrews.<br />

Tighten gently and locate it exactly later (see below).<br />

What size is the wood?<br />

<strong>The</strong> width of the wood:<br />

With any kind of jig you need to size the work to fit the jig’s fixed<br />

pitch. This is the downside of having the speed and easy working<br />

of this particular template. <strong>The</strong> <strong>Pathfinder</strong> Through Dovetail<br />

TD Template has a fixed pitch, but you can use different sizes<br />

of dovetail bit, and have therefore a lot of alternatives of wood<br />

thickness at that same pitch.<br />

As the sockets get larger, in thicker wood, so the pitch gets<br />

tighter, to a point where it looks camped and needs a wider<br />

pitch. <strong>The</strong>n use a larger TD Template.<br />

Making a symmetrical layout<br />

Use the Template to show you where your joints are going to<br />

come on the board end. It’ll show you how many pins you will<br />

have, and whether you should narrow the boards to avoid oversized<br />

end pins.<br />

Find the center line of the board end. When the board is symmetrical<br />

the line will be in the middle of an island or exactly<br />

between two, depending on wheth er you have an odd or an<br />

even number of pins.<br />

Positioning the Tails<br />

Place one piece for tails in the CamLock. Make sure that the<br />

inside is facing you.<br />

1. Zero the cutter: raise the bit and then zero it onto the top<br />

of the board. Place the Bit so that it is positioned over the<br />

middle of the board.<br />

Depth the depthing fo t against the piece for pins<br />

2. Loosen the Drop-pin plate (you might have to relocate the<br />

Locking Keys to a different pair of holes), and bring the drop-pin<br />

forward to about the middle of the line of square islands.<br />

3. Tighten the DropPin Locking Keys.<br />

Track the board so that the centre line is precisely under the bit.<br />

Loosen the keys on the Template.<br />

Even Sockets Drop the Pin and slide the plate so that the pin<br />

drops onto the middle of the middle Island, or in the alley between<br />

the two middle Islands. That should now put the run of<br />

pins/sockets central to the board.<br />

Now lift the Pin, so you can track the dovetail bit to the left-hand<br />

edge of the board. <strong>The</strong>n run to the other end of the board and<br />

check that the board is indeed central and the same both ends<br />

with not too big a pin at either end.<br />

Odd Sockets Drop the Pin and slide the plate so that it goes<br />

between the islands.<br />

Depth the Bit<br />

Zero the bit back onto the board end and use the pin piece to<br />

gauge the depth of cut.<br />

Drop the bit, and you are ready to cut the tails.<br />

Cutting the Tail Sockets<br />

Do this carefully: because the cut is guided, you can cut from<br />

both faces of the tail board, front first and then from the back.<br />

This will ensure that there’s no breakout, specially if you go gently<br />

and your bit is sharp. <strong>The</strong> end pins need special treatment as<br />

you will need to trim the edges before cutting the exact socket<br />

position. On the left edge go away (clockwise) around the board.<br />

You have space for this.<br />

On the right-hand edge come forward. You may need to lift the<br />

18<br />

<strong>The</strong> Dovetail template is held by the Bracket and slides<br />

under the Guide Rails. <strong>The</strong> Drop Pin traces the Tail sockets<br />

by going through between the Islands using a Dovetail<br />

Bit and then traces the pins by going down the slope<br />

of the wedges on either side.<br />

8 does 8,10,12.<br />

<strong>The</strong> Bit is place on the central pin. <strong>The</strong><br />

Two Locking Keys of the Template are<br />

loosed and the Template freed so that<br />

the Drop Pin can go between the Islands.<br />

<strong>The</strong> keys are tightened. That locates the<br />

Template.<br />

<strong>The</strong> Drop Pin goes between the Islands<br />

to make the tail sockets.

