Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Cane</strong> <strong>Sugar</strong> <strong>Refining</strong> with Ion Exchange Resins<br />

Liquid Invert<br />

22<br />

Inversion (%)<br />

Sucrose Inversion<br />

The hydrolysis of sucrose, a disaccharide, to form invert sugar produces an equimolar<br />

mixture of fructose and glucose, two monosaccharides as follows:<br />

Sucrose Fructose Glucose<br />

H+<br />

C 12 H 22 O 11 + H 2 O C 6 H 12 O 6 + C 6 H 12 O 6<br />

Sucrose inversion can be accomplished in a homogeneous fashion by bulk addition of<br />

acid to the syrup with addition of base for neutralization at the completion of the<br />

reaction. However, this produces an additional amount of ash which may exceed the<br />

liquid invert specifications and possibly create significant amounts of HMF (Hydroxymethyl-furfural)<br />

which is associated with color formation. Heterogeneous inversion of<br />

sucrose can be accomplished using a strong acid cation resin (H+ form) such as <strong>Purolite</strong><br />

CT124SH and neutralization of the acids produced from the existing ash in the syrup<br />

with a weak base anion resin, resulting in color and ash removal.<br />

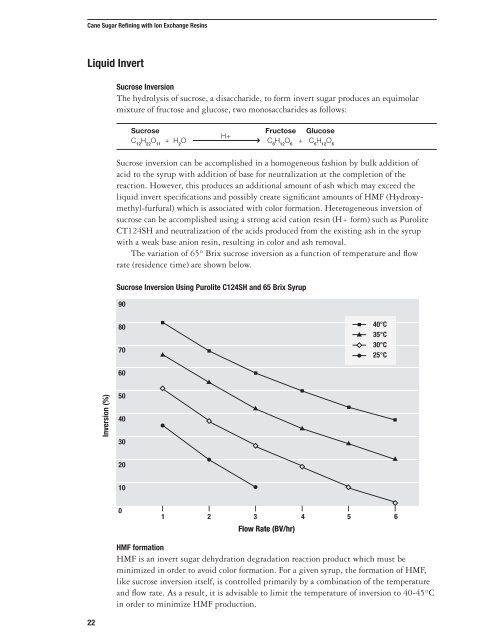

The variation of 65° Brix sucrose inversion as a function of temperature and flow<br />

rate (residence time) are shown below.<br />

Sucrose Inversion Using <strong>Purolite</strong> C124SH and 65 Brix Syrup<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

40°C<br />

35°C<br />

30°C<br />

25°C<br />

1 2 3<br />

Flow Rate (BV/hr)<br />

4 5 6<br />

HMF formation<br />

HMF is an invert sugar dehydration degradation reaction product which must be<br />

minimized in order to avoid color formation. For a given syrup, the formation of HMF,<br />

like sucrose inversion itself, is controlled primarily by a combination of the temperature<br />

and flow rate. As a result, it is advisable to limit the temperature of inversion to 40-45°C<br />

in order to minimize HMF production.