crimping, interconnecting cables, harnesses, and wiring - NASA

crimping, interconnecting cables, harnesses, and wiring - NASA

crimping, interconnecting cables, harnesses, and wiring - NASA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 89 of 114<br />

<strong>NASA</strong>-STD-8739.4 with Change 6<br />

c. The contact shall be crimped to the conductor per the contact manufacturer’s<br />

recommendations or engineering documentation (Requirement). Indentions shall be symmetrical<br />

<strong>and</strong> centered along the longitudinal axis of the crimp barrel (Requirement). Single crimp indents<br />

shall be located opposite of the barrel weld (see Figure 19-30) (Requirement).<br />

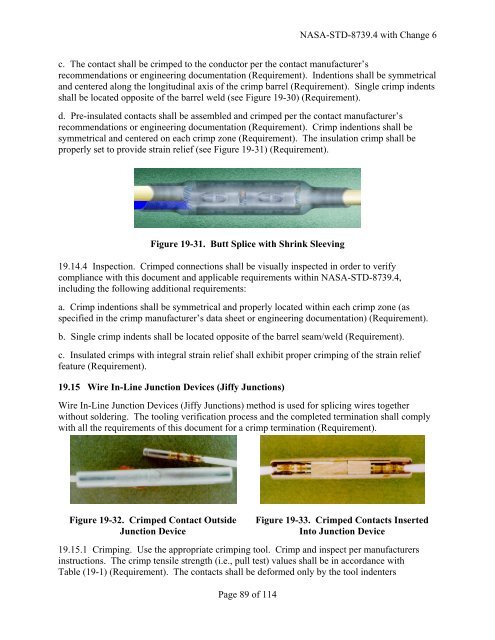

d. Pre-insulated contacts shall be assembled <strong>and</strong> crimped per the contact manufacturer’s<br />

recommendations or engineering documentation (Requirement). Crimp indentions shall be<br />

symmetrical <strong>and</strong> centered on each crimp zone (Requirement). The insulation crimp shall be<br />

properly set to provide strain relief (see Figure 19-31) (Requirement).<br />

Figure 19-31. Butt Splice with Shrink Sleeving<br />

19.14.4 Inspection. Crimped connections shall be visually inspected in order to verify<br />

compliance with this document <strong>and</strong> applicable requirements within <strong>NASA</strong>-STD-8739.4,<br />

including the following additional requirements:<br />

a. Crimp indentions shall be symmetrical <strong>and</strong> properly located within each crimp zone (as<br />

specified in the crimp manufacturer’s data sheet or engineering documentation) (Requirement).<br />

b. Single crimp indents shall be located opposite of the barrel seam/weld (Requirement).<br />

c. Insulated crimps with integral strain relief shall exhibit proper <strong>crimping</strong> of the strain relief<br />

feature (Requirement).<br />

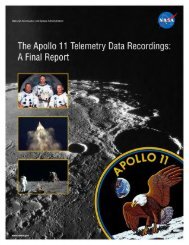

19.15 Wire In-Line Junction Devices (Jiffy Junctions)<br />

Wire In-Line Junction Devices (Jiffy Junctions) method is used for splicing wires together<br />

without soldering. The tooling verification process <strong>and</strong> the completed termination shall comply<br />

with all the requirements of this document for a crimp termination (Requirement).<br />

Figure 19-32. Crimped Contact Outside<br />

Junction Device<br />

Figure 19-33. Crimped Contacts Inserted<br />

Into Junction Device<br />

19.15.1 Crimping. Use the appropriate <strong>crimping</strong> tool. Crimp <strong>and</strong> inspect per manufacturers<br />

instructions. The crimp tensile strength (i.e., pull test) values shall be in accordance with<br />

Table (19-1) (Requirement). The contacts shall be deformed only by the tool indenters