<strong>The</strong> larger Pins look more crowded on<br />

the board end, but it is a matter of<br />

opinion when they look wrong.<br />

At the smaller end of the scale, the<br />

pins could look too widely spaced,<br />

and need a Template with a tighter<br />

pitch.<br />

<strong>The</strong> Bit is placed over the board end and<br />

the Drop Pin plate loosened and brought<br />

up to the middle of the Islands.<br />

<strong>The</strong> Drawing shows the wood tracked out<br />

left to show the position of the Pin and<br />

the Bit and the work in the CamLock,<br />

and the Template reatiative to the<br />

Bracket and Fence.<br />

Pin and cut forward (clockwise again) making a half cut (trim cut) on<br />

the edge of the board.<br />

Put the router back and drop the DropPin again before making a full<br />

cut down the alley between the islands.<br />

Breakout<br />

When making sockets, there is little breakout if you trim cut from the<br />

front and then go round and make the full cut from the back of the<br />

board.<br />

If the boards are thin, you can cut them both at once, but it’s probably<br />

best to do them one at a time, carefully, at first.<br />

Select the pieces for grain and character and mark out which piece<br />

goes where – whether Side (long) or End (short). <strong>The</strong> triangle marking<br />

method is very useful to keep the boards in order.<br />

<strong>The</strong> following is a way of keeping the sockets and the pins<br />

exactly matched up corner for corner.<br />

Put the two tail boards together, in the left hand, ready to go in the<br />

CamLock, with the arrow pointing upward. Somersault the front board.<br />

Now they have both inside faces facing you.<br />

Keeping that orientation, lock the back board in the CamLock and cut<br />

the row of top left sockets. Next the bottom right corner sockets of<br />

the front board, which is now ‘upside down’ and at the top, because<br />

you flipped the board.<br />

Put the boards together (don’t change the orientation) and cartwheel<br />

the boards together. That is, look at them and wheel them through<br />

180°.<br />

Note: <strong>The</strong> Sides will now match up with the Ends with the pin when<br />

they are rotated in this way. <strong>The</strong> pins have to have the thicker part<br />

always facing the machine, and have to be cart-wheeled between<br />

cutting one end and the other.<br />

Now do bottom left corner sockets trim cutting from the front and then<br />

cutting from the back that is from the outside to the inner face<br />

19

and then repeat for the top right corner.<br />

Remember:<br />

1. Put them together and flip the front board. and cut both<br />

rows together.<br />

2. Cartwheel them both together and cut the other two. and<br />

that’s the Tails done.<br />

Making the Test Pins<br />

DO NOT FORGET TO DO THIS...<br />

...before you leave the tails, take a piece of good scrap a little<br />

wider than the width of two sockets and cam it in place under<br />

the bit which is brought forward to cutting position (off). Push<br />

the router away, and squeeze the scrap up a fraction. Cam it<br />

in again, and switch on. Bring the router forward so that the bit<br />

cuts a shallow groove in the top of the scrap. Cut the first pin<br />

position, and then the second making two shallow grooves.<br />

It gives you both the bottom dimension and positions of the<br />

first two tails.<br />

Keep the Test Stick in place and...<br />

Making the pins<br />

...change the dovetail bit for a straight bit. <strong>The</strong> larger the better<br />

(less break-out), but it must fit easily between the pins, and<br />

also be right for the Template. We will check that next.<br />

You now use the wedge shaped Islands on the template, Raise<br />

the Pin.<br />

Now track the Bit to the back edge of the test stick on the right<br />

hand side of the groove so that the left blade is just touching<br />

the right hand edge of the groove.<br />

Unlock the Pin Plate (Pin down) and move it up so that the Pin<br />

comes up against the wedge. Lock the Drop Pin Plate.<br />

Track the Bit to the other side of the groove and align the right<br />

hand blade with the left edge of the groove.<br />

<strong>The</strong> Pin should come up and hit the wedge on the left just as<br />

