Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

15<br />

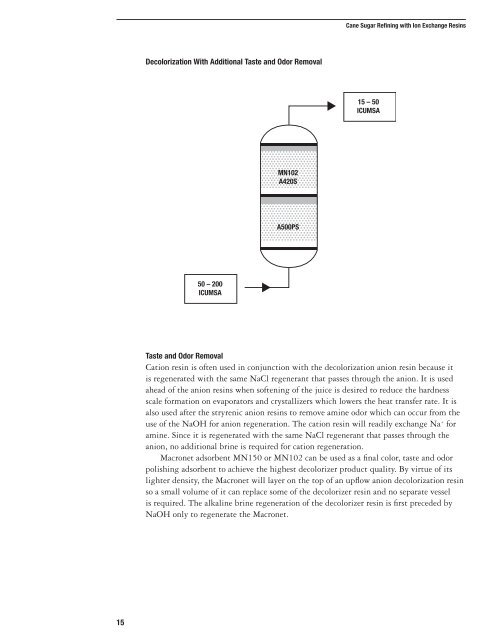

Decolorization With Additional Taste and Odor Removal<br />

50 – 200<br />

ICUMSA<br />

MN102<br />

A420S<br />

A500PS<br />

<strong>Cane</strong> <strong>Sugar</strong> <strong>Refining</strong> with Ion Exchange Resins<br />

15 – 50<br />

ICUMSA<br />

Taste and Odor Removal<br />

Cation resin is often used in conjunction with the decolorization anion resin because it<br />

is regenerated with the same NaCl regenerant that passes through the anion. It is used<br />

ahead of the anion resins when softening of the juice is desired to reduce the hardness<br />

scale formation on evaporators and crystallizers which lowers the heat transfer rate. It is<br />

also used after the stryrenic anion resins to remove amine odor which can occur from the<br />

use of the NaOH for anion regeneration. The cation resin will readily exchange Na + for<br />

amine. Since it is regenerated with the same NaCl regenerant that passes through the<br />

anion, no additional brine is required for cation regeneration.<br />

Macronet adsorbent MN150 or MN102 can be used as a final color, taste and odor<br />

polishing adsorbent to achieve the highest decolorizer product quality. By virtue of its<br />

lighter density, the Macronet will layer on the top of an upflow anion decolorization resin<br />

so a small volume of it can replace some of the decolorizer resin and no separate vessel<br />

is required. The alkaline brine regeneration of the decolorizer resin is first preceded by<br />

NaOH only to regenerate the Macronet.