it did on the right-hand side.<br />

If the Pin runs off the top end of the wedge, when the Bit<br />

is placed, the bit is too small to hit the wedge so change the<br />

bit for a larger diameter straight bit and start the test again:<br />

loosen the drop pin plate and pull the plate forward allowing<br />

you to place this larger bit on the edge of the groove. Slide<br />

the pin away till it nudges the wedge.... and tighten the keys<br />

on the Drop Pin.<br />

Test the other side and check that the blade comes to the edge<br />

of the groove. Do this without moving the sliding bar.<br />

Dry Run<br />

Before cutting the test stick, check that as you run the Pin<br />

down the Wedge either side, the bit will run across the groove<br />

from top right and down at a slope of 1 in 7 to make a pin<br />

with the base the same size as the groove which is the same<br />

size as the dovetail bit. Check that it runs over the stick the<br />

other side also.<br />

Making the Pins in the Test Stick<br />

Now cut the test stick proper.<br />

Zero the cutter onto the scrap and gauge the bit depth using<br />

the piece with the dovetails cut in it.<br />

Drop the bit, Track to the left hand edge of the Stick. Switch<br />

on and make a right-hand cut, from the right side, just kissing<br />

the corner of the groove sloping down towards the left, <strong>The</strong><br />

first pin will allow a right hand cut only.<br />

Track to position number 2, and make a right-hand cut and<br />

then a left-hand cut, from top left side down towards the bottom<br />

right. Be sure to clean the space between the pins. Don’t<br />

worry about breakout until later.<br />

<strong>The</strong> test stick should fit the first and second sockets on the<br />

board with the sockets. And the two should line up on the left.<br />

20<br />

<strong>The</strong> dovetail bit cuts two<br />

grooves to trace the bit<br />

diameter on the stick at<br />

first and second socket<br />

positions<br />

<strong>The</strong> bit is at the back<br />

of the Stick just at the<br />

edge of the groove. Slide<br />

the Pin up to the wedge<br />

till it gently nudges it,<br />

and tighten the Locking<br />

Pins on the Drop-pin<br />

Plate

A right hand cut<br />

<strong>The</strong> Bit is placed at<br />

the edge of the groove,<br />

with the Pin up<br />

<strong>The</strong> Pin Plate is loosened and,<br />

the Pin moved up to touch the<br />

wedge. <strong>The</strong> other side is<br />

checked in the same way.<br />

<strong>The</strong> drop pin plate is tightened.<br />

This sets the position for making<br />

the dovetail.<br />

If it’s too tight, move the Pin Plate towards you, so that it uses a thinner<br />

part of the wedge.<br />

If it is too thin, move it up the wedge to thicken the Pin a fraction. Try the<br />

test on the other end of the stick.<br />

Making the Run of Pins<br />

Now try the run of pins for real. It helps to place the board with the tail<br />

sockets in it, handy, so you can see what you are trying to make. Lay it flat<br />

on the Channel top with the tails towards you. You are making pins to fit<br />

these sockets. Note that the first pin is only cut on the right-hand side of<br />

it, and you will be cutting away the wood and leaving a dovetail pin where<br />

the space is...<br />

So, starting on the left of the board: it’s a Right hand cut only, then<br />

Right – Left, Right – Left, and so on to the last pin<br />

and the last is only a Left....<br />

...unless of course you have a different layout with a tail in the end of the<br />

run instead of a pin. See asymmetric dovetails.<br />

<strong>The</strong>re’s a knack to getting it perfect, but it won’t take long if you take it<br />

gently. This is not your hamfisted dovetail jig; it needs care and finesse!<br />

When cutting the pins try to put an even, gentle pressure on the Wedge<br />

with the Drop-Pin as you bring it forwards, and make sure that your plates<br />

and all sliding surfaces are polished and easy running.<br />

Try the fit.<br />

At the end of the run, lift the router and lift the DropPin. If the fit is right,<br />

you’re ready to go ahead. If not put it back and adjust the fit and trim it<br />

up.<br />

Finding the Pathway<br />

How you make the track through the work is up to you, but it’s worth precutting<br />

from the front edge, going clockwise in and out of the Wedges,<br />

down cutting or climb cutting, to cut the front edge. <strong>The</strong>n there’s no tearout<br />

when you come to work down the Wedges from the back. You do the<br />

majority of the cutting from the back so that the dust flies straight into your<br />

extraction system.<br />

You will find for yourself the best way of running around the pathways – working<br />

left to right or right to left. As with tenons, don’t rush it in the beginning...<br />

you want to make a good job of it first, and become fast and good later.<br />

You should find that the two pieces – pins and tails – fit hand in glove,<br />

breakout free and square.<br />

Asymmetry<br />

You could want an asymmetrical layout for making drawers with cocked<br />

beading, or because you just want it asymmetric, or because the size of the<br />

box is critical but does not fit with the pitch of the template.<br />

One end pin can be made larger.<br />

Alternatively the end tail can be made larger.<br />

Normal <strong>WoodRat</strong> dovetail techniques easily cope with asymmetry, but here<br />

we resort to a bit of cunning.<br />

If you have a bigger pin on one end than on the other, you will have to somersault<br />

the tail board so that the same edge is cut with the bigger pin.<br />

But as is always the case, the pin board must be Cart-wheeled, to keep<br />

its inner face against the machine face, otherwise you will get a zee/zed<br />

instead of a square box.<br />

Start by making pins on one pin board with its corresponding tail board.<br />

Make the opposite corner with the other pin board and its corresponding<br />

tail board. <strong>The</strong>y will match up.<br />

But now when you cartwheel each pin board to make pins in the other end,<br />

you will need to move the template to get the pins in the right positions.<br />

<strong>The</strong> size of the bigger pin (the position of the cut) is got from marking out<br />

the big pin on the end of the pin piece as you would for hand cut dovetails,<br />

placing the tail board over the end of the pin board. Mark the end pin position<br />

with a marking knife.<br />

Place the marked up tail piece with its inner face against the machine face,<br />

and relocate the template so that the bit will cut down the line of that bigger<br />

pin. Re-lock the Template. Now you can run the line of pins for the two<br />

21

emaining corners.<br />

Box with a Box Lid<br />

<strong>The</strong> usual method of cutting off the lid part of a box through a<br />

large pin is impractical with the <strong>Pathfinder</strong>.<br />

You can cut the wood first and make two boxes one for the box<br />

and the other for the lid, but you must be sure to make each part<br />

to the same overall dimensions.<br />

Alternatively, you could make the cut through one of the tails<br />

between the pins.<br />

A variation on this is to use the full MB3 MitreBox and Mitre the<br />

tails so that the lid and box can be fitted together by rebating/<br />

rabetting the lid into the box.<br />

Grooves for Bottoms and Lids<br />

<strong>The</strong> RP3 router plate has the usual slot on the left-hand side so<br />

that it can act as a normal router plate when doing non-pathfinder<br />

work.<br />

So, when grooving for the box bottom and lid, simply place one of<br />

your Starknobs (from the <strong>WoodRat</strong>/LittleRat kit) in the M8 tapped<br />

hole in the HalfPlate and screw the plate down where you need it.<br />

Take out the Cheeks etc. Place the Brush, and feed each piece<br />

through by hand.<br />

Remember: feed on the up-cut if widening the groove.<br />

When feeding small pieces, you’ll need the blue block placed<br />

in the yellow dust chute to stop the workpiece pushing into the<br />

cutter gap.<br />

To make a stopped cut to avoid the groove showing on the outside<br />

off the joint, set the brush down a little from the bit (for protection),<br />

and carefully lift the workpiece up into the cutter at the beginning<br />

of the slot. Feed the workpiece along under the plate cutting the<br />

groove, and drop it when it reaches the end of the groove before<br />

it breaks through the joint.<br />

This takes a little practice, so try it on some scrap first.<br />

Thicknessing the Bottoms<br />

Having run the groove you can thickness the box bottom to fit<br />

the groove by resetting the bit and running the bottom past the<br />

cutter to rebate it, as for normal Woodrat practice.<br />

22

Because the pitch is fixed by the Template, you will need to design<br />

the drawer heights to match the available socket positions on the<br />

template. If the pitch is unsuitable turn the template and try the<br />

pitch on the opposite set. <strong>The</strong> diagram at the end of this section<br />

will help with the design.<br />

<strong>The</strong> Drawer Side is mounted vertical, with its inner face against<br />

the machine.<br />

<strong>The</strong> Drawer Front is horizontal up under the HalfPlate and the<br />

Template with the inside face up, and the two are cut in one<br />

pass... first a series of forward cuts to make the sockets without<br />

tearout, then a pass, down cutting the tails, and then cutting the<br />

pin pockets between the pins of the Drawer Front. This is all done<br />

with the same dovetail bit.<br />

23

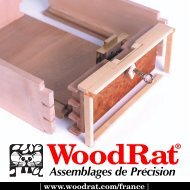

A series of oak and sycamore drawers made<br />

with an early version of the <strong>Pathfinder</strong> Half-Blind<br />

Template.<br />

24<br />

<strong>The</strong> D

ove-<br />

Bracket<br />

Lobed Washer<br />

Locking Keys<br />

Drop Pin<br />

We have a third and very different Template<br />

for lapped dovetails, with a different approach<br />

to its joint. <strong>The</strong> two workpieces are mounted<br />

together in the MitreBox and the same dovetail<br />

bit cuts both of them in one run. It enables<br />

you to dovetail a reasonable sized drawer in<br />

under 5 minutes, because there is no need<br />

to chisel the back corners of the pin pocket<br />

as in normal <strong>WoodRat</strong> half-blind dovetails. It<br />

is very quick. <strong>The</strong> size of bit is given by the<br />

thickness of drawer front and is less critical<br />

than that for through dovetails, as the lap can<br />

vary. Having two differing pitches on the same<br />

Template allows a greater choice of dovetail<br />

Half-Blind or Lapped Dovetails<br />

25<br />

M6 Locking keys<br />

Drop-Pin Plate<br />

Rod Lock<br />

Half-blind Dovetail Template<br />

Locking Lever<br />

Spreader Rod to be stored<br />

Set up the MitreBox MB3 with<br />

both left Cheek screwed to the<br />

Fence and the Right one held<br />

with the Rod Clamp<br />

layout, and each template is designed for a<br />

specific <strong>WoodRat</strong> dovetail bit.<br />

Although intended for drawers, the half-blind<br />

method also gives you full blind dovetails<br />

which you can make into secret dovetails by<br />

mitering them using the Mitrebox, and therefore<br />

you can make boxes with continuous perfect<br />

figured grain with no visible joints.<br />

tail Bit to use You would expect to select the bit to match the thickness of

the drawer front and to allow a nice balance between pin and<br />

drawer side when it shows as you open the drawer.<br />

But, each Half-Blind Template works with only one size of<br />

dovetail bit. Choose bit that corresponds with the Template.<br />

Interestingly one Template can give a range of results.<br />

If you have a range of Templates choose the one that is intended<br />

for the bit you intend to use.<br />

Set-Up<br />

Add the second (right-hand) cheek for half-blind dovetails, as<br />

the drawing above.<br />

Place a drawer side vertically up under the plate and against<br />

the machine face. Cam it in, but not tightly.<br />

<strong>The</strong> Rod Clamp<br />

Set up the clamping system on the threaded rod as shown in<br />

the illustration.<br />

<strong>The</strong> Rod Clamp needs to hold the drawer front firmly, up under<br />

the HalfPlate, in a way that when you loosen the Hand Lever<br />

by half a turn you can slide out the Front piece and slide in<br />

26<br />

<strong>The</strong> drawer Side is held vertical and the<br />

Front is horizontal. between the Cheeks of<br />

the MitreBox. <strong>The</strong> Template (shown faded) is<br />

held by the Bracket and goes with the wood.<br />

<strong>The</strong> Bit goes with the plate and the Pin<br />

directs the Bit around the back of the Side<br />

to form the Tails and then into the Front to<br />

make the pin pockets. It’s all done with the<br />

same Bit at the same depth. <strong>The</strong> spacer is<br />

not shown<br />

<strong>The</strong> Cam Lock holds the two Cheeks apart,<br />

but is able to squeeze together to lock the Front<br />

in place. <strong>The</strong> handle provides a quick release with a half<br />

One Bit, one template, but three very different results<br />

show that there’s lots of room for individuality.<br />

1. A rather heavy<br />

drawer front<br />

2. A classic<br />

design solution<br />

2. A thin drawer<br />

front and weak<br />

looking outer pins

Park Position<br />

27<br />

Place the tail vertical<br />

<strong>The</strong> Separating Stick spaces the Side<br />

and the Front a repeatable distance apart.<br />

<strong>The</strong> Front is pushed up against the plates<br />

above and against the stick.<br />

<strong>The</strong> Drop Pin is up and off to the right taking the Bit<br />

up to the Park Position<br />

Each HB Plate is made for a particular 1in7 dovetail<br />

bit and has a fixed pitch. But there are two different<br />

pitches on each plate which gives a wider choice of<br />

width to match the boards to.<br />

<strong>The</strong> half-plate and router plate are not shown.<br />

the next without snagging, and tighten it so that it does not<br />

move under pressure from the cutting action, which will be<br />

pushing into the end-gain.<br />

So loosen all the inner nuts and washers, and with the hand<br />

lever with the lever towards you, tighten the Big Lobed Washer<br />

so that the Drawer Front – lifted up close under the plates – is<br />

firmly held. Loosen the Hand Lever and slide out the Front.<br />

Slide it back again and tighten, and make sure that the work<br />

piece is firm and will not be dislodged when attacked by the<br />

bit.<br />

Rubber washer Sandwich<br />

Tighten the back nut on the Lobed Washer Nut. <strong>The</strong>n the pair<br />

of nuts (nut and lock nut) on the rubber washer sandwich,<br />

squashing it so that when you push the lever away, the rubber<br />

washers push on the Cheek, releasing the Drawer Front and<br />

giving room for the next one to be slid into place.<br />

You’ll need to push upward on the Drawer Front to make good<br />

contact with the HalfPlate, which will ensure that the Front<br />

dovetails have the same depth of cut as the Side, which is<br />

slid up vertically under the Half-plate.<br />

When all is running nicely we find that it’s best to put the<br />

Drawer Front in first - horizontal, then the Side - vertical,<br />

pushing it up under the Plate and Camming it in loosely. <strong>The</strong>n<br />

lift the Front and tighten the Hand Lever and then retighten<br />

the CamLock on the Side.<br />

Making Classic Drawers<br />

<strong>The</strong> <strong>Pathfinder</strong> allows you to make drawers with all the<br />

characteristics of a classic, craftsman’s piece – fine<br />

dovetails, thin drawer sides, sliding drawer bottom,<br />

etc., but in a fraction of the time.<br />

1. Preparation of work-pieces<br />

<strong>The</strong> better you prepare your work, making the ends of the<br />

Side and Front square and true, and the inner surfaces flat<br />

as can be, the better will be the joint. All the three boards

of the drawer (two sides and one front) need to be as far as<br />

possible the same width. <strong>The</strong> drawer Back should be made<br />

at the same time to the same thickness and cut down only<br />

after it is jointed.<br />

<strong>The</strong> Drop-pin is placed in the router plate and anchored with<br />

the Locking Screws. Loosen the plate to change the position<br />

of the Pin, forward and back, relative to the Bit. <strong>The</strong>re are three<br />

pairs of holes for the M6 Locking Keys.<br />

<strong>The</strong> Drop-Pin runs around the tail islands and then the pin<br />

pocket recesses in the Template in the same pass as the Bit<br />

is cutting the drawer sides, and then the pin pockets, all at<br />

the same depth. This makes it a simple operation, once it is<br />

set up.<br />

You may need to design the drawers to accommodate the<br />

template to some extent, but each template has two different<br />

pitches, for the same dovetail size, so it should not be hard to<br />

find a pitch that’s very close to the height of drawer front you<br />

need. <strong>The</strong> full-size diagram of the possible dovetail runs at the<br />

end of this section should help with the layout.<br />

2. Getting to work<br />

Unless you are doing asymmetrical work like for cock beaded<br />

drawers you can ensure that you make a perfectly symmetrical<br />

arrangement. Take the centre of the board, and match it with<br />

either the centre of the run, or exactly between two pins.<br />

Use the Template and put it the right way round to give you<br />

pitch A or the larger B as right for your design.<br />

Place a piece for tails (a Side) with the inner face against the<br />

face of the <strong>WoodRat</strong> and the corresponding Drawer Front horizontal,<br />

up under the plates, with the inner face facing up.<br />

<strong>The</strong> CNC-cut, Half-Blind Template allied to exactly machined<br />

dovetail bits gives a close fit of pin to tail, that is when the<br />

depth of the bit is just less than the full depth by 0.5mm or<br />

less. Adjusting the depth gives just enough leeway in the fit,<br />

provided that you use a <strong>WoodRat</strong> 1in7 dovetail bit.<br />

<strong>The</strong> template gives exact alignment of pins to sockets, so that<br />

the boards marry up exactly.<br />

This only leaves the depth of the Side, after it has been cut<br />

with tails, to the depth of the pin pocket. And this needs careful<br />

setting, so that there is a minimum of final cleaning up.<br />

<strong>The</strong> Half-blind Layout<br />

Mark the centre line of your board and note whether the pins<br />

will be odd or even in number, and camlock the board in vertically<br />

with the inner face against the machine face.<br />

Fit the Template with its two Locking keys in ready, and slide<br />

it into the Bracket. Don’t tighten yet.<br />

Track the board to line up its centre line mark with the Bit (with<br />

its blades north/south). <strong>The</strong>n slide the Template to line it up<br />

under the Drop-Pin, aligning the Template with either the corresponding<br />

alley (odd number of sockets), or the middle of the<br />

Island (even number). Tighten the Template Locking keys.<br />

Track west and east to check that the two ends of the run look<br />

right, with the Bit covering the two ends equally at both edges<br />

of the Drawer Side.<br />

<strong>The</strong> Layout<br />

Take extra/spare pieces of Side and Front. Place them in the<br />

<strong>Pathfinder</strong>.<br />

Place the Side vertical, with its inner face against the machine<br />

face.<br />

Place the Front (inside up), up under the Half-plate. Hold it<br />

there with the RodLock.<br />

Follow this: making sure you can see the bit clearly.<br />

1. Unlock the router, zero the Bit onto the end of the Drawer<br />

Side and depth the router to the depth of the bit using the scale<br />

on your router, and not to the depth of the wood as with through<br />

dovetails. Set it to the blade length of the Bit, and then unscrew<br />

the depthing foot a couple of half turns. <strong>The</strong> depthing is now<br />

a little less than the blade length. For example depth the 12-6<br />

bit to 12mm and give it a couple of downward turns.<br />

28<br />

A. Even number of sockets: Bit lined up<br />

on the centre line of the board, and the<br />

Template moved to position the Pin to<br />

the middle of the island.<br />

A<br />

B. Odd number of sockets: Bit lined<br />

up on the centre line of the board, and<br />

the Template moved to position the<br />

Pin between the islands<br />

B

Fig 27.1<br />

2. Bring the Bit forward – the blade depth/length<br />

divided by 7 (slope number of Bits). Put the Pin<br />

to the back of the Island and lock down.<br />

L<br />

T<br />

L/7<br />

End view of the Bit against<br />

the end of the Drawer Side<br />

T<br />

WR-8-7-20-10<br />

note that when the Bit is dropped to depth,<br />

the neck will just graze the top back edge of<br />

the Side board. Which is the same distance T<br />

that the pencil mark is into the drawer Front.<br />

<strong>The</strong> cutter is at the<br />

line on the top of the<br />

drawer side.<br />

1. Drawer Side is used to mark the<br />

thickness of the Drawer Front on the<br />

inside face, with knife or sharp pencil.<br />

Fig 27.2<br />

Plan view of the Bit against<br />

the end of the Drawer Side<br />

<strong>The</strong> drawer side is held<br />

by the Cheeks and the<br />

CamLock<br />

27.2/3. Track the Board away left, and Plunge the router fully.<br />

Move the router (Pin up) to line up the flat of the Bit square against<br />

the board end. <strong>The</strong> drawing shows the position of the Bit when<br />

plunged, where the cut at the neck just leaves the full thickness<br />

of the board on its end.<br />